Continuous Wire Drawing Machine

SuperbMelt wire pressing machine helps customers press wires into shape at one time

SuperbMelt Continuous Wire Drawing Machine is used for producing metal wires such as gold, silver, and copper. This machine is capable of pressing wires into the range of 12-3.2mm in one go, which is several times faster than ordinary wire pressing machines, effectively addressing production issues for large-scale chain manufacturers.

- Compared to ordinary wire pressing machines, the Continuous Wire Drawing Machine offers faster wire pressing speed and higher precision, capable of pressing 0-50 meters per minute in one go.

- The Continuous Wire Drawing Machine is suitable for large-scale jewelry chain processing plants, helping factories increase production capacity and reduce labor costs.

SuperbMelt, a professional wire pressing machine manufacturer in China, helps customers solve jewelry chain casting problems!

| Model number | SPB-CWDM |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 30 kw |

| Applicable metal | Gold, Silver, Platinum, copper, and their alloys |

| Shaft diameter | 90mm |

| Calendering pass | 16/18/20 |

| Maximum incoming line | 12mm square rod |

| Minimum output | 3.2mm square wire |

| Rotating speed | 0-50m/min adjustable speed |

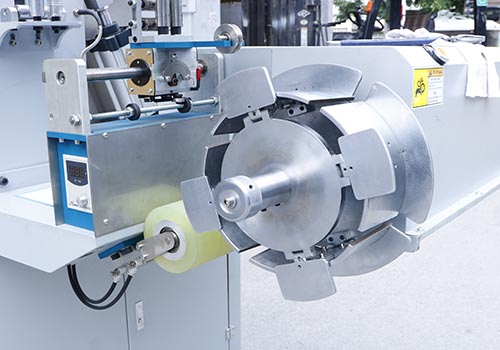

| Rolling method | Constant tension horizontal cable winding |

| Size | 4800*1160*1500mm |

| Weight | 4000kg |

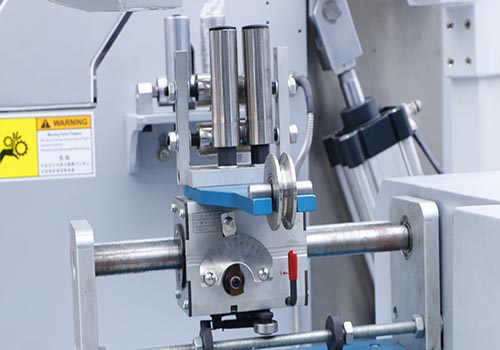

- Multiple sets of straight-line rolling rolls, high efficiency

- Burr-free and lossless finished wire

- Good density of finished material, no breakage, improves wire drawing ductility

- Straightening function before feeding to prevent deviation

- Equipped with spray cooling system to reduce material and rolling surface temperature

- Constant tension horizontal wire coiling

- Automatic emergency stop device, automatically stops operation when material is missing/completion of operation

- Additional protective cover for operator safety

- Metal processing and manufacturing: for producing various metal wires, cables, nails, rivets, screws, etc.

- Jewelry manufacturing: for making jewelry chains, necklaces, bracelets, etc., using metals like gold, silver, copper, etc.

- Electrical industry: for manufacturing various types of wires and cables, including household wires, industrial cables, communication cables, etc.

- Construction industry: for manufacturing construction materials such as reinforcing bars, steel wire ropes, etc.

- Automotive manufacturing: for producing metal wires used in automotive components.

- Electronics industry: for producing various types of wires and wire harnesses used in electronic components.

- Medical device industry: for manufacturing metal wires and wires used in medical devices.

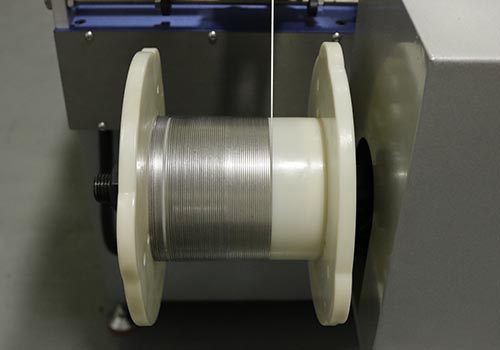

Using coiling wheels instead of manual wire pulling saves labor, increases production efficiency, and reduces labor costs.

Using 20 sets of rolls for wire pressing allows the wire to be pressed into the applicable range at once, increasing the overall wire pressing speed and thus solving the problem of mass production.

Preventing wire coiling misalignment can greatly save labor, increase efficiency, and reduce labor costs.

Why SuperbMelt Continuous Wire Drawing Machine

Any Question About SuperbMelt Continuous Wire Drawing Machine

SuperbMelt FAQ Guide of Continuous Wire Drawing Machine

- Single-block wire drawing machine: Usually utilized for lower production quantities and smaller wire diameters.

- Multi-block wire drawing machine: With many blocks placed in sequence, this machine is appropriate for larger wire diameters and higher production quantities.

- Larger wire sizes can be drawn using a bull block wire drawing machine, frequently in just one pass over a single die.

- Continuous wire drawing machine: Pulls wire through a sequence of dies to lengthen and reduce diameter while operating constantly.

- Wet wire drawing machine: Uses coolant or lubricant to minimize heat accumulation and friction during drawing.

- Dry wire drawing machine: Ideal for drawing some non-ferrous metals, this machine runs without the need of coolant or lubricants.

- A wire drawing machine with a horizontal configuration of dies and pulling mechanisms, ideal for specific uses and limited space.

- A vertical wire drawing machine offers advantages in specific applications and space layouts due to its vertical die and pulling mechanism configuration.

The metalworking industry uses both wire drawing and rod drawing to reduce the diameter of metal rods or wires, however there are some important differences between the two processes:

- The input material for wire drawing is a reduction in the diameter of metal wires. A coil or spool of wire is usually used as the starting material.

- Rod Drawing: In rod drawing, the diameter of metal rods is decreased. Usually, a billet or straight metal rod serves as the beginning material.

- Method: Wire drawing: To obtain the required diameter, the metal wire is pushed through a succession of progressively smaller dies. As a result of this procedure, the wire becomes longer and less diameter.

- Rod Drawing: To decrease the diameter of the metal rod, it is similarly drawn through a sequence of dies in rod drawing. In contrast to wire drawing, rod drawing typically requires fewer drawing stages because the starting material is already closer to the target

- Applications: Wire Drawing: Wire drawing is widely used to create thin wires for jewelry, electrical wiring, mesh, and fence, among other uses.

- Rod Drawing: Rods with a smaller diameter are produced via rod drawing for use in shafts, fasteners, and structural elements.

- Equipment: Wire Drawing: Wire drawing machines usually consist of a straight line of dies, and a capstan or other similar mechanism pulls the wire through each die.

- Rod Drawing: Rod drawing machines are made to handle beginning materials with a bigger diameter and usually require heavier-duty equipment. Their designs may be comparable to those of wire drawing machines.

A Continuous Wire Drawing Machine is a piece of equipment used to reduce the diameter of metal wires continuously, typically by pulling them through a series of dies.

Continuous Wire Drawing Machines work by feeding metal wire through a series of dies, which progressively reduce its diameter while increasing its length.

Continuous Wire Drawing Machines can process various metals, including steel, copper, aluminum, and alloys such as brass and bronze.

The main components include the wire payoff system, drawing dies, capstans, drawing drums, cooling system, lubrication system, and wire coiler.

Advantages include high production efficiency, precise control over wire diameter, improved surface finish, and the ability to process a wide range of wire sizes and materials.

The wire diameter is controlled by adjusting the size of the drawing dies and the speed of the wire drawing process.

Safety precautions include wearing appropriate protective gear, ensuring proper machine guarding, and following lockout/tagout procedures when performing maintenance.

Maintenance tasks may include regular lubrication, inspection of dies and components for wear, cleaning of coolant systems, and alignment checks.

Guide to the Continuous Wire Drawing Machine

Introduction to Wire Drawing: A Historical Overview

Wire drawing is a process that dates back to the early days of metallurgy, where metal wire is drawn through a die or a series of dies to reduce its diameter. This technique has been crucial in the development of various industries, especially in the production of cables, jewelry, and other fine metal applications. Initially, wire drawing was performed manually or with rudimentary machines, but as technology advanced, machines became essential for achieving consistent quality and efficiency in wire production.

The earliest wire drawing machines were introduced during the Industrial Revolution in the 18th century. These early machines were powered by steam or manual mechanisms, allowing for mass production of wire as the demand for electrical components, jewelry, and military applications continued to grow. However, these machines were limited in terms of speed, efficiency, and precision.

With advances in engineering technology, continuous wire drawing machines emerged in the 20th century, revolutionizing the process. These machines significantly improved the precision, speed, and versatility of wire drawing, making it an indispensable part of modern manufacturing.

Why Do We Need a Wire Drawing Machine?

The wire drawing process serves several key purposes in various industries:

- Precision Reduction: Wire drawing reduces the diameter of wire to precise specifications, allowing for the production of wires of varying thicknesses, which are crucial for different applications, from fine jewelry to industrial cables.

- Increased Material Strength: During the drawing process, metal is often cold-worked, which increases its tensile strength and makes it more durable. This is particularly important for wires used in electrical and structural applications.

- Improved Surface Quality: Wire drawing ensures a smooth, clean surface finish on the wire, which is essential for aesthetic purposes, particularly in jewelry and high-end manufacturing.

- Economic Efficiency: Continuous wire drawing machines improve throughput and reduce waste, making the production process more cost-effective. By ensuring consistent quality and reducing material loss, these machines offer better yields and profitability.

Chapter 4:

Differences Between Market Wire Drawing Machines and SuperbMelt Continuous Wire Drawing Machine

While there are many wire drawing machines available on the market, the SuperbMelt Continuous Wire Drawing Machine stands out due to several key advantages:

- High Efficiency: Compared to traditional drawing machines, SuperbMelt’s continuous machine uses a streamlined design to maximize throughput while minimizing downtime. The continuous process means fewer stops and starts, reducing production delays.

- Advanced Technology: SuperbMelt’s machines are equipped with modern features such as advanced digital controls, automated tension regulation, and easy-to-use interfaces, which improve the overall accuracy and efficiency of the wire drawing process.

- Precision and Consistency: SuperbMelt’s machines provide superior precision in terms of wire diameter control. Their advanced die systems and automated tension controls ensure that the wire drawn is of the highest quality with minimal variation.

- Material Flexibility: SuperbMelt’s machines are engineered to draw various materials, including precious metals like gold and silver, with high efficiency. This feature makes them particularly well-suited for the jewelry industry.

- Customization: SuperbMelt offers custom solutions for specific wire drawing needs. Whether you require unique die sizes or specific material handling capabilities, SuperbMelt can tailor its machines to meet your production requirements.

- Energy Efficiency: SuperbMelt’s machines incorporate energy-efficient systems that minimize power consumption without compromising performance, resulting in lower operating costs.

Conclusion: Why Choose SuperbMelt Continuous Wire Drawing Machine?

For companies and individuals in the jewelry manufacturing, electrical wiring, and other industries that require precision and efficiency, the SuperbMelt Continuous Wire Drawing Machine is an excellent investment. With its high efficiency, advanced technology, precision, and customization options, this machine ensures that your wire production process is both cost-effective and scalable.

Whether you’re working with precious metals, high-performance alloys, or standard industrial materials, SuperbMelt’s continuous wire drawing machines are designed to meet the most demanding production standards while improving your overall output and quality.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited