Double Head Rolling Machine

China Professional Electric Jewelry Rolling Mill Supplier

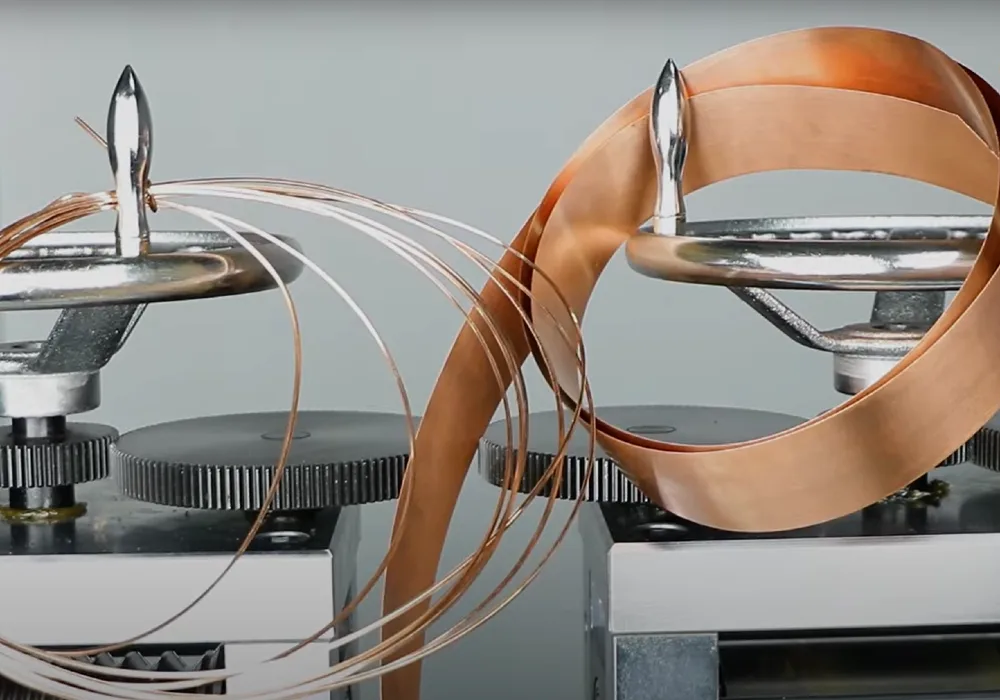

Double-head rolling mill is used for the production of gold, silver, copper, platinum, and other jewelry sheets or wires, allowing for simultaneous rolling of both sheets and wires.

In the later stages of jewelry making, it can be used in conjunction with tube welding machines, bracelet forming machines, wire drawing machines, chain making machines, etc., to complete the production of bracelets, rings, and chains. The double-head design offers higher efficiency, making mass production easier.

Currently, there are many manual rolling mills on the market that are inefficient and produce rough finished products. For larger jewelry manufacturers, choosing a high-efficiency rolling mill that can easily achieve mass production is crucial. The SuperbMelt double-head rolling mill is more suitable for medium-sized or personnel-scarce jewelry manufacturing factories, providing multiple functions in one machine, saving time and labor.

Double Head Design

The double-head design can realize flexible production. One machine can press sheets and wires at the same time, and both sides can press sheets and wires together to improve production efficiency and realize mass production.

Adjustable Speed

The machine is driven by a separate motor, which can realize frequency conversion and speed regulation.

High Hardness Finale

The finale of the machine is made of high-hardness material, which has low maintenance and repair costs and a longer service life.

Active Roller of Linkage Mechanism

The rollers work at the same time top and bottom, which ensures the uniformity of the processed material, so the thickness and dimensional accuracy of the finished product can also be higher.

Stable Machine

Machine body is made of high-quality alloy, the whole machine is thick and heavy, which provides stability for the work of the equipment and avoids the abnormality of the machine when it is working.

Automatic Refueling

The machine is equipped with an automatic lubrication device, which can filter out particles, reduce the tedious work of manual refueling, save more time, and be more humane.

Easy to Use

The machine is compact and simplified, does not occupy too much space in the factory workshop, runs almost without noise, and is easy to use.

No Loss of Finished Product

The pressing of materials will not cause loss. For example, the pressing of wires is grooved according to Italian professional data, which makes the quality of finished products higher and more complete.

Safe and Reliable

The machine is equipped with two emergency stop switches, which can stop the work in an emergency when the machine is abnormal, ensuring the safety of employees and avoiding operation risks.

The double head rolling machine is mainly used in the jewelry manufacturing industry and some metal processing industries. It can be made into metal sheets and wires of corresponding sizes, such as gold, silver, platinum, palladium, rhodium and other precious metals.

Various jewelry styles on the market are inseparable from the use of rolling mills. The birth of a rings and bangles requires the assistance of a jewelry rolling mill. It is necessary to process metals such as gold and silver into sheets, and then use the next step of forming bangles and rings. The production of chains also needs to be processed by a rolling mill to process metal materials into wire rods, and then though the drawing wries and chain making to turn the metal materials into a beautiful jewelry chain.

According to the finished product requirements of different customers, unique sizes can be customized, such as the thickness of the piece, the largest input size and the smallest output size. For medium and large jewelry factories, this is a good choice for rapid prototyping of finished products.

| Model number | SPB-2YXP-10P |

| Power | 7.5kw |

| Voltage | 3 phase 380V,50/60 Hz |

| Roller size | 120*200mm * 2 |

| Roller material | DC53 |

| Rotation | 22/30 Double Speed |

| Rolling thickness | 12mm – 1.0mm |

| Rolling square | 1*1mm ~ 12*12mm |

| Max product width | 190mm |

| Lubrication | Auto Lubrication |

| Size | 980*650*1450mm |

| Weight | 980kg |

Double head rolling mill can simultaneously press wire and sheet, improve efficiency and quickly realize mass production.

The quality of the finished product is smooth and uniform without loss of material.

The finished product has high precision, and the corresponding slot size can be customized, so as to meet the production of various jewelry.

Why SuperbMelt Double Head Rolling Mill

Any Question About SuperbMelt Double Head Rolling Mill

Here's What Our Satisfied Customers Have to Say

Guide of Double Head Rolling Machine

SuperbMelt What Kind of Products can be Pressed?

The rolls of this double-head rolling mill can be customized for different output, finished product size and finished product type requirements. It can largely solve the problem of resource utilization, and the two sides can be flexibly designed to achieve maximum output and efficiency.

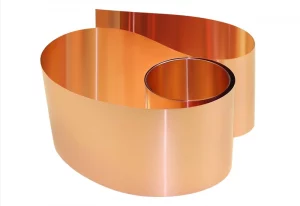

Shape

The processed material will finally be presented in the shape of a sheet or wire, and the sheet mainly pays attention to its maximum and minimum thickness. In addition to determining the required size of the wire, the shape of the finished product should also be specified. Grooves made of wire can be customized as round or square.

Metal

The hardness of different metals is different. Double head rolling mill uses cold rolling method, which is more suitable for ductile metals, such as gold, copper, silver, copper, platinum, palladium, rhodium, etc., can be processed by rolling mills. When these metals fail to work, it is only necessary to anneal the material and then process it.

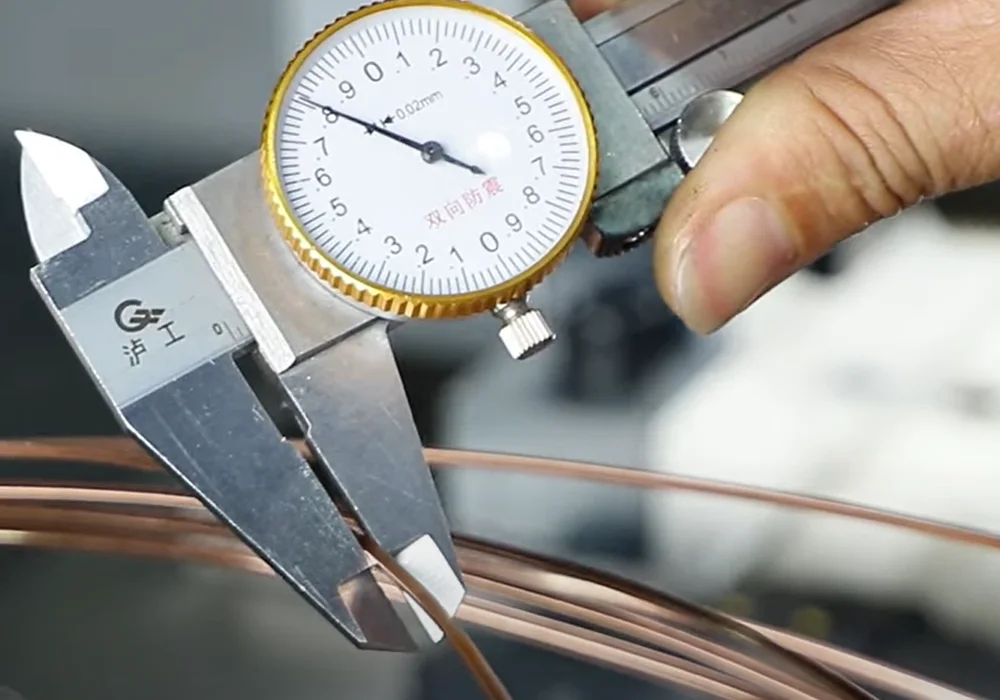

Size

For sheet material, the maximum feeding width of the machine can reach 190mm, the thickness can be realized as minimum as 0.1mm, and the maximum feeding thickness is 12mm. As for the wire, it can be between 14-0.8mm, and the size customization is accepted.

Finished Products

Jewelry rolling mill is a machine commonly used by jewelry manufacturers. With the use of other jewelry equipment, the final product can be made into hollow bracelets, rings, bracelets, necklaces, etc. It is also a more efficient rapid prototyping tool for metal sheet and wire for the metalworking industry.

Operating Process and Precautions

Step 1:Early Inspection

- Ensure that the workbench is clean and no other debris, and check whether the protective device buttons can be used normally.

- Check whether the processing material can be used, such as determining what metal it is and measuring the thickness and width of the material to be processed. Avoid machine damage due to the use of unsuitable materials.

- Check whether the oil level of the fuel tank reaches the standard position, and add it in time when there is no oil to ensure the normal operation of the automatic refueling function.

- Turn on the machine and let the machine run for two laps, check the condition of the rollers, whether there is damage or stains, to avoid waste of materials.

Step 2:Runtime Considerations

- After the inspection is completed, the power can be turned on, and the material can be placed close to the working area of the rolling mill.

- During the rolling process, the screws on both sides can be turned to adjust the distance between the two rollers, and the screws are controlled by the gear on the top of the machine. so turning the gear plate on the top can realize the adjustment of the roller crimp.

- When adjusting the seam every time, avoid too tight adjustment at one time, which will easily cause damage to the machine. The operation should be repeated several times until the desired thickness appears.

- The pressure roller of the electric rolling mill rotates relatively fast, so when putting in the material, you should quickly withdraw your hand to avoid being crushed by the opposite roller.

Step 3:Post-maintenance

- After the rolling work is finished, turn off the power in time.

- The most important part of the rolling mill is the counter roll, so it must be well maintained. It should be noted that a machine with a horsepower of more than 10p should be selected for extremely hard materials, otherwise it is easy to cause pits or indentations on the rollers, which will affect the quality of the finished product.

- When the pressure roller is damaged, please hand it over to a professional for repair.

- The coolant needs to be checked regularly, and replenished in time when it is lacking.

- The machine should be installed in a place without shock source, sunlight and radiation. Keep dry, away from moisture or drafts.

- Regularly check the electrical box to see if the components inside are abnormal.

What is The Difference between Double Head Rolling Machine and Ordinary Electric Rolling Mill?

Production Requirements

The most intuitive difference between ordinary and double head rolling mills is the number of machine press rolls. Double head rolling mills are more suitable for factories with large output requirements. Whether you are a professional sheet maker or wire maker, its output is twice the output of the same horsepower.

For some factories with a wide variety of jewelry production styles, the double-head rolling mill is also very practical, because two pressure rollers can be reasonably used, the sheet and wire pressure can be combined to work at the same time. However, ordinary rolling mills can only achieve these under one roll, and the efficiency will be lower, so the output will be lower.

Various Finished Products

The double-headed rolling mill is more flexible, and the display of the finished product can be diversified. For example, when you need the finished product to have a smooth mirror effect, you can customize the tungsten steel pressing roller.

With the use of the double-headed design, even if you need to press the metal or the finished product various effects, all of which can be easily realized on one machine

Production Speed

Many electric rolling mills have a fixed speed, which makes it difficult to rationally allocate resources, resulting in an inability to increase the production speed.

The double head rolling mill uses frequency conversion to adjust the speed, and the adjustment range on both sides is 0-22 rpm. The speed can be adjusted according to the number of production personnel or production needs, so as to achieve more efficient resource allocation and thus increase production speed.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited