Sheet Rolling Machine Manufacturer

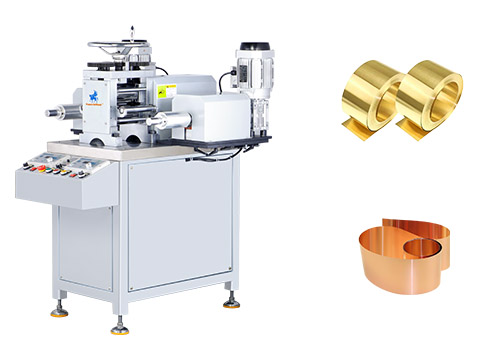

SuperbMelt Rolling Mill Manufacturer: One-Stop Solution for Metal Processing Issues

SuperbMelt Sheet Rolling Machine Manufacturer help clients customize rolling mills with special requirements such as online thickness measurement, coiling, and correction functions. These features enable clients to meet complex metal processing needs.

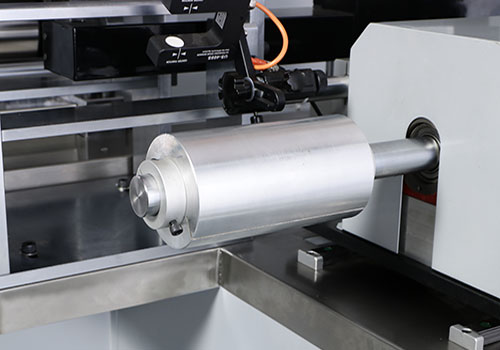

- Coiling: Provides tension during the rolling process, ensuring that the material is rolled more uniformly, and the resulting material is coiled neatly rather than scattered, saving collection time.

- Correction: Prevents material misalignment, which can cause issues with coiling and layer displacement.

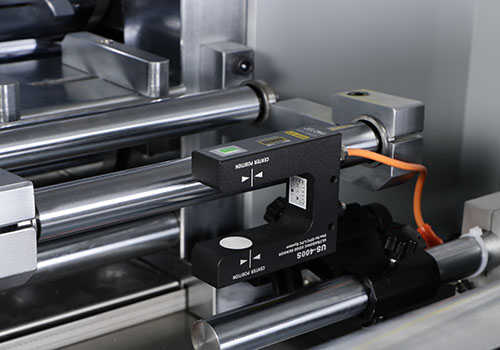

- Thickness Measurement: Thickness is measured during the rolling process, reducing the need for manual measurements.

- Jewelry Manufacturing: This sector of the economy benefits immensely from accurate rolling mills, which enable it to create exquisite jewelry in metals such as gold, silver, and platinum with superior finishes and uniform thickness.

- Electronic & Electrical Components: Rolling mills are used to make metal sheets and strips with exact measurements for electronic components, such as terminals and connections.

- Automotive Industry: Applied to the production of precise-sized metal parts such as brackets, shims, and ornamental trimmings.

- The aerospace industry uses precision rolling mills to fabricate parts for airplanes and spacecraft that need materials with precise mechanical qualities and tolerances.

- Coinage: High accuracy in metal thickness is required because rolling mills are used to create metal sheets from which coins are stamped.

- Medical Devices: Required for the manufacturing of surgical tools and biomedical implants, where surface quality and material consistency are critical.

- Use in construction and architecture: Metal sheets and strips that are made for ornamental elements, structural components that need to be highly resistant to rust, and building materials.

- Crafts & Metal Art: Rolling mills are used by artists and artisans to create distinctive textures and patterns on metal for both artwork and practical goods.

| Model number | SPB-YP-12PZQ | SPB- | SPB- |

| Power supply | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 9 kw | 11 kw | 22 kw |

| Applicable Products | Platinum, gold, silver, copper, K gold and their alloys | Platinum, gold, silver, copper, K gold and their alloys | Platinum, gold, silver, copper, K gold and their alloys |

| Rolled size | 60mm | Within 150mm | Within 300mm |

| Sheet thickness | 25mm- 0.5mm | 1-0.03mm | 30-0.3mm |

| Roller diameter | 150*210mm | Large shaft 180*250/small shaft 60*250 | 220*400mm |

| Dimension | 1130*775*1400mm | 1830*2100*1700mm | 2030*2800*2200mm |

| Weight | 980KG | 1800KG | 2400KG |

- Straightening Capability: This function prevents material misalignment during coiling, avoiding the overlapping and misplacement of layers. It ensures that the material feeds through the mill in a precise alignment, significantly reducing waste and improving product consistency.

- Automatic Cleaning: Equipped with a roller wiping system, the machine automatically cleans the rolling mill rollers, maintaining a flawless surface on the rollers to prevent any damage to the finished product. This helps in achieving a high-quality finish on the metal sheets without defects.

- High Precision: The mill produces extremely flat and uniform thickness products with a tight tolerance of ±0.005 mm. This precision is crucial for applications requiring exact dimensions and contributes significantly to reducing material waste.

- High Hardness Rollers: The rollers are made of materials reaching a hardness level of HRC60-62. This high hardness extends the lifespan of the rollers, reduces maintenance needs, and supports the processing of tougher metals without deforming the rollers.

- Dual-Side Coiling: By allowing coiling on both sides, the machine greatly enhances production efficiency, and the accuracy and straightness of the finished products. This feature is especially beneficial in high-volume production settings, ensuring faster processing times and consistent product quality.

- Real-Time Thickness Display: The mill provides real-time display of the rolling thickness, which offers a reference for the rolling process and reduces the need for frequent manual measurements. This feature helps in maintaining consistent product quality and reduces production errors.

- Adjustable Tension Control: The use of a highly sensitive adjustable magnetic powder clutch to control the tension prevents the material from breaking due to excessive pulling forces. This adjustability is crucial for handling different types of materials and thicknesses, ensuring smooth and continuous production without interruptions.

Equipped with a rewinding function, ensuring product straightness and dimensional stability

Alignment device to prevent sheet displacement causing uneven pressing thickness

PLC Thickness Gauge: The online thickness measurement function allows for real-time monitoring of sheet thickness

Why SuperbMelt Sheet Rolling Machine Manufacturer

Any Question About SuperbMelt Sheet Rolling Machine Manufacturer

About SuperbMelt Sheet Rolling Machine Manufacturer Guide

What is the function of the sheet collecting function of the sheet rolling machine?

Enhanced Production Efficiency:

By eliminating the need for manual intervention and enabling continuous operation, automatic take-up increases efficiency.

Quality Control:

By minimizing possible damage or contamination that may happen during manual handling, automatic recoiling helps preserve the final product’s flatness and cleanliness.

Space Saving:

Compared to manual operations, automatic recoiling systems often take up less room, freeing up important workspace space.

Enhanced Safety:

It lowers the likelihood of workplace injuries by reducing the frequency of direct worker-machine interaction.

Stable and Repeatable Product Dimensions:

Automatic recoilers can preserve consistent roll-up according to predetermined settings, guaranteeing stability and repeatability in product dimensions.

What is the function of the deflection correction function of the rolling mill?

Prevents Material Shift: Throughout the rolling process, the material is kept correctly aligned thanks to the straightening system’s ability to automatically detect and modify the position of the material feed. This keeps the content from straying from its intended course.

Enhances Product Quality: Straightening helps prevent problems like uneven thickness or jagged edges by making sure the material travels through the rollers consistently, which improves the overall quality of the final product.

Minimizes Material Waste: Proper straightening of the material feed position helps reduce waste from material shift, which results in fewer rejections and less reprocessing and lowers production costs.

Boosts Production Efficiency: By minimizing machine downtime and adjustment delays brought on by material transitions, straightening helps the production line run more smoothly and continuously.

Adapts to Different Materials: The versatility and flexibility of modern straightening systems are increased by their ability to handle materials with varying widths and thicknesses.

What is The Difference between Double Head Rolling Machine and Ordinary Electric Rolling Mill?

Guarantees Product Consistency: This feature assists in making sure that the finished product satisfies exact requirements by continually checking the thickness of the material being processed. This is important for applications where quality and functionality depend on homogeneous thickness.

Boosts Efficiency: By enabling instantaneous rolling process modifications, real-time thickness assessment eliminates the need for human inspections and corrections. Production may be greatly accelerated, and downtime can be decreased.

Improves Material Usage: Precise control over material thickness can result in a more economical use of resources by cutting down on waste and possibly even lowering expenses.

Quality Control: To maintain standards of quality and adhere to industry requirements, it is essential to discover deviations from the intended thickness early in the process by continuous monitoring.

Feedback for Process Optimization: By enhancing the mill’s overall performance and rolling settings, the data gathered from thickness measurements may be utilized to increase output quality and yield.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited