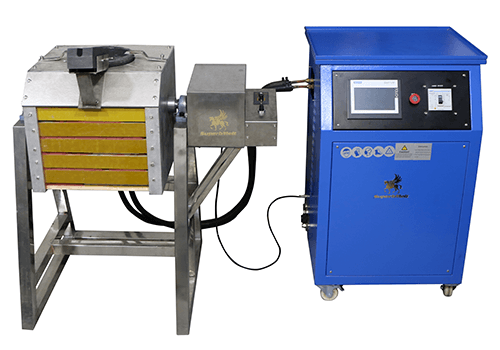

Induction Foundry Furnace

Most Popular 20-30kg SuperbMelt Induction Electric Melting Furnace

SuperbMelt Induction Foundry Furnace is used for melting 20-100kg of gold, silver, copper, alloys, and other precious metals.

Induction Foundry Furnace features a cooling system with circulating cold water, which keeps the surface of the furnace at a constant temperature to prevent burns to workers.

With its simplified power supply structure and separate design of the cooling system and power, the furnace has an extended service life of over ten years, resulting in significant cost savings in production.

- SuperbMelt silver melting furnace adopts solid-state technology, which is the latest and most advanced IGBTs module available worldwide. rgy than KGPS,100% full load.

- The current between the furnace’s coil and the power supply is insulated, which is the safest guarantee for users.

- SuperbMelt silver melting furnace is an easy, convenient and practical way to melt precious metals. It has a split design that allows you to tilt liquids with the push of a button or with a manual lever if you prefer to pour.

- The furnace is equipped with a new type of high-performance asynchronous generator, which can reach the melting point significantly faster and ensure the full mixing and homogenization of the molten metal.

- The precise electromagnetic shielding of the furnace ensures that the energy generated by induction is as small as possible. This method also greatly reduces the electromagnetic load of the user.

- Better process control with a high degree of controllability and repeatability, 24H continuous works realizes a high production rate.

- Efficient circuit with low energy consumption, reliable, easy to maintain and service, easy to install and simple to operate.

- Installation and maintenance are convenient, and IGBT technology saves 15-30% energy compared to KGPS 100% at full load. It can be done via video or our manual guide. This reduces the cost you need to pay for installation by foreign engineers.

- The occupied land for the gold melting furnace is less than 2 square meters. Low pollution, low noise. 24 hours of uninterrupted work, to satisfy your long-term melting.

- It is convenient to replace the crucible different metal materials smelting.

- SuperbMelt silver melting furnace with multi-protective functions to over-voltage, over-current, less water, over-heating with low fault rate and is safe and reliable.

Power Supply Parameter of Multi Tilting Silver Melting Furnace

| Model | RTF-35 | RTF-45 | RTF-70 | RTF-90 | |

| MAX input power | 35KW | 45KW | 70KW | 90KW | |

| MAX input current | 51A | 68A | 105A | 135A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||

| Oscillation frequency | 1K~20KHz | ||||

| Requirement of cooling water | Hydraulic pressure | ≥0.3Mpa | |||

| Flow rate | ≥20L/Min | ||||

| Temperature of water | ≤45℃ | ||||

| Power supply | 70*40*100cm | ||||

| Furnace body | 80*70*90 cm | ||||

| Weight | 220kg | 230kg | 240kg | 250kg | |

Melting Capacity Parameter of Multi Tilting Silver Melting Furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy |

| RTF-35 | 10kg | 30kg | 10kg |

| RTF-45 | 18kg | 50kg | 18kg |

| RTF-70 | 25kg | 80kg | 25kg |

| RTF-90 | 40kg | 120kg | 40kg |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | |||

Graphite crucible for gold/Silver melting Furnace

Any Question About SuperbMelt Multi Tilting Silver Melting Furnace

Shaking and dumping:

When the solution is poured by remote control j melted metal n can be poured more safely into the feeler

Fast and uniform melting of precious metals such as gold and platinum, greatly improving the quality of melting

The SuperbMelt silver melting furnace makes melting precious metals simple, handy, and useful. With its split design, you may tilt liquids with the touch of a button or manually with a lever if you’d rather pour.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

What is included in the Silver smelting kit?

Furnace: heats precious metal materials, such as gold and silver, to the melting point.

Crucible: a vessel in which materials are melted, extremely heat-resistant, made of graphite or ceramics.

Safety equipment: heat-resistant gloves, goggles, etc.

Instructions: various usage methods and smelting tips.

More options available for the Induction Foundry Furnace

SuperbMelt Induction Foundry Furnace Guide

Induction Electric Melting Furnace

- Features of the Induction Electric Melting Furnace:

Small Size, Lightweight, High Efficiency, and Energy-saving: The machinery is lightweight and of a small size, and it provides high efficiency and energy-saving advantages.

Low Ambient Temperature, Minimal Smoke, Favourable Workplace: The furnace maintains a low ambient temperature, emits little smoke, and offers a comfortable workplace.

Simple Furnace Operation; Reliable Melting Process: The furnace’s operation is straightforward, and the melting process is trustworthy.

High-quality Castings, Even Metal Composition, little Material Loss, Uniform Heating: The furnace assures an even distribution of metal composition, little material loss, and high-quality castings.

Quick melting, simple temperature control, and great jewellery application makers and Mining Facilities: For jewellery makers and mining facilities, the furnace allows quick melting and simple temperature control.

- How the Induction Electric Melting Furnace works

Eddy currents are produced within the material by the induction furnace’s alternating electromagnetic field, which causes heating or melting. This alternating magnetic field’s churning action encourages uniformity of composition and temperature inside the furnace. Up to 1250°C can be reached for forging heating, while up to 1650°C may be reached for melting.

In order to achieve certain quality standards, the induction furnace may also be used to heat or melt materials in a vacuum or protective atmospheres like argon or neon. The annealing or melting of soft magnetic alloys, high-resistance alloys, platinum group alloys, heat-resistant, corrosion-resistant, wear-resistant alloys, and pure metals may all be done using the induction furnace to great benefit. Induction melting furnaces and induction heating furnaces are the two main categories of induction furnaces.

How Metal Made?

Mining: Ores are often mined to extract metals. Mining is the process of removing ore from the surface or ground and transporting it to processing facilities for additional processing.

Crushing and beneficiation: To make the ore more manageable, the ore is crushed and ground after mining. After that, beneficiation procedures are used to separate the ore’s metal minerals from other impurities.

Smelting: The metal minerals that are produced by beneficiation frequently have significant impurity levels. High temperatures are used during smelting to melt the metal and remove it from the impurities, producing pure metal.

Some metals need to be refined in order to increase their purity. Chemical and electrolytic procedures can both be used for refining.

Product processing: To produce metal products in a variety of forms and sizes, pure metal is processed using methods including casting, forging, rolling, and stretching.

Where Can i Get My Silver Melted Down

Refinery: If you want to melt down precious metals, you may send your silver to specialised refineries that have the necessary tools and knowledge. They will purify your silver and give it to you, or pay you according to its worth.

Local jewellers: Many jewellers provide services for melting and refining. Your silver may be melted down, and depending on your choices, they can either give you the refined metal or use it to make new jewellery.

precious metal merchants: Some merchants are experts at purchasing and refining precious metals. They could pay competitive prices for your silver and manage the melting themselves.

Self-melting: You may melt your silver on your own using a little melting furnace you can buy. A selection of compact melting furnaces from SuperbMelt are appropriate for this use.

SuperbMelt induction foundry furnace Specifications

- It uses the IGBT+CPU variable frequency induction heating system that was invented in Germany.

- Intelligent control system for Siemens PLC for simple operation.

- This apparatus can melt precious metals such as gold, silver, copper, K gold, alloys, and others.

- The apparatus can melt up to 50 kg of gold, and its capacity is adaptable.

- The furnace has a cooling water circulation protection feature that maintains the furnace’s surface at a consistent temperature, significantly lowering the possibility of workers being burned by high temperatures while processing.

The induction split-type melting furnace, with a maximum batch capacity of 50 kilogrammes of gold, is especially made for high-volume gold melting. It has good performance stability and can quickly heat precious metals.

To assure the safety of the production process, it has overcurrent, overvoltage, and water shortage protection.

The furnace has an electronic tilting feature that enables the metal solution to be poured into moulds without coming into touch with anything.

Induction Foundry Furnace FAQ

1. Which furnace is the best to melt silver scrap?

- Despite the fact that there are numerous types of furnaces available on the market for melting silver scrap, a SuperbMelt silver melting furnace will be your best bet. Due to its higher level of electrical conductivity than the other metals, silver will respond to the induction in this procedure properly. Moreover, silver has good heat conductivity levels.

- An induction silver melting process produces very little pollution and uses little energy. In reality, you can melt silver in a matter of minutes with SuperbMelt’s equipment. Better control and predictable results are what these machines are all about. Visit the official SuperbMelt website today to place your order.

2. Steps for silver smelting? How to smelt silver?

- Prepare silver scraps and silver nuggets and then weigh and measure them.

- Choose a suitable silver melting furnace and preheat the equipment to a temperature suitable for silver smelting, generally 1,100°C (2,012°F).

- Put the silver to be smelted into the crucible equipped with the melting furnace, and then add flux to the crucible. The flux can effectively remove impurities from the silver and improve the fluidity of the molten silver.

- Put the crucible into the preheated melting equipment to melt it.

- After the silver is refined, pour it into a mold to solidify and cool.

- Take the smelted silver out of the mold, clean it, and then do further processing according to the requirements.

3. At what temp does silver melt?

- Silver melts at a temperature of 961 degrees Celsius, which is much greater than that of gold. To melt the silver at the desired temperature more quickly, utilize an induction silver melting equipment made by SuperbMelt. Furthermore, borax can be used to soften the oxidized layer. Our induction furnaces use cutting-edge technology to give you precise smelting and melting processes. Call us right now for a free estimate.

4. How do I pick a silver induction furnace?

When it comes to buying induction silver smelting equipment, you need to consider different things, such as:

- Understand the melting points of the metals you want to melt, as these machines are designed to heat up to a specific temperature limit. Chose a model accordingly.

- Besides, don’t forget to check the maximum melting capacity of the silver melting equipment.

- You should know the energy requirement of the machine.

- Furthermore, budget, business model, furnace crucible, and method of melted metal removal need to be taken into consideration.

5. how is silver refined?

- Silver Material Preparation: The first step in the procedure is to get the silver-containing material ready for refinement. The material may need to be crushed, ground, or otherwise processed in order to reveal the silver particles.

- Then, an electrolytic cell is made by combining two electrodes—a cathode and an anode—with a solution that contains the silver substance. The cathode is often constructed of silver, while the anode is typically formed of an inert substance like platinum or graphite.

- Application of Current: After the electrolytic cell is set up, the electrodes receive a direct current that attracts silver ions to the cathode. Silver ions build up on the cathode to create a pure silver deposit that can be taken out and refined further.

- A sufficient amount of silver can be deposited on the cathode before it can be collected and refined further utilizing further refining techniques like cupellation or smelting.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited