Silver press machine

SuperbMelt Professional Gold, Silver, Aluminum Metal Embosser

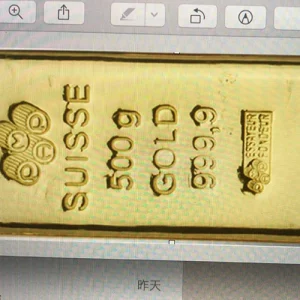

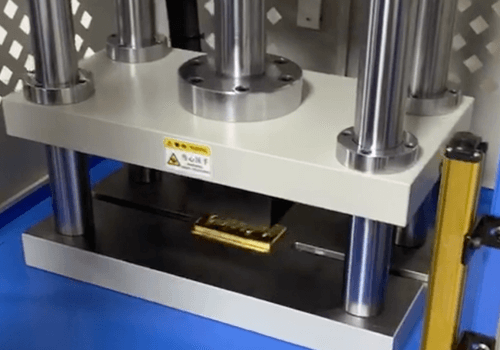

SuperbMelt Silver Press Machine is a versatile coin pressing solution, perfectly designed to meet the embossing needs of gold/silver coins or bars. Whether you’re pressing highly intricate patterns or simple tags, this machine delivers precise and detailed results.

Not limited to gold/silver coin embossing, the SuperbMelt Silver Press Machine is also ideal for nameplates, hang tags, and a wide range of jewelry labeling applications. Its exceptional adaptability makes it an essential tool for jewelers and manufacturers looking to add a professional touch to their products.

Powered by hydraulic technology, the SuperbMelt press applies fluid pressure to the cylinder, ensuring a seamless and efficient pressing process. Each press produces consistently flawless results, creating exquisite jewelry pieces with sharp, clear markings.

| Model number | SPB-HLP10 | SPB-HLP20 | SPB-HLP30 | SPB-HLP40 | SPB-HLP50 |

| Nominal/ton | 2.5-10 | 5-20 | 8-30 | 10-40 | 15-50 |

| Max stroke/mm | 100-200 | 100-250 | 100-250 | 300 | 300 |

| Opening height/mm | 300 | 350 | 350 | 400 | 400 |

| Descending speed/mm | 88 | 68 | 48 | 38 | 38 |

| Rising speed/mm | 88 | 68 | 48 | 38 | 38 |

| Worktable area/mm | 450*350 | 500*400 | 500*400 | 600*500 | 600*500 |

| Table height from the ground/mm | 850 | 850 | 850 | 850 | 850 |

| Voltage/V | 380 | 380 | 380 | 380 | 380 |

| Motor power/kw | 3.75 | 3.75 | 3.75 | 5.5 | 5.5 |

| Weight/kg | 580 | 660 | 800 | 980 | 1200 |

- Adopting four-column and three-plate structure, the planar accuracy of the movable plate fish table is high, the four-axis precision linear self-lubricating guide sleeve is controlled, and the vertical accuracy is high.

- Imported high-quality hydraulic components, electrical components, low noise, high performance, stable operation

- Simple operation, pressure, stroke and closing height can be adjusted by pressing process requirements.

- Two-handed operation, with emergency stop and inch movement function, infrared hand protector, optional three-sided cover, safe and efficient.

- Press height, stroke, worktable size can be customized according to customer requirements. It can be equipped with cooling system, blowing device, pressure retaining device, pressure relay, force measuring display, PLC operating system, etc.

Metal Embossing Machine

A equipment used to emboss designs and patterns into metal surfaces is called a metal embossing machine. By exerting pressure to the metal surface using a specialized embossing die or roller, it raises the metal surface’s surface pattern.

It is possible to emboss a range of metals, including gold, silver, aluminum, brass, copper, and stainless steel, using the hydraulic SuperbMelt metal embossing machine. They are frequently employed to create ornamental metal goods like nameplates, signage, and gifts.

Follow the manufacturer’s directions when operating a metal embossing machine and put on the appropriate safety gear, such gloves and goggles. A metal embossing machine may be a very useful instrument in the production of high-quality metal items if it is used and maintained properly.

Helpful Resources For Your Reference (SuperbMelt Metal Embossing Equipment Specialists)

More SuperbMelt Gold and Silver Casting Machines For Your Choice

Any Question About SuperbMelt Hydraulic Logo Stamping Machine

FAQ Guide of Silver press machine

- 1. What materials can the silver press machine handle?

- 2. Does SuperbMelt provide mold design services?

- 3. Does the machine support double-sided coin pressing?

- 4. What’s the difference between manual and automatic Silver Press Machines?

- 5. How to prevent silver from cracking or deforming during pressing?

- 6. What thickness of silver can be pressed with these machines?

- 7. What is the pressing force range of the machine?

- 8. Is it easy to switch between different molds?

- 9. How to prevent silver blanks from sticking to dies?

1. What materials can the silver press machine handle?

The silver press machine can handle a variety of soft and precious metals, including:

- Silver

- Gold

- Copper

- Brass

- Platinum (in some models with higher tonnage)

- Alloys commonly used in coins and jewelry

These materials are suitable due to their malleability, allowing for detailed and precise embossing without cracking or excessive wear on the molds.

2. Does SuperbMelt provide mold design services?

Yes, SuperbMelt provides professional mold design services. You can submit your artwork, logo, or design concept, and their engineering team will create customized embossing molds tailored to your product specifications. The molds are made from durable materials to ensure long service life and high precision during coin or tag pressing.

4. What’s the difference between manual and automatic Silver Press Machines?

The key differences between manual and automatic Silver Press Machines are as follows:

| Feature | Manual Silver Press Machine | Automatic Silver Press Machine |

|---|---|---|

| Operation Method | Requires manual loading, positioning, and pressing | Performs pressing cycle automatically with minimal input |

| Speed & Efficiency | Slower, suitable for small batches | Faster, ideal for mass production |

| Labor Requirement | Higher – operator must be present throughout | Lower – operator mainly oversees operation |

| Precision & Consistency | Depends on operator skill | More consistent and repeatable results |

| Automation Level | Low or none | High – may include auto-feeding and auto-ejection |

| Best For | Small workshops, prototypes, custom pieces | Factories, high-volume, continuous production |

| Cost | Lower upfront cost | Higher investment, but better ROI for large-scale use |

In summary:

Manual machines are best for low-volume, flexible production.

Automatic machines are ideal for high-efficiency, high-consistency mass manufacturing.

5. How to prevent silver from cracking or deforming during pressing?

1. Use Proper Annealing

Anneal the silver blanks before pressing to relieve internal stress and soften the metal.

Heat the silver to around 600–650°C, then allow it to cool slowly.

2. Choose the Right Pressing Force

Adjust the hydraulic pressure according to the thickness and hardness of the silver.

Excessive force can cause cracking; insufficient force can result in incomplete impressions.

3. Use High-Quality Molds

Ensure molds are clean, smooth, and properly aligned to avoid uneven pressure.

Sharp edges or poor mold fit can damage the silver surface.

4. Maintain Consistent Temperature & Humidity

Extreme cold or dryness can make silver brittle. Process silver in moderate ambient conditions when possible.

5. Lubricate If Necessary

For thicker or more complex pieces, apply a thin layer of lubricant (such as die release wax) to reduce friction during pressing.

6. Use Annealed Silver Blanks of Appropriate Purity

Blanks should be of at least 99.9% purity and free from impurities or defects that might affect formability.

7. Press in Stages (for complex designs)

If the design is deep or highly detailed, consider using multiple light presses instead of one hard press to reduce stress.

6. What thickness of silver can be pressed with these machines?

The thickness of silver that can be pressed with silver press machines depends on the machine’s tonnage and design, but typically:

Standard machines can press silver blanks with thicknesses ranging from 0.5 mm to 8 mm.

Heavy-duty models (with higher tonnage, e.g., 50–100 tons) can handle silver up to 10 mm or more, especially for bars or deep embossing applications.

General guideline:

| Application | Recommended Thickness |

|---|---|

| Jewelry tags & nameplates | 0.5 – 2 mm |

| Silver coins | 1 – 5 mm |

| Silver bars | 4 – 10 mm |

7. What is the pressing force range of the machine?

SuperbMelt offers hydraulic press machines ranging from 10 to 500 tons. Whether you need to press metal coins or metal bars of any kind, feel free to contact us for a customized solution.

8. Is it easy to switch between different molds?

Yes, switching between different molds on the SuperbMelt silver press machine is quick and easy. The machine is designed with:

User-friendly mold mounting system

Allows for fast alignment and secure installationStandardized mold sizes

Ensures compatibility and reduces setup timeOptional quick-change mold fixtures

Speeds up changeover for high-efficiency production

This makes it convenient to switch between different coin sizes, designs, or applications such as coins, bars, and jewelry tags with minimal downtime.

9. How to prevent silver blanks from sticking to dies?

1. Use a Die Release Agent (Lubricant)

Apply a thin, even layer of specialized die release spray, wax, or light oil to the mold surface.

Common options: PTFE spray, silicone-free metal forming lubricants.

2. Ensure Proper Mold Surface Finish

Keep dies smooth and polished to reduce friction and adhesion.

Avoid scratches or buildup that could cause sticking.

3. Maintain Correct Pressing Temperature

Silver that is too cold may become sticky or brittle; a mild preheating (30–50°C) can improve release.

4. Use Clean, Oxide-Free Blanks

Dirty or oxidized blanks are more likely to adhere. Clean with alcohol or lightly polish before pressing.

5. Apply Anti-Stick Coating to Molds

Some molds can be treated with non-stick coatings like Teflon or nitriding to improve long-term performance.

6. Adjust Pressing Force

Excessive pressure may cause deformation and sticking. Use optimal tonnage for your material and design.

7. Regular Cleaning of Dies

Frequently clean dies during production runs to remove residue, especially when pressing large volumes.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited