Induction Gold Melting Furnace

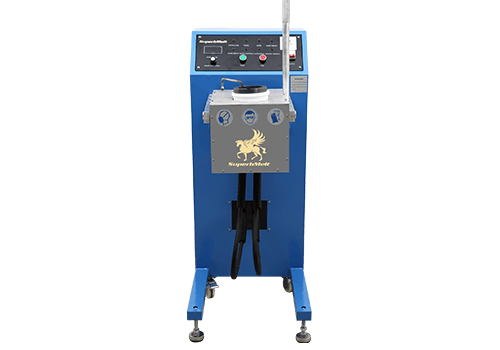

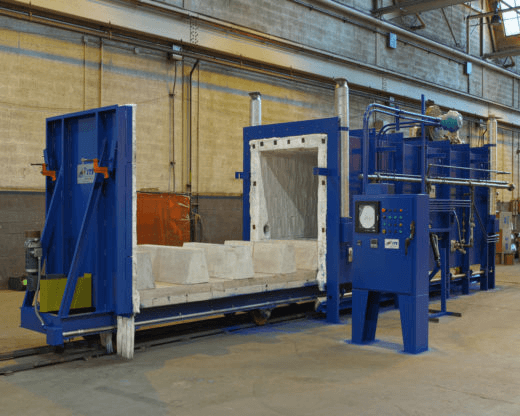

The Most Popular SuperbMelt 3-5kg gold (Ag, Cu, Al etc) Melting Furnace on the Market

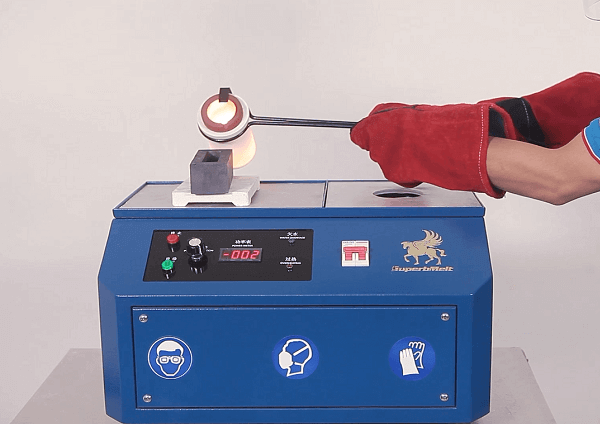

Induction gold melting furnace is designed for melting 1g – 12kg gold and other precious metal like silver, copper, palladium.

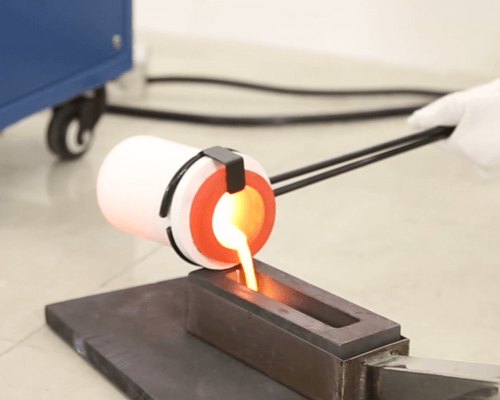

It is based on the latest and most advanced IGBT induction technology, the top speedy melting could be realized within 2-4 minutes. The crucible is extractable by means of matched tong.

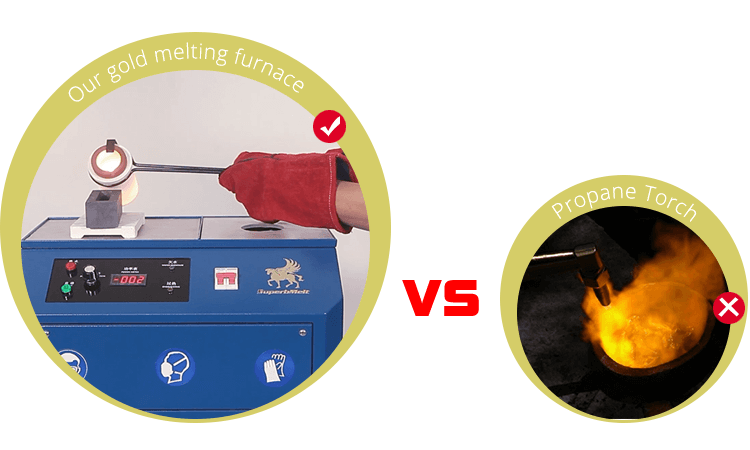

SuperbMelt gold melting machine is the better choice for lab, jewelry shop , research institute and mining company comparing with gas melting device and resistance melting type.Before shipping, we will make testing videos for each machine to ensure quality.

Clere here to see more gold melting furnaces with different capacity

Gold Melting Furnace Parameters

| Model number | SPB-DH1 | SPB-DH2 | SPB-H5 | SPB-H8 |

| Photo |  |  | ||

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw | 15 kw | MF 15kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes | 4 minutes | About 5 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.6 kg 18K Gold: 2.0 kg 925 Silver: 1.2 kg | 24K Gold: 7.0 kg 18K Gold: 5.0 kg 925 Silver: 1.5-3.0 kg | 24K Gold: 12 kg 18K Gold: 8.0 kg 925 Silver: 5.0 kg |

| Max temperature | 1600℃ | 1600℃ | 1800℃ | 1800℃ |

| Temperature control k-type | Optional | Optional | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm | 530*530*900mm | 680*500*1180mm |

| Weight | 20 kg | 25 kg | 72 kg | 92 kg |

| Heating technology | Induction heating | Induction heating | IGBT Induction heating | IGBT Induction heating |

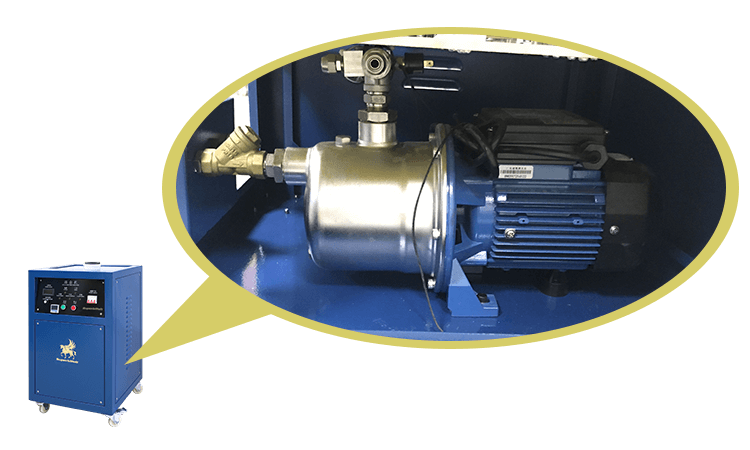

| Water pump | Optional | Optional | Equipped | Equipped |

Environmental Protection

The melting equipment is energy saving and low pollution. Therefor it is environmental protection, even working indoors in the factory will not cause physical harm to the staff.

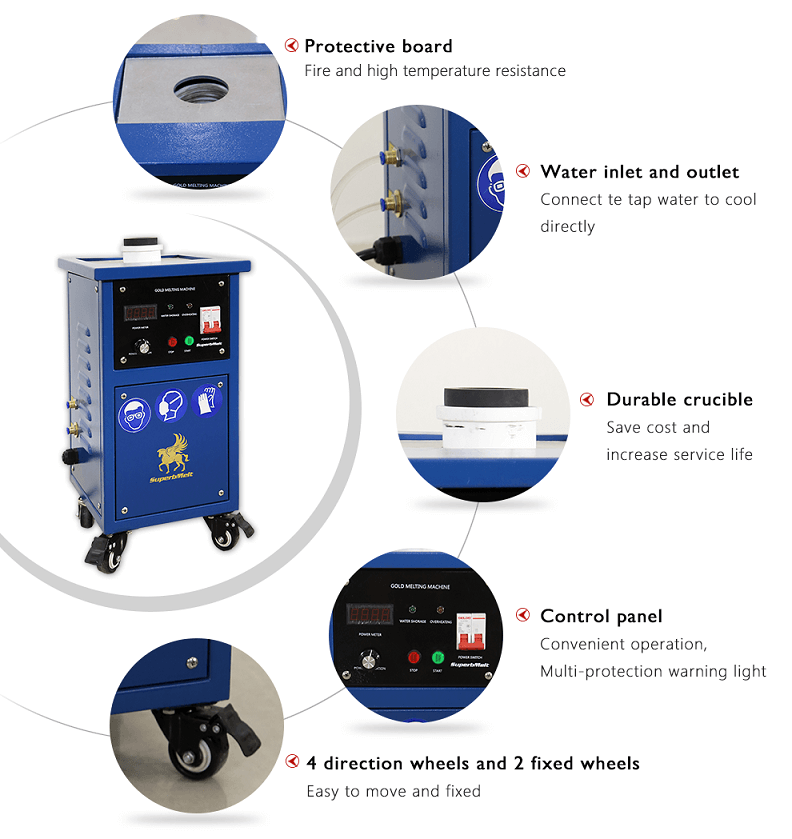

Compact Machine

Light weight and easy installation, it have economic Space Occupation, which suitable for small and medium refining and jewelry equipment factories.

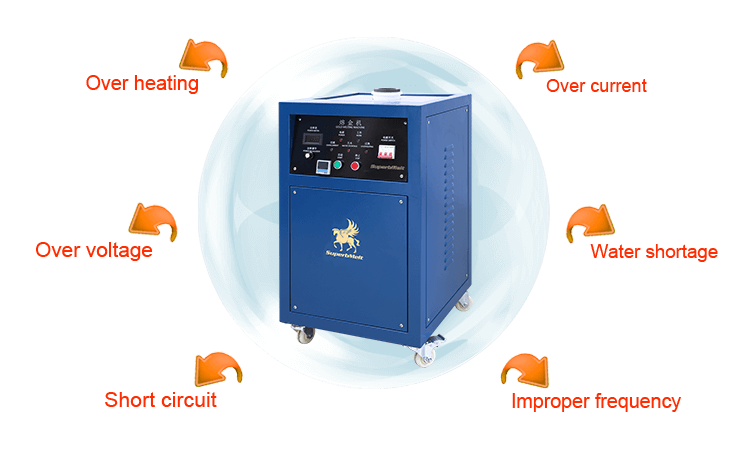

Monitoring and Diagnosis System

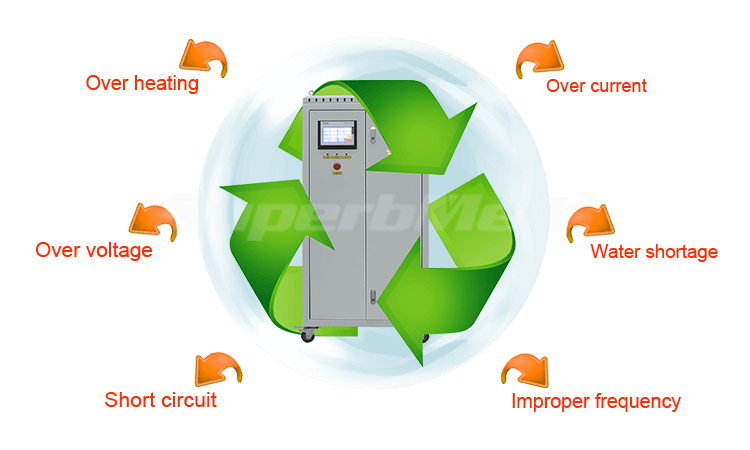

Enhanced monitoring and diagnostics system of SPB-H series gold melting furnace, guarantee the machine of high stability, reliability and security.

High Quality Assurance

Strict Supplier Management System and ISO 9001:2015; CE Quality Management System guarantee high quality of each equipment.

Continuous Working

100% duty cycle and work stably,which can reach 24hours continuous working ability at maximum power.

IGBT Technoloy

SuperbMelt gold melting furnace takes Use of solid-state IGBT inverter and power regulation, soft switch three resonance and frequency automatic tracking technology.

It is simple and smart to use, also better guarantees the purity of the finished metal.

Fast Melting

The top speedy melting rate can finish per batch within 3 mins nearly.Greatly improved work efficiency.

Amazing speedy melting

If you are looking for speedy milting machine for small batch gold, silver and copper melting, our gold melting furnace is the perfect solution.

Video Introduction of 2kg Gold Melting Furnace

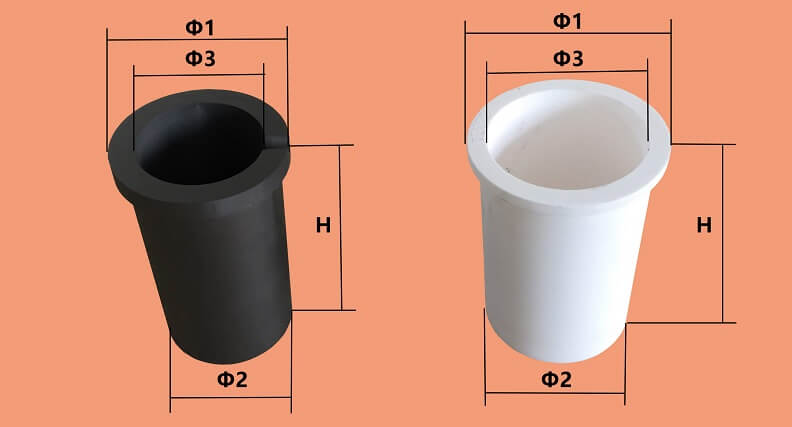

Graphite crucible for gold/Silver melting Furnace

Crucible for induction gold melting furnace

Crucible is one of the most important accessories of gold melting furnace, and the 2 coordinate with each other to provide the most perfect conditions for gold melting.

| Description | Weight(g) | Size(mm) | |||

| Ф1 | Ф2 | Ф3 | H | ||

| 1kg Graphite crucible | 160 | 58 | 46.5 | 35 | 88 |

| 2kg Graphite crucible | 240 | 68 | 57 | 43 | 108 |

| 2.5kg Graphite crucible | 300 | 68 | 58 | 43.5 | 120 |

| 3kg Graphite crucible | 390 | 72 | 66 | 51 | 110 |

| 4kg Graphite crucible | 500 | 85 | 75 | 60 | 130 |

| 5kg Graphite crucible | 700 | 100 | 88 | 69 | 132 |

| 5.5kg Graphite crucible | 800 | 104 | 92 | 69 | 155 |

| 6kg Graphite crucible | 1650 | 112 | 98 | 76 | 178 |

| 8kg Graphite crucible | 1900 | 125 | 112 | 90 | 185 |

| Model | SPB-H2 | M.MF03 |

| Photo |  |  |

| Heating principle | Induction heating | Resistance heating |

| Power | 3.5kw | 1.7kw |

| Melting time | 2kg gold is molten within 2mins nearly | 2kg gold is molten within 20mins nearly |

| Moten metal stirring | The magnetic field will stir the molten metal to realize mixing alloy abundantly based on induction heating | No stirring function. it is by resistance heating transferring |

| Power consumption | The induction heating furnace can save over 10 times power consumption per kilogram than the resistance heating furnace | |

| Cooling system | Need water cooling | No need water cooling |

| Protection alarm | Over voltage warning, Over current warning, lack of water warning, phase loss warning, improper frequency warning | Simple working |

| Working time | Theoretically, 24 hours continuous working | After 2-3 hours working, need 30 mins stop working for cooling |

| Remark | If you have requirement about melting time and long time working, the induction gold melting furnace is the best choice. The resistance furnace is more simple and cost saving. Generally, the life time of induction gold smelter is much longer than resistance one. | |

The bulk of information presented in this article confirms the degree of usefulness of Induction Gold Melting Furnace as a great gold melting method. It can melt big amount of gold without experiencing any problem. Using induction furnace helps in saving some melting time, and because it has the capability of building up heat, it can rise to correspondingly high heat levels. As an environmentally friendly method, induction furnace does not produce smoke, pollutants, dust or any other kinds of harmful emissions. The machine does not need external cooling system because it has induction coils, water-cooling system, and induction power supply that constantly keep the coils of the furnace and its internal parts cool.

This is why induction gold melting furnace is very popular with gold miners because it provides unique opportunity to maximize production within a short period of time. When compared with the traditional gold melting method, induction metal melting furnace is cost-efficient, manageable, and peaceful to the environment.

On the other hand, Electric Arc Furnace is the opposite of what induction furnace stands for. Its heating system is powered by non-clean energy generation system—combustion, and it is practically non-environmental friendly. It takes a lot of time to start it and cool the system. And it costs a lot to make its procedures environmentally friendly.

However, resistance furnace comes between both induction furnace and electric arc furnace, but it does not possess the same sterling qualities of the induction furnace.

Induction gold melting machine is one of the indispensable equipment in the precious metal refineries and jewelry manufacturers. Whether you are a goldsmith, a jeweler or just an ordinary person, choosing the right machine will greatly increase your productivity.

It can satisfy 1-12kg metal smelting, suitable for small and medium-sized factories, tell us the capacity of your factory and your finished products, and we will recommend you the most suitable model.

As the premier manufacturer of metal melting furnace, choosing us will be your right decision.

Why SuperbMelt Gold Melting Furnace

Helpful Resource For Your Reference ( An expert about gold melting furnace )

More Gold Melting Furnace and Gold Casting Machines for Your Choice

Any Question About SuperbMelt Gold Melting Machine

FAQ Guide of Gold Melting Furnace

- Does an induction furnace use less electricity?

- What is the difference between smelting and melting?

- Can I get 9999 gold from your melting furnace?

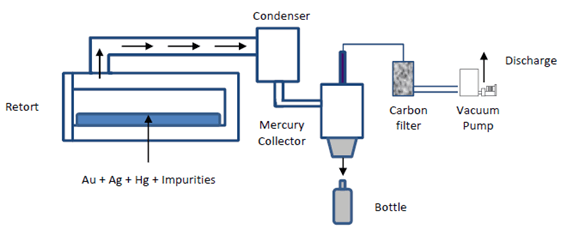

- How do you separate gold from other metals by melting?

- How do you get gold from gold ore?

- How do you get impurities out of gold?

- Can I melt silver at home?

- How can I calculate the efficiency of my furnace?

- How hot can an induction heating get?

- What are the advantages of electric heating over other types of heating?

- Does induction use less electricity?

- How is the melting rate calculated in the induction furnace?

- Can I melt my own gold?

- Does melting gold purify it?

- What is the process of smelting gold?

- What chemicals are needed for gold recovery?

- How much gold is there in gold ore?

- Can you melt gold off electronics?

- What is a gold smelter?

- What is the best way to melt gold?

- Does gold melt easily?

- How fast can gold melt?

- How do I purify gold at home?

- Can I melt my own gold at home?

- Can you melt gold off gold plating?

- Does gold lose weight when melted?

- Can I melt silver and gold together?

- How can I reduce the power consumption of my induction furnace?

- How many types of induction melting furnaces can we provide?

- How many important factors to consider when choosing the best induction melting furnace?

Does an induction furnace use less electricity?

Foundry is one of the most energy intensive metallurgical industries. Various sections of foundry melt, pattern making, melting, core making compressed air, etc. Knowing the amount of energy needed to run a foundry, foundry owners are looking for means to save the cost of energy in some part of the metallurgical business by efficient and optimal running of furnaces.

The furnaces commonly used in foundries are cupola furnaces and foundry induction furnaces. In induction melting, a medium frequency furnace is found to be more energy efficient when compared to the cupola furnace. The feature of the medium frequency furnace is its high rate of power input resulting in less melting time. It can be run as batch type where full metal of a heat can be tapped out and the next heat can be started with solid charge making it more energy efficient than line frequency furnace.

The following will contribute to saving foundry induction furnace energy.

Furnace lining material, thickness and its sintering play an important role in energy saving.

The scrap size is an important parameter in reducing energy consumption. It is better to melt small pieces of metals in order to save energy.

There transferring molten metals, there should be no delays. This also helps to save energy.

What is the difference between smelting and melting?

Smelting is the process by which a metal is obtained either as an element or as a simple compound, from its ore by heating beyond the melting point with the presence of oxidizing agents such as flux. In other words, smelting is the process of applying heat to ore in order to extract a base metal. For example, extracting gold from its ore.

Melting on the other hand is a process of changing metal from solid state to liquid state especially when heat is applied.

Can I get 9999 gold from your melting furnace?

9999 gold represents gold that is 99.9% pure. We produces clean and efficient induction precious metal melting furnaces. These melting furnaces are used in processing gold, silver and platinum group metals. We ensure our technologies increase metal recovery and lower processing costs in each step of production.

With the range of precious metals applications in the jewelry, medical, mining industries, the efficiency and cost effectiveness of induction melting is derived with the equipment.

However, our gold smelter cannot purify gold, it needs to be refined further.

How do you separate gold from other metals by melting?

The first thing to do when separating gold from other elements is place the ore in the heated crucible, remove the crucible and allow some of the metallic mixture to cool down. Add some nitric acid and hydrochloric acid to the metallic mixture, the acid will dissolve other metals and you have the gold left at the base of the crucible.

How do you get gold from gold ore?

Getting gold from gold ore requires the process referred to as “smelting”. The ore is placed in an induction furnace crucible with a mixture of flux. This flux is responsible for quick and easy removal from gold from its ore as well as removing impurities. The induction gold smelting furnace is then fired up at 1149 degree celsius. After heating, the impurities flow up while the gold remains at the base of the crucible. Scoop out the slag and pour your gold into a mold, which are referred to as dore bars after they are melted.

How do you get impurities out of gold?

Submerge unrefined gold in a mixture of nitric and hydrochloric acids. This method will dissolve the ore and separate the gold from impurities, which can later be washed away. The remaining substances will be water and gold, the latter having a high purity level.

Another way of removing impurities from gold is to add flux while smelting the gold. After melting, the slag is removed, leaving behind a purer gold.

Can I melt silver at home?

Silver’s melting temperature is 961 degree celsius, which is higher than gold. Melting gold is easy when compared to silver, but like every other metal, melting silver is not difficult. You can melt silver at home when you follow the right procedure, using the right equipment.

There are a lot of ways silver can be melted but we will explain how silver is melted with borax. Borax is used to melt the metal because it helps in softening and dissolving the oxidized layer from the ore. This process is known as borax flush, which helps in exposing the fresh layer of the metal for further use.

The melting process should be carried out in a well ventilated area.

Place your silver in a melting crucible and ensure it is large enough to hold the metal when it starts boiling. If the material you are melting is more, it is advisable to melt in batches. Melting in batches will enable a fast melting process.

You can use a gold induction furnace to melt the silver in the crucible. The time taken to melt this metal can be easily monitored with an induction gold melting furnace compared to when you use a propane torch.

Make the mixture of borax and soda in the proportion of 1:1. For 1kg silver, 500g of the mix will be enough to melt the silver.

Add this mixture to the already melting silver. You can also add sodium nitrate step by step till you see the metal.

Remove the slag from molten silver. You can turn the molten silver into your mold with the help of heat resistant gloves and thongs.

How can I calculate the efficiency of my furnace?

Induction furnace efficiency is calculated thus: Heat output divided by heat input multiplied by 100.

I.E- Furnace efficiency= heat output X 100

heat input

= heat in stock (material) (kCals) X100

Heat in fuel/electricity (kCals)

How hot can an induction heating get?

Induction heating finds applications in processes where temperature can be as low as 100 degree celsius and as high as 3000 degree celsius. It is also used in short heating processes lasting for less than half a second.

What are the advantages of electric heating over other types of heating?

Electric heating offers a great alternative to traditional gas and oil fired furnaces. The advantages of electric heating furnaces are stated below.

Efficiency- Although electricity may cost a bit more than gas or propane, a well maintained electric metal melting furnace is more efficient than other furnaces.

Safety- The machine is safer to use in terms of its alarm system that warns users of error that can lead to dangers; and the fact that there is no emission of noise and odour that can be harmful to health.

Conservation of energy- You use less energy and you save cost as well with it. All heat generated by the machine is used within the furnace.

High melting quality: The electric gold melting machine has an electromagnetic stirring system that causes molten metal to have a uniform consistency.

It has a user friendly control panel. Therefore, there is adequate power control.

Time taken for melting is less when compared to other furnace types.

Does induction use less electricity?

Induction heating is simply a method of transferring heat energy. Two laws that govern induction heating are: Electromagnetic induction and the joule effect. The gold melting furnace inductor is usually made of copper to limit electric losses. The inductor in almost all cases is internally water cooled. It consists of a crucible made up of suitable refractory material surrounded by a water cooled copper coil.

In an induction gold melting furnace, the charge is melted by heat generated from an electric arc. The alternating magnetic field produced by high frequency current induces powerful eddy currents in the charge resulting in a fast heating process, thereby saving energy compared to electric arc furnaces.

How is the melting rate calculated in the induction furnace?

2 tons 1 hr divided by 0.8. is 2.0 ÷ 0.8 = 2.5 Tons / Hour should be the required furnace melt rate at 1600 degree celsius. Note that the melting rate of each furnace differs.

Can I melt my own gold?

Yes, you can melt your gold. Gold has a melting temperature of 1064 degree celsius, which means that if you have the gold and silver melting equipment and other tools to achieve more than 1064 degree celsius, then you can melt gold on your own. Therefore, with the right furnace and the right crucible, you can melt your gold. Ensure that the melting is done in a well ventilated space with appropriate protective tools.

Does melting gold purify it?

Fire refining of gold was the primary method of purifying gold before chemicals or electrochemistry was used.

Gold will not oxidize in a very hot flame, but many other metallic impurities will, and will float to the top to be removed. Melting alone will not purify gold but melting in an oxidizing atmosphere with no flux or melt covers will oxidize most non-precious metals that will separate.

What is the process of smelting gold?

Smelting gold is done by using high pressure, heat and various chemicals such as flux to break down the ore and melt the gold to separate it from impurities.

When the mixture of gold and flux are placed in a smelting equipment, both materials melt in the smelting equipment. The gold smelting equipment is heated at 1064 degree celsius. It takes a few minutes for the mixture to liquify in an induction furnace. After the metal melts, the precious metal and impurities separate.

The molten gold is then poured into molds to form bars or other desired shapes.

Other processes of smelting gold are: Miller process and Wohlwill process.

The Miller process uses gaseous chlorine to extract impurities when gold is at its melting point. Impurities separate into a layer on the surface of molten purified gold. The Miller process is rapid and simple, it produces gold of only 99.5% purity.

The Wohlwill process increases purity to about 99.99% by electrolysis. In this process, gold ore is placed in an electrolyte solution of hydrochloric acid and gold chloride. Under the influence of an electric current, the gold migrates to a negatively charged electrode (cathode), where it is restored to a highly pure metallic state, leaving the impurities as residue.

What chemicals are needed for gold recovery?

Sodium metabisulfite is commonly used to precipitate dissolved gold out of aqua regia and chloride solutions. When it is dissolved in water, sulfur dioxide is created which is excellent at precipitating gold from the solution.

How much gold is there in gold ore?

The amount of gold found in gold ore varies. Gold is generally found in two types of deposits: lode (vein) or placer deposit.

Can you melt gold off electronics?

Gold can be melted off electronics and the process is very easy but the chemicals used are dangerous and should not be performed without prior knowledge or equipment. Ensure you handle all chemicals (nitric acid) with care and use protective tools like gloves, goggles, glass apparatus, a gas mask or respirator and a well ventilated space or outside area is highly recommended.

Break the circuit boards into smaller pieces and place your circuit board in a glass container that can withstand extreme heat.

Pour concentrated nitric acid into the glass container with the circuit boards. As you add the acid in. Burning fumes will start coming out of the container.

Stir the mixture with a glass rod until the contente becomes fluid in form. Since gold requires stronger chemicals to dissolve, the nitric acid will melt all plastics and metal parts of the circuit board without harming the tiny golds.

Drain the nitric acid from the mixture. Use a filter to separate the gold from the liquid. There you have your gold from electronics circuit boards.

What is a gold smelter?

A gold smelter refers to any equipment or process used to extract gold from its ore, usually by heating. For example: a foundry induction furnace, propane furnaces, electric arc furnaces, etc.

What is the best way to melt gold?

For the most excellent gold melting experience, we recommend a gold and silver melting equipment. A gold and silver melting equipment uses certain inherent properties already inherent in the metal to cause it to melt in the presence of an electromagnet. The electromagnet in a gold and silver melting equipment is used to generate a pulsing electromagnetic field around the metal to be melted.

Benefits derived from the gold and silver melting equipment are; it does not take up space, there is control over the melting process, it is energy efficient, electromagnetic stirring makes molten metal uniform, no heat loss, etc.

Does gold melt easily?

Gold melts easily when the melting furnace is able to reach its melting temperature of 1064 degree celsius. A gold and silver melting equipment can conveniently reach this temperature in no time.

How fast can gold melt?

Melting is not about speed but about temperature and heat transfer. Increase the heat, then the metal melts faster, as long as the temperature is above the melting point. In addition to this, the melting furnace in use contributes to how fast a metal reaches its melting temperature. For example, in a gold and silver melting equipment, your gold can melt within 2 to 4 minutes.

How do I purify gold at home?

You can easily purify gold at home using this simple DIY process. The process involves adding nitric acid to gold and then adding hydrochloric acid.

Allow this mixture to sit for like 30 minutes, afterwards, filter to remove impurities and treat to neutralize the acids in the solution. The outcome will look like a muddy solution at the base of the container, this “mud” is the gold.

Rinse the muddy part three to four times with water, then treat with aqueous ammonia. After white vapor forms, rinse the gold thoroughly with water and allow to dry.

Can I melt my own gold at home?

Yes, you can melt your gold at home. The only complex thing about gold melting is getting heat, once you have an appropriate heating furnace, then melting gold at home becomes a piece of cake.

Can you melt gold off gold plating?

Preheat your soldering tool to 377 degree celsius to 419 degree celsius. Ensure that your soldering tool reaches at least 377 degree celsius before attempting to melt. If the tool does not reach the minimum temperature, melting cannot take place. Clean the gold item with boric acid and water.

Does gold lose weight when melted?

Typically, loses for refining gold are 0.1% to 0.25% from melt or mass loses and another 0.1% to 0.3% on assay or undercarat loses.

For silver, typical loses from refining are 0.2% to 0.45% from melt or mass loses and another 0.3% to 0.8% on assay or undercarat loses.

Can I melt silver and gold together?

Yes, you can melt gold and silver together and the resulting metal is referred to as “electrum”.

Gold melts at a temperature of 1064 degree celsius while silver melts at 961.8 degree celsius. To alloy these two metals, melt the gold to hot liquid, add the silver metal. This will dissolve immediately in the blazen liquid gold.

The heating process is what does the alloying so trying to stir up the liquid metal will not help or quicken the alloying of the two. The heat needs to stay as concentrated as possible.

Once the flames turn from bright orange to a bright yellow, this confirms that your metal is thoroughly atomically combined which is important to assure a well-rounded metal alloy. If the metals are not well blended, they may be problematic at the production phase.

Alloying gold with silver is beneficial as it makes both metals hardy in endurance and more flexible in construction. The bright and light color shades are also quite beautiful to look at and adorn.

How can I reduce the power consumption of my induction furnace?

Here are the major ways in which you can reduce the power consumption of a smelting equipment to reduce energy cost without sacrificing productivity.

Maximize the use of your smelting equipment- One of the best ways one can reduce how much energy their smelting equipment uses is by using the equipment more effectively. Short holding times can improve the efficiency of your smelting equipment, because longer holding time requires more energy consumption.

Make any necessary changes to your operating procedures- Another great way to reduce your smelting equipment energy consumption is by replacing your current melting equipment. Ensure you give your foundry a thorough investigation to determine some of the best operational changes that you can make to cut down on energy use.

Boost your charging speed- Apart from long holding times, charging speed can also have a major impact on the use of your smelting equipment. Long charging times caused by manual or magnetic crane charging can lead to more energy use. You want your charging to be done rapidly and efficiently, use automatic charging systems.

Streamline your temperature measurement- When you check the temperature of the smelting equipment regularly, you are losing valuable time and wasting needed energy. By using a computerized temperature control system, you can reduce the need to check furnace temperature.

How many types of induction melting furnaces can we provide?

We provides different categories and designs on metal smelting machine to suit various sizes of melting applications.

- Mini 1-2kg metal induction melting furnace- The mini gold furnace is capable of melting precious metals and other base metals in a minimum capacity of 1 to 2kg. The melting temperature is 1600 degree celsius which gets melting done in 2 minutes. Therefore, melting approximately 30kg of metals in one hour. The features include; light weight, does not require a lot of space, saves energy, cost of operation is low, and provides high melting efficiency.

- Integrated 3-10kg metal induction melting furnace- It can melt metals between 3 and 4 kg capacity within 2 to 4 minutes. The precious metal melting furnace is able to melt at 1800 degree celsius in 3 minutes for medium scale melting operations. The features include; safety features that alerts users of dangerous operating conditions, zero pollution during melting, low power consumption, easy induction maintenance, reduction in precious metal loss, high melting quality, etc.

- 1-4kg platinum induction furnace- It melts precious metals and other metals at 2600 degree celsius in 5 minutes. The furnace is able to accommodate between 1 and 4kg of metals in a single melting operation. The features of the platinum furnace include; ease of operation, ease of maintenance, fast melting process, compact size, high melting efficiency, etc. Suitable for use in laboratories, scrap metal business and jewelry making industries.

- Manual tilting 20-30kg metal induction melting furnace- This is more bigger model that able to occupy about 20 to 30kg of metals at once. It is used in mining industries and foundries and other large scale melting capacities. The melting temperature is 1800 degree celsius and it is capable of melting metals within 8 minutes. The features include; a water cooling system that regulates the furnace to prevent overheating, therefore, you can melt for long hours, removal of molten metal is easy, easy to use, consistent molten metal, environmentally safe, etc.

- Chain tilting 10-50kg metal induction melting furnace- It is capable of melting between 10 to 50kg of precious metals. The high energy ratings and high temperature of melting ensures a faster melting process thereby saving 15 to 30% of power. The features of this induction goldmelting furnace include; chain tilting mechanism for easy removal of molten metal, interactive control interface that allows you to completely be in charge of the melting process, induction heating technology that reduces power use to the minimum, etc.

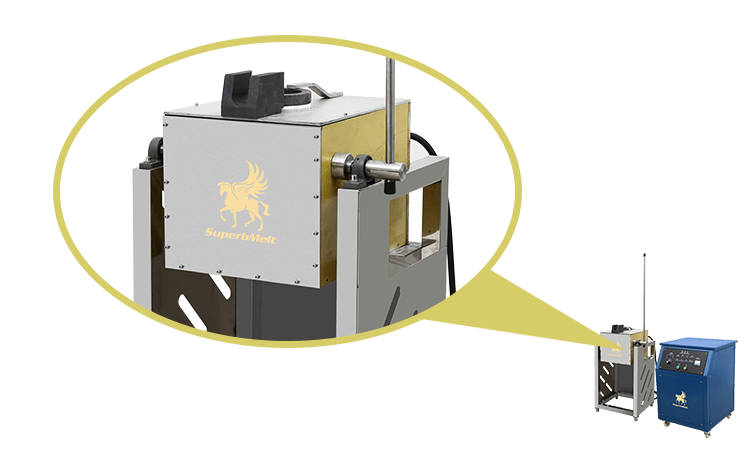

- 10-100kg motor tilting induction metal melting furnace- It is able to melt large batches of ferrous and nonferrous metals between 10 to 100kg. The power input requirement is between 15KW to 160KW, hence, saving 15 to 30% of energy. The machine is designed for one man pouring action. Other advantages of this model include: it is able to work continuously for long hours, the crucible replacement is easy for different materials, more efficient than other gas-fired or coal-fired furnaces, makes zero noise or harmful gases when in use, etc.

- 50-250kg hydraulic tilting induction melting furnace- The hydraulic tilting furnace is a very large capacity induction furnace able to melt between 50 to 250kg of ferrous and nonferrous metal at once. The power requirement is between 45KW and 160KW, therefore saving energy. It comes with a hydraulic tilting design which can be controlled with the aid of a remote panel trolley. Features of the hydraulic tilting gold melting machine include: ease of use, able to melt for long hours, fast and efficient melting process.

How many important factors to consider when choosing the best induction melting furnace?

Below are the important factors to consider before choosing an induction gold melting furnace:

Control: Induction gold melting furnaces are usually easy to install and offer you a high level of control during the melting process.

Size: The size of the furnace you choose will be dependent on the size of your production and how much metal you need to melt at a time.

Production rates: Gold induction furnaces are capable of heating and melting very fast. For companies that require large production requirements, it allows you to increase production rates.

Refraction: Different sizes of gold induction furnaces have different refraction rates. Smaller gold induction furnaces require minimum refraction rates while larger furnaces require greater amounts. The size you invest in will be determined on the size of your business.

Oxidation melt loss: Core type induction gold melting furnaces reduce the amount of oxidation that occurs during melting. This leads to lower rates of loss throughout the process and provides a large yield ratio. It is important to always keep the oxidation rate in mind when buying the melting equipment.

Cleanliness: The melting machines are perfect for businesses that want to maximize cleanliness. When compared to other furnaces, it do not use combustion to provide heat, this means there is no waste to clean up after melting.

Noise factor: When buying a gold melt machine, it is important to consider the noise fator. Some metal melting models are designed to be efficiently noiseless.

Efficiency: A good gold melting oven should be able to perform a smooth and efficient melting process for effective production.

Safety: A small induction gold melting furnace should be safe for operators and the working environment generally.

Cost: Consider the budget you have before choosing a melting gold machine that will meet your needs.

Warranty: A good metal melting machine manufacturer should have warranty of up to two years. At Supernmelt, we provide warranty for all furnaces.

Ultimate Gold Melting Furnace Buying Guide

Let’s dive right in:

The precious metals industry has come a long way. From just being the exclusive preserve of alchemists and a few prospectors, the business of precious metals has become an all-inclusive playing field.

As much as there are still large casting furnaces, there are now also small scale equipment to experiment with. Small furnaces, homemade gold melting furnaces, and various other small scale systems have made the melting technology accessible to anyone who is interested in the industry.

One thing that is common to everyone in the precious metals business is the choice of the right machine to choose. Either you’re an engineer at a big company trying to select a large scale furnace to handle all of your production throughputs. Or you could be one of the DIY enthusiasts of mining and precious metals.

Whichever category you belong to, choosing the right equipment to work with can be a little challenging or even confusing. You may find it difficult to make a decision on which type or size of electric gold metal furnace (or any other similar system) to buy. If you are in these shoes, then you are reading the right article.

Below we have compiled a comprehensive guide to help you choose the perfect precious metals refining system. Regardless of whether you’re trying to buy a homemade gold smelting furnace, silver smelting furnace, or you’re looking for a large-scale induction furnace for sale.

We’ve got something here to help you make an excellent choice.

Let’s start by taking a look at the best Gold melting furnace manufacturer and the kind of products they have to offer. Making the right choice starts with having an idea of exactly what’s available to choose from.

And we are proud to introduce SuperbMelt(one of the top metal melting furnace supplier in China) to you, the unarguable industry leader as far as precious metal mining and refining equipment is concerned.

We have more than a decade and half of consistent and top notch R&D under our belt. This puts us in a perfect position to develop the best machines; systems that work and deliver the highest value and returns on investment.

We have got wide and varied experience from the vast number of projects we have handled and successfully delivered. All over the world, from Australia to Asia (Thailand, India, Indonesia), to the Middle East (Iran), and across the oceans to Europe (Georgia, Kazakhstan, Turkey, Kyrgyzstan), we has consistently delivered to customers’ utmost satisfaction. We have left a trail of happy and fulfilled clients around the globe who have continued to work with us to meet their precious metal refining needs and requirements.

We would love for you to be among these satisfied customers. And that is why we have created this write-up. To start by helping you identify which exact equipment you need for your refining or smelting/melting project. We will surely have a machine that suits your specifications perfectly and will fulfill the exact objective that you have in mind.

This is because we always have silver melting furnace, gold melting machine, melting pots for sale, and more. However, in the event that we don’t already have such an equipment or device on ground.

Our team of highly efficient and technically sound engineers are on hand to work with you and develop a custom made and uniquely tailored device to deliver your exact requirements.

Our wide range of products (Gold, silver, or copper melting furnace, home casting furnace and other products) are the best in the market because of the advanced technology that drives their production.

We have developed our version and application of the IGBT induction heating technology and taken advantage of it. This has been one of our foremost research focus over the years because it’s a technology that has found application in a wide array of fields.

Our assiduous team of researchers have been able to work on and develop a unique application of the IGBT tech for use in our furnaces and casting machines. The result of this is the development of highly efficient and energy saving induction heating systems which deliver high and variable heat levels for effective melting.

With these systems you have the luxury of choosing exactly how hot you want your furnace to be. Another advantage of this advanced technology is its environmental friendliness, you can maintain your high profit margins without causing too much damage to the environment.

We don’t just sell you a machine and leave you to figure it out on your own. Our conscientious and affable sales engineers will provide continuous technical assistance, including help with installation and preliminary operations.

Our support system is strong enough to ensure that you have someone to talk to at every point about any issues that come up in the operation of the machines you purchase from us.

A lot of people make the mistake of thinking that gold melting furnace price is the most important factor to consider when selecting a furnace. This point of view is wrong. The most important thing to consider is the features and capabilities of the furnace (or precious metal refining device) that you require. Now that we’ve given you a glimpse into what we do and we have done in the past. You should be convinced that we are in the best position to help you select the right melting machine.

To do that, let us, first of all, check out the array of various machines we have and see whether there’s something you may like among them.

The Kinds of Gold Melting Furnaces that SuperbMelt can Provide

In this section, we’ll be embarking on an in-depth analysis of the various available gold melting furnaces for sale. This will be an extensive review of the capacity of each machine in terms of capacity (weight and size), technical details, and the range of customers who can find them useful. Please note that all of these furnaces were built with utmost precision and high level professionalism. They are of various sizes, and you are sure to find something that’s amenable to your purposes among these.

1.1, Mini 1-2kg gold melting furnace

This compact and self-contained unit is the perfect device for your small scale gold melting operations. With a seamless design based on a non-obtrusive shape, light weight, and easy operation, the mini gold melting oven provides you with high efficiency without the stress of complex operating procedures.

Despite its small size, you may still perform relatively large melting operations on it, this will have to be in batches of 1-2kg however. You don’t have anything to worry about as far as quality and performance is concerned because this device is ISO CE SGS approved.

What this means is that the professional bodies tasked with ensuring the quality of gold melting furnaces and other products have certified this machine as being fit for use. You can therefore be rest assured of the high level of quality and performance that you’ll get from this device.

How is this furnace better than others on the market

You may be wondering what the difference is between this particular product and those offered for sale by other automatic metal melting furnace manufacturing companies. Well, there’s a world of difference. The Mini 1-2 kg electric gold melting furnace can heat up your raw precious metals from room temperature to a mind blowing 1600℃. That is about one third of the sun’s surface temperature, and this mini furnace reaches its maximum temperature in only 2 minutes. With the capability of working continuously over a long period of time, you can heat up to 150 kg of gold within just 5 hours.

These performance indices put the machine in a class of its own, it is therefore your best bet if you’re looking for high quality performance in a portable system.

Who can use the Mini 1-2kg gold melting furnace?

The following are the groups of people who can benefit from using the mini 1-2 kg model:

- Small to medium sized gold manufacturing or refining start-ups: If you run a small business and are still trying to find your feet in the precious metals refining company, this machine is highly suitable for you. This stage of the business is where you have less capital to invest and more time and hard work to put in. The mini gold melting oven allows you to get maximum value even in the absence of large scale capital intensive furnaces. Although a little more time may have to be expended due to the large number of batches required.

- Foundries and Jewelry Recyclers: For those who are involved in melting down scrap jewelries and other gold products, and refining them into new. The mini gold melting furnace is equally perfect. With its quick melting period, this machine will allow you to be done with the melting stage as soon as possible and move on to the other aspects of the recycling process.

- Personal Gold mining Enthusiasts: There are people who are interested in the collection and refining of gold, not for any business reasons but just as a personal hobby. If you belong to this category, then this Mini 1-2 kg gold melting oven is the best bet for you. Its compact size means you don’t need to acquire a whole new property or convert your whole garage to a personal foundry. However, it is important that you keep safety paramount in using the mini furnace. Ensure that it is kept in a place that is out of reach of children. Also, make sure it is used in a well-ventilated area, and be sure to make use of gloves, safety googles, and nose protection.

How it works

The superb performance of the mini gold melting furnace is based on the advanced IGBT induction technology already mentioned. This is the power house of its quick heating feature and is also responsible for the ability to vary the temperature within the furnace as desired.s

The operation of the mini gold furnace is pretty easy and can be learnt as quickly as possible by just about anyone with the ability to read. The controls are properly labeled and colored in a way to provide an intuitive approach to its operation. Either you’re a vastly experienced personnel in operating furnaces, you will definitely find it easy to use the mini gold melting furnace.

However, if it happens that you experience any difficulties with the use of this machine. A detailed and well-explained users’ manual accompanies it on purchase. The users’ manual will guide you step by step in making a safe and proper use of the furnace.

Finally, if you still have difficulties with operation or installation after using the users’ guide. You can always contact our customer support. We have a strong network of efficient technicians and engineers on hand who are more than capable of assisting you with whatever issues may arise.

Advantages

- Utility and Flexibility: Despite the fact that the name of the product specifically includes the word “gold”. The functionality of this furnace is not limited to only gold. Other metals like Silver and Copper can also be melted using the 1-2 kg furnace. This flexibility means you don’t have to purchase another furnace separately for melting different metals. Cumulatively you end up with less costs and more profits in the long run.

- Green Technology: It was designed with the protection of the environment in mind. You can be rest assured that your gold or silver melting has no negative effect on the environment. There is zero emission of poisonous gases and you don’t have to worry about any pollutants being released into the air around you.

- Ease of Use: With very simple controls, a detailed users’ guide, tutorial videos, and a step by step installation manual. Installing and using the 1-2 kg gold melting machine is as simple as listing the alphabets.

1.2, Integrated 3-6 kg gold melting furnace

Quite on the bigger side and designed for larger scale operations than the 1-2kg mini gold furnace. The Integrated 3-6 kg gold melting machine can handle medium scale operations while still providing the same superior performance. Did we say the same superior performance, the correct description would be a better performance.

This integrated gold melting furnace can reach a maximum temperature that is as high as 1800℃. You would have to put in a lot of effort to find a similar product in the gold refining and processing market that gets close in terms of performance. The maximum temperature (of 1800℃) in only 3 minutes. This will be a huge boost for the productivity and timeliness of your foundry and mining operations.

Comparative Advantages of the integrated gold melting furnace

- Safety features: An omnidirectional warning system accompanies this furnace and triggers off a warning when potentially dangerous operating conditions are being approached. This safety feature is a great advantage that ensures maximum up time and therefore, the highest possible profits.

- Zero Combustion: The major cause of environmental pollution has to do with the emission of carbon based effluents into the atmosphere. These are often as a result of the combination of oxygen with fuels. The integrated gold melting furnace successfully avoids this process, achieving the melting of metals in a completely environmentally safe manner. Most other furnaces similar to this available for sale make use of processes that generate slightly toxic gases. These cumulatively harm both the operator and the environment in the long run. Therefore, it is the safest choice for you to purchase.

- Low Power Consumption: With just 15kw, you can have this highly efficient machine melt as much as 6kg of gold in just 3min! This is huge as far as cutting power costs is concerned. The implication of this is that for three quarters of the energy required by the average furnace, you’ll get about twice the average output in terms of melted precious metals. You are therefore assured of increased profits and a more efficient production system.

- Ease of Maintenance: Designed with a removable crucible and easily accessible interior. The machine can be cleaned within a few minutes or taken apart for maintenance checks. You don’t have to pay extra to have technicians give you a helping hand every time a minor issue comes up. This is particularly suitable for commercial operators who have more than one furnace and often have to pay so much to have them maintained all the time. A built in water pump is another feature that makes the maintenance of this furnace very easy. There is no need to seek cooling water from external sources. All you need to do is connect a hose to the water supply and the in-built pump will create the required suction to draw in cooling water and prevent the system from overheating. In the event of crucible damage, we have replacement gold crucibles for sale. You don’t have to replace the whole furnace just for a faulty crucible.

- Loss reduction: In comparison with the more commonly used propane torch, or some homemade gold smelter, the integrated gold smelters reduces the loss of precious metals. Having a large percentage of your desired raw metal getting wasted due to an inefficient furnace system is something no gold refiner wants to experience. The integrated gold melting furnace with its compact and self-contained design ensures maximum precious metal recovery.

- Assurance of Quality: A 2 year warranty from the manufacturer (which is greater than the industry average of one year) shows a high commitment to quality and customer satisfaction. Clients from all over the world who have purchased, installed, and used this furnace all have glowingly positive comments. You can be sure that the product you are about to purchase is nothing but the best among the machine available for sale.

Who is the integrated gold melting machine suitable for?

The 3-6 kg mass specification becomes useful for you if you have a:

Gold Refining Laboratory: Due to the necessity of running different experiments and checking a wide variety of samples, Gold and other precious metals refining laboratories seeking to purchase a small furnace will find this medium range furnace very useful. Either you plan on running batch experiments, trying out different samples in groups. Or your plan is to run a continuous 24 hr operation (or more). The 3-6 kg gold melting machine can handle all your experimental needs.

The superior temperature control made possible by the IGBT technology allows you to set your desired experimental conditions. This means you have repeatable and reliable results which are often very important to the success of any experiment. And in the event that you need any modifications to the original design of the machine for your specific experimental requirements. Our engineers and technicians are more than capable of working with you to deliver your exact needs.

Old Jewelry Refining plants: Melting down old jewelry items, purifying them, and casting fresh ingots for the production of new jewelry is a highly lucrative business. If you’re looking for a casting furnace?to move your business to the next level and drive your profit margin even higher, then the integrated gold melting furnace is exactly what you need. You can stack in far more old jewelries for melting than the average small scale furnace and have everything melted down within just a couple of minutes.

Metal/Gold foundries: Although this has been mentioned under the 1-2 kg mini gold melting furnace, it is only proof that we always has something for you to work with regardless of the size of your business. For foundries that are on a moderately large commercial scale, the integrated gold melting furnace will come in handy and suit your business requirements perfectly.

Again, it is important to note that this furnace is not suitable for melting just Gold alone. It is too versatile to be restricted to just a single metal. Copper and silver, among other metals, can all be melted in the integrated gold furnace with equally outstanding results.

1.3, Platinum melting furnace

Let’s get this straight from the beginning. The name might be a little ambiguous. The 1-4kg Platinum melting equipment does not work strictly for melting platinum alone. This highly compact furnace can operate equally efficiently in melting a plethora of other kinds of metals. Gold, palladium, Silver, Copper, Aluminum, and of course, Platinum itself are all metals for which the 1-5kg Platinum melting furnace is suitable in carrying out melting operations.

You don’t need to search for a separate silver or copper melting furnace being offered for sale. Apart from just these metals themselves in their pure form, the 1-4KG platinum melting furnace also works just perfect for alloys of the above mentioned metals. No matter the heterogeneous nature of the metal combination you plan to melt. This furnace does the job impeccably and in record time.

The technology behind the manufacture of this furnace is top of the line and the results achievable within the given time will surely blow your mind. This furnace is sure to deliver beyond your wildest performance expectations and give returns that match, and even far exceed your investments. You may be wondering what it is about this furnace that makes it deserving of all the hype and excitement that we seem to be building around it. To put your doubts at rest, below is an interesting stat to convince you.

- 2600℃ under 5 minutes: Try to beat this with any other gold smelting furnace, silver melting furnace, or generally any casting furnace of a similar size on the market, we’ll wait. The 1-4kg Platinum melting equipment is powered by the highly proficient IGBT technology. This takes the interior of the furnace to a maximum temperature of 2600℃ without you having to wait till eternity for your precious metals to turn liquid.This is an outstanding future of the furnace, but there are far more reasons why this furnace is something you should purchase as soon as possible in order to move your foundry and precious metal refining business to the next level.

- Intuitive Operation: As much as everyone wants to achieve good turnover ratios and generate the maximum profit. We still want to do it as easy as possible. No matter how efficient an equipment or machine is, it becomes counter-productive when you need to get an advanced degree just to figure it out.This is not the case with the 1-4kg Platinum melting furnace. The controls were intentionally designed with the ease of the operator in mind. With start-up and shut down operations that can be learnt in under 5 minutes (the amount of time it takes to reach maximum temperature). And even in the even that difficulties arise in trying to figure out the operational procedures.A detailed user’s manual spelling out the usage and controls of the furnace accompanies it on purchase. This will guide you every step of the way and point out all you need to either efficiently operate or troubleshoot the furnace. If you still can’t figure out some parts of the operational procedure. Our team of technicians and engineers are at your beck and call. All you have to do is get in touch with customer support and your issues are as good as fixed already.

- Homogeneity of Molten Metal: A common problem often faced by many operators in the use of furnaces is the inability to mix the smelted gold after melting. Considering the high temperatures involved in gold smelting (and that of other elements), you can’t just reach inside and try to mix it properly.Unfortunately, there are disadvantages that come with not having a homogenous mixture. One is the clumping together of particles at some point, and if allowed to cool with such, knots may form. Another is the formation of holes or discontinuities within the cross section of the final product made with such molten metal.The 1-4kg Platinum Melting furnace solves this problem interestingly. With an in-built stirring system, you can be sure that no clumps or holes are getting formed in your molten material. The continuous electro-magnetic stirring system keeps the molten mixture well mixed, giving you the assurance of a smooth and well finished jewelry product when the process is over.

- Compact Size: Getting ample space for a furnace to fit in is usually another big issue for operators of jewelry plants. There are often a lot of other devices and machines to use and they have to be economical with space in order to have everything under the same roof. The 1-4kg Platinum Melting furnace easily solves this problem with its economical size. Despite the efficiency of this technological wonder, it is unobtrusive in size and fits snugly in a not-too-big space. This unique combination of utility and portability is something you’ll be hard-pressed to find anywhere else. Again, here’s another reason why the 1-4kg Platinum melting furnace is the best choice for your foundry.

Who’s this furnace Meant for?

Here, we take a look at the various categories of individuals or businesses that will find this furnace useful for their operations and purposes.

- New Business R&D Units: Often, the cost of setting up a standard Research and Development laboratory for new companies can be quite on the high side. Yet, R&D is an indispensable part of expansion and progress, especially in the precious metals industries. A furnace like the 1-4 kg platinum melting furnace delivers the advantages of Research on a small scale without causing the company to go bankrupt.A furnace like this can be used to experiment with tractable amounts of precious metal at various temperatures. It then becomes possible to try out various melting processes, and figure out what works and what doesn’t. This furnace is also suitable for laboratory use because of the well-covered design which will prevent any fumes from escaping and fouling up the environment.

- Jewelry Refinery Plants: This is another industry that stands to benefit immensely from the use of the 1-4kg platinum melting furnace. With the maximum temperature of 2600o C in five minutes, you can easily melt as many old jewelry items as possible within a short period of time, getting more in return and increasing your turnover quickly.

1.4, 12kg gold (Pt, Ag, Cu, Al) smelting equipment

Think of a smelting equipment that is capable of melting either 12 kg of gold, 4kg of platinum or 6kg of silver and you have this piece of technological wizardry. This is obviously more on the larger scale than any of the previous ones.

Businesses or laboratories that require batch operations with more volume in every single batch will find this smelting machine a great source of relief. It will help to prevent repeated replacement of raw precious metals since it can contain twice the volume of the average smelting machine.

We understand that smelting presents a possible health problem to workers and operators due to the release of toxic gases. However, our advanced IGBT technology goes about achieving the maximum possible temperature in such a way that the toxic by-products of the smelting process are as minute as possible. Beyond just ensuring worker safety, this feature is also an effort in ensuring environmental protection.

We don’t only make profit Cgenerating machines, we are also concerned about ensuring that the equipment we build are not sources of degradation to the environment.

If you’re still not convinced yet about how exactly this gold metal smelting equipment stands out among others, then we have compiled a list of advantages below:

- Availability of choice in various model types: With the 12kg gold smelting equipment, you are not just restricted to a single, one size fits all model. Rather, there are three different model types available for you to choose from each numbered SPB-TB2, SPB-TB4, AND SPB-TB5. All of these offer different forms of trade-offs between capacity, operational efficiency, melting time and maximum temperature.This is not to say they differ in quality. In fact, they have many similarities, for example, they all have a power rating of 15 kilowatts and work with a three phase 380V power supply at frequencies of 50/60Hz. Even more, all the labels are equipped with a water pump and they all weigh 95 kg, while measuring 740x500x1360mm in size. However, the subtle differences are only there to ensure that you can pick something that is completely suited to your operational requirements and fits your budgetary plans. Below is a table highlighting the various models and what they offer:

Model number SPB-TB2 SPB-TB4 SPB-TB5 Power source Three phase 380V±10%, 50/60Hz Three phase 380V±10%, 50/60Hz Three phase 380V±10%, 50/60Hz Power 15 kw 15 kw 15 kw Applicable metal Platinum, palladium, gold, silver, steel, copper

and their alloysPlatinum, palladium, gold, silver, steel, copper

and their alloysGold, silver, steel, copper and their alloys Max capacity 2kg platinum 2kg platinum 12kg gold / 6kg silver Melting time 2 minutes 3 minutes 5 minutes Max temperature 2800℃ 2800℃ 1800℃ Dimension 740*500*1360mm 740*500*1360mm 740*500*1360mm Weight 95 kg 95 kg 95 kg Heating technology IGBT Induction heating IGBT Induction heating IGBT Induction heating Water pump Equipped Equipped Equipped Cooling way Water cooling Water cooling Water cooling - Ease of Maintenance: Buying a new furnace or smelting machine is only a part of the story. The part of the business that gives foundry and jewelry refining plant owners nightmares is when it’s maintenance time. Maintenance can be a pretty tricky operation for many reasons. The first is the amount of effort it takes to dismantle a furnace or smelting equipment and get it cleaned or put in proper shape. Another part that makes operators loathe this process so much is the amount of important downtime lost when maintenance is going on.A lot of production which would result in profit often has to be halted in order to properly run maintenance or even routine cleaning on smelting equipment. This is not the case with the 12kg gold smelting equipment. An easily replaceable crucible design ensures that the crucible can be extracted and cleaned in just a couple of minutes. This convenience significantly reduces the necessary downtime for maintenance activities. You can therefore get your cleaning and scraping out of the way in a couple of minutes and restore your smelting equipment into operational mode as quickly as possible.

- Tilting Furnace design: Since the period of the industrial revolution, the days of the huge steel factories. The spillage of molten metal has always been a safety risk for operators of furnaces. The metals industry has been consistently on its toes trying to find a way around this issue. Apart from hurting furnace operators, spillage also leads to wastage of the molten metal.To ensure safe and efficient operations therefore, these two problems have to be sufficiently dealt with. Our tilting furnace design is a perfect solution to these problems. With the tilting furnace design, transferring molten metal (after smelting), either into the mold or anywhere else just got easier.No wastage due to spillage, no workers’ skin peeling from accidental spills. Just lift the lid, pull down the lever, and watch your molten metal flow as smooth as velvet into whatever container you want to transfer it into.

- 24-hour operation: Ever had to use a furnace that had its coil or some other internal part get burnt out after operating for a long period of time? You will definitely agree that this is a very annoying situation. Why spend scarce resources on an equipment that will only last for some hours before requiring repairs or some part replacement? The 12kg gold smelting equipment can work all day round without giving the slightest hint of dysfunctional operation.The only limits to its operation are human tiredness and perhaps electricity supply. As long as you have a stable source of power and consistent man power (staff on various shifts for example). Our gold smelting equipment will deliver sublime performance day in day out and week in week out. There is no limit to how much you can boost your bottom line profits with an efficient machine like this one.

1.5, 20-30KG gold (Ag, Cu, Al) smelting furnace

Now we’ve left the small and medium size furnace categories and we’re approaching the really big guys. This massive 20-30kg packs all the wonders of technology that we’ve outlined in the previous furnaces. But in this case, they are even slightly upgraded and better.

The 20-30kg Gold smelting furnace is a winner anytime and is sure to put you ahead of your competitors in the precious metals business. Various companies that have ordered this product over time have kept giving us sterling reviews. In fact, a particular company claimed to have made so much that they ordered another unit of the same furnace all over again.

It’s understandable if you find all of this a little too good to be true. But by the time you’re done going through the various distinctive features and characteristics, you’ll understand why this equipment is such an absolute banger. And we hope that you’ll get in touch to purchase one or more units too.

So, let’s get to it, what are the things that stand the 20-30kg gold smelting furnace out among equivalent machines on the market?

- Split Tilting Furnace Design: Remember the tilting furnace design we mentioned earlier? The one that ensures safely pouring the molten metal without spillage or wastage? Well, it’s gotten a nice upgrade with the 20-30kg smelting furnace. Considering the size of this furnace, it’s obvious that the normal tilting design might not be as effective.This is why we incorporated a separate tilting system, which is standalone from the main furnace body. No matter how much molten metal you’re pouring into the mold, you can stay completely safe without fear of wastage or operator injury. This is an innovative feature that ensures that you still get the same high level of quality despite the increased amount of metal being handled.

- Compact Design: There is a kind of complexity associated with the circuits and components required for putting together a working heating system. Because of this, many traditional furnace designs have circuits and wires that are jumbled together and just all over the place. This is not so for the 20-30kg melting furnace.With our enhanced IGBT technology coupled with a micro-chip supported circuitry, all the parts and components are tidily arranged in isolated, yet interconnected, units. In the event of repairs or maintenance, all you have to do is order a replacement unit rather than having to take each component apart for troubleshooting.

- Intrinsic Hazards Prevention:Another frequent issue that is associated with heating systems is that of electric hazards. Heating- especially for smelting or melting applications- requires a lot of electricity. Because of this increased load, the probability of high voltage trips occurring is greatly increased.Also, melting of wires which are not too strong leading to short circuit and tripping off is another common issue that occurs with furnace systems.?With this smelting furnace however, we have taken proactive steps to ensure that none of this problems occur in any way. All of the parts used, from wires to even the tiniest screws, are of the highest possible quality.They are capable of accommodating a slightly higher level of electricity than is required. Also, an emergency trip system is included, powered by a sensor that can immediately sense inordinately high voltages and cut off electricity supply instantly. Frequency spikes, over current, or water shortage are all circumstances that have been adequately envisioned with preventive systems in place to contain them should they occur during operation. This meticulousness with safety is another factor that makes 20-30kg smelting furnace stand out.

- Availability of Options: We believe in offering our clients options to choose from. No matter how good a device is, we understand that requirements vary as well as purchasing power. With the 20-30kg gold smelting furnace, you have the ability to choose from two different models- the SPB-TB25, and the SPB-TB35. Both are virtually the same as far as the core functions and specifications are concerned.But slight differences in volume and weight of raw metal to be melted ensure that you can find something more amenable to your production needs. Regardless of which model you eventually choose to buy, you can be assured of the same maximum temperature of 1800oC achieved in just between 6 and 8 minutes. Below is a table outlining the differences and guiding you on the right smelting furnace model to choose.

Model number SPB-TB25 SPB-TB35 Power source Three phase 380V±10%, 50/60Hz Three phase 380V±10%, 50/60Hz Power 25kw 35kw Max current 36A 51A Applicable metal Gold, Silver, Copper, Brass, Bronze, and their alloys Gold, Silver, Copper, Brass, Bronze, and their alloys Melting time 6-8 mins 6-8 mins Max capacity 24K Gold: 25.0 kg

925 Silver: 12.5 kg24K Gold: 30.0 kg

925 Silver: 15.0 kgMax heating temperature 1800℃ 1800℃ Power size 690*500*1210mm 690*500*1210mm Furnace size 650*520*1800mm 650*520*1800mm weight 200kg 215kg Heat technology IGBT Induction heating IGBT Induction heating Water pump Build-in Build-in Cooling way Water cooling Water cooling - Versatility: Wouldn’t it be a waste if a furnace this big and high tech was designed only for melting gold? Of course it would, that is why the 30kg smelting furnace is capable of not melting just gold, but other precious metals like Silver, Brass, Bronze, and Copper. Alloys of these metals can also be melted as well. You don’t have to be worried about inconsistencies in color or texture from melting various metals together.An electromagnetic stirring system ensures that proper mixing is done, effectively eliminating any separation. This makes the furnace highly useful especially for jewelry refining plant where an assortment of old jewelry materials are often brought to be refined into new products.

All of the above are the various benefits of purchasing the 20-30kg gold smelting furnace. To enjoy all of these coupled with unmatchable customer services, all you have to do is get in touch with us and place an order.

1.6, 10-50kg chain tilting gold melting furnace

It’s normal practice to save the best for the last, and that’s what we’ve done here. The description in the title of this subsection does not refer to a single equipment. Rather, it refers to a range of melting furnaces capable of melting precious metals ranging between 10kg to 50 kg of Copper, Silver, or gold.

This collection of super melting machines present a far superior performance than any of the ones we have mentioned so far. High energy ratings as well as high temperature limits ensure that heating is done in no time. Below are some of the distinguishing features of this furnace range:

- Chain Tilting Mechanism: We’ve already highlighted the tilting furnace design on the last two furnaces we discussed. But this time, it’s on a whole different level. When you’re dealing with a furnace that has the capacity to handle 50kg of gold, you can be sure that the volume of molten metal that will be produced is not negligible. This is why extra care must be taken in ensuring that splashes are spillage are prevented. To achieve this aim, a chain system has been incorporated for controlling the tilt mechanism. Driven by the induction furnace motor, your molten metal gets transferred into the old in an extremely safe manner that cancels out waste. This is the best as far as electric melting furnaces for sale go, and you can’t afford not to add this piece of technological magic to your company’s inventory.

- Interactive Control Interface: A touch screen control panel based on Siemen’s PC control system gives you absolute control over your smelting furnace. The start and stop options only require a tap on a screen. Controlling a furnace has never been this easy, and it will take quite some research and tinkering to get a more intuitive system to work with. Also, operation parameters like Output power, Output current, output voltage, output frequency, and heating temperature are all options to select right off the screen. You can also monitor the amount of time spent in operation and easily take preemptive steps in the event of any abnormalities or undesirable operations. All of this make the furnaces in the 10-50kg Chain tilting furnace range an absolute delight for operators and business owners all over the world.

- Induction Heating Technology:Currently the most efficient technology for systems that require the supply of heat. Apart from heating metals to their melting point in a short time, this innovative technology also consumes far less power. Adding this to the deployment of our IGBT research, your furnace gives you far more output while requiring way less electricity/energy input than the average furnace. You get to spend less on settling power bills, this frees up more funds for you to invest in your business, and perhaps, purchase another Furnace.

- Assurance on Installation, Maintenance, and Troubleshooting:When you do business with us, you are unconsciously signing up for the best possible customer service. In addition to our team of engineers and technicians who are eager to assist you. We also have a strong customer service team that will easily guide you by phone or mail to handle any minor issues. All the furnaces in the 10-50kg chain tilting range have the replaceable crucible design which make maintenance and repairs 3easy to handle. But even if you’re facing any issues with this, our team is just a phone call or an email away from assisting you and getting your furnace back in operation.

The combination of the points above with the benefits and features already mentioned previously for other furnaces results in a high performance furnace. As you already know, we like to leave the buyer with choices, and this range of furnaces is not an exception. Below is a table of the various choices you have to choose from.

Power Supply Parameter Of Chain Tilting Electric Induction Furnace

| Model | MF-15 | MF-25 | MF-35 | MF-45 | |

| MAX input power | 15KW | 25KW | 35KW | 45KW | |

| MAX input current | 23A | 36A | 51A | 68A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||

| Oscillation frequency | 1K~20KHz | ||||

| Requirement of cooling water | Hydraulic pressure | ≥0.2Mpa | ≥0.3Mpa | ||

| Flow rate | ≥6L/Min | ≥20L/Min | |||

| Temperature of water | ≤45℃ | ||||

Melting Capacity Parameter Of Tilting Melting Furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy |

| MF-15 | 3kg | 10kg | 3kg |

| MF-25 | 5kg | 20kg | 5kg |

| MF-35 | 10kg | 30kg | 10kg |

| MF-45 | 18kg | 50kg | 18kg |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | |||

Now that we’ve looked through the various furnaces that are available for sale, it’s time to check out the various categories of people or industries that require them and which of these furnaces they may find useful. You will definitely fall under one of these categories, and we can assure you that there has a furnace that will meet your precious metal melting needs.

Gold Melting Furnace for Personal Gold Miners

You may not be very familiar with the term ‘personal gold miners’. This is because they are more commonly referred to as ‘recreational gold miners’. When the gold mining industry is discussed, it is more common to hear about all the big gold dealers and the multimillion dollar companies involved in the industry.

However, they are only a part of the story. In actual fact, there’s a less talked about aspect of the gold mining industry and these are the recreational miners. Recreational miners are people who take up gold mining just as a hobby. Along the line, they may make enough discoveries or unearth enough nuggets or gold to actually make a fortune. But the recreational gold miner is in the trade primarily as a pastime and not necessarily for the money.

In this chapter, we will be taking a look at the kind of furnaces that recreational gold miners may find useful. But before we dive into machines and their technical details, let’s check out how recreational miners have evolved over time.

2.1, The origin of recreational gold mining

Recreational gold mining didn’t start out as ‘recreational’. The gold prospectors of the 19th century weren’t looking for hobbies or something to kill time with. They were out to make MONEY.

Like everyone knows, gold is a very precious and scarce commodity. Perhaps because of its familiar luster and ability to resist corrosion or damage over a long period of time.

Therefore, the early prospectors were eager to get out in the field and be lucky enough to find a rich vein and make thousands or millions of dollars. Their major technique of extracting gold from geological formations was a method called panning. This involved pouring water in a pan containing sediments suspected to harbor gold.

The pan would then be shaken until the gold descended while water and the other rocks stayed afloat. This method is still in practice today by gold mining enthusiasts who are the present day ‘recreational gold miners’.

There were two major events that involved a massive rush of gold prospectors to areas considered to have large deposits. One was the Witwatersrand Gold rush in South Africa around the year 1886, a lot of Gold mining enthusiasts had heard about possible deposits and they converged on the area to see if they could make their fortune. Interestingly, this gold rush was what led to the creation of present day Johannesburg, South Africa.

Another important gold rush in the history of gold prospecting occurred earlier. This took place between 1848 and 1855 when as much as 300,000 or more gold prospectors besieged the district of Coloma in California. They worked at this area and some of them struck luck, hitting it big, while others weren’t so lucky and had to leave empty handed.

When the gold of this area ran out, it triggered a smaller gold rush in the Cariboo region of British Columbia. About 30,000 gold prospectors, many of them from the California days came down here to again try their luck with cashing in on the gold craze.

The gold industry has evolved from the period of the gold rushes. With the advent of technology and large scale mining with advanced equipment, larger companies with better funding have taken center stage. Manual gold mining methods like Panning or Sluicing are no longer economical in mining gold for commercial purposes. For this reason, over the turn of the 20th Century, and now the 21st century, individual gold miners now tend to be involved in the business more for pleasure and leisure.

Within this period of time, recreational gold mining has taken shape and become an established pastime for so many people. There is even an association for prospectors and recreational miners; The Gold Prospectors Association of America”. Established in 1968, the association seeks the protection of the interests of prospectors, the prevention of environmentally harmful mining and the defense of the rights of Americans to mine and prospect for gold.

Various countries have different legislations concerning recreational mining. In some countries, mining is completely disallowed for various reasons. These reasons include the prevention of pollution due to impurities found alongside gold such as mercury. Some other countries allow the prospecting of gold to various degrees of liberty.