Gold Melting Pot

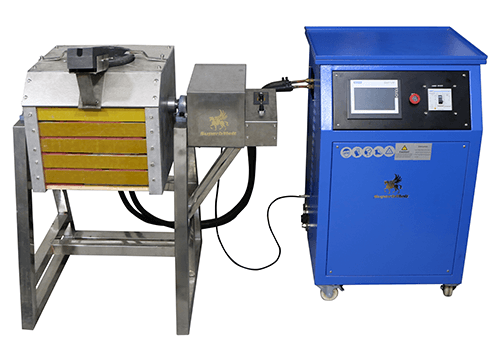

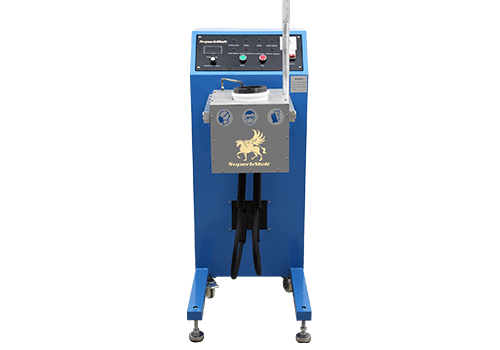

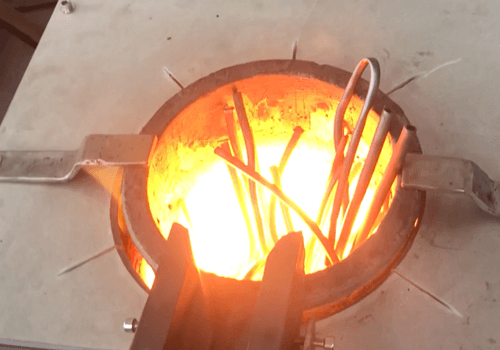

SuperbMelt motor tilting gold melting pot (SPB-MTF) for 10-100kg non-ferrous melting

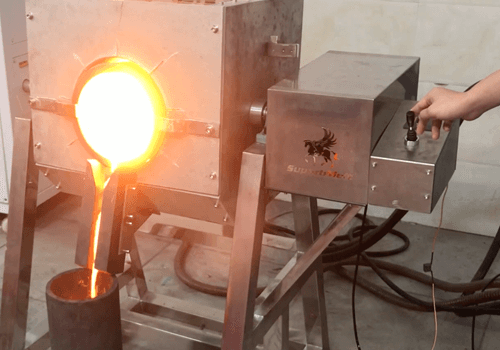

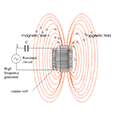

This motor tilting gold melting pot is designed for 10-80kg ferrous and non-ferrous metal melting based on induction technology.

SuperbMelt motor tilting gold melting pot is constructed for one-man pouring action. Tts body is mounted onto a steel frame. By manual control, the furnace body can be set in any position when tilting.

According to ferrous melting or non-ferrous melting, the crucibles will be taken use of different material. Graphite crucible is special for non ferrous metal like copper, gold, silver, aluminum. Silicon crucible is suitable for ferrous metal.

The small land occupied, fast melting and energy-saving are its obvious features. That is the cost performance choice for metal casting with small capacity.

Power Supply Parameter of Motor Tilting Gold Melting Pot

| Model | MTF-15 | MTF-25 | MTF-35 | MTF-45 | MTF-70 | MTF-90 | MTF-110 | MTF-160 | |

| MAX input power | 15KW | 25KW | 35KW | 45KW | 70KW | 90KW | 110KW | 160KW | |

| MAX input current | 23A | 36A | 51A | 68A | 105A | 135A | 168A | 240A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||||||

| Oscillation frequency | 1K~20KHz | ||||||||

| Requirement of cooling water | Hydraulic pressure | ≥0.2Mpa | ≥0.3Mpa | ||||||

| Flow rate | ≥6L/Min | ≥20L/Min | |||||||

| Temperature of water | ≤45℃ | ||||||||

| Generator box | Weight | 28kg | 29kg | 52kg | 52kg | 57kg | 91kg | 99kg | 134kg |

| Volume | 51×28×49cm | 65×35×58 | 78×40×88 | 78×50×88 | |||||

| Transformer box | Weight | 35kg | 35kg | 35kg | 38kg | 52kg | 68kg | 95kg | 95kg |

| Volume | 62×30×53cm | 64×48×58 | 64×65×61 | ||||||

Melting Capacity Parameter of Tilting Metal Melting Furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | |

| MTF-15 | 3kg | 10kg | 3kg | MTF-70 | 25kg | 80kg | 25kg | |

| MTF-25 | 5kg | 20kg | 5kg | MTF-90 | 40kg | 120kg | 40kg | |

| MTF-35 | 10kg | 30kg | 10kg | MTF-110 | 50kg | 150kg | 50kg | |

| MTF-45 | 18kg | 50kg | 18kg | MTF-160 | 100kg | 250kg | 100kg | |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | ||||||||

Motor Tilting Gold Melting Pot Features

- Medium frequency metal melting furnace can be used for the melting of gold, silver, steel, stainless steel, brass, aluminium, lead, zinc and so on.

- Comparing with SCR/KGPS technology, IGBT technology can save 15%-30% energy and is much more efficient than gas-fired and coal-fired method.

- Small light, a lot of models can be selected to melt different amount of metals. Not only is it suitable for the factory, but also suitable for the college researching companies to use.

- The crucible replacement is very easy for different metal material.

- The occupied land for the induction metal melting furnace is less than 1 square meter.

- Modular design, ease of maintenance, no need to repair any special foundations, requires low operation cost, easily operable, produces no pollution and noise.

- 24 hours constant working will meet your long time melting.

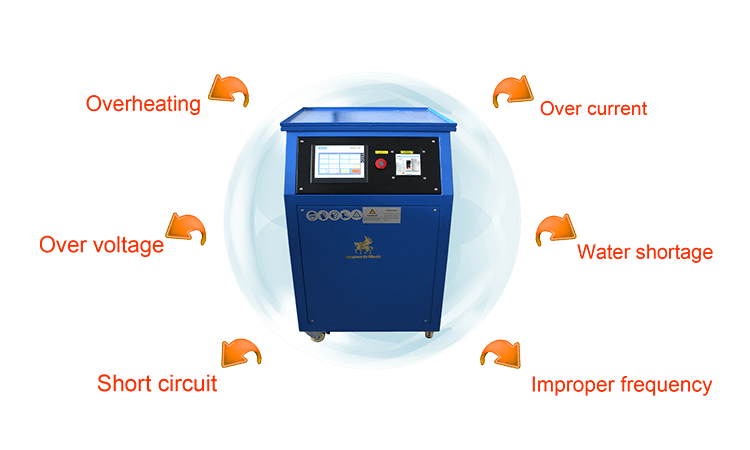

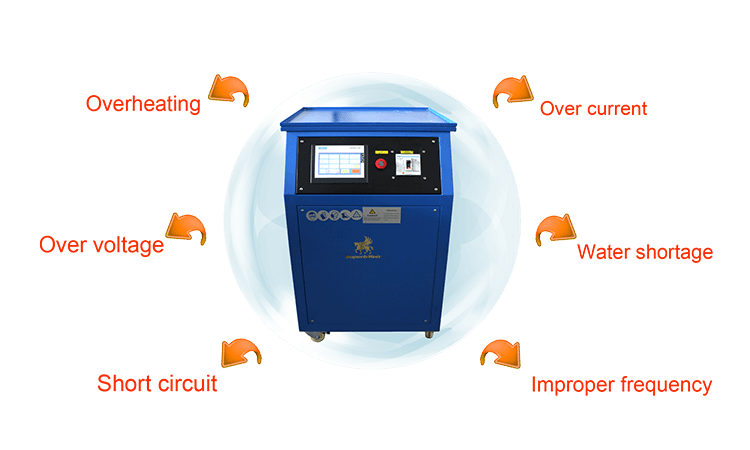

Power protection warning

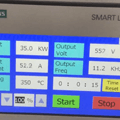

PLC control Panel of Motor Tilting Gold Melting Pot (optional)

- Lower power consumption, the IGBT technology saves 15-30% energy than KGPS,100% full load.

- Installation and maintenance are convenient, it can be finished by video or our manual guide. So it reduces the cost which you need pay for the engineers abroad for installation.

- Low pollution, low noise.

- Induction metal melting furnace with multi-protective functions to over-voltage, over-current, less water, over-heating with low fault rate and is safe and reliable.

Link here to know more about the PLC

- 100% successful start-up rate, power factor > 95%.

- The comprehensive full load design is available for 24-hour continuous operation.

- Perfect and complete protection functions, increasing machine’s reliability & stability.

- Wide frequency range from 1KHZ to 20KHZ, working frequency can be designed by changing the coil compensating capacitor according to the melting material, quantity, stirring effect desire, working noise, melting efficiency other factors.

- A maximum ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

Graphite crucible for gold/Silver melting Furnace

Why SuperbMelt Motor Tilting Gold Melting Pot

Helpful Resource For Your Reference ( An Expert about SuperbMelt Motor Tilting Gold Melting Pot )

More SuperbMelt Metal Melting Pot For Your Choice

Any Question About Motor Tilting Gold Melting Pot

FAQ Guide of Gold Melting Pot

- Does gold lose value when melted?

- How do you smelt gold with borax?

- How do you separate gold from other metals by melting?

- How do you smelt gold jewellery?

- How many degrees does it take to melt gold?

- What is borax used for in melting gold?

- Can you melt down gold to make jewellery?

- Could we melt silver in this induction melting furnace also?

- How much gold is lost when melted?

- How do you get gold from gold ore?

- How do you get impurities out of gold?

- At what heat does gold melt?

- What flux do you use to melt gold?

- How much borax does it take to melt gold?

- What is the process of smelting gold?

- Can you melt gold in cast iron?

- What chemicals are needed for gold recovery?

- Can you melt gold off electronics?

- What is the best way to melt gold?

- How fast can gold melt?

- How do I purify gold at home?

- Where can I get my gold melted down?

- What can I use to melt gold at home?

- Can you melt off gold plating?

- How do I smelt gold dust, ores and mines to collect gold?

- What temperature can the induction melting furnace reach?

- What is the difference between an electric arc furnace and an induction furnace?

- How to choose the induction melting furnace you need?

- How do you know if it is real gold?

Does gold lose value when melted?

No, pure gold doesn’t lose its value. Instead, it acquires more value. Since gold is mined in an impure nature, the process of melting is required to help purify the gold. All the gold materials and pieces in circulation today underwent the melting process.

Although, you might want to note that the melting process involved in gold purification is a bit tedious and can lead to spillage if care is not taken. Issue of spillage creates room for loss of a substantial amount of pure gold. To avoid such problems, it’s advisable you adopt advanced melting methods when looking to smelt your recycled gold or gold ores.

How do you smelt gold with borax?

To smelt gold using borax, you would have to create a mixture of disodium tetraborate {borax} and sodium carbonate. This mixture is generally regarded as a flux.

After such mixture is obtained, application of the flux on the gold before heating would enable the impure substance attached to the gold rise to the top of the cubicle when heated.

Borax which is also known as sodium tetraborate or disodium tetraborate is one of the most used oxidizing agents for smelting gold. Its usage in the smelting gold process requires a mixture with sodium carbonate.

Note that: when applying the borax mixture to the gold, special attention should be placed on gold materials with rough surfaces to avoid engaging in a smelting process that doesn’t guarantee the attainment of gold piece or bars of high purity.

How do you separate gold from other metals by melting?

To separate gold from other metals by melting, you would have to remove or pour out the impure substance that rises to the top of the material after a liquified form {molten} of the precious metal has been attained.

It’s essential to keep in mind that for the impure substance contained in the gold material to rise to the top, the application of flux on the content must be done effectively, and the melting point for the gold materials must be observed.

How do you smelt gold jewellery?

Gold jewellery is commonly smelted by gold recyclers. Just like the process involved in smelting gold ores, jewellery requires proper application of flux on the materials before being placed in a heating furnace.

To remove impurities, you must allow the jewellery melt to the required melting point. It’s advisable you make use of induction heating furnace so you can accurately calculate the temperature range of the melting furnace at all times.

When the required melting point is reached, the impure substance contained in the jewellery will rise to the top. Pour out the impure substance then place gold in a mold to dry.

How many degrees does it take to melt gold?

To melt gold, you would require a furnace that can heat as far as 2000 degrees Fahrenheit although the estimated melting point for gold is 1945 degrees Fahrenheit. Due to the high intensity of heat required to melt gold, utilizing an induction furnace remains the best bet for saving time and money. With smelting technique like propane torch and resistance furnace, it’s impossible to estimate the actual amount of heat reaching the precious metal at a time. Smelting gold without an accurate measure of its melting degree creates room for chaotic outcomes.

What is borax used for in melting gold?

Borax is used for oxidizing the gold piece or material before or during the smelting process. Gold smelting involved the removal of impurities from gold. Note that gold can be melted without being smelted, but it cannot be smelted without being melted.

Borax, when mixed with sodium carbonate, serves as an oxidizing agent that enables impurities such as zinc, copper, iron and any other impurity in the gold rise to the top when the gold is melted to a specific degree. This process enables goldsmiths or metal melting companies to obtain gold piece or end products of higher purity.

Can you melt down gold to make jewellery?

Yes, to make jewellery, the gold material must be melted down. Jewellery has, for a long time, served as the most patronized by-product of gold.

Note that due to gold’s fragile nature, most times to attain a piece of shiny and more durable jewellery, pure gold is mixed with alloys. Most of the jewellery available in the global market are mixed with such materials. White gold and rose gold jewellery are by-products of this mixture. It’s essential to bear in mind that jewellery casting is a complicated process.

If you haven’t engaged in the art before, it’s advisable you consult an expert to put you through before you engage in the gold melting process.

Could we melt silver in this induction melting furnace also?

Yes, you can melt silver with our induction melting furnace. The induction melting furnace is designed to melt different types of metals. The mini and integrated melting furnace is suitable for melting a small amount of ferrous and non-ferrous {precious metal} metals.

If you are looking to melt a large amount of metals like zinc, copper and other ferrous metals with our induction heating machine, you would have to opt for the motor tilting melting furnace or the hydraulic tilting melting furnace. You can check out the machine specification guide for detailed info on suitable metals.

How much gold is lost when melted?

If you are melting an 18-carat gold to obtain 24-carat gold, you will lose over 25% of the gold after the melting process. In situations where you are melting 9-carat gold and 18-carat gold combined to get 24-carat, you would lose up to 50% of the gold.

The amount of gold lost is dependent on impurities and the combustible nature of the alloys contained in the gold material. In a few scenarios, you might also experience gold loss based on the melting process used and the carat of gold being melted. The gold lost during melting is as a result of the other alloys contained in the gold going out as slag or combusting into thin air.

How do you get gold from gold ore?

To get gold from gold ore, you would have to make use of an effective gold smelting technique. The three gold smelting methods available include, induction heating, propane torch and resistance furnace. Induction heating remains prevalent amongst the other two for the rare advantages it offers. While it remains one of the most expensive methods, its usage and durability can be seconded to none. In situations where you can’t obtain an induction heating machine, you can opt for propane torch. Resistance furnace is the least recommended.

How do you get impurities out of gold?

Getting impurities out of gold requires smelting and then refining. The smelting process removes impurities such as copper, iron and zinc while the refining process is necessary to extract precious metals like silver. Note that to remove impurities via smelting, a flux {oxidizing agent} is required.

Gold smelting does not provide users with 99% pure gold. Obtaining 99% pure gold would require a refining process. There are a lot of gold refining companies that would enable you to remove any remaining impurities at affordable rates.

At what heat does gold melt?

Gold melts at 1064 degree celsius in the appropriate temperature. This means that the melting of gold can only be achieved with flames or furnaces that reach this temperature. A propane flame is hot enough to melt pure gold. It will also melt gold alloys but the melting process does not separate gold from other elements like silver or copper.

Gold jewelry is generally not made from pure 24karat gold, which is too soft to be durable. Gold items below 24karat are not pure, they contain a small percentage of silver, copper or zinc. The addition of these elements slightly changes the melting point, which means a propane torch melts lower purity gold more quickly. For instance, 18karat gold has a melting point of 926 degree celsius. 14karat gold has a melting point of 879 degree celsius.

What flux do you use to melt gold?

Flux is a critical component of the refining process. In metal refining, flux is used to remove impurities and change fluidity of the melt. Once activated by the furnace temperature, the flux breaks down and lowers the melting points of all the other materials in the crucible. As the refining process continues, the flux causes the other materials to oxidize and break down even further. One of gold’s most noteworthy properties is that it is extremely resistant to oxidation, so it is unaffected by this reaction and sinks to the bottom.

The composition of flux varies depending on the materials being melted. Some ingredients in refining flux are anhydrous borax, boric acid, soda ash, silica, fluorspar, potassium carbonate and manganese dioxide.

The most commonly used flux are; borax, silica, hydrochloric acid, ammonium chloride, sodium nitrate, sodium carbonate and zinc chloride.

How much borax does it take to melt gold?

The size of gold being melted will be determined by the amount of borax that will be used. Use two pinches of flux per ounce of gold jewelry and more for dirty scraps. If you are going to use the potato method, just add one pinch of borax into the potato hole before melting the gold.

What is the process of smelting gold?

The first step in gold processing involves processing the gold ore. The ore contains gold once mined and processed by separating gold minerals from the crude matter holding the ore together. The gold ore is then pulverized using pressure to create particles.

These particles are then heated in a gold smelting furnace at temperatures above 1064 degree celsius, the melting point of gold. The heating process burns most of the impurities other metal elements remain.

Some chemicals found in gold ore can be quite dangerous to both the health of the smelter and the longevity of the smelting equipment. It is therefore important to remove those harmful elements from gold materials before smelting takes place.

Once the raw ore has been processed, the next step of the gold smelting process involves the use of flux to remove impurities from gold. At this stage most of the impurities in the gold material are traces of other metal elements.

Gold can easily be purified at this stage by using chemicals such as potassium cyanide or mercury. These two chemicals are often used in gold purification because they make gold elements to coagulate together, forming gold nuggets and clumps. This is why they are easily separated from other materials.

Once the gold has been purified, it is placed in a furnace to be melted in readiness for it to be molded into ingots.

Can you melt gold in cast iron?

You can melt gold in a cast iron but we do not recommend this. You will lose a lot of materials which will solder itself onto the crucible walls. A graphite crucible or SIC crucibles are better alternatives to melting than a cast iron.

What chemicals are needed for gold recovery?

Sodium metabisulphite is commonly used to precipitate dissolved gold out of aqua regia and gold chloride solutions. When it is dissolved in water, sulfur dioxide gas is created which is excellent at precipitating gold from the solution. Sodium metabisulphite is a popular choice in this process because it is more selective in precipitating gold by itself.

Can you melt gold off electronics?

Everything from old PCI cards, IC pins and other types of electronics have some amount of gold present in them. These parts can be processed and the gold recovered.

Gold can be melted off electronics with the following equipment and procedure. Note that to carry out this procedure, you have to use protective equipment and carry this out in a well ventilated space.

After cutting out your circuit boards, to remove the precious gold bearing parts, throw these parts into a mixture of muriatic acid and hydrogen peroxide in a glass container. After a week, the acid becomes darkened and the gold is slowly flaked off into dust. The gold dust is then separated from the mixture using a filter. The extracted gold is then melted at 1064 degree celsius.

What is the best way to melt gold?

Gold can be melted using a propane torch, a 1200 watt microwave oven, or a gold melting furnace. The best and most cost effective way to melt gold is to use a gold melting furnace.

The induction gold melting furnace offers many benefits of gold melting over other methods of melting. Induction melting is considered a ‘green technology’, as it doesn’t put off any harmful emission into the atmosphere, since the heat is generated by the alternating magnetic current into graphite or SIC crucible. Other advantages of melting with an induction gold melting furnace include: fast heat up time, saves energy, frequency stirring for more homogeneous melts and induction heating technology does not heat up the atmosphere the user is working in.

How fast can gold melt?

The speed of melting gold will be determined by the method, furnace used for melting and the size of material. Melting gold with an induction gold melting furnace takes about 2 to 15 minutes. A shorter melting time for smaller gold melting materials and more time for larger materials. In other words, gold melts quickly as soon as the temperature reaches 1064 degree celsius. A slower heating source will take a longer time to melt gold. When using traditional methods for melting gold, it takes more time.

How do I purify gold at home?

The two acids that are used in this process are concentrated hydrochloric and nitric acids. Nitric acid is very corrosive, when combined with hydrochloric acid, it becomes more corrosive, hence, purifying gold must be done in controlled conditions.

The process of purifying gold on a small scale involves adding nitric acid to gold and then some hydrochloric acid. Allow this mixture to sit for 30 minutes. The acid should have a clear emerald green colour. If the colour is murky, filter through a filter funnel to remove impurities. Treat to neutralize the acids in the solution with urea and water.

Where can I get my gold melted down?

It is possible to melt down old gold for sampling purposes and melted into bars. Melting old gold is not straightforward but it is possible. A lesser karat gold item may be difficult because it has different metals with different melting points. You can melt down your gold on your own depending on your level of expertise or a jeweler can do that for you. New jewelry can be created with the melted gold, if the material is insufficient for the new jewelry pieces, additional metal can be added.

What can I use to melt gold at home?

You can melt your gold with a mini gold melting furnace. This mini furnace for sale allows small jewelry businesses as well as hobbyists to carry out precious metal melting on their own. Melting with a gold melting furnace has a number of benefits; portable, easy to operate and move around, fast melting process, less energy consumption, highly efficient melting process, etc. This therefore makes it a better alternative to a propane torch or a kiln.

Can you melt off gold plating?

Preheat your soldering tool to a temperature of 377 to 419 degree celsius. Ensure you don’t start the heating process until the soldering tool reaches at least the minimum temperature (377 degree celsius) because the gold will not melt. Clean the gold with boric acid and water. Scrub gently with a brush. Rinse and dry.

For a gold ring, continue the process:

Remove all stones and non-gold clasps from the ring to ensure that the only material to be melted is gold.

Place the gold plate ring in a vise. Ensure the ring fits tightly into the vise to avoid burning accidents.

Bring the soldering tool closer within 12 inches of the gold ring and continue heating the ring until it changes. Slowly move the soldering tool back and forth to evenly heat the gold. Allow the gold to be completely cooled before cleaning and polishing.

How do I smelt gold dust, ores and mines to collect gold?

Smelting gold is the ability to extract gold from the ore it is combined with. To collect gold from mines, its ore or from gold dust, gold concentrate is combined with flux, such as borax or other materials of mixtures in a crucible. The flux acts to decrease the melting temperature and viscosity of non-gold materials in the concentrate so that they are easily separated from the gold during the melting process. Small amounts of concentrates usually around 50 to 100 grams are used in direct smelting. Concentrate and flux are heated in the crucible to the temperature at which gold melts, 1064 degree celsius. Miners use gold smelting furnaces to smelt gold from its ore. After this temperature is maintained for some time, the material in the crucible will melt and can then be poured out of the crucible to cool.

What temperature can the induction melting furnace reach?

Induction gold melting furnaces do not have a limit to the temperature they can heat and melt. However, the refractories and materials that contain the heated or melted materials have limitations. The highest temperature typically reaches 3000 degree celsius. This makes it suitable for higher temperature metals such as platinum groups.

The temperature of an induction gold melting furnace coupled with a graphite crucible for melting reaches 1600 degree celsius. This is suitable for melting gold and silver.

What is the difference between an electric arc furnace and an induction furnace?

The induction gold melting furnace utilizes coiled heating elements embedded within a crucible or integrated into the walls of the heating chamber itself. These coiled heating elements convert electrical energy into heat, which radiates through the material with outstanding degrees of thermal uniformity. This however restricts the utilization of combustible fuels.

The helically wound induction coils are made from refractory heating metals and ceramics enhance service longevity and allows good compatibility with extra controls. Extra controls can be put in place and thermal cycling can be automated to decrease production time and emission of toxic metal vapors in the furnace.

An electric arc furnace on the other hand heats charged material by means of an electric arc. The arc melts down scrap steels and ore through the use of graphite electrodes. When power is fed into the furnace, the electricity jumps between the two energized electrodes and into the neutral grounded electrode. In other words, the working principle of an electric arc furnace includes charging the electrode, melting the metal and refining. The electrodes are moved down onto the scrap, then the arc is produced between the electrode and metal.

How to choose the induction melting furnace you need?

There are different gold melting furnaces that meet different melting needs for business, research and education or mining. When considering the cost of an induction gold melting machine, other things should influence your choice of gold melting furnace. Below are the things to consider before choosing an induction gold melting machine:

Melting capacity and energy needs– The size of an induction gold melting machine will determine if it is suitable to meet the unique needs of your company. Gold melting furnaces range in size from small sizes of 1 to 2kg to 250kg. Your choice will be determined by the amount of metals you want to melt.

As for power supply, you have to know how much energy requirement to keep the induction gold melting furnace running. You will notice that while some induction gold melting furnaces need high voltages, others only need a moderate supply of power. Ensure that you have enough power to run your gold melting furnace.

High quality furnaces- Look at the quality of the induction gold melting furnace before buying. The materials used to make the induction gold melting machine must be suitable. Some gold melting furnaces are made from the best materials, others may be from poor materials.

Furnace melting point- An induction gold melting furnace is meant to have a specific limit. You have to know if the heat will be enough to melt your materials. Every metal has different melting points, therefore you should choose a gold melting furnace whose melting temperature is above that of the metal you are melting.

How do you know if it is real gold?

There are several ways of identifying real gold. They are;

Magnet test- Holding a magnet close to the gold can determine the authenticity of gold. When a magnet is held close to the gold, if the magnet attracts the gold then it is fake and vice versa.

Visual inspection- The marking or hallmark tells you what percentage of gold items it consists of. The jewelry hallmark is usually printed on jewelry clasps or inner bands of rings.

Performing a density test by weighing the gold on a scale. Most of the time the hallmark may be false.

Using a nitric acid test- A little amount of nitric acid is dropped on the gold item, if there is no reaction, this means the gold is original; if there is a green or milky colouration, the gold is fake.

The magnifying glass test- This is a straightforward method of testing originality of gold. The magnifying glass helps to discover any signs of discolouration, colour, shinines and the hallmark purity.

The float test- The jewelry piece is placed in a bowl of water. If the gold sinks to the base of the bowl, it is original; if the gold floats, the gold is fake. This is not 100% accurate.

The scratch test- You can perform this test by rubbing the jewelry across any material of your choice (black jeweler stone, unglazed ceramic plate or unglazed porcelain tile). Analyze the colour of the produced streak, if the gold is real, it shows a golden, yellow colour. However if the streak is black, the gold item is fake.

Skin test- Hold the gold item in your hand for a couple of minutes. If it is fake, the sweat on your skin will cause a chemical reaction with the metal.

Handheld XRF analyzer- You can perform the most accurate gold test with the handheld XRF analyzer. This simply works by pointing the analyzer directly at your gold and it will display all elements present in the gold item along with the percentage on each element. With this, you can determine the authenticity of your gold without destroying your gold compared to other methods of testing.

Gold Melting Pot Buying Guide

Application Field of Gold Melting Pots

When it comes to obtaining pure metals, gold melting pot have been the number one resource the mining industry and the world at large have banked on for years.

Before we go any further, it might interest you to know that melting pots are specialized equipment used to reduce metal oxide in other to acquire a pure base metal. With that in mind, this buying guide contains a comprehensive review of the services and benefits SuperbMelt gold gold melting pots offer.

1.1, Smelting the Gold Ores

Smelting is a process required for the removal of non-metal impurities from your newly acquired gold ores. The smelting process gives room for you to market your gold in its purest form. Note that gold ores can’t be used in their raw form for the creation of jewellery or electronic making smelting a necessary procedure.

How to Melt Gold

- Crush the gold ore and place in a gold pot.

- Heat gold pot to 1064 degrees

- Add oxidizing agents like cyanide to separate impurities.

- Pour in a mold and leave to cool.

1.2, Recycling Old Gold

Do you have worn out electronic devices around the house? Its high time you made a little extra cash from the raw materials they possess. Gold is used in electronics to plant contact between switch, relays, and connectors. This implies that almost every electronic device lying around has an ounce of pure gold to offer.

However, it’s important to note that recycling gold from old electronics is stressful and expensive. But if you know how to melt gold and you are less busy and need some extra cash, there is no harm in exploring the valuables available in the junkyard.

How to Melt Down Gold

- Check for pieces containing gold. Gold most times make up two percent of the metals or plastic housings in which it is held.

- Strip out the metals then use chemical compounds that react with gold to extract the precious metal.

- You can also melt down the whole metal component with a gold melting pot kit to separate the pure gold from impurities.

- Add oxidizing agent to the gold pot when smelting to remove any remaining impurities.

Old Jewellery Recycling

Jewelleries are the most common resources were pure gold can be found. When looking to recycle old jewellery you must be familiar with the gold melting process. Note that the melting pot for silver and gold jewelleries are the same so you don’t need to look to opt for an entirely new pot when looking to smelt silver jewellery.

How to Melt Down Gold Jewellery

- Gather the piece of old gold jewelleries togethers and weigh them.

- After getting a precise measurement, opt for a gold pot measuring in size and weight.

- Heat to melting point while including suitable oxidizing agents

- Pour into suitable mold and leave to dry.

Note that this process does not leave you with pure gold. If you are on the lookout for how to melt gold jewellery into pure gold; its essential you send the metal to a gold refinery after it forms solid bars.

1.3, For Jewellery Casting

Gold comes in three forms, White Gold, Yellow Gold, and Rose Gold. While all of them are suitable for casting pieces of jewellery, they come with different metal plating and require different alloys—you might want to check out which would be ideal for the task at hand before casting.

Application of Gold Melting Pot in Jewellery Casting

Since the inception of gold smelting machines, jewellers have enjoyed a massive rise in the supply and demand chain. Issues of shrinkage and porosity, which have remained prevalent in the jewellery casting world for decades has reduced drastically.

How Melt Gold with Gold Melting Pots

- Apply flux {oxidation compounds like Borax, Sodium Nitrate and Silica} to the gold material.

- Place in the furnace and allow to heat at over 900-degree Celsius.

- Pour out flux and any other impurities floating at the top of the liquified material

- Place in a mold and allow to dry.

1.4, For Industrial Application

Gold smelting pots are widely used for smelting non-ferrous metals. Ranging from copper, silver, aluminium, gold, and the likes, its durability has seen it grow to become a piece of renowned equipment for completing smelting tasks within a probable time frame.

The industrial application of gold smelting machines goes beyond the gold smelting industry, for a start, we would be focusing on the impact the smelting machine has had in the Computer, Phones, and Electronic Industries. {in the coming chapters, you would get a detailed overview of its application in other industries}

Gold in Computer, Phones, and Electronic Industries: it’s no news that gold is an essential factor in the creation of computers and electronics. In computers, gold is used as connectors for mounting memory chip into the motherboard. Gold has become a dominant part of electronic devices due to the interruption voltages, and currents can cause. Its usage as relays, connectors, and switches in the mobile industry is also on the rise. With that being said, gold in the above-listed industry wouldn’t produce the remarkable result desired when mixed with impurities. Superbmelt gold smelting furnace remains the number solution for tackling such issues.

How to Smelt Gold Nowadays

While the gold smelting industry is among the few that had a hard time adapting to the highly esteemed change, the impact its growth has had in hundreds of other sectors have seen it move to the top of the food chain within a short time.

To provide you with all the information you would need to smelt your gold at home or a gold smelting company; we would be discussing the three most common method used in smelting gold worldwide.

2.1, How to Melt Gold by Propane Torch

The propane torch method retained a great spot at the forefront of the smelting industry for decades. Although, since the inception of the induction smelting furnace, a lot of renowned gold smelting enterprises and companies have neglected its wheels.

While its usage has lost its widespread footing, it’s still as productive as ever, and we know a lot of individuals till fancy the home use privileges it offers. To ensure that you embark on your gold smelting journey on the right footing, we would be highlighting the critical impact and steps involved in using a propane torch to smelt gold.

Items Required

- Gold ore

- Cubicle

- Flux {mixture of sodium carbonate and borax}

- Propane touch

- Ingot

Steps Involved

- Look for a cubicle capable of withstanding heat of over 1,950-degree Fahrenheit or make provision for a piece of potato and create a hole at the middle.

- Apply flux {mixture of sodium carbonate and borax} to the gold material

- Insert gold into your cubicle or potato and apply the heat from your propane torch directly.

- Pour out impurities that would rise to the top after the precious metal liquifies and then pour into mold.

Note that the usage of propane torch in melting gold is stressful and time consuming. Making use of this smelting process can keep you smelting less the 2kg of gold the whole day.

2.2, How to Melt Gold by Resistance Furnace

Who said you couldn’t acquire real value for your worn-out gold pieces of jewellery or the gold contained in spoilt electronics from the comfort of your home? With this section providing all the information you would need to design a homemade resistance furnace and the steps involved in acquiring the desired output, you wouldn’t have a hard time smelting gold in your pyjamas. Bear in mind that you would have to get your hands dirty.

How to Melt Your Own Gold by Resistance Furnace

- Look for a cubicle strong enough to withstand heat with any metallic object of choice.

- Attach a hair dryer to the cubicle via a metallic pipe.

- Set cubicle in a dogged hole surrounded with firebricks.

- Place gold inside then allow to heat. Use the hairdryer to regulate the heat.

- When it’s getting to its melting point, add a mixture of Sodium nitrate, silica, and sulphuric acid

- After heating, pour out any impurity that rises to the top.

- Pour gold into a mold and leave to cool.

Note that resistance furnace is quite inexpensive but it involves a risky and strenuous process. A lot of skilled experts still end up spilling hot metals on their body when smelting gold with a resistance furnace.

2.3, How to Smelt gold in Induction Pots

Induction furnaces are electrical furnaces that generate heat capable of liquefying metals. Induction furnaces remove the paperwork or stress involved in creating a resistance furnace or looking for a probable cubicle to smelt your gold via a propane touch. With induction furnace, you can wake up in the middle of the night, smelt as much gold as you want and get back to bed without getting your hands dirty.

You might be wondering, ‘How does it work?’ not to worry, we would get to that in a bit. When we talked about the innovative change the 21st century had brought to almost every sector—particular reference was made to the metal smelting industry due to the introduction of the induction furnace.

Items required to smelt gold with the induction Furnace

- Gold

- Flux

- Induction smelting furnace

Steps involved

- Apply flux on the surface of the gold

- Place into am induction furnace

- Set in desired temperature and leave to heat

- After heating, pour out the impurities, then leave gold to cool.

- In scenarios where you are uncertain about the metal density, you can collect test samples using a vacuum tube.

Amongst all the gold smelting process available on our list, induction furnace remains the most priced smelting pot for silver and gold. Whether you are looking to melt gold nuggets or you are trying to navigate your way around how to melt gold and make jewellery, induction melting pots remains the most suitable option

The Kinds of Gold Melting Pots that SuperbMelt can Provide

We have stated some the application field for gold smelting machine and the probable ways for smelting gold in the 21st century. But we said nothing about the type of gold smelting machines available and the industries in which they can be applied because we didn’t want to leave you with such listings when proper reference to its origin have not been made.

3.1, Mini 1-2kg Induction Furnace for Sale

The max temperature range is 1600-degree Celsius. Can hold within 1 to 2kg of gold at a time.

Every metal has its meting point. While most metals require high temperature to melt, without the right temperature, you can end up burning yourself or spending more than the estimated time melting a tiny piece of metal.

SuperbMelt is tailored towards serving you better. A lot of melting machines available in the market would require the technicality of an expert or technician to set up. Our Mini 1-2Kg gold melting furnace comes with an installation guide not just on paper format but also as in an MP 4 format.

The video tutorial ensures that you don’t have to rely on the credibility of any technician or have to spend hours beyond the estimated set-up time trying to install or use your newly acquired smelting machine.

3.2, Integrated 3-10Kg Gold Melting Pot

With Integrated 3-10Kg gold melting furnace, you can melt over 2000kg of gold a day without causing any environmental hazard or pollution. Designed with green technology, you don’t have to worry about toxic fumes or gas.

SuperbMelt has been in the front line of the metal melting and casting industry for over 15 years. Before any machine is sent to the market, its reliability, stability and security are checkmated.

To legitimise this claim in the mind of our customers, the Integrated 3-10Kg gold melting furnace comes with two years warranty. SuperbMelt can be held liable for any unprecedented event within the first two years after purchase.

3.3, 20kg-30kg Manual Tilting Gold Melting Pot

Created with high-quality equipment, the machine provides users with the ability to heat any mental of choice at 1800-degree Celsius. 20kg-30kg manual tilting melting furnace can smelt up to 30kg gold within 6 to 8 minutes.

This SuperbMelt smelting furnace has two models to its name SPB-TB25 and SPB-TB35. Both operating with the IGBT induction heating technique, they can be used to melt Gold, Silver, Copper, Brass, Bronze, and their alloys.

Features and Benefits of 20kg-30kg Manual Tilting Melting Furnace

Electromagnetic Shielding. Not wanting to bore you with industry jargons; electromagnetic shielding increases proficiency. Operating a machine that is prone to electromagnetic interference can leave you with more workload than you scheduled.

To enable you save time while sticking to a schedule, the 20kg-30kg manual tilting melting furnace is shielded with an electromagnetic casing capable of making the induction process produce an efficient result while utilizing minimal energy.

This also reduces compactness. In scenarios where appropriate equipment in the furnace requires change, you wouldn’t have to spend hours losing the whole machine. The electromagnetic load is also highly reduced.

Like most of our other listings, the 20kg-30kg manual tilting melting furnace possesses a 24 hours functionality time. Our mode of production ensures that all our machines contain materials from famous brands. Operating as an AAA credit audited enterprise, we possess certifications from ISO CE SGS.

3.4, 10-50Kg Chain Tilting Gold Melting Pot

10-50Kg chain tilting gold melting pot is suitable for smelting platinum, copper, gold and silver. Operating at a max temperature of 2800 degree Celsius with a turnaround time of 10 to 20 minutes, it is regarded as a priceless smelting furnace for Precious metal refineries, Jewellery casting companies, Aviation industry and the likes.

Features and Benefits of the 10-50Kg Chain Tilting Gold Melting Furnace

It’s never a funny sight to have to send in your smelting machine to the mechanic on a daily or weekly basis. Smelting machines remains a rare commodity due to inefficiency on the path of most of the manufacturers.

With the glaring evidence that SuperbMelt machines are designed to serve you better, you can bank with our 10-50Kg chain tilting gold melting furnace rest assured that issues like overheating, high voltage, shortage of water, short circuit or coil spoilage wouldn’t be a regular trend.

Round the clock usage. When we say round the clock, we mean every single minute of the day. From morning till night and night till morning—the 10-50 Kg chain tilting gold melting furnace is designed to remain operational.

We are making this claim with a two years warranty at stake because we believe in the high-quality materials our R&D team used in creating the 10-50Kg chain tilting gold melting furnace.

At the beginning of chapter one, we made mention of a few industries where the usage of gold is quite dominant. The aviation industry has enjoyed the usage of gold in designing space jets, aeroplane and equipment since time inception.

While the requirement for this size of smelting machine can be regarded a bit too big for the electronic industry, its usage in the aviation industry is quite rampant. It has triggered adoption in a few renowned electronic companies.

3.5, 10-100 kg Motor Tilting Gold Melting Pot

10-100kg motor tilting machine which comes with an advanced tilting mechanism, can be used in smelting both ferrous and non-ferrous metals. The motor tilting furnace can melt any metal between 20 to 30 minutes when hot and 40 to 50 minutes when cold. Usage of this furnace would grant you access to melt up to 100kg metal at a go. Probable fields of application include refineries, metal melting companies and gold mining companies.

Features and Benefits of the 10-100kg motor tilting gold melting pot

Most metal smelting experts are familiar with the fact that every metal has its meting point. Since the 10-100kg motor tilting smelting pot for gold was designed to smelt both ferrous and non-ferrous metals, cubicles suitable for these purposes were provided.

The 10-100kg motor tilting melting furnace comes with a graphite and silicon cubicle. The graphite cubicle can be used in smelting non-ferrous metals while the silicon cubicle is suitable for smelting ferrous metals.

Before we talk about the maintenance cost, we must stress the fact that the machine’s operational price also falls under this same ‘Low’ category. Operating the 10-100kg motor tilting melting furnace does not require any technical expertise or training beyond 5 minutes.

Tailored towards ensuring that you don’t run into issues while making use of our machines, the 10-100kg motor tilting melting furnace comes with a compact design and green technology ensuring that hazardous fumes are not emitted during the smelting process. The compact design style ensures that changing any worn-out equipment or material from the smelting furnace does not require a total overhaul of the entire machine. Easy drag and drop replacement is very much possible.

Are you tired of having to pay high electrical fees each time you make use of your smelting machine? Purchasing the 10-100kg motor tilting melting furnace would ensure that you enjoy a melting speed far better than the average while paying less for electricity.

Factories: melting metals in large scale have always been a pain in the ass to most reputable companies due to lack of proficient smelting machines. Before the inception of induction heating machines, most factories could hardly melt over 5000kg of metals a day, hindering their productive capabilities by a considerable margin.

With the 10-100 kg motor tilting melting furnace offering options beyond what the usual propane touch or resistance furnace smelting technique can afford, it has grown to become a household name in numerous ferrous and non-ferrous metal melting factories.

3.6, 50-250kg Hydraulic Tilting Gold Melting Pot

50-250kg Hydraulic Tilting Melting Furnace is undoubtedly the biggest melting furnace in our store. The hydraulic tilting furnace comes with a remote panel trolley making it easy for workers to pour out melted without being scared of spillage.

This smelting furnace can smelt up to 250kg of non-ferrous or ferrous metals at once with a maximum melting time of 50 minutes. Its reliability and compact design make it the best silver smelting pot for big refineries, gold mining companies and metal melting companies looking to enjoy metal melting experiences comparable to no other.

Features and Benefits of the 50-250kg Hydraulic Tilting Gold Melting Pot

Easy to Use. Yeah, the 50-250kg hydraulic tilting melting furnace is quite bulky and might look all complicated to the average mind, but when it comes to operations, the reverse is the case. The control panel does not leave much room for workers to stress themselves attending any expensive training section.

The smelting machine provides an intuitive control panel that can be accessed easily at all times. The attached trolley also comes with controls that are simple to navigate. Although, since we wouldn’t like you taking long glances at buttons and options that shouldn’t take more than a second to navigate, the 50-250kg hydraulic tilting melting furnace comes with a user manual accessible in a video and written format.

Adherence to the instructions attached would get your machine working at optimal speed less than 30 minutes after purchase.

It won’t come as a surprise if you are in doubt as to whether the 50-250kg hydraulic tilting gold smelting pot is capable of offering the same 24 hours functionality that all the machines available in our store operate with. The 50-250kg hydraulic tilting silver smelting pot is designed for big metal smelting factories and companies smelting metal on a large scale on a daily.

Knowing how vital 24 hours functionality is to our customers, the 50-250kg hydraulic tilting melting furnace is designed to operate at the optimal speed for over 24 hours. The machine is optimised to provide users with a lifelong smelting experience.

Conclusion: How to Choose the Right Gold Melting Pot

- According to Gold Capacity

Goldsmith or gold miners looking to smelt between 1kg to 500kg of gold in a day are advised to opt for the mini gold smelting pot, or the integrated gold melting furnace.

Metal research institutes, laboratories and gold miners looking to smelt over 10kg to 1000kg gold can utilize the manual tilting melting furnace or chain tilting gold melting furnace.

The motor tilting melting furnace or hydraulic tilting melting furnace is a suitable choice for refineries and metal melting companies tasked with smelting over 50kg to 5000kg or more gold on a daily.

- According to consumer business model

What’s your business size? Before purchasing any machine from our online store, its essential you check out the size of your business and the model that would be suitable for you. You can check out our model specification list for more details.

- Consider the Price

What’s your budget and is the affixed price range within its range. There are numerous types of gold smelting pots available. matching budget with a melting pot shouldn’t be a problem.

- Think of Applicability

How many kilograms of gold would you be smelting on a daily? Are you looking for a gold melting pot for a big refining company or for home use? Try to estimate the workload applicable before opting for any of the gold pots available on our list.

- The reputation of the dealer

The type of experience and income you would get from a gold pot is highly dependent on the mode of manufacture. Before purchasing a gold smelting pot, try to vet the dealer’s reputability, checkout the dealer’s portfolio, if possible, ask for testimonials from previous clients.

Finally

Going through the gold smelting journey and the industry it has developed thus far has been quite impressive. But this buying guide wouldn’t do much good if emphasis on how you can choose the right gold smelting furnace for your business is not made. To ease this process lets highlight the two most sought out criteria by which factory owners, gold miners, smelting companies and other businesses and enterprises making use of ferrous or non-ferrous metals to pilot their daily activities.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited