Wax 3D Printer

SuperbMelt lost wax printer is used by jewelry manufacturers to produce high-quality jewelry.

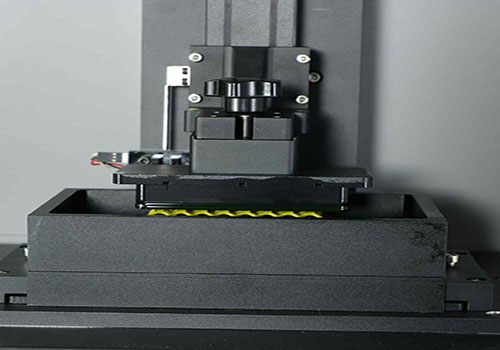

SuperbMelt White Wax 3D Printer can achieve 100% ashless combustion, making it suitable for high-demand precision jewelry design. It uses Castable 50% Wax Resin, a mixture of wax and photosensitive resin, which has similar performance and texture to wax. Due to its high wax content, this machine allows direct casting, with effects equivalent to traditional wax.

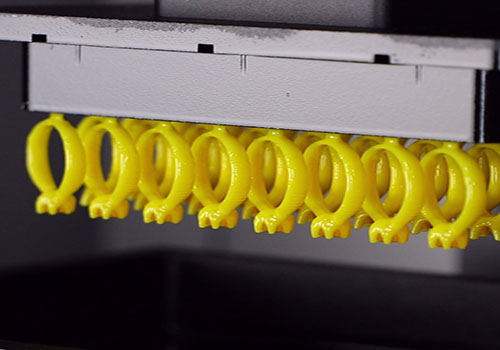

It is especially suitable for large-sized jewelry styles with smooth and perfect surfaces. The printed products can be directly used for casting jewelry made of gold, karat gold, platinum, silver, copper, and other materials.

With lost wax 3D printing technology, jewelry manufacturers can achieve higher quality, more complex, and personalized castings to meet various customer demands. This technology significantly enhances production efficiency and product quality, making it an indispensable tool in modern jewelry manufacturing.

| Model | SPB-W100 |

| DLP Resolution | 2560*1440 |

| X/Y Pixel | 43μm |

| Light Source | UV LED 405nm Texas |

| Print Layer Thickness | 0.025-0.1mm |

| Forming Size | 108mm*60mm*120mm |

| Data Format | STL/SLC |

| Machine Power | 1phase 220V,50Hz, 350W |

| Printing speed | 15-28mm/h |

Features

- 100% Lost Wax Casting:Burns cleanly without residue, ensuring high-quality jewelry output.

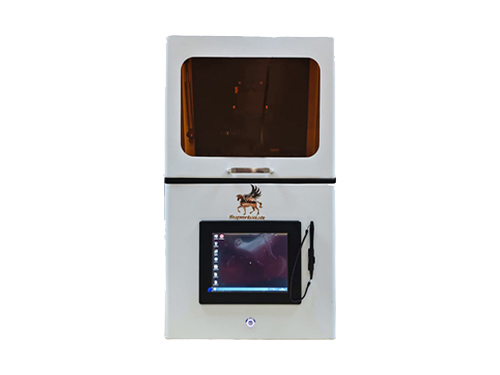

- Efficiency and Ease-of-Use:Simple structure, integrated computer design, easy operation, one-key printing, and quick material replacement.

- High Printing Speed:An oxygen supply system enhances printing speed by 3 times compared to traditional methods.

Benefits of Lost Wax Casting

- Complex and Intricate Designs: Allows for detailed and precise designs, ensuring high-quality end products.

- Material Efficiency:Reduces material waste and costs due to reusable wax molds.

- Versatile Metal Use:Compatible with various metals like gold, platinum, silver, etc.

- Mass Production:Suitable for large-scale manufacturing, meeting commercial production requirements.

The SuperbMelt 3D wax printer is designed to meet the demands of modern jewelry production, providing a reliable, efficient, and high-quality solution for creating intricate and beautiful jewelry pieces.

- 1. Custom Jewelry Design: Make jewelry according to each customer’s unique requirements.

Create elaborate and one-of-a-kind designs that are difficult to accomplish using conventional techniques. - 2. Model-making and prototyping: Make new jewelry designs quickly so they may be tested and evaluated.

Before final manufacturing, create precise and thorough models for client approval. - 3. Jewelry Mass Production: Create many identical replicas of a design in an efficient manner for the creation of commercial jewelry.

Make ensuring that big production runs are accurate and consistent. - 4. High-Precision Casting: To cast elaborate jewelry items, use high-precision wax models.

Ideal for casting copper, silver, platinum, and other precious metals. - 5. Complex Geometries: Construct intricate and delicate forms that are difficult to make using conventional casting techniques.

Perfect for tiny walls, undercuts, and intricate patterns. - 6. Rapid Design Iteration: Facilitate rapid design iterations and revisions in response to user input.

Shorten the design cycle by permitting fast creation of updated models. - 7. Small Batch Production: Ideal for creating jewelry collections that are limited edition or made in small batches.

Give yourself room to adapt to changing consumer needs and market developments. - 8. Creative and Experimental Designs: Assist designers and artists in pursuing fresh imaginative ideas.

Encourage the creation of innovative and avant-garde jewelry designs. - 9. Educational Goals: Jewelry design and production methods are taught at educational institutions.

Give kids practical exposure with cutting-edge 3D printing technology. - 10. Jewelry Adjustments and Repairs:

Make precise replacement components or parts for jewelry that has been damaged.

Make changes to current designs to provide fresh features or enhancements. - 11. Exhibition & Display Models: Make top-notch models to display new collections at trade fairs and exhibits.

Make exhibit items for showrooms and jewelry retailers.

Best 3d Wax Printer For Jewelry

The 3D wax printer for jewelry from SuperbMelt is created to satisfy the expanding needs of the jewelry production sector. Our wax printer produces products of remarkable quality and accuracy using cutting-edge technology and precise engineering. Jewelry designers who want to easily produce intricate and sophisticated designs should choose the Castable 50% Wax Resin.

Our 3D wax printer is simple to operate thanks to its user-friendly software and intuitive user interface. It can create high-resolution wax models that can be utilized for casting right away, which will save you time and effort during the production process.

The 3D wax printer from SuperbMelt is also made to last, with a robust design that guarantees dependable performance for years to come. For jewelry producers looking to cut costs and increase production efficiency, it is a great investment.

Look no further than SuperbMelt if you’re seeking for the best 3D wax printer for jewelry. The ideal method for producing elaborate jewelry designs is to use our Castable 50% Wax Resin along with our cutting-edge 3D printer.

Why SuperbMelt Jewelry Wax 3D Printer

Any Question About SuperbMelt Jewelry Wax 3D Printer

More SuperbMelt 3D Jewelry Printers For You To Choose

Here's What Our Satisfied Customers Have to Say

3D Resin Wax Printer Maintenance Tips

To Clean

Clean the printer after each use: Use a soft cloth or tissue to remove any excess resin from the resin tank, build plate, and other areas of the printer.

3D Printer Resin Tank

Change the resin tank regularly: Over time, the resin tank may develop scratches or other damage that can negatively affect print quality. Change the resin tank every few prints or whenever you notice any damage.

3D Printer Base Plate

Check and clean the build plate: Before each print, make sure the build plate is clean and free of any debris or residue. Use isopropyl alcohol and a soft cloth to clean the build plate if necessary.

SuperbMelt Wax 3D Printer FAQ

A unique kind of wax known as “investment casting wax” or “lost wax casting wax” with a castable 50% wax resin composition is typically utilized in 3D printing. This kind of wax is made specifically for casting jewelry, a procedure that entails creating molds from wax designs and then using the molds to pour molten metal into to create the finished metal portion. Investment casting waxes are designed to have a low melting point, excellent flexibility, and a good surface finish, which makes them perfect for producing complex and elaborate wax patterns for premium metal components and jewelry. A clean, exact mold cavity is left behind for casting the finished piece of jewelry or metal thanks to the ease with which investment casting wax can be readily melted and burned away from the mold.

No, the materials used in wax and resin 3D printers are not interchangeable. To produce finished items, resin 3D printers use liquid photopolymer resins that are ultraviolet light cured. varied varieties of resin may need varied curing times and light intensities, and resins are particularly made to match the printer’s light source and curing procedure. Additionally, resin tanks that are compatible with the particular resin type being used are frequently needed for usage with resin 3D printers.

On the other hand, wax 3D printers employ wax materials made specifically for investment casting. Because of the wax’s low melting point, high flexibility, and fine surface polish, it is perfect for making intricate and detailed wax patterns that may be utilized in the investment casting process to manufacture high-quality jewelry.

Even though certain 3D printers could be able to work with a variety of materials, it’s crucial to make sure the material is appropriate for the hardware and software of the printer. Using mismatched materials can lead to print errors, poor print quality, and even printer damage. It is therefore best to always use the supplies advised by the printer’s producer.

If you design and cast some high-precision jewelry, the most suitable 3D printer to buy is a wax printer. If you design and cast some ordinary jewelry, then you are more suitable to buy a 3D resin printer

- It is perfect for jewelry or metal casting due to its excellent wax burn off qualities. A cavity is left after the wax design is burned off, and this cavity can be filled with molten precious metal.

- Detail and Accuracy: Wax printing can create complex patterns and minute details with a high level of accuracy and detail. This makes it a well-liked option for jewelry making and other applications where accuracy is essential.

- The wax is simple to use and may be heated and reused as needed. It is also a cheap substance that makes it possible to produce goods in small quantities.

- Wax can be used as a sacrifice material in investment casting, where it is melted out of the mold and replaced with metal or ceramic, therefore it is compatible with a wide range of materials.

- In addition to jewelry, wax can also be used to create dental and medical models, as well as sculptures and other works of art.

A 3D wax printer is a type of 3D printer that creates elaborate, realistic wax objects using wax ingredients. The jewelry industry then uses these patterns for investment casting, in addition to a variety of other uses in fields like engineering and dentistry. To create a 3D model, the procedure often entails melting wax and extruding it into thin layers. The finished wax patterns can be used to make investment casting molds, enabling the fabrication of extremely precise and fine metal jewelry or parts.

- Print quality: Choose a printer that generates crisp, detailed prints with a smooth finish.

The 3D wax printer from SuperbMelt is created using high-precision technology and German-imported components. - Resolution: For greater precision and detail in your jewelry designs, choose a printer with a high resolution.

The resolution of SuperbMelt’s printer is 1920 x 1080. - Build Volume: Select a printer with an acceptable build volume based on the size of the object to be produced.

The SuperbMelt printer can print up to (96mm*54mm*120mm) in size. - Usefulness: Look for printers with simple controls, user-friendly features, and intuitive software.The printer from SuperbMelt is touch-activated, simple to use, and straightforward to run.

Design jewellery models with forms, details, sizes, etc. using CAD or other 3D modelling tools. Import the intended model into the jewellery 3D printer software, then set up the print parameters, support generation, and slicing to get it ready for printing. Load the printer with the necessary paper, turn on the machine, and start printing.

Choosing a jewelry 3D printer requires considering resolution, material compatibility, printing speed, and the ability to generate suitable support structures for jewelry.

White wax materials must be added with an oxygen generator to react.

Benefits:

(1) Oxygen will enter the printing tank through the underlying oxygen-permeable membrane to accelerate the flow of the liquid and shorten the printing time

(2) The surface of the printed product is smoother, and subsequent casting is easier to handle

SuperbMelt Lost Wax 3D Printer Guide

The role of a lost wax 3D printer

lost-wax 3D printer is used to create complex 3D models and parts. It utilizes wax material for printing, stacking layers of wax to gradually form the desired object. This printing technology finds wide applications in jewelry manufacturing, crafting, medical device production, and other fields. The advantages of the lost-wax 3D printer lie in its ability to quickly and accurately produce intricate-shaped parts, while also saving on material and labor costs. It provides the jewelry industry with an efficient and competitive manufacturing solution.

1.1, How are jewelry models cast?

There are several methods for casting jewelry models, with the most common being 3D printing, manual carving, and CNC machining.

3D printing is the most prevalent method, and 3D printed jewelry models can be divided into resin printing and lost-wax printing. Resin printing is suitable for creating complex and high-precision jewelry models, while lost-wax printing is suitable for crafting more delicate jewelry models and can be used in the subsequent metal casting process.

1.2, How to Use Lost-Wax Casting for Jewelry Rings

Making Wax Models: Create a wax model of the ring using 3D printing technology after designing it with CAD software. Make sure the wax model is of the highest calibre and closely depicts the final product.

Fix the wax models into wax sprues to assemble the wax trees, which will take the form of a tree. To maximise casting efficiency, many wax rings may be fastened to a single wax sprue.

Investing the Wax Models: To progressively build up a coating, submerge the wax tree in ceramic slurry. Permit the slurry to solidify and dry out.

Wax Burnout: Put the covered wax tree in a hot furnace to burn away the wax. In this process, the wax melts and forms a hollow inside the ceramic mould.

Melting the chosen metal (such as gold, silver, or platinum) in a crucible while preheating the ceramic mould is the process for metal casting. Pour the molten metal into the ceramic mould with care.

Allow the metal to cool and harden inside the mould before removing it. After cooling, take the ceramic mould out of the furnace and let the metal cool until it is safe to handle.

Remove the ceramic mould to expose the finished cast jewellery ring for cleaning and finishing. Polish the surface and remove any leftover ceramic slurry. To obtain the desired design, further finishing procedures, such as gemstone setting or surface texturing, might be carried out.

Verify the cast ring’s quality by closely looking for any flaws or irregularities. Make any required corrections or modifications.

Final Treatment: To improve the ring’s beauty and shield the metal from oxidation, apply the preferred surface treatment or coating.

1.3, Benefits of Lost Wax Casting for Jewelry

Lost wax casting makes it possible to create complicated and sophisticated jewellery designs while guaranteeing accurate dimensions and forms and preventing mistakes that may happen during conventional handcrafting. Jewellery may display distinctive characteristics and creative flare thanks to this technique. Reusing the wax moulds used throughout the casting procedure reduces material waste, encourages environmental sustainability, and lowers costs. Additionally, lost wax casting provides shorter production cycles than conventional hand carving, boosting production efficiency and delivery timeliness.

Jewellery manufacture is more adaptable and diversified thanks to lost wax casting, which works with a number of metals including gold, platinum, silver, and more. It produces beautiful jewellery that is delicate and elegant and has a more upscale appearance. To satisfy the needs of big orders and commercial production requirements, lost wax casting is appropriate for large-scale mass manufacturing.

SuperbMelt Wax 3D Printer

2.1, introduce

SuperbMelt Lost Wax 3D Printer is ideal for small-batch jewelry manufacturers, using Castable 50% Wax Resin, a blend of wax and photosensitive resin, which exhibits similar properties and texture to wax. Due to its high wax content, this machine allows for direct casting, achieving results comparable to traditional wax casting.

2.2, Specification

DLP Resolution: 19201080

X/Y Pixel: 50μm

Light Source: UV LED 405nm Texas Instruments DMD chip

Print Layer Thickness: 0.025-0.1mm

Forming Size: 96mm54mm*120mm

Data Format: STL/SLC

Machine Power: 350W

Input Voltage: 110-220VAC 50/60Hz

Conclusion

The SuperbMelt Lost Wax 3D Printer is a valuable tool for creating complex 3D models and parts, especially in the jewelry manufacturing industry. By utilizing a blend of wax and photosensitive resin, the printer can produce high-quality wax models suitable for direct casting. This technology allows for precise dimensions and intricate designs, ensuring the production of delicate and exquisite jewelry pieces. The process involves CAD design, wax model creation through 3D printing, wax burnout, metal casting, and final finishing. Lost wax casting offers benefits such as reduced material waste, shorter production cycles, and compatibility with various metals, making it an efficient and versatile solution for mass production needs in jewelry manufacturing.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited