XRF Gold Tester

Most Popular SuperbMelt Precious Metals Handheld XRF Gun for Gold, Silver, Platinum

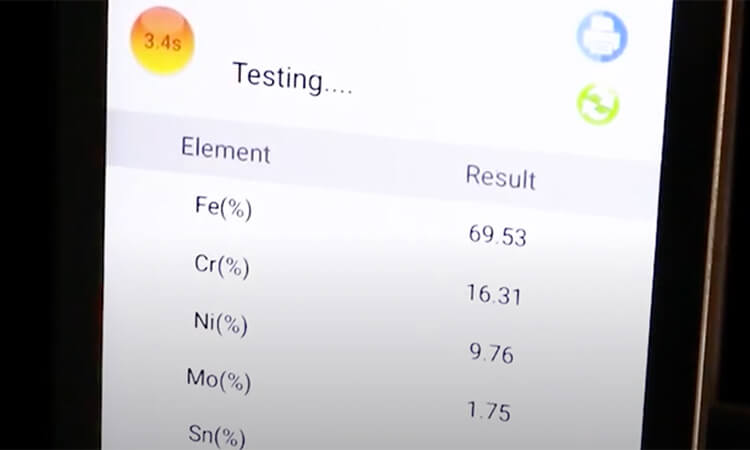

A non-destructive analytical tool, the SuperbMelt XRF Gold Tester can not only find and analyze gold, but also find and analyze metal elements dating back to No. 12-92. The XRF Gold Tester has a detection accuracy of up to +-0.05%, although the accuracy decreases with decreasing content.

When a sample is excited by a primary X-ray source, the XRF Gold Tester measures the fluorescent X-rays that are released by the sample. Every element that is present in a material creates its own distinct fingerprint, or specific set of fluorescence. Because each material’s fingerprints are unique, handheld XRF gold analysis is a fantastic tool for both quantitative and qualitative evaluations.

Construction and environmental engineering, mining and exploration, precious metals recovery, oil and gas, automotive, etc. are some of the industries that employ XRF Gold Tester .

The XRF Gold Tester are made for simple, accurate, and dependable elemental analysis and offer unmatched metal identification.

| Analytical Method | Energy dispersive X ray fluorescence analytical Method |

| Elements Measuring Range | Atomic number from 12 to 92 [elements from magnesium(Mg) to uranium (U)] can be measured |

| Simultaneous detector elements | Simultaneous analysis 40 elements |

| Microcomputer system | Customized system; CPU: 1G ; system memory: 1G ; extended stored maximum support 32G ; standard 4G for mass storage data |

| The content range | ppm~99.99% |

| The detection time | 1-60 seconds (a second report results) |

| A built-in system | GPS, WIFI, Bluetooth |

| Power Supply | Rechargeable lithium battery, standard is 9000mAh, sustainable work up to 12 hours; optional is 27000mAh superbattery with wide voltage 110V ~ 220V universal adapter for recharging power supply |

| Detection Objective | Solid, liquid, powder |

| Detector | SDD detector or Fast-SDD detector (optional) |

| Detector resolution | Minimum can reach 128eV |

| The excitation source | 50KV/200uA- silver target end window integrated miniature X ray tube and high voltage power supply |

| Collimator and filter | Collimator diameters are 4.0mm and 2.0mm, 6 kinds of filters with automatic switching functions |

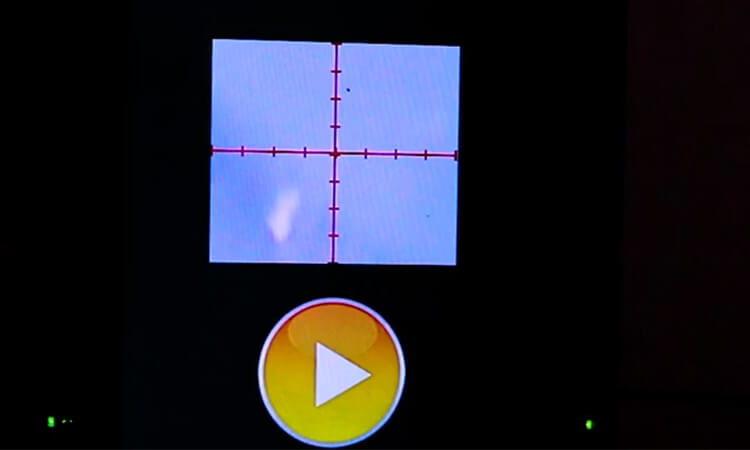

| Video system | 500W pixel high resolution camera |

| Display screen | Brand new 5 inch transflective LCD touch screen, the resolution is 1080×720 |

| Detection limit | The minimum detection limits at 1 ~ 500 ppm |

| Safety | Multiple safety protection, no tests, no radiation, radiation levels at work are far below the international safety standards, and has no sample telemetry, automatic shut X light tube function. Standard radiation shields, thickened wall alloy test instrument |

| Specialty | Ore special edition analysis software, using intelligent one key test |

| Convenience of application | Key intelligent matching the best curve that no need to select curve |

| Data transmission | Digital multi-channel technology, SPI data transmission, quick analysis, the high count rate; waterproof mini USB, and can be connected with a desktop computer |

| Operating ambient humidity | ≤90% |

| Operating environmental temperature | -20℃~+50℃ |

| Instrument dimension | 244mm(Length)x 90mm(Width)x 330mm(Height) |

| Instrument weight | 1.7Kg |

| Intelligent warning signalsIndicator system | Green light means power on, red flushing means testing and yellow flushing means the problems |

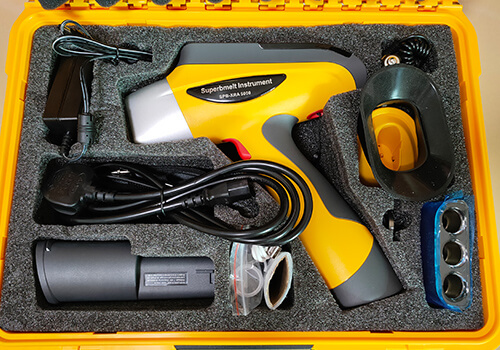

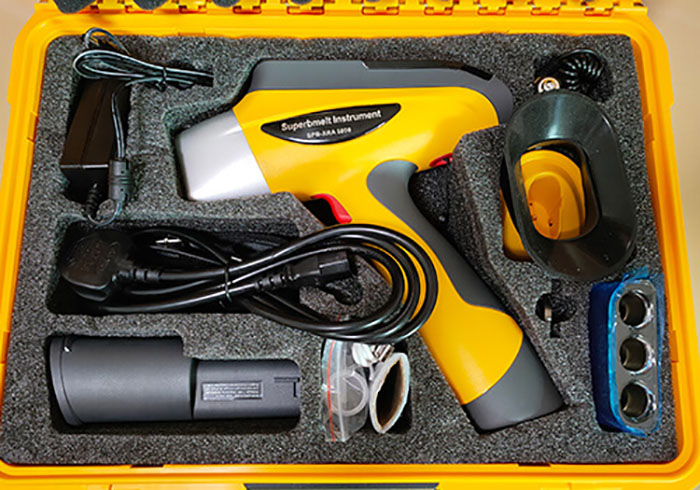

| Accessories | Three-military-protection-box is compression, waterproof and shock absorption. Universal charger and car charger, 4G SD memory card and card reader Two lithium battery and charger, PDA accessories, radiation shield. Optional accessories: the large battery, seat type test support, Bluetooth printer, mill, manual pressure machine, and other options can to choosen… |

- The handheld XRF analyzer is lightweight and best for performing crucial tasks for any weather condition, field environment and location. Therefore, no need to worry about lifting heaving analyzing equipment to different locations.

- The handheld XRF analyzer saves significant expense and time when compared to traditional laboratory analysis.

- The shorter measurement times and superior detection capacity increases your productivity.

- The XRF portable analyzer is able to detect and measure these elements in materials: Au, Ag, Ti, V, Cr, Mn, Fe,Sn, S, Hf, Ta, Mo, W, Si, Sb, etc.

- The handheld XRF gold analyzer can detect contaminant metals and elements with little to no sample preparation, therefore providing fast and decisive results.

- The handheld XRF analyzer has a rapid nondestructive detection and quick measurement by simply aiming at the material and able to report results of detection within seconds.

- The large lithium battery is 27000mAh, this is capable of powering the XRF gold analyzer continuously for three days. A built in memory battery can replace the battery power should the main battery go off on site after three days.

- The handheld alloy analyzer has a professional inbuilt application software that features easy testing and getting quick results.

- The portable XRF analyzer has an inbuilt 500W pixels high definition camera that can observe the sample’s testing position which makes the measurement of elements accurate.

- The handle XRF gold analyzer has a collimation filter system that has a combination of 12 groups, this makes it possible for the handheld analyzer to meet your requirements.

SuperbMelt XRF Gold Tester Application Industry

SuperbMelt XRF Gold Tester Accessories

How Much Does XRF Gun

The elemental composition of materials is determined via an XRF (X-ray Fluorescence) equipment. It excites atoms in a sample with X-rays, causing them to release distinctive fluorescent X-rays that are subsequently detected and studied.

Because they can swiftly and precisely ascertain the elemental makeup of numerous materials, XRF devices are utilized in a wide range of industries, including mining, environmental testing, and materials analysis.

How Much Does XRF Gun?

An XRF machine costs between a few hundred and a few thousand dollars, primarily dependent on the business you work in, the services you require, and the outcome you seek.

The XRF device from SuperbMelt offers an accuracy of five thousandths when it comes to the detection and analysis of elements prior to No. 12-92. The detection is more precise the lower the purity, and it has a very fashionable, gun-like look! Additionally, compared to the majority of XRF analysis devices on the market, its price is more affordable.

Built-in battery, handheld design, convenient to use anytime, anywhere.

How to Maintain Gold Jewelry?

1. Since gold jewelry can attract dirt and oil to the skin, routine cleaning is crucial. Jewelry can be gently cleaned using a soft brush, warm water, and a light soap. Completely rinse with water, then pat dry with a soft cloth.

2. It’s crucial to maintain gold jewelry carefully because it is susceptible to scratches and other damage. To prevent dents and tangles, keep it in a jewelry box or pouch with a cloth lining. Multiple objects shouldn’t be kept together because they can damage each other by rubbing against one another.

3. Gold can be harmed and discolored by chemicals like bleach and chlorine. Before swimming or using household cleansers, take off any gold jewelry.

4. Gold jewelry that is worn during activity may catch on clothing or other items, leading to damage or even loss. Before engaging in any strenuous activity or exercise, please take off your jewelry.

Advice: Your gold jewelry should be professionally cleaned if it has become extremely tarnished or has acquired a lot of dust and grime. Bring it to a trustworthy jeweler who focuses on gold jewelry for a complete cleaning and examination.

Why SuperbMelt XRF Gun

Any Question About SuperbMelt Handheld XRF Analyzer

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Gold Platinum and Silver Purity Charts

| Material | Karat | Millesimal fineness | Percentage |

| Gold | 24K | 999.9 | 99.99% |

| Gold | 22K | 916.7 | 91.67% |

| Gold | 18K | 750 | 75% |

| Gold | 14K | 583.3 | 58.33% |

| Gold | 10K | 416.7 | 41.67% |

| Silver | 999 | 999 | 99.9% |

| Silver | 958 | 958 | 95.8% |

| Silver | 925 | 925 | 92.5% |

| Silver | 900 | 900 | 90% |

| Silver | 835 | 835 | 83.5% |

| Silver | 800 | 800 | 80% |

| Platinum | 950 | 950 | 95% |

| Platinum | 900 | 900 | 90% |

| Platinum | 850 | 850 | 85% |

More SuperbMelt Metal Testers For You To Choose From

Any Question About SuperbMelt XRF Precious Metal Analyzer

Why do you need a Professional XRF Analyzer?

Professional portable XRF analyzers are a high-tech analytical solution created to handle the demanding requirements of an industrial sector that is continually expanding. The expert portable XRF analyzer aids in streamlining expenses, reducing risk, and boosting productivity.

From material discovery through incoming inspection, manufacturing, and quality control, the portable XRF spectrometer offers high performance in-field testing tools that give materials and coating analysis that adds value to the production lifecycle.

XRF Metals Analyzer FAQ

- 1. Do you really know that Precious Metals are Real?

- 2. Impure Gold Types that cannot be ldentified by Simple Methods

- 3. Identify and Avoid Fake Precious Metals

- 4. What is XRF?

- 5. What elements can XRF detect?

- 6. How Accurate is an XRF Gun?

- 7. Are the X-rays in XRF harmful to the human body?

- 8. What Elements Can XRF Detect?

1. Do you really know that Precious Metals are Real?

Precious metals are real and to detect the originality of a precious metal, a handheld XRF analyzer is needed. Precious metals are valuable, therefore making jeweller or other manufacturers to mix metals and other materials to fake the appearance of gold, silver, platinum or palladium.

Gold plating and counterfeit items are just some of the challenges that jeweller, gold traders and pawn shop owners face on a daily basis. Businesses require accurate results to remove variability and subjectivity from determining item value to ensure a profitable transaction.

The handheld XRF analyzer accurately determines the content of gold and all precious metals such as silver, platinum and palladium in materials. For precious metal analysis, such as jewelry or dental alloys, fast and nondestructive handheld XRF analyzers which require little sample preparation are most frequently used for analysis of precious metals.

2. Impure Gold Types that cannot be ldentified by Simple Methods

- Chemical assay, fire assay and other alternative methods of testing precious metals seem increasingly out of date in the 21st century. The handheld XRF analyzer puts the state of the art metal testing method into your hands.

- Precious metals are today of interest for jewelry, industrial use, and investment. With the handheld XRF analyzer, materials can be detected and tested for content and purity with extreme cases.

- Detecting the authenticity of precious metals can be done in a number of ways. The most common methods are:

- Naked eye or using a jeweller’s loupe- An experienced jeweler can verify the authenticity and quality of some jewelry by looking at it under magnification. This method is not always accurate.

- Weight/density measurement- Gold is a dense metal, the idea behind this test that if you drop a gold piece in water and measure how much liquid it displaces, you can determine whether it is pure gold. However, gold is often alloyed with other metals in legitimate jewelry, making this test unreliable.

- Markings- Gold jewelry sometimes has identifying marks that indicate its purity, such as 24k or 20k, but these can be faked.

- Nitric acid- A piece of gold is scratched against a testing slab to leave a mark. Nitric acid is applied to the mark to see whether it will dissolve. Depending on the acid’s concentration, the purity of the gold can be determined. This method however causes damages to precious metals.

- XRF analysis method is a completely nondestructive method, XRF analysis leaves the jewelry intact and undamaged. The portable XRF analyzer sends x-rays into the jewelry, exciting the atoms and causing them to fluoresce energy back to the analyzer’s detector. This tool uses fluorescence x-rays to determine the jewelry’s material chemistry.

- With the use of the Silicon Drift Detector (SDD), it is used for fire assay analysis of precious metals. Fire assay determines precious metal content by measuring weight loss after removing base metals through cupellation. Handheld XRF analyzer on the other hand uses x-ray fluorescence to excite the sample and calculate returning characteristic x-rays.

- A skilled operator of fire assay can produce results that are accurate up to 0.035%. This process takes time and most times results often differ when testing is done several times.

- Anyone above the age of 18 can be taught how to operate the handheld XRF analyzer in less than an hour.

- For speedy and accurate evaluation of precious metals, handheld XRF is the tool of choice.

3. Identify and Avoid Fake Precious Metals

Handheld XRF analyzer works accurately when it comes to analyzing precious metal swiftly, precisely, easily and non-destructively. This is a tremendous value to all precious metal specialists, recyclers, refiners, miners, bulk jewelry producers, etc.

Given today’s high value for precious metals, many jewelry stores have become involved in the purchase of old jewelry and scrap jewelry. Using a handheld XRF analyzer, it is possible to determine the content of the item offered for sale and its karat value in less than a minute.

The handheld XRF analyzer can identify karats and percentage of gold and percentage of silver, platinum and palladium in less than 5 seconds as well as perform a complete analysis in less than 10 seconds. Since the handheld XRF displays the value to one hundredth of a decimal point, you will not only be able to identify if the precious material you are buying is below karat, you will also be able to identify by exactly how much.

This non-destructive method can analyze gold (Au), silver (Ag), Platinum (Pt), Palladium (Pd) and many more precious metal and base metal alloys: karat gold, low grade gold, gold plated, gold plated, silver grades, platinum alloys.

Using handheld XRF analyzers to test and analyze precious metals encompasses a multitude of advantages. Precious metals are not exposed to harsh chemicals during testing and analysis.

4. What is XRF?

The non-destructive analytical method known as X-ray fluorescence (XRF) is used to ascertain the elemental makeup of materials. By exposing a sample to high-energy X-rays, which excite the sample’s atoms and cause them to generate X-ray fluorescence light, XRF analysis is carried out. The elemental makeup of the sample is then ascertained by measuring and analyzing this fluorescence emission. A vast range of materials, including metals, minerals, ceramics, polymers, and more, can be subjected to XRF investigation. In fields including mining, metal refining, manufacturing, and environmental analysis, it is frequently employed.

5. What elements can XRF detect?

The handheld XRF analyzer is able to detect the following elements in materials: Titanium, Vanadium, Chromium, Manganese, Iron, Cobalt, Nickel, Copper, Zinc, Gallium, Germanium, Zirconium, Niobium, Molybdenum, Ruthenium, Rhodium, Palladium, Silver, Tin, Antimony, Hafnium, Tantalum, Tungsten, Rhenium, Platinum, Gold, Latin Plumbum, Bismuth, Magnesium, Aluminium, Silicon, Phosphorus and Sulphur. Other materials the XRF analyzer can detect are: plastic, soil, ore, ceramic, paint, paper, etc.

6. How Accurate is an XRF Gun?

XRF analysis provides a fast, accurate and most importantly a nondestructive method to test the purity and composition of metals, alloys, geochemical materials, etc. Generally, heavier elements are slightly more accurate than lighter ones. Accuracy in the range 0.1 to 100% is higher than the range of 1ppm to 1000ppm. Accuracy is generally better for metals than for minerals and plastics. Accuracy will also be better if a powder sample has low particle size or if a massive test sample is flat. The accuracy of the difference between XRF value and assay can be as good as 0.2 to 0.5% for gold in jewelry. Accuracy can also be improved by adjusting the response of the instrument for a given type of material using reference samples. There are additional reasons to use XRF analyzers and not chemicals like nitric acid when it comes to analyzing precious metals such as jewelry. The traditional acid test for gold involves placing a small drop of strong acid onto the metal’s surface. This type of testing could leave a mark on the jewelry which is dangerous to the skin. Acid testing is not accurate and does not give the exact karat in gold testing.

7. Are the X-rays in XRF harmful to the human body?

If not handled carefully, X-rays from XRF (X-Ray Fluorescence) equipment can be damaging to the human body. The risk is quite minimal, though, because these devices only produce a small, well regulated amount of X-rays. Additionally, the majority of contemporary XRF devices have security mechanisms that reduce the possibility of being exposed to dangerous X-rays. To protect the operator and others around them, it is crucial to adhere to the manufacturer’s safety instructions when using an XRF equipment.

8. What Elements Can XRF Detect?

| Elements | Liquid Form | Solid Form | Powder Form |

|---|---|---|---|

| Aluminum | ✔️ | ✔️ | ✔️ |

| Antimony | ✔️ | ✔️ | ✔️ |

| Arsenic | ✔️ | ✔️ | ✔️ |

| Barium | ✔️ | ✔️ | ✔️ |

| Beryllium | ✔️ | ✔️ | ✔️ |

| Boron | ✔️ | ✔️ | ✔️ |

| Bromine | ✔️ | ✔️ | ✔️ |

| Cadmium | ✔️ | ✔️ | ✔️ |

| Calcium | ✔️ | ✔️ | ✔️ |

| Carbon | ✔️ | ✔️ | ✔️ |

| Cerium | ✔️ | ✔️ | ✔️ |

| Cesium | ✔️ | ✔️ | ✔️ |

| Chlorine | ✔️ | ✔️ | ✔️ |

| Chromium | ✔️ | ✔️ | ✔️ |

| Cobalt | ✔️ | ✔️ | ✔️ |

| Copper | ✔️ | ✔️ | ✔️ |

| Dysprosium | ✔️ | ✔️ | ✔️ |

| Erbium | ✔️ | ✔️ | ✔️ |

| Europium | ✔️ | ✔️ | ✔️ |

| Fluorine | ✔️ | ✔️ | ✔️ |

| Gadolinium | ✔️ | ✔️ | ✔️ |

| Gallium | ✔️ | ✔️ | ✔️ |

| Germanium | ✔️ | ✔️ | ✔️ |

| Gold | ✔️ | ✔️ | ✔️ |

| Hafnium | ✔️ | ✔️ | ✔️ |

| Holmium | ✔️ | ✔️ | ✔️ |

| Indium | ✔️ | ✔️ | ✔️ |

| Iodine | ✔️ | ✔️ | ✔️ |

| Iridium | ✔️ | ✔️ | ✔️ |

| Iron | ✔️ | ✔️ | ✔️ |

| Lanthanum | ✔️ | ✔️ | ✔️ |

| Lead | ✔️ | ✔️ | ✔️ |

| Lithium | ✔️ | ✔️ | ✔️ |

| Lutetium | ✔️ | ✔️ | ✔️ |

| Magnesium | ✔️ | ✔️ | ✔️ |

| Manganese | ✔️ | ✔️ | ✔️ |

| Mercury | ✔️ | ✔️ | ✔️ |

| Molybdenum | ✔️ | ✔️ | ✔️ |

| Neodymium | ✔️ | ✔️ | ✔️ |

| Nickel | ✔️ | ✔️ | ✔️ |

| Niobium | ✔️ | ✔️ | ✔️ |

| Nitrogen | ✔️ | ✔️ | ✔️ |

| Osmium | ✔️ | ✔️ | ✔️ |

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited