Hollow Bead Making Machine

As a precious metal equipment expert, we provide a one-stop service to solve any problems with your hollow bead making line.

How to Make Hollow Bead?

At Superbmelt, we offer you solution machines that will help make your hollow beads production process seamless. We offer our customers throughout the world different machines that process raw materials from the beginning to the end of the production of the hollow balls. All our machines ensure you have speed, efficiency and accuracy when producing hollow balls.

Superbmelt hollow bead making machines range from the sheet splitting machine that cuts and prepares thin sheet metals for piping in the pipe making machine. The pipe making machine makes the perfect hollow tube and welds it together smoothly. The pipe drawing machine helps you to get your desired bead diameter. The hollow ball making machine automatically cuts the pipe into beads. Finally, the faceting machine makes diamond designs on your hollow balls. With our machines at Superbmelt, we offer solutions in terms of speed, affordability, precision and technical support for your hollow ball production company.

Supermelt has highly innovative technology experts and we have been creating and supplying machines throughout the world for over 15 years that meet clients needs and solve production problems.

In order to make your hollow bead production fast and high quality, here are the steps and machines you need:

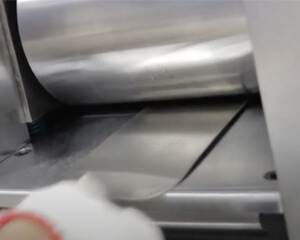

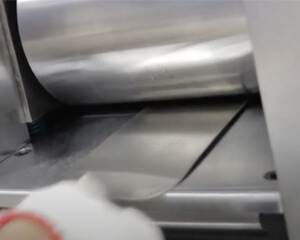

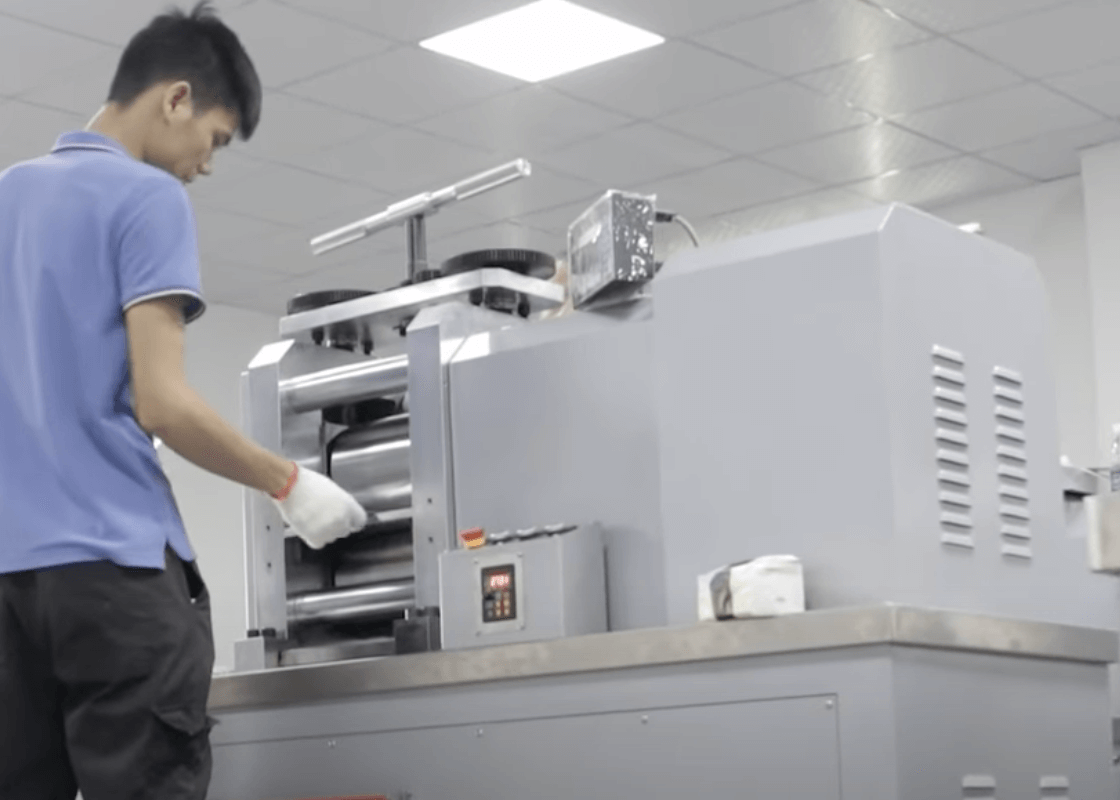

Step 1: Roll the sheet into desired thickness- At this stage, you need the rolling machine to flatten out your thick sheet metal. The machine gives you an extremely flat sheet with a uniform thickness. After rolling, the rolling machine gives the sheet surface a mirror effect.

Step 2: Sheet splitting- At this stage, you need the sheet splitting machine. The sheet metal becomes expanded and requires cutting off the excess material. You can cut your sheet metals into the required width. This stage prepares the sheet metals for welding into tubes.

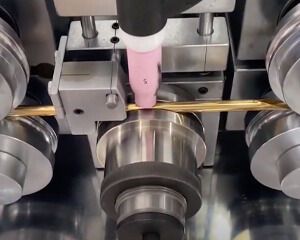

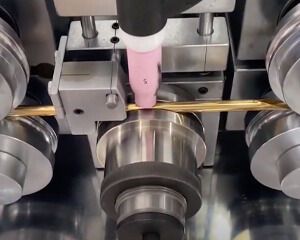

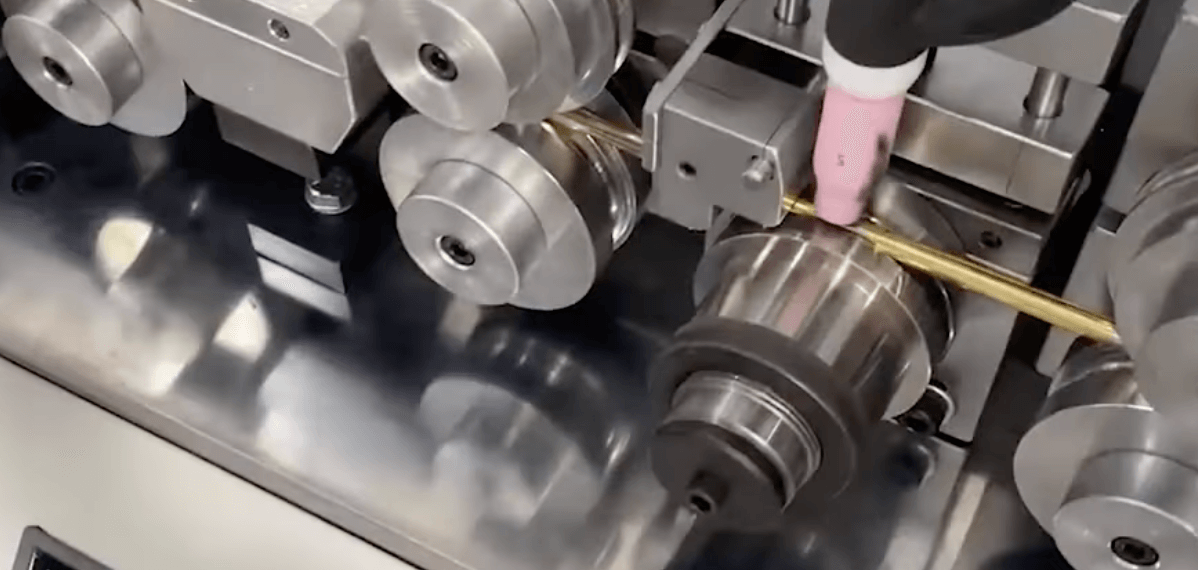

Step 3: Weld the sheet into hollow tubes- You need the hollow tube forming machine at this stage. The machine helps to perfectly fold the thin metal sheet into a tube and weld the sides together perfectly. The machine can work with metals like gold, silver, copper, and so on.

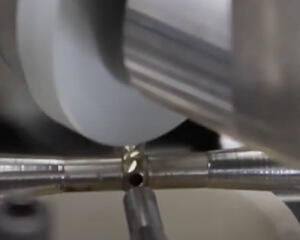

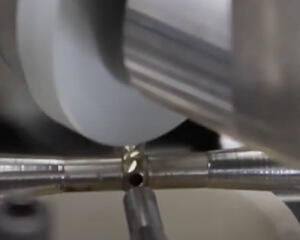

Step 4: Drawing the hollow tube to the required diameter size – In the entire drawing process, it is necessary to repeatedly draw the hollow tube until the diameter of the hollow tube is reduced to 2-14mm, which is also the size range of the usual hollow bead.

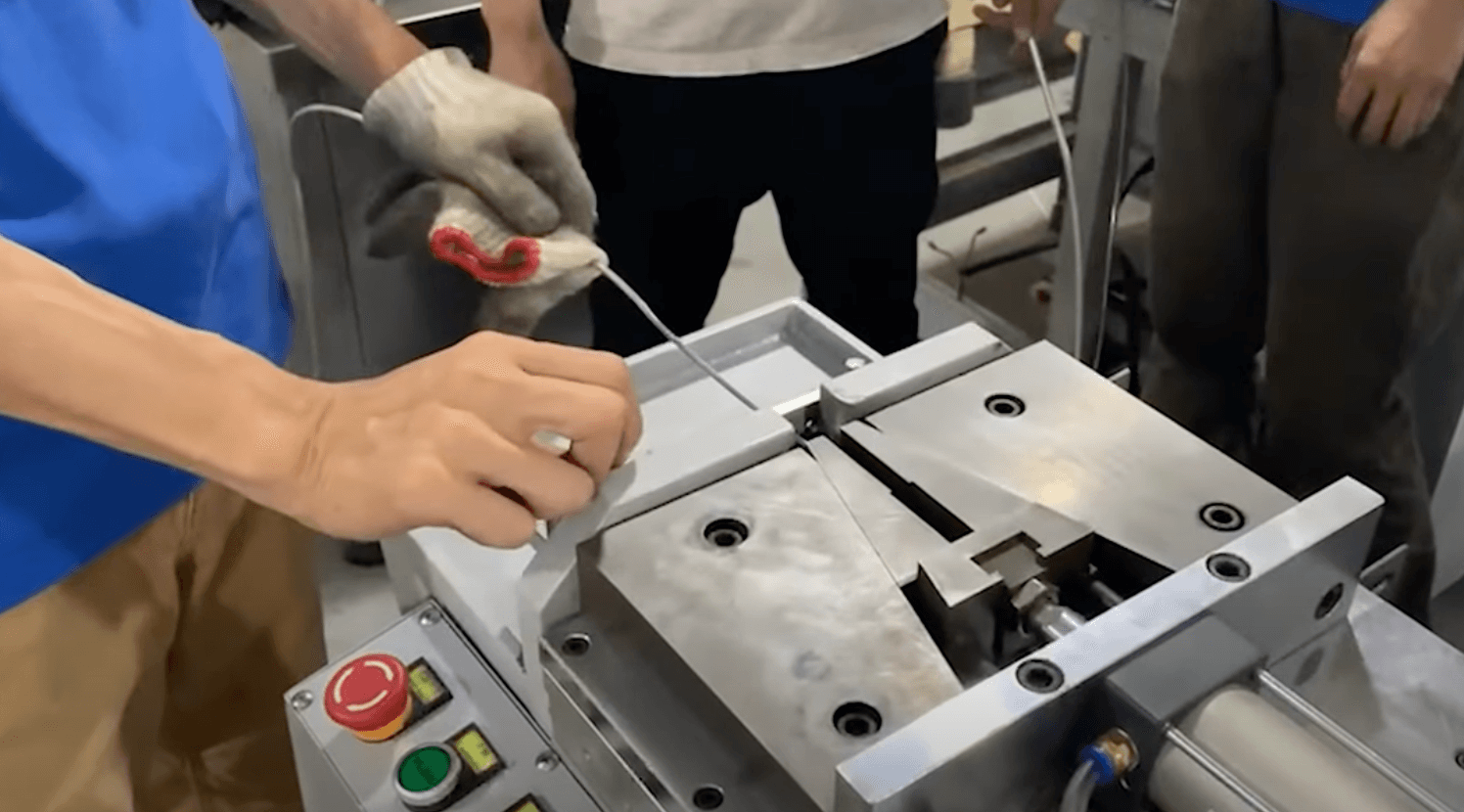

Step 5: Form hollow tubes into balls- The hollow ball making machine is required at this stage. The hollow tube making machine is an automated machine that makes different shapes and sizes of hollow balls. With this machine, you can create up to 120 pieces of balls in a minute.

Step 6: Diamond cutting head surface- At this stage, you need the diamond cutting machine to design the hollow balls. The diamond cutting machine uses diamond technology that makes precision cuts and designs on the bead surface. This leaves your hollow beads smooth and attractive.

Hollow Bead Making Line Process

1st Jewelry rolling mill

3rd Hollow tube making machine

5th Hollow ball making machine

Roll the sheet to required thickness

Sheet splitting to required width

Weld the sheet into a hollow tube

Tube drawing to required diameter

Form the hollow tube into a bead

Diamond cutting bead surface

2nd Sheet splitting machine

4th Pipe drawing machine

6th Bead diamond cutting machine

1st Jewelry roll mill

2nd Sheet splitting machine

3rd Hollow tube making machine

4th Pipe drawing machine

5th Hollow ball making machine

6th Bead diamond cutting machine

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

How to make hollow bead: Hollow ball making process line configuration solution

What is the hollow bead?

Hollow beads of different shapes and sizes are some materials specifically used for jewelry, tools, and product manufacturing processes. They generally resemble as hollow balls with varied thicknesses of the outer layers. These beads come in versatile designs and are extensively used in the jewelry manufacturing industry.

Since the demand for hollow beads has risen in the jewelry market, the need for their production in bulk amounts has increased too. Therefore, most commercial jewelry makers are integrating hollow bead making machine to simplify the manufacturing process. Let’s get to know about their types and applications.

1.1, What is the types of hollow bead?

There can be various hollow beads available for jewelry manufacturing, depending on their metal type. You can manufacture hollow beads out of various precious metals such as gold, K-gold, silver, and copper, etc.

Different shaped metallic beads produced in the SuperbMelt hollow bead making machine:

- Cylindrical

- Round shaped

- Square metal beads

- Tubular bugle beads

- Oval-shaped

- Drum shaped

Shapes of the hollow balls can also be customized. Some popular shapes are abacus bead, bamboo knot bead, teardrop bead, etc.

1.2, What is the application of hollow bead in the jewelry industry?

These small hollow beads are very much used in various decorative components. From clothing to jewelry and daily accessories to decorative items, their applications can be virtually endless. However, in jewelry industry, these small beads are specifically used as adorning materials that enhance the beauty of jewelry items.

Hollow beads can be used in creating a necklace, bracelets, earrings, anklets, and many more with a multitude of size variables. An automatic bead maker machine can make it easier to produce hollow beads of any size and metal thickness.

How to make gold bead by SuperbMelt machines?

The demand for durable and stylish gold beads-made chains is now increasing at a higher rate among both men and women. Well, this is the right time to take advantage of this opportunity and start your own hollow bead-making production line. But for that, you need to find the best and cost-effective solution for producing gold hollow beads. This is where you can trust SuperbMelt.

We offer the best hollow bead making machine that comes equipped with a lot of useful features to make production faster and smooth. SuperbMelt’s bead maker machine is widely used in hardware, jewelry, and other different industries. It is so powerful that it can hammer 2mm to 14 mm beads, abacus balls, special-shaped balls, olive balls, and more. Now, let’s talk about the production process of the gold bead.

2.1, Process the sheet under the continuous casting machine

You can use SuperbMelt’s continuous casting machine to cast different types of high-density metals, for example, gold, platinum, silver, and more. This machine works on converting the liquefied form of any precious metal into a solidifying strand. It can be used to specifically cast metals of uninterrupted lengths. Utilize this machine, and you can quickly cast the desired metals into the required shapes.

Our powerful metal casting machine comes with stirring and automated temperature control features so that the users can cast metal into hollow beads. When you do a continuous casting process in our machine, the molten metal forms semifinished slabs required for rolling the finishing mills. SuperbMelt’s continuous casting machine has various molds where you can direct the semifinished metal in the required mold to get the desired shapes.

2.2, Roll the sheet to required thickness

When it comes to making durable gold hollow beads, you need to make sure that the thickness and width of the sheet are good. Forget about the manual task; use SuperbMelt’s jewelry roll mill to give the metal sheet a perfect thickness. We offer a range of rolling machines that can meet the different widths and thicknesses you require. Due to various integrated technologies in this machine, the operator can easily arrange the thickness of the metal sheet to get the desired result.

You can easily get this powerful machine under your budget. Buy our flat rolling mills ideal for jewelers and craftsmen. Once done, you can use an annealing furnace to properly heat the gold to bring back the work hardening effect that is quite normal during the bending or drawing process. For a high-quality annealing furnace with the best features, you can always trust SuperbMelt.

We have the industry’s most advanced annealing machine that has PID intelligent temperature control unit, alarm, and water timer features. Once processed through an annealing machine, you need to make the sheet into a thin one to make beads.

For this, a wire drawing machine can work well. You will get perfect surface roughness, diameter, straightening degree, and internal microstructure.

2.3, Cut out the required width sheet to form a hollow tube

Once you have rolled out the required thickness of the precious metal sheet, it’s time to cut out the necessary width from the sheet to form the hollow tube. You can use SuperbMelt’s metal sheet splitting machine to cut the required width.

You can draw the pipe to get the required diameter for the hollow tube to make the associative hollow beads. Once the hollow tube is prepared with the appropriate diameter, you can use the hollow bead making machine to make hollow beads.

2.4, Weld the sheet into a hollow tube

Now you have the right type of sheet for your hollow bead; it’s time to convert the thin sheet into a hollow tube. For this, you will have to weld the sheet. You need to make sure the joints are durable enough to sustain normal wear and tear. For this, the manufacturer of beads can use SuperbMelt’s desktop welding machine. It produces accurate and durable welding results and can weld multiple sheets faster.

There is also our laser welding machine that offers a supreme level of automotive process for conducting the welding operations. In contrast to the traditional process of metal welding, this laser welding machine operates in a non-contact procedure that can meet almost all the requirements of the operator while delivering a clean and eco-friendly welding performance.

The application of this machine is widely processed for dental dentures, keyboard welding, and battery sealing cap welding and is ideal for sensor welding. Moreover, this machine shows extreme efficiency for generating attractive finishes for the products.

It is suitable for conducting small welding seams, large welding depth, and high welding quality. For an effortless and faster operation of making hollow tubes out of the welding sheet, you can use these advanced apparatus.

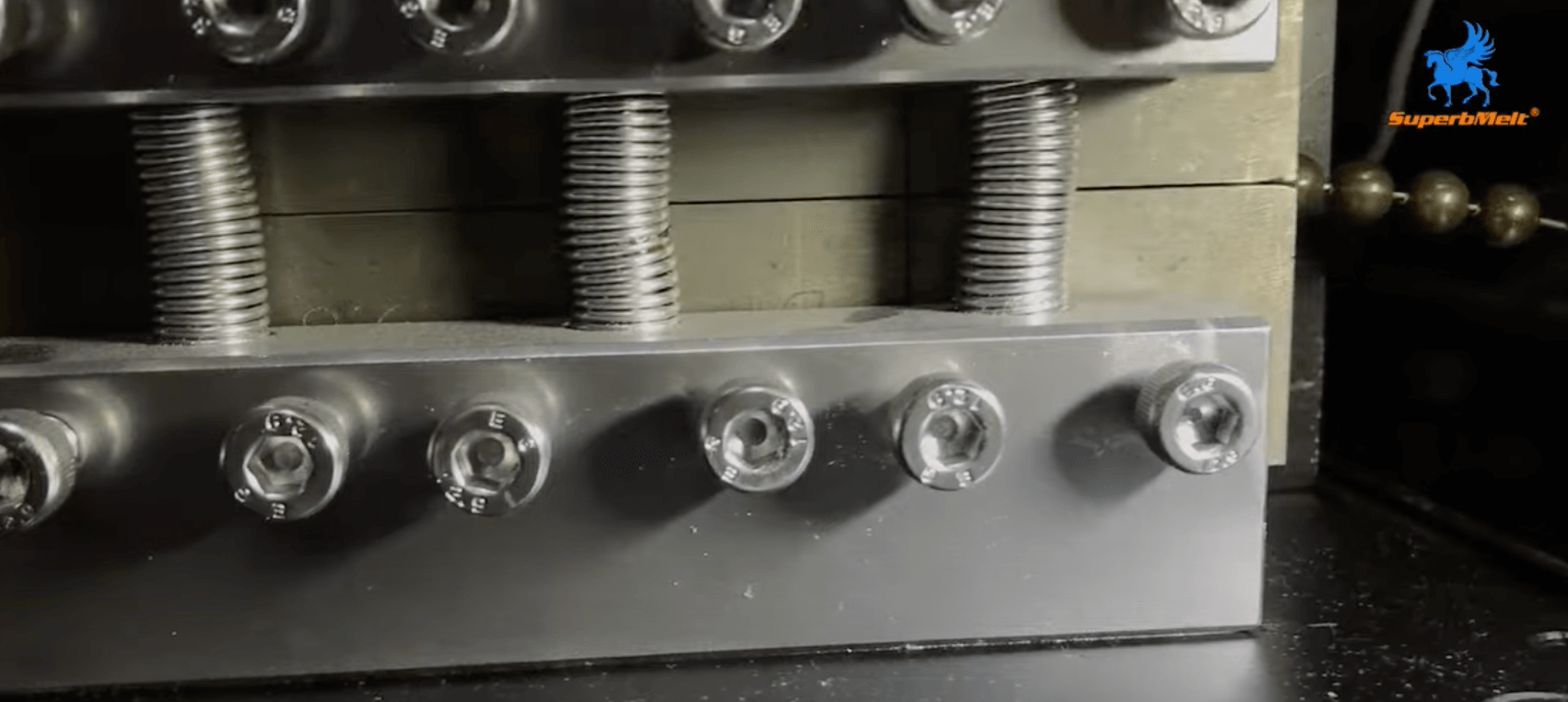

2.5, Drawing the hollow tube to the required diameter size

The pipe drawing machine is equipped with dies with different apertures, and the hollow tubes are inserted into these molds. The machine has a chain-driven drawing function to pull the hollow tubes out of the mold, and then shrink the diameter of the hollow tubes. The drawing is carried out in order from large to small, and finally a hollow tube with the required diameter can be obtained.

Throughout the drawing process, the hollow tube needs to be drawn repeatedly until the diameter of the hollow tube is reduced to 2-14mm, which is also the size range of the hollow tube, which is the usual hollow bead.

2.6, Form the hollow tube into a hollow ball

After creating the hollow tubes, it’s time to create hollow balls. This is where SuperbMelt’s hollow ball making machine comes to play. The machine is designed and developed to automate the hollow bead production process. You can use this to make different types of hollow beads, for example, abacus balls, special-shaped balls, olive hollow balls, and more. Speaking about the features, the machine is very fast, reliable, and efficient.

In fact, it can easily produce more than 120 hollow beads within just one minute. Besides, it has mechanical feeding support to make sure it functions at maximum precision. What’s more? Every hollow ball is pressed around six times to keep the shape even. The machine can be used to make beads from copper, silver, platinum, and more jewelry-making material. Our hollow bead making machine can be extremely helpful for any beading project.

Moreover, it can be an ideal machine for making a sustainable approach with making metal beads since our ball making machine does not make any unpleasant deafening noise as well as pollute the environment. This machine would simply form hollow tubes and cut the balls in large numbers, i.e., about 120 in no time. Such a process efficiently reduces the costs of labor and shortens the production turnover period.

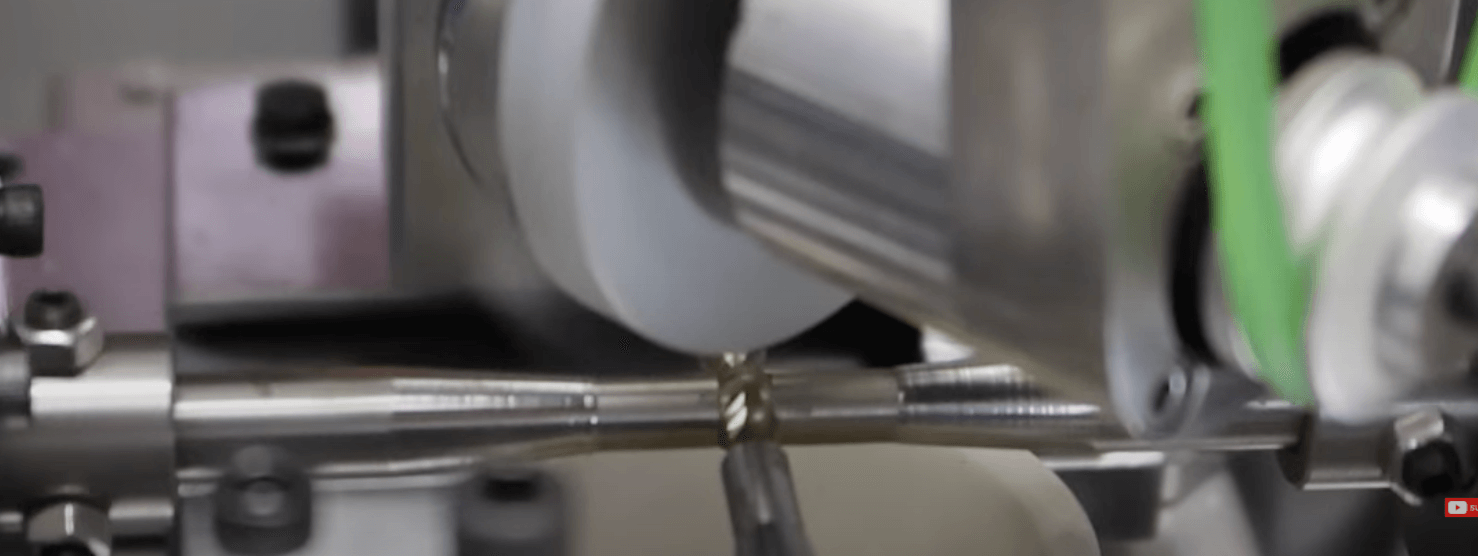

2.7, Diamond cutting bead surface

Once you are done with making beads, it is important to ensure that all the beads are in perfect shape. For that, you can use a jewelry hammering machine offered by SuperbMelt. After that, you need to create the pattern or design on the bead surface.

Most of the beads come with diamond cutting patterns. For this, you can use SuperbMelt’s chain faceting machine. Not just diamond cut, with this, you can make mirror finish lapping, plain lines, chamfer step cut, bevels cut, and more. For more detail, feel free to get in touch with SuperbMelt now.

With the rising demand for durable and stylish hollow bead chains, most jewelers are now searching for new ways to boost the capacity of their production. If you are one of them, then it’s time to give SuperbMelt’s bead bracelet making machine a try.

This can be the most efficient and effective solution for them. When our machine is functioning, it will complete the entire production process. It can carry out feeding, stamping, and other processes. Produce more than 120 beads every minute and increase your production capacity.

Well, you might be thinking why you should go for the hollow bead making machine offered by SuperbMelt? Remember that not all suppliers can offer you the best quality machine and features. However, to help you out in this, we have mentioned some tips that can help you to choose the best and more reliable bead making production line. Keep reading to explore more.

How can you choose bead making production line?

- Understand the scale of the factory and what certificates are available

In order to find the best bead supplier according to your requirement, you have to make sure they are qualified professionals who carry a wide range of different bead products. Because the more range of varieties you have for beading supplies, you could have more scope to make wide varieties of jewelry items in unique and colorful designs.

However, you can make your own bead making production line by getting a hollow bead making machine in your jewelry workshop. Technological advancement has made it possible for such machines to perform automatically to produce a mass of metal beads in accurate shape and size within a minute. But choosing a reliable machine supplier is crucial.

Before finalizing a supplier of a bead ball making machine, the buyers should make sure that the supplier is reliable. They should check their certificates. It is also crucial to check the scale of the factory to know its production process and quality.

It is also advisable to ensure that the supplier is certified by well-known professional certification bodies. Well, if you find it challenging to locate such a supplier, you can go for SuperbMelt. All the machines available at SuperbMelt are ISO CE SGS approved. We follow the required industry standards while making the machines.

- Does the factory have mature solutions and cases?

What does that mean? Well, it is about the total years of experience the supplier has. The experts always suggest partnering with a supplier who can provide you with the complete solution to establish your bead-making production line.

You can buy different machines from different places. But acquiring them can be very costly and time taking. How about getting all the machines from just one place? This can be possible if you choose SuperbMelt as your gold hollow ball making machine supplier.

SuperbMelt is quite popular for providing all the required machines that one needs to set up a production line. What’s more? The company has more than 15 years of experience in this field. A complete metal processing service can be done through SuperbMelt.

All the innovative and automatic SuperbMelt machines are popular for offering smooth, reliable, and fast processes for smelting, casting, or metal forming, ideal for various industries. SuperbMelt can be your one-stop solution for making gold jewelry items.

Since hollow metal beads are extensively used in jewelry manufacturing, SuperbMelt offers top-notch machines that can come in handy while processing a faster jewelry-making service.

This company’s production line can deliver you automatic machines like continuous casting machines, jewelry roll mills, wire drawing machines, chain making machines, hammering machines, and jewelry faceting machines, etc., to prepare the precious metals for jewelry beads production process.

- Has the factory delivered enough success stories?

It is a good idea to go through the success stories of the machine supplier. Why? By reading their success stories, you will get to know how their solutions have helped people to start their own bead-making businesses. Besides, it also demonstrates the machine and service quality offered by a company.

In the success stories, the clients will share their experience of working with the company, and that information will help you to decide whether you should choose them or not. Thus, it’s essential to go through the company’s testimonials to estimate their past consumers’ satisfaction level with the company’s service.

Some machine manufacturers and suppliers also have a portfolio page where they mention whichever industries they have worked with before. This would help the customers determine whether or not their machines would be suitable for their industry. Sometimes, success stories can reveal a lot of things about technical support quality.

Well, SuperbMelt has many success stories, and we have successfully helped hundreds of our valuable clients to establish their business without spending a lot of money and without dealing with any technical challenges.

Since SuperbMelt is integrating innovative technologies to automate its machinery, the company also provides the support system to educate the clients and offer consultancy services till they efficiently operate in the devices to produce fine jewelry.

- Go to the factory for on-site inspection

Even though it is not a compulsory point to consider, you can consider this point to learn more about the supplier. Nowadays, one can find all the important information from the official website of the company.

But still, visiting the site physically will offer a detailed insight into their production process. What’s more? Before buying a hollow bead making machine, you can try it out at the site to learn how it works.

SuperbMelt can surely offer you passes for on-site observation. Since the company’s production line is very extensive, the customers can also try out other machinery in line to automate your jewelry production process from jewelry casting to making. Furthermore, SuperbMelt also has knowledgeable and reliable gold and jewelry machinery experts to help goldsmith and gold miners smelt gold.

With more than 15 years of experience, SuperbMelt can provide various machinery solutions to diverse industries to improve their production efficiency. If you are a jewelry manufacturer, get in contact with SuperbMelt to build the full line of jewelry production processes.

SuperbMelt adopts various inventive technologies to update their machines which can save on precious metal wastage while improving the jewelry items quality for customers. While you are interested in buying a SuperbMelt gold hollow ball making machine, you can ask for other accessories associated with the machine to manufacture various types of beads of different sizes and designs.

- Learn about factories online, official websites, social platforms, videos, in-depth investigations, etc.

Is there anything that you need to consider before choosing a reliable hollow ball making machine supplier? Yes. You should check the social media profile of the company where you can find the reviews given by the old clients. Those reviews will prove the credibility of the supplier. Besides, visit the official website and check the listed machines.

There you can find all the details, including specifications, parameters, and features of the machines, to check whether they can satisfy your production requirements. Check the website for their content publications such as videos, articles, and blogs.

These contents can give you a great insight into their auxiliary facilities. Their articles and blogs can give you information about what features and advantages you can get from their production line.

Similarly, the videos can offer you some demonstrative content of various machines that can come in handy while operating on those devices. The video contents can be your primary source to know what you should expect from the machine you are going to buy. Additionally, you can go through various review websites online to make an in-depth investigation of your potential suppliers.

Consider all these things, and you can successfully choose the right supplier for your bead-making production line. If you want to know more about our hollow ball making machine and how it can help you, have a look at the FAQ section.

FAQ guide

What is the working principle of hollow ball making machine?

The hollow ball making machine is so powerful that it can hammer 2mm to 14 mm balls, olive balls, abacus balls, and more. It is used to cast different types of high-density metals like platinum, gold, silver, and more. Here you need to ensure that the thickness, as well as the width of the sheet, is good enough. Here the hollow ball making machine grinds the metal with inertia and force, and friction power. The raw materials go through a hollow shaft neck and into the hollow cylinder for grinding. The grinding mediums involve different types of the diameter of the cylinder. The ball making machine works with sliding motion, rotation between the grinding metal that provides a grinding effect on raw material and produces beads. With this process, the hollow tubes create hollow balls. The machine is designed to make different types of hollow beads. Additionally, the machine is very fast, efficient, and reliable.

What are the advantages of automatic hollow ball making machine?

The hollow ball making machine offers so many benefits to the manufacturers for making stylish and durable metal beads such as:

- High quality

The hollow bead making machine gives high-quality metal beads to the manufacturers. The working principle of the machine is in such a way that you get the best beads out of it. No matter what type of beads you are making, the customer or client will always check the quality, and this machine ensures quality with its high-quality production ability.

- Uniform shape

One of the major advantages of using a bead maker machine is it offers a uniform shape to the beads. When you are designing and gold/silver bracelet or chain, then you need to have uniformly shaped beads, and that is where this machine won't disappoint you. Each ball presses six times, and that gives an even shape to the bead. It has the ability to make 120 uniform beads every minute that will further enhance the production capacity.

- Uniform thickness

Apart from the uniform shape, the hollow ball making machine also offers uniform thickness to the beads. So if you are taking orders in bulk, you can set the thickness as per the requirement and produce a huge number of beads in minimal time. This automatic thickness control of bead maker machine is an exceptional advantage over the traditional metal bead production process. Since the mechanical feeding ensures preciseness of each feeding, the beads are also come out in even shapes. Every bead size comes between 2mm to 14mm, with a standard thickness of 0.08mm to 0.45mm. The holes size in each bead comes with a standard size, too, i.e., 0-0.8mm to 0-5.2mm, which is an impressive delivery for producing high-quality beads.

- Large output

As we have mentioned before, the machine has the ability to produce 120 beads in just 1 minute. Just imagine how many beads you can make in one hour. The best thing about the machine is it gives huge output that makes the production effort easier.

- Reduce labor input

If you are working with a manual machine, then there are so many laborers you need to hire. You need someone every single step, but it won't be the case with the automatic hollow ball making machine. You can produce different types of metal beads without using much labor. You just have to make a few adjustments, and you are good to go. This will not only reduce the production time but also save a lot of money. You don't have to invest in manpower; instead, you can use the money in different applications.

Which materials of hollow ball can be processed?

There are various materials of hollow ball that can be processed, such as:

- Stainless steel

Stainless steel is one of the popular materials used in various products. In the past, it has been used in making beads to produce jewelry. Stainless steel can be processed in the machine to make beads as well. Stainless steel doesn't react with oxygen, so it is corrosion resistant as well, which makes it great for various applications. It offers a shiny look, and that's why it is used in making various products in both the jewelry and hardware industry.

- Gold

Gold can also be processed with the machine. Gold jewelry is in high demand as well. Gold looks very attractive as well, and it is one of the high selling materials on the market. The high use of goal beads can be found in the jewelry industry.

- Silver

Silver is cheaper and easily available. It has a high demand as well and is used for making various products. Silver is also processed to make silver bracelets and beads as well.

- Copper

Copper can also be processed with this ball making machine to produce copper beads.

What are safety features of automatic hollow ball making machine?

The hollow ball making machine is widely used in the hardware and jewelry industries. This machine can easily make 2mm to 14 mm balls automatically. It can also complete the process of stamping, feeding, and others easily. There is no waste gas, and it produces low noise, wears less, and minimal failure rate.

Do operating bead making machines require special training?

- Operating a bead making machine is not tough at all, and with a jewelry hollow bead production engineer, you can operate the machine. Even if you don't have an engineer, you can learn how to operate by seeing some videos and instructions that we provide. The process is not complicated, and a person without any experience can easily operate the machine with only a few days of training. So if you want to start your production line, then you can buy this machine without worrying about the operating system.

- If you are entering this industry for the first time, then you will get full support from us. You can start the production as instructed on the video and manual that would be provided by us. The machine will be debugged so that you can use this machine directly. If you are still worried about it, then we will give you on-site guidance and training as well.

- We have highly experienced professionals and experts who can guide you through the process. This machine has all the safety mechanisms, and most importantly, it is automatic, which will be easier to use. So if you want to start your business with this machine, you can purchase this machine without having a second thought.

What does the hollow bead look like?

The hollow bead made by the hollow bead making machine is 3D in shape and looks like a shiny drop. As small beads, the products look uniform and polished. The way the beads look depends on their shape, size, and material. Since most of the beads are made of metals like gold, the beads have a golden gleam.

Since the bead maker machine is accurate in its process, the overall look of the bead is uniform and smooth. The beads are smooth from inside and out so that jewelry making and other processes go on smoothly. Since the beads are used in jewelry making, the look of the beads matters a lot.

The gold beads made by the machine look perfect and lustrous, so the jewelry made from the beads looks equally brilliant. The gold beads are made according to the most recent styles, and thus, the beads look stylish. Though tiny, the beads look stylish with a golden finish. Apart from the stylish look, the beads also look to be the perfect size for jewelry creation. These days, different shapes and sizes of beads are used in jewelry making.

Depending on the size and shape, the beads look different in each lot. The beads have the perfect curvature to be incorporated in chains and necklaces. The beads also can be incorporated in new bracelets and bangles. Depending on the material used for the creation of the beads, the overall look of the beads is altered. The look of the bead is sophisticated enough to be used in jewelry.

Apart from gold, silver, and other precious metals are also used in bead maker machine. The bead maker machine creates beads with the exact specifications fed into its system. Thus, the beads look exactly the way needed for jewelry. The beads look like the exact replica of the goldsmith's imagination.

What machines are used to process raw materials into hollow bead?

Before the bead maker machine makes the beads, different machines process the raw material used for bead making. The most common machines used are continuous casting machines and rolling mill machines. The continuous casting machine processes high-density precious metals like gold and silver to create strands and sheets for the desired shape of jewelry. In the continuous casting machine, the liquid metal is cast to give it a proper solid shape. The continuous casting machine gives a semi-finished touch to the gold or silver metal before it proceeds to the rolling mill machine.

- A continuous casting machine gives the gold material a uniform look by casting the material in a steady-state form from the liquid state. The resultant material is smooth and uniform in look. Once cast in the continuous casting machine, the metal shows subsections of the sheet. The raw material can then be given the desired shape of a sheet or a wire, depending on the requirement. The continuous casting machine comes equipped with automatic stirring control and temperature control so that it is easy to shape up the metal. The operator can use this powerful casting machine easily to get the required raw material for hollow bead making.

- The next machine that is used to process the metal for hollow bead making is the rolling mill machine. After passing through the continuous casting machine, the metal is put into the rolling machine for further processing. The rolling mill machine creates sheets of equal thickness, perfect for making hollow beads. Rolling mill machines are used in jewelry making because sheets of precious metals are used for making jewelry. Even before the beads are made, the sheets of precious metals are needed. This is because beads are made from metal sheets of uniform thickness.

- The rolling mill machine adds metal through extrusion, and the overall output of the machine is the thinning of the raw material for the precise thickness of sheets. Since the creation of jewelry and beads is an intricate, delicate work, there is a need for precisely thin sheets. The rolling mill machine creates the perfect sheets for jewelry making and reduces the hassle for the goldsmith. The rolling mill machine creates such sheets that are smooth and have a mirror finish on them.

- Such sheets with a mirror finish are the best for the creation of gold beads and other jewelry components. The rolling mill machine has good safety performance with an emergency stop mound layer. The rolling mill machine helps in the creation of metal sheets without much flash or loss of metals. The rolling mill machine has an automatic fuel refilling option so that the complete process of rolling metals is without any hitches.

- The annealing furnace is also one of the machines used for further processing of raw materials. The annealing furnace is used to create a work hardening effect on the sheet needed for bead making. The annealing furnace is used to heat the sheet so that the sheet hardens for further processes of bead making.

- The annealing furnace has intelligent temperature control features that give superior control over the output of the machine. The annealing furnace also has a superior smart alarm system that allows proper running of the machine. Moreover, the furnace also has water timer features in its framework.

- Once the sheet is drawn inside the annealing furnace, the sheet is put through the wire drawing machine to make the sheet thinner. The sheet thinning is needed to get the perfect raw material condition for the creation of gold beads. The use of a wire drawing machine helps in getting the perfect thinness and microstructure for bead making. After drawing the sheet on a wire drawing machine, the raw material has perfect roughness and friction coefficient so that the bead is properly made.

- Another machine that is used for processing raw materials is the desktop welding machine that creates hollow tubes for bead making. The desktop welding machine creates hollow tubes from the sheets of metal. The welding process is a very accurate one that creates uniform shapes and sizes of tubes.

- The welding process is very important to follow so that good beads can be created. The welding machine creates good tubes that can withstand wear and tear to the material. The welding machine creates tubes at a faster pace and with durable results. The welding machine is easy to use and operate for large-scale tube formation. The welding machine welds the sheet into the right dimensions for the tubes.

- The tubes create the initial skeleton for the beads. The creation of tubes is very necessary before the use of a hollow bead-making machine. Apart from these machines, other machines are also used for the processing of metal sheets into hollow beads for jewelry. Good quality machines with advanced features become a necessity for the bead-making process.

What are the different shapes of hollow bead on the market?

The beads made by the bead maker machine can be of different shapes. In jewelry-making, different types and shapes of beads are used. From small beads to oversized beads, everything is in fashion when it comes to jewelry. The different shapes of gold and silver beads used in jewelry are round, cylindrical, squarish, etc. Round hollow beads are some of the most common types of beads used in jewelry.

These beads have a round shape and a shiny, smooth finish. Round beads are used in necklaces and bracelets. While round beads were earlier in fashion in jewelry, beaded jewelry is making a comeback. So, round beads are also seeing an increase in demand. Cylindrical beads are also very popular and sometimes used in combination with round beads.

The cylindrical beads have a long cylinder-like shape and are used to fill up the length of the jewelry. While round beads give fullness to the jewelry design, cylindrical beads give a sleeker look to the jewelry. Squarish beads also have a huge demand in the current production trends because they are used in contemporary jewelry. Square beads give an unusual look to the jewelry. Often squarish beads have rounded edges with the body of a cube.

Squarish beads are therefore called cube beads too. Another shape of beads is a teardrop. Teardrops or pear-shaped beads give a touch of softness and elegance to the jewelry. Teardrop-shaped beads of gold give a feminine quality to the jewelry. Many women prefer wearing teardrop bead jewelry.

Teardrop beads of precious metal are used in earrings and necklaces. These shapes of beads are usually the most used beads in jewelry. Other shapes of beads also include pyramid-shaped and barrel-shaped beads. These shapes of beads are used in contemporary and traditional jewelry designs.

What is the capacity of SuperbMelt's Hollow bead making machine?

Our SuperbMelt hollow bead making machine is integrated with various additional features to produce fine quality metallic hollow beads. Since it's an automatically working machine, it can complete about all the steps of the jewelry beads production process, starting from feeding to stamping and many more. Our innovative approach made it possible for the hollow ball making machine to give extremely fast production efficiency for about 120 pieces of metallic hollow ball beads per minute.

In the jewelry industry, making jewelry beads is very essentials since not just gemstone, diamond, or pearl beads are in the trend anymore, but various metallic beads are gaining popularity over wearing beaded jewelry pieces. However, making high-class, supreme quality, and long-lasting hollow balls of different styles and shapes can be a very complex and exhausting process in just the manual process using traditional techniques of jewelry making.

Using our range of jewelry-making apparatus such as SuperbMelt metal testing machine, casting machine, jewelry rolling mill, wire drawing machine, hollow tube forming machine, and hollow bead making machine, etc., you can produce ideal jewelry beads thoroughly with the automotive process. This hollow bead-making machine is designed to process a wide range of precious metals such as gold, karat gold, silver, alloy beads, etc., which have lightweight and can produce thin walls.

All the hollow beads produced from the beading machine for bracelets can have a thickness of about 2mm and a diameter of 14mm. Moreover, our machine can customize many styles of hollow bead balls, such as olive balls, abacus balls, and special-shaped balls, etc. Most of the popular shaped jewelry beads can be produced with our SuperbMelt hollow bead making machine e.g.water drop bead, bamboo knot bead, various animal-shaped beads, bugle beads, etc.

Is a hollow bead a good investment?

Our SuperbMelt hollow bead making machine is integrated with various additional features to produce fine quality metallic hollow beads. Since it's an automatically working machine, it can complete about all the steps of the jewelry beads production process, starting from feeding to stamping and many more. Our innovative approach made it possible for the hollow ball making machine to give extremely fast production efficiency for about 120 pieces of metallic hollow ball beads per minute.

In the jewelry industry, making jewelry beads is very essentials since not just gemstone, diamond, or pearl beads are in the trend anymore, but various metallic beads are gaining popularity over wearing beaded jewelry pieces. However, making high-class, supreme quality, and long-lasting hollow balls of different styles and shapes can be a very complex and exhausting process in just the manual process using traditional techniques of jewelry making.

Using our range of jewelry-making apparatus such as SuperbMelt metal testing machine, casting machine, jewelry rolling mill, wire drawing machine, hollow tube forming machine, and hollow bead making machine, etc., you can produce ideal jewelry beads thoroughly with the automotive process. This hollow bead-making machine is designed to process a wide range of precious metals such as gold, karat gold, silver, alloy beads, etc., which have lightweight and can produce thin walls.

All the hollow beads produced from the beading machine for bracelets can have a thickness of about 2mm and a diameter of 14mm. Moreover, our machine can customize many styles of hollow bead balls, such as olive balls, abacus balls, and special-shaped balls, etc. Most of the popular shaped jewelry beads can be produced with our SuperbMelt hollow bead making machine e.g.water drop bead, bamboo knot bead, various animal-shaped beads, bugle beads, etc.

Is a hollow bead a good investment?

The traditional methods of making beads involve the utilization of flames and hammering the thin metallic substances. All those processes can pose a major safety hazard where you can potentially injure yourself or the beads getting out of shape, thereby wasting the precious metals.

But with the use of our SuperbMelt hollow bead making machine, the automatic hollow ball making process, operators can produce metallic beads faster and in a uniform shape within seconds. In the traditional process, the balls are formed in extremely uneven shapes, which can later lead to the use of a cumbersome process, so it increases the operational cost while producing poor output.

Our automatic hollow ball making machine is very much capable of minimizing subsequent metal processing steps while yielding an extremely high output in a minimum time span which can reduce the operational cost significantly. The low cast bead production can have much thickness to the beads that can make the jewelry heavy at the end.

Additionally, the relative processes involved in the traditional methods can be more complex, and the finished product can consume a lot of time and money in the operation, ultimately making the production process rather slow. Moreover, our bead maker machine can generate substantially thin and uniform beads with extreme durability and various metal optimization features, so you can complete the operation with much less labor than the traditional process of metal bead production.

Conclusion

Hollow ball making machine is now extensively used in various product manufacturing industries such as hardware machines, tools, and equipment, the jewelry industry, etc. These machines have many facilities to prepare metallic hollow balls in various shapes in a more fast and efficient way, contrary to other traditional ways.

The SuperbMelt hollow bead making machine is advanced designed to cut and roll the precious metals to get a shiny diamond effect during procuring metallic hollow beads. These unique technologies are very much helpful with cutting the metal balls automatically in a 360-degree rotating motion.

When you do the job manually, these small items are rather difficult for hammering and cutting the metal in various shapes and sizes, not to mention it can potentially increase the risk of getting injured.

SuperbMelt hollow ball making machine is very precise in following its integrated technologies and mechanisms, which is why the machine keeps a strict check on the quality of the balls produced. With so many auxiliary facilities, this machine is a one-stop solution for manufacturing top-notch metal beads of versatile shapes. With about eight different types of axes in the machine, you are able to give diverse designs to the ball.

Additionally, the ball making machine is equipped with multiple patents that enable the operator to make facets on the spherical surface of the metallic balls and holes. Our SuperbMelt beading machine for bracelets operates on automation facilities which further simplifies the mechanism of producing metal beads such as automatic bead loading units, LCD, Keyboard, protection covers, spare belts, and many other electronic parts.

Our hollow ball making machine is able to cut metallic wires of any thickness to form ball beads within seconds, effortlessly due to the various automatic features in accurate sizes, especially with using a 3D laser scanner.

Due to the supreme machine’s capacity, in each feeding, the bead making machine can generate about 120 pieces of beads per minute. Additionally, with the shaft-type transmission, every bead ball presses about six times to shape all the beads evenly.

If you want an extensive collection of jewelry manufacturing machines, SuperbMelt can facilitate you with many innovative and highly efficient precious metal processing tools and equipment. In our inventory, you can find the gold testing machine, laser marking machine, dot peen marking machine, jewelry rolling mill, wire drawing machine, hollow tube forming machine, hollow tube forming machine, Logo stamping machine, coin press machine, etc.

From large to small industries, anyone can enjoy the advantage of working in an automatic mechanism for jewelry production. With all these innovative features that complete the bead-making process automatically, starting from feeding, cutting, stamping, hammering, and so on, it would be very convenient to maximize your dead production using our hollow bead making machine.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited