Mini Laser Engraving Machine For Metal

Chinese Manufactured 20W Mini Metal Laser Engraving Machine

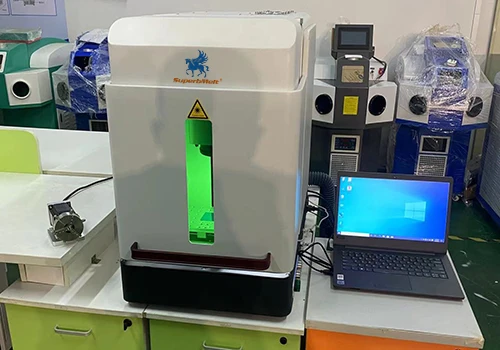

SuperbMelt MiNi Laser Engraving Machine for Metal is a top-of-the-line engraving equipment specially designed for processing gold, silver, alloys, and platinum jewelry. This machine harnesses the powerful 20W laser to assist jewelry businesses in achieving precise engraving.

Unlike traditional manual engraving methods, our laser engraving machine offers numerous advantages, such as the ability to quickly and precisely complete art or jewelry engravings, enhanced accuracy, and complexity of engraving. It helps jewelry manufacturers achieve batch production, saving time and costs.

This compact high-speed laser marking machine significantly reduces time and cost expenditures. Perfectly suited for jewelry stores with limited processing space, its small size does not compromise quality or efficiency.

| Type: | Mini Laser Engraving Machine For Metal |  |

| Número de modelo: | FLMM-series | |

| Laser power: | 20W/30W/50W | |

| Marking range: | 100mm×100mm | |

| Marking speed: | ≤10000mm/s | |

| Power supply: | AC220V±10%/50Hz | |

| Cooling method: | Air-cooled | |

| Positioning method: | Red ray positioning | |

| Accessibility: | 3 red ray assisted focus | |

| Lifting stroke: | 250mm |

- Unmatched Stability:

Our laser technology utilizes fiber optic transmission, ensuring increased oscillation, minimal loss, and exceptional stability. Achieve higher product yields with reliable performance.

- Remarkable Speed:

Benefit from seamless integration of cutting-edge hardware and software, coupled with high-speed imported galvanometer mirrors. Boost your productivity with marking speeds of up to 10,000mm/s.

- Unparalleled Convenience:

The compact design allows for handheld operation and optional fly marking configuration, providing utmost flexibility for your marking needs.

- Zero Consumables:

The fully air-cooled fiber laser guarantees a long lifespan without the need for consumables, resulting in low maintenance and operational costs.

- Automatic Height Adjustment:

Effortlessly control the focal distance with the one-touch automatic height adjustment feature, ensuring precise and convenient operation.

Invest in the SuperbMelt MiNi Laser Engraving Machine for Metal today and unlock a world of high stability, exceptional speed, unmatched convenience, zero consumables, and automated height adjustment. Maximize your efficiency and elevate your marking capabilities with our cutting-edge laser engraving technology.

Application Range: The SuperbMelt MiNi Laser Engraving Machine for Metal is widely used for marking and engraving in industries such as automotive, integrated circuits (IC), electronic components, silicon wafers, electronics, electrical appliances, communications, computers, clocks, glasses, jewelry, and craft decorations.

Compatible Materials: This machine is specifically designed for engraving on various metals, making it suitable for all types of metal materials.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Mini Laser Engraving Machine For Metal

SuperbMelt Laser Engraving Machine Related Products

Mini Laser Engraving Machine for Metal Guide

Introduction

SuperbMelt Desktop Laser Marking Machine for Gold Jewelry: High-Speed Engraving, Increased Productivity, and Convenient for Small-Scale Jewelry Businesses.

The SuperbMelt Desktop laser marking machine for gold jewelry offers high-speed engraving capabilities, allowing for improved productivity. Its compact and convenient design makes it suitable for small-scale jewelry processing businesses. The open-style working platform facilitates the placement of materials, and it can also be integrated into a production line for streamlined operations. This machine effectively caters to the processing requirements of large-format materials, providing efficient and precise processing capabilities.

1.1,Specifications:

- Laser Type: Fiber laser

- Laser Power: 20W-45w

- Engraving Area: 100mm×100mm

- Engraving Speed: Up to 10,000mm/s

- Compatible Materials: Gold, silver, alloys, and other metal materials

- Working Platform: Open-style platform

- Integration: Can be integrated into a production line

- Dimensions: 1200*600*1450mm

- Weight: 20kg

- Cooling System: Air-cooled

- Maintenance: Low maintenance requirements

- Operating Cost: Low operating cost due to the absence of consumables

- Control Panel: Computer control + digital drive signal

1.2, laser marking machine working

A device that employs a laser beam to etch or mark items is called a laser engraving machine. The idea behind it is that the high energy density of the laser beam causes the material on an object’s surface to vaporise or oxidise, producing the desired pattern or text. Three components make up the workings of a laser engraving machine: the laser generator, the optical system, and the control system.

What is a laser engraving machine?

Aside from increased productivity, laser engraving equipment also allow for the production of rounded, smooth surfaces during the engraving process. These devices successfully reduce deformation and internal stress by swiftly lowering the temperature of non-metallic materials.

Based on the kind of laser used, laser engraving machines may be divided into two categories: CO2 non-metal laser engraving machines and fibre metal laser engraving machines. While high-end models include CO2 metal RF tubes, CO2 non-metal laser engraving machines often use glass laser tubes for home purposes.

Utilise laser technology to its fullest extent for the most precise and effective engraving possible. Invest in a laser engraving equipment right now to see how it may completely revolutionise your company.

2.1, How to Use a Laser Engraving Machine for Ring Making

To generate the required ring design, use CAD software. Make sure the design is compatible with the software used by the laser engraving equipment.

Choose an appropriate material for the ring, such as gold, silver, or any metal that may be engraved with a laser.

Follow the manufacturer’s directions for setting up the laser engraving equipment. Ensure that the equipment is calibrated correctly and adjust the laser focus according to the ring material thickness.

To keep the ring from moving while the engraving is being done, secure it in the specified fixture or clamp.Open the software for the laser engraving equipment and import the ring design.

Remove the ring from the fixture when the engraving is finished.To improve the ring’s beauty, carry out post-processing procedures including cleaning and polishing.

2.2, 20 watt laser engraver

20 watt SuperbMelt laser engraver is made for precision engraving on all types of metal. It uses a 20-watt laser to carve patterns, lettering, or other designs onto surfaces. The engraver is able to operate effectively on all types of metal thanks to this degree of power. The 20-watt laser engraver is ideal for a variety of projects, including small-scale industrial tasks, arts and crafts, customization, signs, and producing precise details.

Conclusion

The top-of-the-line jewellery engraving tool for processing gold, silver, alloy, and platinum jewellery is the SuperbMelt MiNi Laser Engraving Machine for Metal. It produces beautiful engravings with unmatched precision using a 20W laser. Contrary to conventional procedures, this machine offers a variety of benefits, such as larger applications, improved precision, and astounding engraving speeds. The little high-speed laser marking machine is the ideal choice for jewellery businesses with limited processing area due to its compact form, which considerably lowers time and cost expenditures.

The machine stands out for its exceptional stability, speed, convenience, lack of consumables, and automated height adjustment function. It offers convenience with a compact design, achieves remarkable speeds with state-of-the-art hardware and galvanometer mirrors, eliminates consumables with its air-cooled fibre laser, and offers precise control with one-touch automatic height adjustment. High stability is ensured through fibre optic transmission.

The SuperbMelt MiNi Laser Engraving Machine for Metal is a wise investment since it offers great stability, speed, convenience, no consumables, and automated height adjustment. Utilise this innovative laser engraving technique to improve efficiency and your marking skills.

Application: The SuperbMelt MiNi Laser Engraving Machine for Metal is extensively employed in many different industries, including the automotive, IC, electronics, communications, jewellery, and craft decorating sectors.

Compatible Materials: Because this machine is made primarily for engraving on different metals, it may be used with any type of metal.

The SuperbMelt MiNi Laser Engraving Machine for Metal is the perfect instrument to advance your artistry whether you’re producing customised jewellery items, complicated patterns, or exact engravings. With this cutting-edge engraving machine, discover the power of high accuracy, efficiency, and adaptability in jewellery production.

FAQ Guide of Mini Laser Engraving Machine For Metal

- 1. What can a 20W fiber laser do?

- 2. What engraving machines is good for outside rings

- 3. What tool is used for engraving on silver

- 4. What is fiber laser marking machine

- 5. What is the advantage of laser engraving machine?

- 6. What is the difference between laser cutting and laser engraving?

- 7. What are the different types of laser engraving machines?

- 8. What maintenance and cleaning procedures are required for a laser engraving machine?

- 9. What is the difference between CO2 and fiber laser engraving machines?

- 10. How often does the laser tube in a laser engraving machine need to be replaced?

1. What can a 20W fiber laser do?

20W fiber laser can perform high-precision engraving on metal surfaces, including gold, silver, copper, stainless steel, and other metal materials.

2. what engraving machines is good for outside rings

rotating Axis Laser Engraving Machine: This kind of engraving device often has a rotating axis that can retain and rotate the ring, enabling the laser to continually etch the ring’s outside perimeter.

Handheld Laser Engraving Device: The outer circle of the ring may be directly engraved with this hand-operated portable laser engraving device. It is appropriate for intricate engraving and customised patterns since it provides flexibility and precision.

Fibre laser engraving machines use a fibre laser as its light source, which offers a high energy density and accurate control. It is appropriate for a variety of metal materials since it can engrave the outside of the ring in a fine, high-definition manner.

3. what tool is used for engraving on silver

The type of instrument used to engrave silver jewellery, such as a laser, CNC engraving machine, pneumatic engraving, or manual engraving, depends on the needs and tastes of the person.

4. what is fiber laser marking machine

A marking tool that makes use of a fibre laser as its light source is called a fibre laser marking machine. The laser beam is sent over fibre optics to the marked item, where it reacts with its surface to cause chemical or physical changes and produce the desired marking effect. High energy density, accuracy, speed, and non-contact marking capabilities are the distinguishing features of fibre laser marking devices. They may be used to engrave on any kind of metal.

5. What is the advantage of laser engraving machine?

Widely applicable, high engraving efficiency, high safety and reliability, energy-saving and environmentally friendly.

6. What is the difference between laser cutting and laser engraving?

By heating the material to a molten or vaporised condition using the high energy density of the laser beam, laser cutting then blasts the molten or vaporised material away using airflow or other auxiliary techniques. Laser cutting can achieve a high-precision and quick cutting process and is suitable to a range of materials, including metals, plastics, wood, etc.

In order to create the engraving of patterns, text, or designs on the material, laser engraving uses the high energy density of the laser beam to etch or oxidise the surface of the material. Laser engraving can produce very precise and exquisite engraving effects on a number of materials, including metal, plastic, glass, leather, etc.

In general, whereas laser engraving focuses more on engrave and embellish things, laser cutting focuses more on cutting and separating materials. Although they use different processing techniques and application areas, both use laser technology to accomplish high-precision and high-efficiency processing.

7. What are the different types of laser engraving machines?

Devices that are frequently employed in the sphere of advertising production are laser engraving machines. They fall into one of three categories: YAG (yttrium aluminium garnet) laser engravers, galvanometer-based laser engravers, and CO2 (carbon dioxide) laser engravers.

8. What maintenance and cleaning procedures are required for a laser engraving machine?

Laser engraving machines require regular maintenance and cleaning to ensure proper operation and extend their lifespan. It is necessary to maintain the reflector and focusing lens, clean the lenses, check the optical path before each operation, maintain and clean the cooling system, maintain and clean the mechanical system, ensure the screws and couplings are secure and well-maintained, lubricate and maintain the guide rails, pulleys, and tracks, and maintain the bearings.

9. What is the difference between CO2 and fiber laser engraving machines?

Variations in Laser Types:

A fibre laser is used by the Fibre Laser Marking Machine.

A CO2 gas laser is used by the CO2 laser marking machine.

Various Laser Wavelengths:

The operating wavelength of the Fibre Marking Machine is 1064 nm.

The operating wavelength of a CO2 laser marking machine is 10.64 m.

Application Field Variations:

Most non-metallic materials and certain metal items may be engraved using a CO2 laser marking machine.

Most metals and a few non-metallic materials may be engraved on using a fibre laser marking machine.

10. How often does the laser tube in a laser engraving machine need to be replaced?

The usual lifetime of lasers is 5000–10000 hours. The internal temperature of the laser tube steadily rises when it is used constantly for longer than four hours. The burden on the laser tube increases if the temperature rises faster than the laser tube can cool. Continuous use of a laser tube in a hot environment shortens its lifespan quickly.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited