Silver Melting Furnace

Top Manufacturer in China

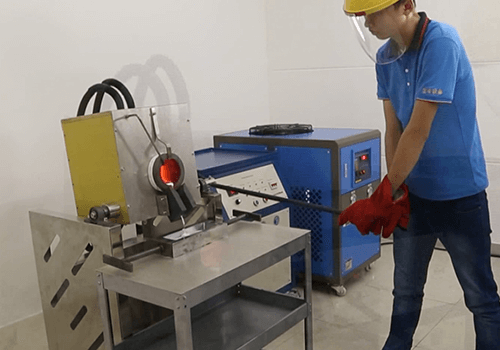

- Produce professional gold and silver melting furnaces for range 0.5kg-250kg

- Fast induction melting to increase customer production output

- Automatic temperature control device to ensure high product quality and fast melting time

- Various models for different application scenarios, such as jewelry shop or social industrial production

Apply Our Best Quotation

Gold & Silver Melting Furnace Solution Provider

Whether it’s a high- or low-volume mining facility, precious metals refining can use induction melting systems to achieve rapid smelting. There are also precious metal wholesalers and retail buyers who use high-quality smelting furnaces to melt their gold, silver, copper, etc., which can be analyzed more accurately.

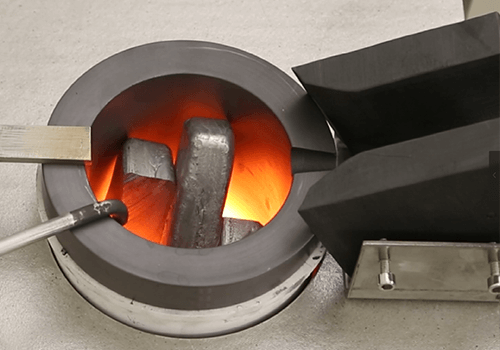

Heat is generated by an alternating magnetic current and then enters a graphite or SIC crucible to melt the gold and silver. The advantages of the gold and silver melting furnace are fast heat-up time, Frequency stirring and IGBT induction heating technology can obtain a more homogeneous melt and also ensure that the working environment is not affected.

SuperbMelt provides high frequency, medium frequency, low frequency and other gold and silver induction melting furnaces, suitable for different customer needs,ranging from 0.5kg to 250kg silver.

The melting furnace has a long life and has temperature control technology, and the melting time of most materials does not exceed one hour.

The melting temperature is between 1600 degrees celsius and 2800 degree celsius capable of melting ferrous and non ferrous metals.

Superbmelt silver melting furnace list

SuperbMelt Desktop Silver Melting Furnace is a portable size gold and silver melting equipment for small scale melting, ideal for jewelry stores, small jewelry studios, and even personal use for metal recycling, jewelry making.The smelting can be completed for the maximum amount of silver in 3-5 minutes.

This melting furnace achieves fast and efficient melting through induction heating, which not only saves time and energy, but also can work continuously for 24 hours.

If you are ready to enter the jewelry industry, or as a gold prospector want to replace an energy-efficient and smelting equipment, you can contact us for more details.

Parameter

- Max Capacity:1kg

- Max Temperature:1600℃

- Application:silver, copper, aluminium, gold, brass, bronze, etc

The SuperbMelt vertical gold melting machine adopts IGBT+CPU variable frequency induction heating power supply, which makes the equipment operate with strong stability and is an ideal choice for many old jewelry refineries and gold foundries.

The power and melting capacity of the equipment can be customized, and the melting time also depends on the power and melting capacity. Generally 3-7 minutes can complete a furnace smelting. Equipped with water and electricity separation equipment, with overcurrent, overvoltage and water shortage protection.

Parameter

- Max Capacity:3kg

- Max Temperature: 1600℃

- Application: gold, silver, copper, iron etc.

SuperbMelt tilting gold melting machine is a high-frequency electric furnace, which can be used to refine all kinds of jewelry raw materials, and the equipment is easy to operate.

The tilting design makes the operation more convenient and labor-saving, and effectively prevents the solution from overflowing or splashing. At the same time, the machine is also equipped with an all-round warning system, which will remind you in time when improper operation occurs. Better protection of operator safety.

We will be equipped with accessories such as jackets, crucibles, water pipes, etc., as well as professional training courses, which can make your melting work easier.

Parameter

- Max Capacity:6kg

- Max Temperature:1600℃

- Application:gold, silver, copper, iron etc.

SuperbMelt split smelting furnace is a very efficient and economical smelting equipment, we have considered various factors when developing this smelter, such as footprint, safety, efficiency and so on. Therefore, many gold refineries, mining companies, and gold prospectors can find their productivity has greatly improved after using our equipment.

Our gold smelting furnace has an electromagnetic stirring system, which ensures the homogeneity of the metal solution, thereby promoting the output of high-quality metal finished products, which helps to drive the sales volume of customers.

The crucible and the outer casing of the machine can be disassembled, which is more convenient for the maintenance of the machine.

Parameter

- Max Capacity:10kg

- Max Temperature:1600℃

- Application:gold, silver, copper,brass,bronze,and their alloys

SuperbMelt melting furnace is capable of melting almost any metal. Widely used in large manufacturers of copper casting, cast iron, precious metal recycling, and precious metal casting.

It can accommodate 3 different furnaces at the same time, and adopts chain-type motor-driven pouring technology, which can not only pour the melt easily, but also greatly improve the production efficiency.

Due to the automation of the chain, the tilting speed can be easily controlled, and the equipment is set with a fixed pour point function, which effectively prevents the splash of the metal solution, avoids the risk of operator injury, and improves work efficiency.

Parameter

- Max Capacity:10-50kg

- Max Temperature:1600℃

- Application:gold, silver, copper,brass,bronze,and their alloys

SuperbMelt silver melting furnace has a small footprint and can melt 10-100kg of silver, and the melting speed is fast. It has a water cooling design for the furnace body. When the melting temperature rises to 15,00 degrees Celsius, the furnace body can still be maintained at about 30 degrees Celsius, and the human body can touch it. This feature greatly improves the safety of the machine and protects the safety of the operator more effectively.

This machine has electric tilting and manual tilting two ways, and the operation is highly automated. This allows the solution to be poured easily and without splashing, making it convenient and safe.

Parameter

- Max Capacity:30-120kg

- Max Temperature:1600℃

- Application:gold, silver, copper,brass,bronze,and their alloys

SuperbMelt electric induction melting furnace can melt different kinds of metals under the condition of using the same furnace, which reduces the time and cost of replacing the furnace and saves a lot of money.

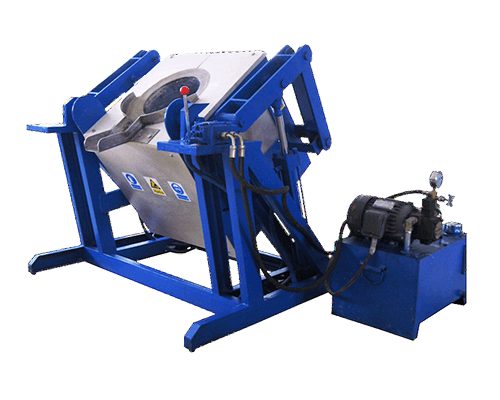

The melting furnace is equipped with a hydraulic tilting design and is controlled using a remote hydraulic station. This function effectively protects the safety of employees.

Using the PLC control system, the whole smelting process becomes very intelligent, and there is no need to worry about excessive use or operation errors.

Parameter

- Max Capacity:10-50kg

- Max Temperature:1600℃

- Application:gold, silver, copper,brass,bronze,and their alloys

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Silver Melting Furnace Buying Guide

The valuable metals industry has made some amazing progress. From simply being the selective protect of chemists and miners, valuable metals have become a comprehensive battleground.

As much as there are still enormous projecting furnaces, there is currently limited scope hardware to try different things. Little furnaces, custom-made silver melting heaters, and other limited scope frameworks have made the silver Melting Furnace innovation available to any individual interested in the business.

One thing that is basic to everybody in the valuable metals business is the correct machine’s decision to pick. You may be an engineer at your or organization attempting to choose a huge scope heater to deal with the entirety of your creation throughputs. Or then again, you could be one of the DIY enthusiasts of mining and valuable metals.

Whichever classification you have a place with, picking the correct gear to work with can be somewhat difficult or, in any event, confounding. You may think that its hard to settle on a choice on which type or size of the electric silver metal furnace (or some other comparative framework) to purchase. If you are in these shoes, you are perusing the correct article.

Beneath, we have assembled a complete manual to assist you with picking the ideal valuable metals refining framework. Whether or not you’re attempting to use custom made silver smelting furnaces or silver smelting equipment, or you’re searching for an enormous scope acceptance furnace available to be purchased.

We have something here to help you settle on a magnificent decision. We should begin by investigating the best Silver melting furnace maker and the sort of items they have to bring to the table. Settling on the correct decision begins with having a thought of precisely what’s accessible to what’s.

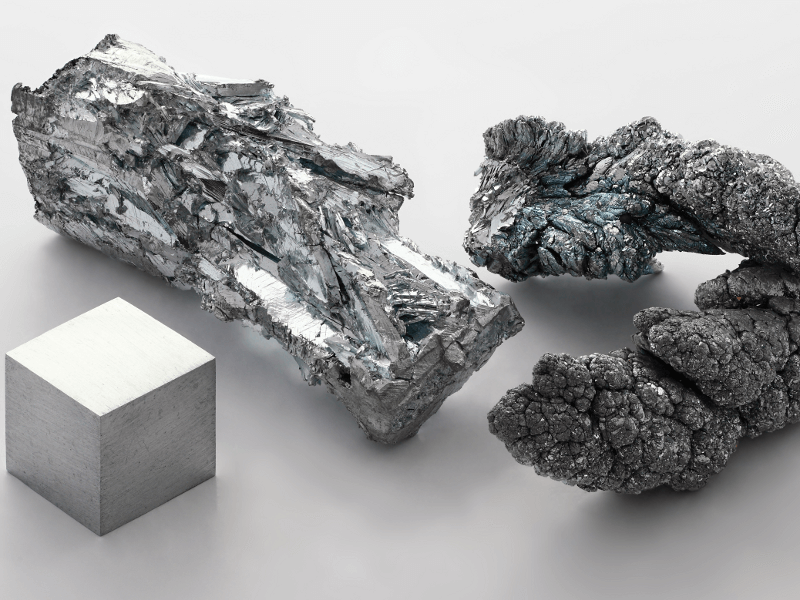

How to Melt Silver Nowadays

Silver is the most ordinary of all the precious metals. It is used in electronics, jewellery, medical supplies, and various industrial purposes. Silver was also a major medium mode of currency throughout the world until the nineteenth century. As a result, silver is present in a huge amount in our world. As a copious precious metal, individuals today like to work with it for numerous reasons.

Although silver is a good and attractive metal for beginners to start their work with, melting any metal is pretty complex if you don’t have an expedition’s. Still, with some work, knowledge and the proper supplies of silver melting equipment and a silver melting machine or gold and silver melting machine, beginners can begin melting and casting silver.

1.1, How to melt silver by propane kiln

Using Propane kiln is a frequently used method of melting silver at home. One has to put their silver in the crucible, then place the crucible on a fireproof surface and place it inside the propane kiln. If borax has been added to the silver, it will melt quicker. Heat thoroughly and slowly.

Safety tips

- Consider consulting a professional if you have no basic knowledge of melting silver.

- Melt the silver in a safe area in your home

- Ensure you are wearing a face shield and safety goggles to protect your face and eyes. Also, wear a heavy apron and heat-proof gloves on both hands.

- Do not melt silver near anything flammable, which is very dangerous.

1.2, How to melt silver by resistance furnace

The resistance furnace melting system or electric silver melting furnace is built for mining operations. It is more time-consuming when contrasted with the induction furnace system. However, it offers a huge range of temperatures, up to 1500 degree Celsius. Its temperature-controlling feature is automated.

Resistance furnaces are sealed, and this prevents heat from escaping from the vacuum created in the system. It also contains a gaseous medium that prevents oxidization and hardening of silver sample some is working on. However, a resistance furnace is not appropriate for melting large quantity of the silver-this type of furnace is made for small to mid-sized mining operations.

1.3, How to melt silver in an induction furnace

Silver can be dissolved in many ways, yet we will clarify how silver is softened with borax. Borax is utilized to melt the metal since it helps in softening and dissolving the mineral’s oxidized layer. This interaction is known as a borax flush, which helps uncover the metal’s new layer for additional utilization. The melting interaction ought to be completed in an all-around ventilated zone.

Spot your silver in a melting crucible and guarantee it is adequately huge to hold the metal when it begins bubbling. If the item you are melting is more, it is fitting to soften in bunches. Dissolving in bunches will empower a quick softening interaction. You can utilize an induction furnace to melt the silver in the cauldron.

Silver Melting Furnace for Silver Mining

The downturn has hit the precious metal industry in the economy. Both silver and gold miners are starting to shut down mines that are not making much profit. Precious metal prices have been plunging. Unfortunately, the precious metal cost is not following that downfall.

During these difficult times, anything that can save costs is vital. Inductions melting furnaces that melt precious metals, like Copper, silver and gold, have become much better and more productive with modern technology.

2.1, Introduction (How to get silver from silver mines)

Silver is usually found in the mixed state in nature, generally in lead or copper mineralization, and by 2000 BCE, mining and purifying silver-bearing lead ores were ongoing. Lead ores were smelted to get an impure lead-silver alloy which was then fire refined by cupellation. The most-known ancient mines were located at the Laurium silver-lead credit in Greece; this was mined actively from 500 BCE to 100 CE. Spanish mines were also a key source.

Even though some silver-containing ores consist of silver as their hugest metal value, virtually none has silver as its main component. A distinctive ore might contain 0.085 per cent silver, 0.5 per cent lead, 0.5 per cent copper and 0.3 per cent antimony. After floatation parting, the concentrate would consist of 1.7 per cent silver, 10 to 15 per cent copper, 10 to 15 per cent lead and 6 per cent antimony.

About 25 per cent of the silver produced comes from ore mined for their silver value; the other 75 per cent comes from ores that have as their major metal value either zinc, Lead or Copper. All these ore minerals are sulfides; usually, lead is present as galena (PbS), Copper as chalcopyrite (CuFeS2), zinc as sphalerite (ZnS). The mineralization generally consists of large amounts of pyrite (FeS2) and arsenopyrite (FeAsS). The silver mineralization is generally argentite (Ag2S), proustite (Ag3AsS3) and polyposis [(Ag, Cu)16Sb2S11].

Silver-containing ores are mined by open-pit or underground procedures and then crushed and ground. Since virtually all the ores are sulfide, they are amenable to floatation separation, by which a 30 to 40 fold concentration of mineral is mainly achieved. Of the three main types of mineralization, lead concentrates includes the most silver and zinc concentrates the least.

The explicit extractive metallurgy procedures applied to a silver-containing mineral concentrate depend on whether the major metal is zinc, copper or lead.

- From Zinc concentrates

Zinc concentrates are roasted and leached with sulfuric acid to mix their zinc content, leaving a residue containing silver, gold and lead along with 5 to 10 per cent of the concentrates’ zinc content. This is processed by slag fuming, where the residue is melted to form a slag through which ground coal or coke is blown along with air.

The zinc is lowered to the metallic form and is vaporized from the slag, while the lead is transformed to the metallic form and diffuses the silver and gold. This lead bullion is regularly collected and sent to lead refining.

An induction furnace can extract silver from zinc concentrates—the zinc metal recovered from the purified solution by electrolysis. The zinc produced with the electrolysis procedure undergoes melting in the induction furnace, whereas the silver remains as the residue, which is later removed.

- From Copper concentrates

The purifying and converting of copper sulphide gathers bring about a “rankle” copper that “contain” 97 to 99 per cent of the silver present in the first concentrate. These contain the silver initially present in the gather; however, a lot higher focus; for instance, a silver substance of 0.2 per cent in the sulfide amass can bring about a sludge containing 20% silver.

This is melted in a small induction furnace to oxidize all metals essentially present aside from silver, gold, and platinum-bunch metals. The metal recuperated, called doré, contains 0.5 to 5 per cent gold, 0.1 to 1 per cent platinum metals, and the equilibrium silver. This metal is cast to frame anodes and electrolyzed in an answer of silver-copper nitrate. Two distinctive electrorefining procedures are utilized, the Moebius and Thum Balbach frameworks.

- From lead concentrates

Lead concentrates are first broiled and afterwards smelted to create lead bullion from which contaminations like antimony, arsenic, tin, and silver should be taken out. Silver is taken out by the Parkes interaction, which comprises adding zinc to the liquid lead bullion.

Zinc responds quickly and totally with gold and silver, shaping insoluble mixtures that buoy to the bullion’s highest point. These are taken off, and their zinc content recuperated by vacuum countering. The excess lead-gold-silver build-up is treated by cupellation, an interaction wherein the build-up is warmed to a high temperature (around 800 °C, or 1,450 °F) under firmly oxidizing conditions. This high temperature can be easily obtained by using an induction furnace.

The induction furnace is preferred rather than an electrical resistance furnace. It enhances kinetics by causing induction stirring of the alloy in the furnace and removes heating resistors’ consumption.

The respectable silver and gold stay in the essential structure while the lead oxidizes and is taken out. The gold and silver combination along these lines delivered is refined by the Moebius or Thum Balbach measure. The build-up from silver refining is treated by affination or separating to think of the Wohlwill interaction’s gold substance.

2.2, Applicable types of melting furnaces

In metallurgy, the quantity of heat that should be applied to arrive at silver’s melting silver’s use must be accomplished using heaters. In numerous occurrences, furnace-levels of heat are normally needed in the underlying phases of metallurgical cycles. The liquefying furnace varies by design, usefulness, and innovation they run on.

Preferably, a decent silver melting heater burns-through as little heat and fuel as could be expected while softening the metal.

The main types of gold silver melting machine or just silver melting machines are

- Propane kiln

- Resistance furnace

- Induction furnace

ii. Propane Kiln:

The propane kiln works on the heating principle of Propane gas burning, i.e. the propane gas consumption provides the power to this kiln; no external power source is needed. The average melting time differs for different metals, but for silver, it takes about 30 minutes to melt 1 kg of silver. The maximum temperature which the propane kiln can obtain is up to 1200 degree Celsius.

As the propane kiln uses propane gas, so there is no electronic power consumption. There is no molten metal stirring function present in the kiln. One will need to replace the heating torch if they use the propane kiln frequently, and depending on the propane supply, the working time varies.

If you want to use a propane kiln to melt your silver or any precious metal, at first, you need a crucible to let you hold the metal as it melts. The impurities present in the metal can be removed using flux. But one has to keep safety as the main priority because it is accident-prone. After the meeting, you can cast your silver and shape it.

ii. Resistance furnace:

A resistance furnace is a greater amount of current going through conductor joule heat created by an electric furnace for heat wellspring. In this interaction, the furnace goes about as the heat source. It utilizes electric warming components to change over electrical energy into the last warmth energy. The heat energy is then utilized to heat metal. Resistance heater can be utilized to smelt high measures of silver, yet it actually probably won’t be the best technique out there.

This technique probably won’t be extraordinary, particularly when you are hoping to try not to cover huge electric power bills first of all. Once more, a resistance furnace may create heat intricacies, which might lead to unevenly purified silver. Hence, attempt to utilize other melting techniques to guarantee that pollutants are taken out from the silver metal you are chipping away at.

iii. Induction Furnace:

The induction furnace utilizes electromagnetic induction to produce heat to melt metals. The induction furnace is heated quicker and has higher thermal proficiency. The heat is produced in the furnace, so the warming velocity is high. The oxidative consuming loss of components in an induction furnace is less since there is no super high temperature of the induction furnace arc.

Induction melting furnaces work on a drastically unique rule to the dome rendition. The induction furnaces utilize coil heating components implanted inside a crucible or incorporated into the heating chamber’s dividers and produces a magnetic field. This transforms electrical energy into heat radiated through the material with a remarkable level of heat consistency.

The magnetic field can alter headings relying upon the course of the current stream. A substituting current that goes through the coil causes a magnetic field that adjustments a similar way at a similar speed as the current. For example, an attractive field switches bearings 60 times each second if the current is 60Hz AC.

Regardless of whether you are a prepared smelter or an amateur, you can generally do well with an induction furnace. These machines are customized to smelt silver and other non-ferrous metals of any size. They additionally are extraordinary for applications that require a precise stock of warmth energy for projecting purposes.

An induction furnace includes a nonconductive crucible that holds the charge of metals that should be melted, and a loop of copper wire likewise encompasses it. There is a forceful rotating current that is moving through the wire. The coil makes a quickly switching magnetic field that enters the metal.

The magnetic field guarantees that eddy flows and circular electric flows are instigated inside the metal. It does this through electromagnetic induction. When the metal has been melted, the eddy currents’ lively blending is brought about to guarantee that uniform blending is accomplished.

2.3, Comparison

| Types | Propane Kiln | Resistance Furnace | Induction Furnace |

| Consumption of energy | High | Highest | Low |

| Price Performance | High | Low | Highest |

| Generating energy | There is a need for unclean energy through trough combustion | Electric or slag generation | There is clear generation of energy through electromagnetism |

| Environmental friendliness | Less environmental friendly | Less environmental friendly | Most environmental friendly |

| Degree of productivity | High | Higher degree of productivity | Highest degree of productivity because there is no cool down or heat up cycle needed. And it has a high start up time. |

| Heating Speed | A bit slower heating method | The slowest heating system. | The fastest heating system. |

| Homogenous Melts | Does not have an electromagnetic stirring character | It does not have an electromagnetic stirring character | The electromagnetic heating character makes it really simple to produce a homogenous melt. |

| Working time | Requires to rest for 30 mins after working for about 3hours | Requires to rest for 30 mins after working for about 3 hours | Works continuously for 24 hours |

| Molten Metal stirring | There is no stirring function available as it is by transfer of resistance heating | It is done by transfer of resistance of resistance heat | The magnetic field mixes the molten metal to achieve an abundant fixture of alloy based on induction heating. |

| Protective Alarm | None | None | · Over Voltage Warning. · Over current warning · Phase loss warning · Absence of water warning · Improper frequency warning. |

Silver Melting Furnace for Precious Metals DIY Enthusiasts

Many individuals collect silver, especially women, with a huge collection of silver jewellery and a collection of broken or damaged silver chains and bracelets that they cannot wear anywhere. The advantage of solid silver jewellery is that they never lose their metal value to melt the jewellery easily.

It is easier to melt these jewellery scraps into a silver nugget which can be resold or reused to make new silver jewellery at a low cost. Hence, a silver melting furnace is necessary for DIY enthusiasts.

3.1, Why do DIY precious metal enthusiasts need a silver melting furnace?

We will like to explain the main reason why DIY precious metal enthusiasts require silver or other precious metal melting furnaces:

- Melting is a significant valuable metal extraction measure:

DIY enthusiasts utilize different techniques to recuperate silver and other valuable metals from scrap and different sources. The converse electroplating strategy that was referenced before includes the utilization of synthetics. Lamentably, a portion of these synthetics can be very destructive and surprisingly hurtful to human wellbeing.

This is additionally combined with the way that the responses may set aside some effort to occur. However, dissolving is an entirely reasonable choice. The cycle begins with melting down the amalgam, metal residue, scrap electronic circuit or old gems. A furnace is an ideal approach to accomplish this reason. Along these lines, valuable metal enthusiast needs a furnace to advance their valuable metal extraction or recuperation measure.

- Alloys are many a time experienced:

Regardless of the source from which the raw silver is being sourced-panning and sluicing by sporting excavators or salvaged materials and different irregular potential transporters of silver. One regular trait of silver and other valuable metals is that they barely at any point show up in isolation.

They’re frequently blended with different metals as amalgams to move these different metals and recuperate significant metals. Once more, valuable metal dissolving heaters are the ideal approach to complete this by venturing out of dissolving down the combination into a liquid structure. In this manner, the furnace is significant for DIY valuable metal enthusiasts and will be profoundly essential in rescuing valuable metals from both compounds and salvaged materials.

3.2, Selecting the appropriate silver melting furnace for the DIY metal enthusiast

Do-It-Yourself valuable metal fans likewise a few existing techniques for getting the melting of their crude metals. We have effectively examined Propane burners and opposition heaters for individual silver diggers. What’s more, DIY devotees additionally utilize blow lights for dissolving.

Nonetheless, these can indeed do a limited amount of a lot. The time needed to get the crude metals up to and past silver’s softening masilver’s1.8 degree Celsius with these metals is frequently restrictive. Likewise, as is frequently the situation for DIY valuable metal lovers, the salvaged Material’s measure to be dissolved might be very a lot and completing this will prompt numerous groups.

3.3, Conditions necessary for good silver melting

There are a few steps that one should follow while trying to melt their silver

- Gather your silver supplies

Secure things to melt. You need to discover a few things to meltdown. Fortunately, albeit silver is viewed as an uncommon metal, it is genuinely normal in our everyday activities. The most regular silver uses are gems, even though we can track down a generous measure of silver coins, just as silver in modern applications.

Customary utilization for silver incorporates making coins, adornments, enhancing things and cutlery.

- Get a foundry crucible

A foundry crucible is a compartment that is utilized for metal creation. Crucible or Pots are made of clay, aluminium, graphite, and silicon carbide. They are incredibly heated safe and won’t melt under similar conditions as the metal you are attempting to dissolve down.

Ensure you get a crucible that is a fitting size for your venture and fits as a fiddle. Maintain a strategic distance from the old crucible with breaks or unreasonable wear. You will utilize your crucible to store your silver as it melts and transforms into its molten structure. You will then pour the molten silver out of the crucible into a cast or form.

Secure yourself a furnace or a blow torch. The furnace or torch is the thing that you’ll be utilizing to melt your silver to its melting point. In that capacity, the furnace or blow torch are basic things in melting silver. Contingent upon the measure of melting you’ll be doing, you can choose between a furnace or torch.

Buy safety hardware to ensure yourself. Melting silver, or some other metal for that reality, is possibly hazardous. You need to get yourself some great security gear to ensure yourself. Make sure to take heaps of care when you melt silver, and don’t do so except if you are not appropriately ensured.

- Melting the silver

Put on your safety apparatus and secure the territory. Place the crucible or crucible with the silver item on or in your furnace. The principal thing you require to do is place your silver in the crucible and place it on or in your heater. This will swap contingent upon the sort of furnace you have. You would prefer not to heat your furnace and afterwards place your crucible inside, which will expand the opportunity of you harming yourself.

Heat the furnace to a temperature that surpasses the melting point of silver. The major thing you need to do is heat your furnace to the proper temperature. Contingent upon what sort of furnace you have, this may take a little or a ton of time.

Apply your torch to the silver if you’ve decided to use a blow torch. In case you’re utilizing a furnace crucible and are dissolving on a more limited size, you may have decided to utilize a blow torch to melt your silver. If so, take your torch and apply it to the silver. Keep your torch above the silver, and it will gradually warm the silver up.

Silver Melting Furnace for Silver Mining Laboratories

4.1, Introduction

Mining has truly progressed significantly from its unassuming beginnings. From an action carefully implied for miners and fortune searchers, it has developed into a mammoth industry utilizing different experts across various information fields.

Financial specialists, coordination experts, customary diggers, metallurgists, mining architects and analysts all have a task to carry out in the contemporary mining and valuable metals industry.

Curiously, the situated experts in the gold mining industry expect experimentation to improve their exchange’s nature continually.

Colleges and Universities preparing understudies and future experts in these fields require research facilities that should be furnished with working furnaces. This will assist with testing and evaluate different working conditions. Understudies build up a superior comprehension of the mining interaction and improve when they get into the business.

Aside from schools, the corporate or modern gold mining world also requires research facilities furnished with furnaces. Exploration is a ceaseless interaction, and thus, experts in the Silver mining industry need to keep testing and find new things.

Consequently, silver (and other valuable metals) mining organizations require Research and Development (R&D) labs. These research facilities should be outfitted with furnaces for completing trials at high temperatures.

4.2, Laboratory related specialities in mining that require furnaces

In this portion, we will be checking out the various fields under silver mining and how furnace laboratories might be useful for them.

- Metallurgy:Just like the name suggests, this field is about the investigation of metals. The way clarifies its application and utility to silver mining that silver and other valuable metals are metals (no play on words intended). Metallurgists are hence required in the silver mining industry to explore and improve the current comprehension of the properties of silver and other valuable metals. Regularly these examinations are completed at high temperatures. Thus, metallurgists require the utilization of silver melting furnaces in their research facilities to help with their examinations.

- Material Science and Engineering:This is a more extensive field under which metallurgy falls. Material researchers and architects study the properties of materials in general, metals and non-metals notwithstanding. What’s more, their partners in metallurgy, Material researchers, and designers also need furnaces prepared labs to aid their exploration and investigation of material properties. This agreement will help understand the properties of the different compounds and minerals in which valuable metals are found over the long haul. Understanding these will help improve partition measures and enhance the recovery of valuable metals from their minerals and amalgams.

- Mining Engineering:This field is about the extraction of silver, other unadulterated metals, and minerals from their underground (or something else) stores. Mining designing is a significant calling to the silver and valuable metal mining industry because it impacts the business. Universities, universities, and specialized schools looking to outfit understudies with the necessary information to mining engineers all need furnaces prepared research centres. Regularly, the underground repositories containing silver and other valuable metals are at high temperatures and pressing factors. Thus, to re-enact this condition and grow comparably improved mining measures, Mining engineers need research facilities outfitted with furnaces.

- Silver refining:The Silver Refining Plant solutions cover the full scope of interaction steps and material-dealing with streams, from silver Doré anodes to silver granules and bars. It offers a superb mix of imaginative cycle innovation, effective dealing with, high adaptability, and security. Thus, every silver refining company needs an R&D department to carry out regular tests and find the best solutions. Companies also offer a full suite of support services to assist someone in maximizing plant uptime, consisting of spares delivery and installation and remote assessment of equipment status.

4.3, Furnace types applicable to each kind of Laboratory

This portion is a combination of the various kinds of furnace that are suitable for each field mentioned previously:

- Metallurgy:Metallurgy research centres, both at the academic and mechanical levels, require a medium measured furnace for their trials. We are sure that the coordinated 3-6kg silver melting furnace will be valuable for this reason.

- Material Science and Engineering:Apart from the Integrated 3-6kg furnace endorsed for Metallurgy labs above, MSE labs will likewise track down the 1-4kg platinum melting furnace valuable as a result of its adaptability. What’s more R&D lab, we would likewise suggest the 10kg coordinated Tilting Silver Melting Furnace.

- Mining Engineering:For mining engineers, the main prerequisite is high temperature instead of high volume; we would suggest either the Mini 1-2kg silver melting furnaces or the coordinated 3-6kg silver melting furnace.

- Silver Refining:Here, a mix of both volume (space) and high heat is required. We would consequently suggest the 20kg – 30kg Split Manual Tilting Induction Melting Furnace to accommodate this. For mid-range Silver refining organization, a solitary furnace may fill the twofold need for standard creation to explore certain events.

Conclusion

DIY enthusiasts should buy machines that give them a longer period of warranties and machines that uses popular brand main electric components. Individuals should choose professionally certified machines to be among the top companies that produce quality machines. The company should also have professional engineers who can help you out when facing any problems.

It would be greatest to know how the company controls its machines’ quality and whether they carry out regular tests in their quality control system to ensure top-quality. Those who want to build a plant for silver smelting or a foundry for jewellery casting should choose a company that will provide the entire program for you. You can buy a silver smelter for sale from companies which provides you with the best conditions and facilities along with the machines.

We hope to have cleared out all your queries through this article and given you a basic knowledge of what you shall need if you are interested in melting and smelting their silver and crafting their silver jewellery.

FAQ Guide

Could I get 9999 silver from your silver melting furnace?

Our induction melting furnace can not purify silver. It could smelt silver ore or sand to remove non-metal impurities to extract silver and other metals. Some customers used it for melting old silver to make silver bars. For purifying purpose, it needs a refining system.

What is the heating principle for silver melting?

It is induction melting. That is what we focused on always.

Could we use this furnace to melt most metals like iron, gold, silver, copper and aluminium.

Yes, our machine could melt most metals. But for melting ferrous metal and non-ferrous metal, it needs to equip different coil and crucible to realized both melting. For iron, steel melting, we make use of silica crucible(Alumina crucible) for melting. For gold, silver and Copper, we make use of graphite crucibles.

Does this machine need a water chiller?

Yes, this machine needs a water chiller.

Could we use single phase 220v this machine?

Yes, we can use single phase 220 v for this machine as a power source with 50/60 Hz.

How to solve the silver lost in your furnace?

Temperature control will set the silver compound’s dissolving point to abstain from overheating to bring misfortune. The silver permit should be dissolved at an offered temperature to guarantee that there is no misfortune. Except if you are utilizing some unacceptable Silver Smelting Machine, you will want to assume responsibility for whatever is going on in the Silver melting furnace. Before you start dissolving, you need to guarantee that you set temperatures to the right levels. There should be any silver lost in the heater as long as you are utilizing the suggested methods.

At what temperature does pure gold melt?

Pure gold melt at 1064 degree Celsius (or 1945 degree Fahrenheit).

How many ways do gold and silver smelt?

Smelting gold and silver can be done using high heat, pressure and various chemicals such as flux to break down the ore and melt the gold or silver to separate it from impurities. Gold can be smelt by using the Miller process and Wohlwill process. Silver can smelt by using a furnace.

Can you melt 10k gold?

Yes, you can melt 10K gold by using a propane blow torch. The gold should be placed inside a crucible. Then put the crucible on a fire-resistant surface and direct the blow torch toward the gold within the cauldron. If you put in the chemical borax to the gold before, you will melt it at lower temperatures, which might require you to use a torch. You can also use a furnace to melt your gold.

Can you melt 9 carats and 18-carat gold together?

Yes, you can melt 9 carats and 18-carat gold together, and if equal amounts of 18 carats and 9-carat gold are melted together, it becomes 13.5 carats, but it is doubtful there are equal parts, so the finished portion of gold will be marked 10 carats. Carats can be combined, but that will result in an alloy which is an odd carat.

Can you melt down different karats of gold together?

Yes, you can melt down different carats of gold together. This is how you solder or weld two pieces of gold together using a lower carat that melts a bit sooner and binds them together.

Can you melt down gold to make jewellery?

Yes, you can melt down your gold at home to make jewellery. You can place your gold in a crucible and heat it to about 1100 degree Celsius at which point the gold begins to melt. When the gold reaches a molten state and flows together as one mass, you can pour the molten gold in a casting mould to make a nugget or jewellery and then allow it to cool down.

Can you melt silver at home?

The melting point of silver is 961 degree Celsius. Melting gold is considered easier than melting silver but like every other precious metal melting silver is not impossible even at home. If you go after the right process and use the right equipment, you can melt silver at home.

Can you melt old gold rings to make new ones?

Yes, you can melt old gold rings with sentimental value but do not fit you and make them into a new ring, although precious metal is not quite as straightforward.

Can you melt silver and gold together?

Can you melt silver in a kiln?

Yes, silver can melt in a kiln, although many problems can be faced if not done carefully, it is possible.

Can you melt silver with a propane torch?

Yes, you can melt silver with a propane torch. However, it is not appropriate to use a propane torch for a large amount. And if you mix the silver with borax, the task of melting with a propane torch will become easier or else it will take a lot of time.

How do you get gold from gold ore?

How do you get impurities out of gold?

Lower crude gold in a combination of nitric and hydrochloric acids. This strategy will disintegrate the ore and separate the gold from pollutants, which can later be washed away. The excess substances will be water and gold, the last having a high virtue level. Another method of eliminating pollutants from gold is to add flux while smelting the gold. After dissolving, the slag is taken out, giving up a cleaner gold.

How do you melt and purify silver?

You can melt silver using an induction furnace or propane burner by heating it to silver’s melting point silver is 961.8 degree Celsius. You can purify silver using nitric acid by placing the silver in a container, adding three parts distilled water to 1 part of nitric acid, placing the container on the stove, and letting it simmer until all metals are gone. Take an un-iodized salt, drop it into the water and nitric solution, and then add ten tap water parts.

How do you melt silver with borax?

Make a mixture of borax and soda in the proportion of 1 to 1. For 1 kg silver, 500g of the mixture will be enough to melt silver. While you are melting the silver using a propane burner, add the melting will be done more easily. Then remove the slag from molten silver and cast it in a mould.

How do you remove copper from silver?

To remove Copper from silver, you need to heat the ore sample to a sufficient level such that the silver melts, but the Copper remains in the still-solid state so that you can easily remove the Copper.

How do you remove impurities from silver?

You can use a mixture of nitric and hydrochloric acid to remove the impurities from silver as this will dissolve the ore and separate the silver from any impurities, which is later washed away

How do you distinct gold from other metals by melting?

The primary activity, while isolating gold from different components, A. The primary activity is to place the mineral in the heated crucible, eliminate the crucible, and permit a portion of the metallic combination to chill off. Add some nitric corrosive and hydrochloric corrosive to the metallic combination; the corrosive will break up different metals, and you have the gold left at the base of the crucible.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited