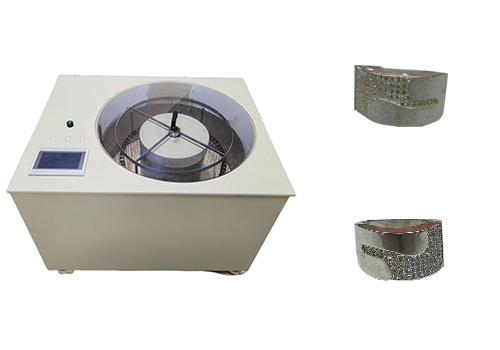

Electro Polishing Machine

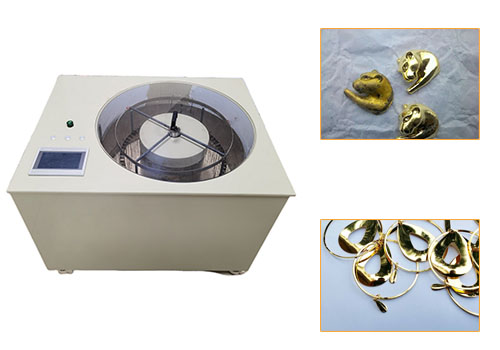

SuperbMelt newly developed electrolytic jewelry polishing machine.

SuperbMelt Electro Polishing Machine can simultaneously complete the no-dead-angle polishing of 20-138 pieces of gold、silver and copper jewelry rings and bracelets, enhancing the aesthetic appeal of the jewelry while also boosting your production efficiency. It is an ideal choice for jewelry processing plants and electronic component manufacturing facilities.

- Efficiency: Compared to traditional polishing, electropolishing can complete the polishing process much faster, over ten times the speed of traditional methods, significantly enhancing production efficiency.

- Low Cost: This method can polish hundreds of jewelry pieces at once, reducing labor costs compared to traditional polishing, and also minimizes physical wear on the products, thereby lowering costs over the long term.

- High-Quality Finish:Electropolishing uniformly treats complex and small jewelry parts, ensuring every corner is precisely polished, improving the overall quality and aesthetics of the finished product.

| Model number | SPB-GR3

|

SPB-GR2

|

SPB-GR1

|

| Power supply | AC 220V/DC 0-15V | AC 220V/DC 0-15V | AC 220V/DC 0-15V |

| Power | 1kw Max 50A | 2.3kw Max 150A | 4.5kw Max 300A |

| Machine hook | 20pcs | 60pcs | 138pcs |

| Batch productioncapacity | Silver: 6.5kg Copper:6.5kg K gold:5kg | Silver: 52kg Copper:52kg K gold:40kg | Silver: 97.5kg Copper:97.5kg K gold:75kg |

| Electrolyte capacity | 5L | 40L | 75L |

| Metal electrolyte ratio | Copper: 1.7L electrolyte: 1.3L water Silver: 1.3L electrolyte: 2.6L water K gold: 4L electrolyte (No water) | Copper: 13L electrolyte 26L water Silver: 13L electrolyte: 26L water K gold: 40L electrolyte (no water) | Copper: 25L electrolyte/ 50L water Silver: 25L electrolyte/ 50L water K gold: 75L electrolyte (no water) |

| Size | 465mm*335mm*41mm /28kg | 81mm*1010mm*700mm /70kg | 810mm*600mm*70mm /120kg |

| Abrasive dosage | 3 kg | 15 kg | 25 kg |

| Applicable metal | copper , silver, K gold, (No pure gold, platinum) | copper , silver, K gold, (No pure gold, platinum) | copper , silver, K gold, (No pure gold, platinum) |

- Jewelry Manufacturing: Excellent for polishing jewelry made of priceless metals like platinum, silver, and gold, such as necklaces, bracelets, earrings, and rings. For processing these goods’ intricate details and complex shapes, electropolishing works particularly well.

- Watchmaking: The process of creating a perfect, smooth surface by polishing the cases and other parts of luxury timepieces.

- Medical Device Manufacturing: Used to polish implants and surgical tools, which have very strict requirements for hygienic standards and surface finish.

- Automotive Industry: Used to polish exterior trim pieces and vital automotive performance components, like exhaust system components, to improve look and performance.

- Electronics Industry: Excellent for enhancing electrical performance and corrosion resistance when polished, precision electronic components include connectors and metal sections of printed circuit boards (PCBs).

- Aerospace Industry: Used to polish metal parts of spacecraft and airplanes to improve corrosion resistance and lower air resistance.

- Manufacturing of Pipes and Valves: Used in the polishing of industrial pipes and valves, which frequently have to endure the strict durability standards of extremely corrosive conditions.

- High Capacity Processing: This feature improves batch processing capabilities by processing 20 to 138 pieces of gold, silver, and platinum jewelry, such as bracelets and rings, at once.

- No-Dead-Angle Polishing: Electropolishing technique achieves high-standard polishing results even on intricate designs by precisely polishing all of the jewelry’s corners and intricacies.

- Enhanced Production Efficiency: Compared to conventional methods, the machine’s rapid and effective polishing capabilities save a significant amount of polishing time and increase production.

- Cost Savings: Lowers operating expenses over time by minimizing costs related to material consumption and mechanical wear.

- Environmentally Friendly: Electropolishing has a smaller environmental impact than chemical polishing since it employs fewer hazardous chemicals.

- Widespread Applicability: This product has a variety of uses, including polishing electronic devices and jewelry as well as other precision components.

- Better Product Quality: Particularly in the high-end market, uniform polishing improves the items’ overall appearance and competitive advantage.

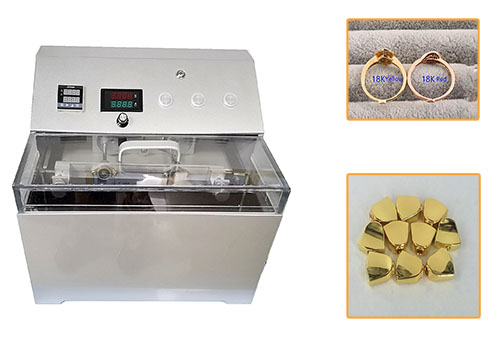

Before and after comparison of jewelry ring polishing:

360° no dead angle polishing, fast speed, good quality.

Each session can hang 20 to 138 pieces of jewelry for electropolishing, thereby increasing production efficiency.

By changing the electrolyte, different metals including gold, silver, copper, and k gold can be polished.

Why SuperbMelt Electro Polishing Machine

Any Question About SuperbMelt Electro Polishing Machine

About Guide to the SuperbMelt Electro Polishing Machine

Working principle of electrolytic polishing machine

The electrochemical reaction process, which is used to brighten and smooth metal surfaces, forms the main basis of an electropolishing machine’s operation. The specific actions and guidelines are as follows:

Equipment Setup: The metal component that needs to be polished serves as the anode in the electropolishing process, while an inert substance often serves as the cathode. Specific compounds are present in the electrolyte solution that submerges both electrodes.

Electrolytic Reaction: The metal surface at the anode starts to disintegrate when the power is turned on and a direct current runs between the anode (the metal section being polished) and the cathode. A gradually smoother surface results from a higher disintegration rate at the surface’s protruding areas where the current density is higher.

Metal Dissolution: The electrolytic action on the metal surface eventually dissolves the microscopic protrusions, smoothing off the surface. This dissolution process largely modifies the surface’s microstructure without appreciably changing the workpiece’s macroscopic size or shape.

Impurity and Oxide Removal: In order to improve the metal’s look and corrosion resistance, the electrolytic process also aids in the removal of impurities and oxide layers from its surface.

Polishing Completion: Following the electropolishing procedure, the metal component needs to be taken out of the electrolyte solution, carefully cleaned to get rid of any remaining electrolyte and loose metal fragments, and then allowed to dry.

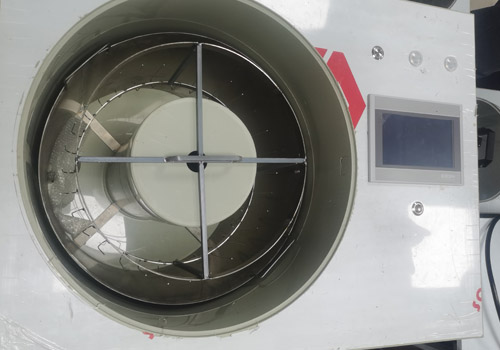

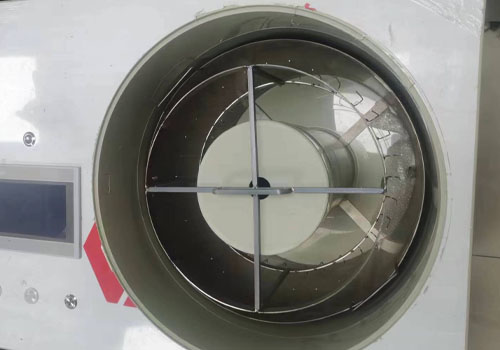

1.1,Hook

Place the jewelry that needs to be polished on the hook, then place the hooked jewelry into the polishing machine. Start the machine to perform electropolishing through the liquid.

1.2, Electrolyte Solution

Modern jewelry polishing techniques use automated procedures and cutting-edge technologies to provide consistently high-quality results quickly. These methods erase surface flaws and improve the sheen and luster of jewelry items by using specialized tools such polishing machines with revolving brushes, abrasive wheels, or polishing chemicals.

Modern technologies like electrochemical polishing and ultrasonic polishing have arisen in addition to conventional mechanical polishing techniques. While ultrasonic polishing uses high-frequency vibrations to provide accurate and consistent polishing results, electrochemical polishing uses electrolytic solutions and electrical currents to eliminate surface flaws and enhance surface smoothness.

1.3, Energize

After adding the electrolyte solution according to the ratio, start the machine directly to begin electrolysis.

Introduction to the Electro Polishing Machine

2.1, differences between an electropolishing machine and a manual polishing machine

- Mechanism of Action: To produce a smooth and glossy surface, electropolishing machines employ an electrochemical process that involves ion exchange in an electrolytic solution to polish the material. To remove flaws from the surface, manual polishing machines use physical abrasion using polishing compounds and pads.

- Finish Quality: When electropolishing is done instead of hand polishing, the surface is usually more even, spotless, and reflective. Additionally, it can access regions that conventional tools might overlook that are tough to reach.

- Efficiency: Compared to manual polishing, which requires more time and labor, electropolishing equipment may process numerous parts at once and frequently do the operation faster.

- Operator talent Level: Electropolishing yields more consistent results with less reliance on operator talent than manual polishing, which demands a great deal of expertise and experience to achieve a consistent finish.

- Surface Improvement: Electropolishing boosts the object’s resistance to corrosion and eliminates small surface imperfections without changing its shape. It also improves the appearance of the product. The main goal of manual polishing is to enhance the surface’s look; nevertheless, when material is removed, this process occasionally results in minor dimension changes.

- Application: Complex and delicate geometries, as well as materials that are challenging to polish by hand, are perfect candidates for electropolishing. Hand polishing is more adaptable and suitable for a wider range of materials.

2.2, What are the benefits of an electropolishing machine?

- Better Surface Finish: Electropolishing results in a shiny, clean, and smooth surface finish. By eliminating surface flaws like burrs, microcracks, and other abnormalities, it improves the metal’s visual appeal.

- Enhanced Corrosion Resistance: The outermost layer of the material, which contains impurities and pollutants that might cause corrosion, is removed throughout the procedure. This produces a surface that is more resistant to corrosion, which is especially advantageous for metals like stainless steel.

- Improved Cleanability: Electropolishing results in a smooth, non-porous surface that is simpler to clean and disinfect. This is particularly crucial for sectors like semiconductors, food processing, and medicines.

- Deburring: Without the need for labor-intensive manual deburring procedures, electropolishing efficiently eliminates burrs. This is especially important for parts where burrs could lead to a mechanical failure or where access is difficult for conventional deburring equipment.

- Fatigue Life Improvement: Electropolishing can extend the fatigue life of metal components by eliminating stress risers and surface imperfections. For parts that experience cyclic stress in their operating environment, this is essential.

- Microfinish Improvement: By considerably reducing metal surfaces’ roughness, electropolishing can produce finer finishes than are possible with mechanical polishing techniques.

- Access to Complex Geometries: Where mechanical finishing tools might not be able to reach, the procedure can readily polish complex and intricate shapes. It is therefore perfect for parts with difficult-to-reach locations.

- Non-Distortive: Electropolishing does not considerably change the part’s dimensions, in contrast to various mechanical finishing techniques. It preserves the accuracy of precise dimensions by just eliminating a thin exterior layer of material.

- Product Contamination is less likely thanks to the ultra-smooth surface, which is important in sectors including semiconductor manufacturing, food processing, and the biomedical industry.

- Process Consistency: Electropolishing ensures consistent quality across several items and batches by offering great process reliability and predictable results.

2.3, What is the metal loss for an electropolishing machine?

The wear and tear of an electropolishing machine is influenced by the processing time. For example, processing a 10g gold ring for 3-5 minutes results in a consumption of about 0.2% to 0.3%.

How to choose the right jewelry polishing machine

Comparing Other Polishing Machines with Electropolishing Machines: Polishing Method

Electropolishing Machines: Enhance the smoothness and brightness of the surface by removing a thin layer through an electrochemical process. This technique works particularly well for microscopic surface smoothing and refinement.

Mechanical Polishing Machines: To obtain a smooth finish, these machines usually utilise physical abrasion using buffing wheels and polishing compounds. This technique may occasionally be more severe when it comes to fine jewelry.

consistency of finish

Electropolishing: Without causing distortion to the object, it offers a consistent, clear finish even in complex and difficult-to-reach locations.

Mechanical Polishing: The buffing wheel may not reach every region equally, which could lead to uneven finishes, especially on complex designs.

Impact on the Integrity of Material:

Because electropolishing doesn’t require physical contact, it is typically seen as mild. It lessens the possibility that the jewelry will be distorted when being polished.

Mechanical Polishing: Soft metals or delicate designs may occasionally be deformed by physical touch or pressure.

Surface Improvement:

Electropolishing: By eliminating minute flaws where corrosion may originate, this technique not only increases corrosion resistance but also improves attractiveness.

Mechanical polishing: Mostly enhances appearance, although the abrasive nature of the process may cause corrosion-prone micro-scratches.

Speed and Efficiency of the Process:

Electropolishing: Often finishes the polishing process more quickly than mechanical methods and can handle numerous pieces at once.

Mechanical polishing: Usually more labor-intensive and slower, especially for intricate objects.

Advantages of Machines for Electropolishing

When these techniques are contrasted, electropolishing’s benefits become clear:

Outstanding surface Quality: Electropolishing produces a surface that is dependably smooth, bright, and clean-looking.

Non-Contact Process: This chemical, non-mechanical method reduces the possibility of the jewelry being physically harmed.

More Precision and Detail: Where mechanical tools might falter, electropolishing works wonders for intricate and precise designs.

Efficiency & Scalability: It is more efficient in high-volume manufacturing environments since it can handle huge batches.

Enhanced Durability of Jewelry: The jewelry’s corrosion resistance and durability are greatly increased by smoothing and perfecting its surface.

In conclusion, electropolishing machines offer clear advantages in terms of quality, efficiency, and safety for the material being polished, even though the choice of a polishing machine depends on unique needs, materials, and intended outcomes. They are especially well suited for processes that value superior finishes and deal with materials that gain from the special advantages of electropolishing.

Electropolishing Machines Provided by SuperbMelt

4.1, Small electropolishing machine

For dedicated do-it-yourself jewelry enthusiasts as well as small jewelry manufacturers, the SuperbMelt Mini Electropolishing Machine is an essential equipment. This machine, which offers outstanding results for gold, silver, and copper items, is specifically intended to satisfy the needs of professional-grade jewelry finishing. It is engineered for precision and ease of operation.

This equipment’s customized electrolyte capacity (1.7L for copper, 1.3L for silver, and a special 4L for K gold) enable exact electrolyte ratio adjustments to suit different metal types, improving the uniformity and quality of the polishing process. With dimensions of 465 x 335 x 41 mm and a weight of about 3 kg, the SuperbMelt Mini is incredibly efficient in situations when time and space are limited.

This electropolishing machine is ideal for small-scale manufacturing where precision and excellence are paramount. It allows for up to 20 pieces per session, allowing for a high throughput without compromising the painstaking attention to detail that the jewelry industry demands. The SuperbMelt Mini is an indispensable tool for fans and pros alike, simplifying the polishing procedure and guaranteeing a perfect finish for every item.

4.2, Medium electropolishing machine

The SuperbMelt Medium Electropolishing Machine is a unique option for jewelry manufacturers who want to maximize output without sacrificing quality because of its high-speed production capabilities, remarkable efficiency, and little metal loss.

With a capacity of up to 52 kilograms each session, this machine is capable of polishing 60 pieces of jewelry, making it ideal for handling large batches of jewelry. Each type of metal—copper, silver, and K gold—has its own specialized electrolyte solution that ensures quick and even polishing of every piece. This expedites the manufacturing process while preserving a consistently excellent finish, which is essential for high-end jewelry goods.

Moreover, the SuperbMelt Medium Electropolishing Machine has an extremely effective material usage system. The exact regulation of electrolyte volume and composition minimizes metal waste to the bare least. In the jewelry sector, where material prices have a substantial impact on overall profitability, this efficiency is especially crucial. This machine offers a cost-effective solution that improves profitability while producing extremely high-quality visual outcomes by minimising metal loss during the polishing process.

Owing to its large capacity, sturdy design (81 x 1010 x 700 mm; 15 kg), and weight, the machine fits particularly well in professional settings where time and space are valuable resources. Because of its dependable performance and quick processing speed, it is a vital tool for companies looking to grow their output sustainably and profitably.

4.3, Large electropolishing machine

The best option available to large-scale jewelry makers is the SuperbMelt Large Electropolishing Machine, especially for companies that specialize in bulky products like bracelets and rings. This high-volume, high-quality piece of equipment is perfect for polishing up to 138 pieces of jewelry in a single session, weighing anywhere from 75 to 97.5 kg. Its design allows it to handle large volumes without compromising quality.

The SuperbMelt Large Electropolishing Machine has a large 75-liter electrolyte capacity and is designed to work with various metals that have varying electrolyte ratios.

To ensure effective ion exchange and smooth finishes, it uses 25 liters of copper electrolyte combined with 50 liters of water for copper.

The setup is the same for silver; to get the ideal shine, use 25 liters of silver electrolyte and 50 liters of water.

In order to maintain the purity and shine of the K gold, the machine uses a specific method that involves adding 75 liters of K gold electrolyte without the use of water.

The machine’s sturdy yet small size, measuring 810 x 600 x 70 mm and only 25 kg, makes it ideal for professional workstations handling lots of jewelry. Its design prioritizes usability and operational efficiency, making it possible to process big batches fast and with little downtime.

Due to its high output design, the SuperbMelt Large Electropolishing Machine is the best option for large ring or bracelet producers who require polishing capabilities that are dependable, quick, and efficient. This machine not only increases production but also supports the consistent supply of beautifully finished items, which is crucial for remaining competitive in the high-volume jewelry market. It does this by drastically cutting the processing time while guaranteeing each piece satisfies high-quality requirements.

4.4, LThree-in-one electropolishing machine

Jewelers who need to handle several metal kinds at once will find the SuperbMelt Medium Electropolishing Machine to be an exceptionally effective and adaptable instrument. This machine is very beneficial for businesses trying to optimize their production processes since it can polish several jewelry batches in one operation with ease and efficiency. It is designed to handle a total of 60 pieces, 20 pieces of each of gold, silver, and copper.

The machine has a 4 liter electrolyte capacity, which is divided to meet the distinct needs of each type of metal:

It uses 1.3 liters of copper electrolyte to 2.6 liters of water for copper jewelry, which ensures excellent polish and effective material removal.

With 1.3 liters of silver electrolyte and 2.6 liters of water, the setup for silver jewelry is similar to that of copper and is designed to provide a shining finish.

To preserve the superior quality and inherent shine of K gold, the apparatus employs an alternative method utilizing 4 liters of pure K gold electrolyte, devoid of any water.

With dimensions of 420 x 310 x 36 mm and a weight of only 1.5 kg, the SuperbMelt Medium Electropolishing Machine is incredibly light and small, making it the perfect choice for small to medium-sized enterprises with limited space. Its little size belies its tremendous performance, as it can process three distinct types of metal at once without sacrificing the quality of the finished product.

Manufacturers who need to maintain a high throughput while making sure that every component made of various metal kinds is polished to the highest standards will find this machine especially useful. Processing more than one metal at once improves operational efficiency, boosts productivity, and decreases downtime. For jewelry companies trying to keep their production line flexible and producing high-quality products, it is an essential tool.

Conclusion

Electropolishing machines play a crucial role in the jewelry processing industry. Compared to manual polishing machines, electropolishing machines achieve surface polish through an electrochemical process, providing a more uniform, flawless, and reflective surface. Not only do they enhance corrosion resistance, but they also eliminate microscopic surface defects, making the products more attractive. Additionally, electropolishing machines are easy to operate, highly efficient, and excel in handling complex geometries and materials that are difficult to polish. Therefore, when selecting jewelry polishing equipment, it is essential to choose the right machine based on unique needs such as quality, efficiency, and material requirements. SuperbMelt offers a variety of electropolishing machine specifications, providing jewelry manufacturers with a range of options to meet high quality, high efficiency, and high safety polishing demands, whether for small-scale production or large-scale batch production.

FAQ Guide of Electro Polishing Machine

1. What is the difference between electroplating and electropolishing? What solution is used for electropolishing?

Although both electroplating and electropolishing are electrochemical techniques used in metal finishing, their functions and mechanics are different:

The process of electroplating:

Electroplating is mostly used to apply a thin layer of a different metal to a metal surface. This can improve characteristics including electrical conductivity, wear resistance, corrosion resistance, and aesthetic appeal.

Procedure: The workpiece to be coated serves as the electrolytic cell’s cathode, or negative electrode, during the electroplating process. The anode, or positive electrode, is usually composed of the coating metal, while the electrolyte is a metal salt solution of the coating metal. Metal ions from the electrolyte deposit on the cathode and form a new surface layer upon the application of an electric current.

The end product is a metal object that has a layer of another metal applied to it. By varying the current density, the electrolyte’s composition, and other factors, the coating’s thickness and quality may be managed.

Electropolishing:

The main purposes of electropolishing are metal surface polishing, smoothing, and deburring. It improves the metal parts’ shine, smoothness, and cleanliness. By getting rid of tiny flaws and dirt that can cause corrosion, it can also increase resistance to corrosion.

Procedure: The metal workpiece serves as the electrolytic cell’s anode during the electropolishing process. Lead or stainless steel are common examples of inert materials used to make the cathode. A combination of acids and other substances makes up the electrolyte. The metal workpiece’s outer surface gets oxidized and dissolves into the electrolyte when an electric current is introduced. This evens out surface high spots and smoothes down microscopic flaws and roughness.

As a result, the surface is more reflective and usually smoother. In addition to removing a thin layer of material that contains pollutants and embedded impurities, this technique can also improve the cleanliness and surface polish.

2. What solution is used for electropolishing?

A chemical mixture is utilized in the electropolishing solution, which must both react chemically with the material’s surface and efficiently carry electricity. The electrolyte’s composition varies according to the kind of metal being treated, however some typical components are as follows:

acidity:

Because it works well to polish aluminum and stainless steel, phosphoric acid (H3PO4) is frequently utilized. It brightens and evens out surfaces.

When electropolishing stainless steel, sulfuric acid (H2SO4) is frequently used with phosphoric acid. It assists in taking off the metal’s outer coating.

Nitric acid (HNO3): This acid is occasionally used alongside other acids, particularly for metals that corrode readily.

Glycerol ether:

To alter the electrolyte’s conductivity and viscosity, ethylene or propylene glycol may be added to acid solutions.

Alcohols:

Isopropyl Alcohol: Added to enhance the solution’s wetting qualities and aid in the polishing procedure.

Other substances:

Uses for chromic acid (H2CrO₄) include cleaning precision items and other specific uses. However, because of health and environmental concerns, its use is declining.

Although they have some uses, hydrochloric acid (HCl) and hydrofluoric acid (HF) are less frequently utilized because of their strong reactivity and possible side effects.

To attain the required surface smoothness while maintaining process safety, the electropolishing solution’s precise formulation needs to be closely regulated. The electrolyte’s temperature and concentration, the voltage and current applied, and the length of the electropolishing process are important variables that must be precisely controlled to produce desirable outcomes.

3. Do you need to passivate after electropolishing?

Although it’s not usually required, passivation following electropolishing is advised, especially for some metals like stainless steel. Passivation may be advantageous even after electropolishing for the following reasons:

- Enhanced Corrosion Resistance: Electropolishing leaves a higher concentration of chromium and nickel on the surface of stainless steel after successfully removing iron and other impurities. As a result, a passive coating of chromium oxide grows naturally, preventing corrosion. But passivation can strengthen this layer even further, making sure that any exposed iron is completely oxidized and that the surface has the highest possible resistance to corrosion.

- Removal of Contaminants: Electropolishing smooths and improves surface finish quite well, although minute residues or contaminants may still remain. A nitric acid or citric acid bath is commonly used in the passivation process to assist remove these residues and encourage the growth of a new, homogeneous oxide layer.

- Uniformity of the Passive Layer: Electropolishing, particularly on intricate geometries, can occasionally result in microscopic surface irregularities. Ensuring a consistent protective oxide layer on all surfaces is facilitated by passivation.

- Standard Compliance: In order to achieve hygienic and durability standards, laws may call for both electropolishing and passivation for specific applications, particularly in the food processing, medical, and aerospace industries.

- Because electropolishing leaves high quantities of chromium on the surface of stainless steel, it creates a passive layer by itself. However, passivation can improve the passive layer’s endurance and efficacy even further. This procedure is especially crucial in applications where the highest possible corrosion resistance is required.

4. What are the effects of electropolishing?

1. Enhanced Surface Finish Smoothness:

Electropolishing reduces overall surface roughness by selectively removing material from the peaks of tiny surface imperfections. The surface becomes glossier and smoother as a result.

Aesthetic Enhancement: Electropolishing leaves a bright, clean, and highly reflective finish that is visually pleasant since it can polish without mechanical abrasion.

2. Greater Corrosion Resistance Passivation:

This method, which is particularly effective in stainless steel, eliminates free iron from the surface, primarily leaving a higher concentration of components that resist corrosion, such nickel and chromium. By doing this, the metal’s inherent passivity is increased, strengthening its resistance to corrosion.Uniform Protective Layer: The metal is more durable in harsh conditions because of the smoother, less porous surface that prevents corrosive chemicals from adhering to and penetrating it.

3. Deburring Surface and Edge:

Metal components can effectively be free of burrs and sharp edges through electropolishing. This is crucial in situations where these flaws could cause contamination, part failure, or harm to other components.

4. Sanitation and Isolation

Contaminant Removal: Microorganisms and manufacturing residues, as well as other embedded or adherent pollutants, can be successfully removed from metal surfaces with this method.

Perfect for High-Purity Applications: Because of this, electropolishing is very useful in sectors that demand high standards of sterility and cleanliness, such semiconductors, food processing, and pharmaceuticals.

5. Diminished Product Stickiness

Non-stick Surface: Products have less of a tendency to adhere to the surface thanks to the smooth, non-porous finish. This is especially helpful for applications involving molds, dies, and other materials where clean release qualities are crucial.

6. Fatigue Life Enhancement

Removal of Surface Stress Concentrators: Electropolishing can increase the fatigue resistance of metal components and prolong their operating life by smoothing the surface and eliminating flaws where fractures might start.

7. Accuracy in Dimensions

Minimal Removal of Material: Even while electropolishing removes material from the metal’s surface, it often only removes material that is a few microns thick and does it very evenly. This makes it possible to enhance surface properties without appreciably changing the part’s size or fit.

8. Improved Prepareness for Inspections

Simpler Inspection: Parts may be visually inspected and tested non-destructively more easily on a smoother, cleaner surface, which guarantees superior quality and adherence to stringent industry regulations.

5. Does electropolishing prevent rust?

Particularly for stainless steel and other corrosion-resistant alloys, electropolishing can greatly aid in preventing rust. It helps prevent rust in the following ways:

1.Improved Resistance to Corrosion

Oxide Layer of Chromium: The high chromium content of stainless steel is a major factor in its resistance to rusting and corrosion. Through the selective removal of iron and contaminants, electropolishing raises the chromium-to-iron ratio on the surface. This encourages the passive chromium oxide layer to form, which keeps stainless steel from rusting naturally.

Dense and Uniform Passive Layer: The integrity of this passive layer is improved by electropolishing, which creates a uniform and smooth surface. Better resistance to rust is offered by a homogeneous, discontinuity-free coating.

2. Leveling Off

Reduced Surface Area: Electropolishing lessens the amount of surface area exposed to oxygen and moisture, two environmental elements that can lead to rust, by smoothing the surface.

Removal of Surface Residues and impurities: Electropolishing gets rid of residues and imbedded impurities that can cause corrosion. Rust can result from localized corrosion, which is less common on clean surfaces.

3. Disbursing

Elimination of Tiny Defects: The procedure eliminates burrs and other tiny defects that could collect moisture and impurities, creating possible places for the start of rust. Electropolishing lessens the possibility of rust forming by smoothing these spots.

4. Better Water Removal

Non-retentive Surfaces: Electropolishing leaves a smoother surface that is less prone to retaining pollutants and water. Due to the enhanced drainage, moisture does not remain on the surface, thus lowering the chance of rust.

Electropolishing is a very useful technique for improving corrosion resistance and decreasing the chance of rust, but it does not completely prevent rust, particularly in harsh environments or when the metal is left unmaintained and exposed to harsh chemicals or saltwater. Even on surfaces that have been electropolished, rust can still be prevented over the long term by routine cleaning and proper environmental protection.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited