Wire Drawing Machine

The primary function of the wire drawing machine, also known as the gold wire machine, is to reduce the diameter and shape of a wire using a series of dies. It achieves this by passing the wire through consecutive dies, each with a smaller hole diameter than the previous one.

As the wire is pulled through the dies, it becomes longer and thinner, resulting in improved tensile strength and a smoother surface finish. The gold wire machine finds applications in various industries, including jewelry production, for working with different metals such as copper, gold, silver, and more.

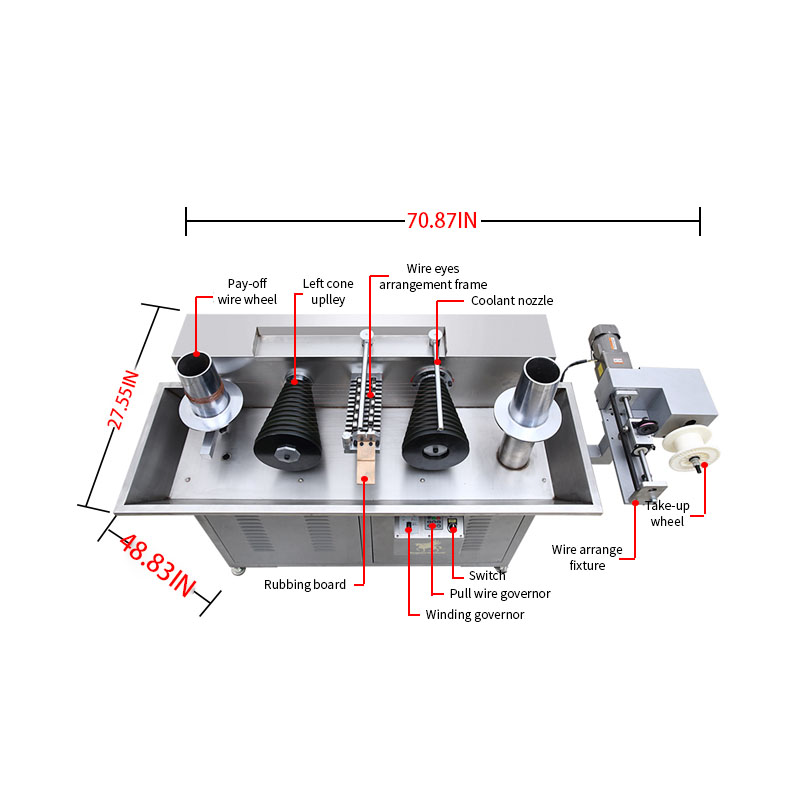

Wire Drawing Machine Parameter

| Model | SPB-6WDM | SPB-12WDM |

| Power source | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz |

| Power | 2.2kw | 4kw |

| Application | Au, Ag, Cu wire shrinkage | Au, Ag, Cu wire shrinkage |

| Dies capacity | 6 pcs per time | 12 pcs per time |

| Wire diameter range | 2.2mm→0.2mm | 2.2mm→0.2mm |

| Drawing speed | 0-50 m/min | 0-50 m/min |

| Dimension | 1800*700*1230mm | 1800*700*1230mm |

| Weight | 370kg | 390kg |

| Cooling way | Automatic liquid cooling | Automatic liquid cooling |

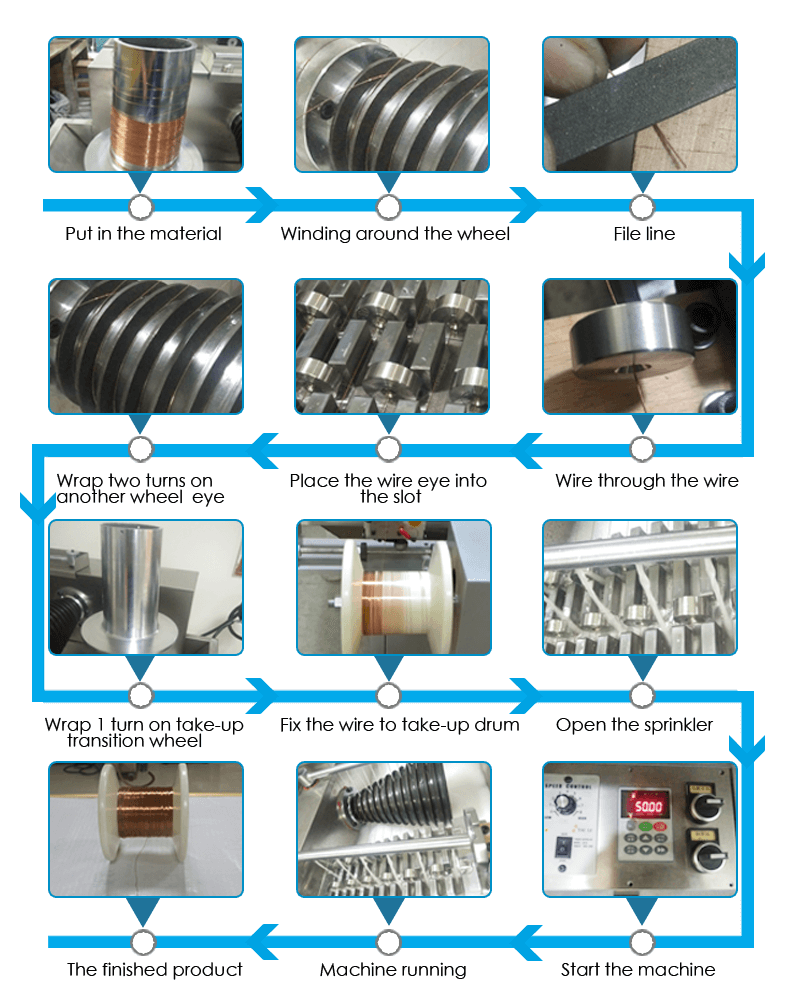

Operation process of wire drawing machine for gold, silver and copper

Application of wire drawing machine

Advanced control systems make sure that the wire is drawn to exact tolerances and specifications, producing high-quality wire with reliable qualities.

Simple to use: Modern wire drawing machines frequently include completely automated user interfaces that make them simple to use and maintain.

Versatility: Metals, polymers, and composite materials may all be processed using wire drawing equipment.

Low maintenance: Most wire drawing machines are made to last and have sturdy parts that need little upkeep.

Energy efficiency: Many wire drawing machines are made with energy-saving features like variable-speed drives and regenerative brakes that assist cut down on energy use and running expenses.

The machine has high working efficiency. Line wheel is made precisely of imported materials and the carburization on its wheel surface improves abrasive resistance.

The motor adopts step less speed modulation design and is equipped with automatic winding displacement and rewinding machine.

The whole machine is equipped with automatic cooling system which can automatically stop the machine when the work is finished.

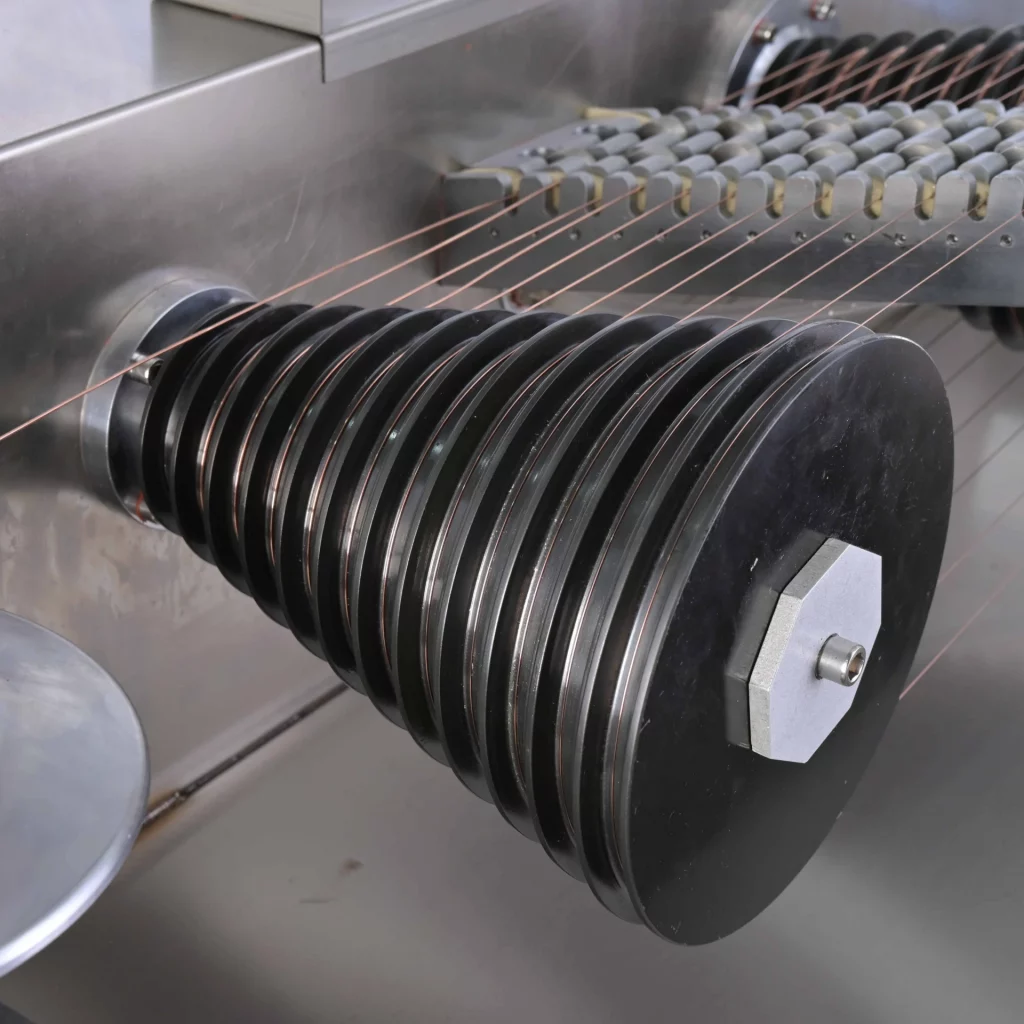

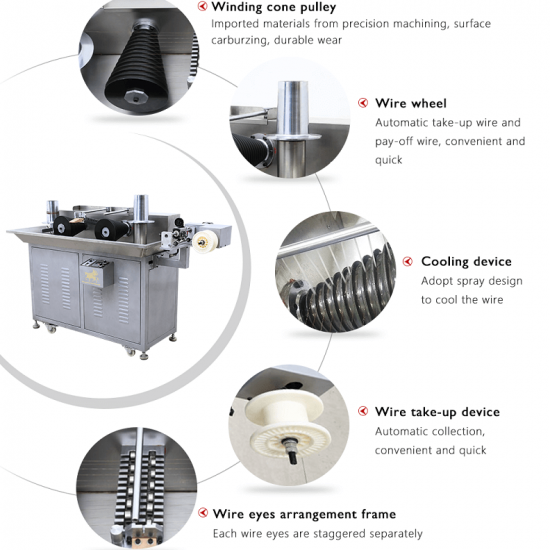

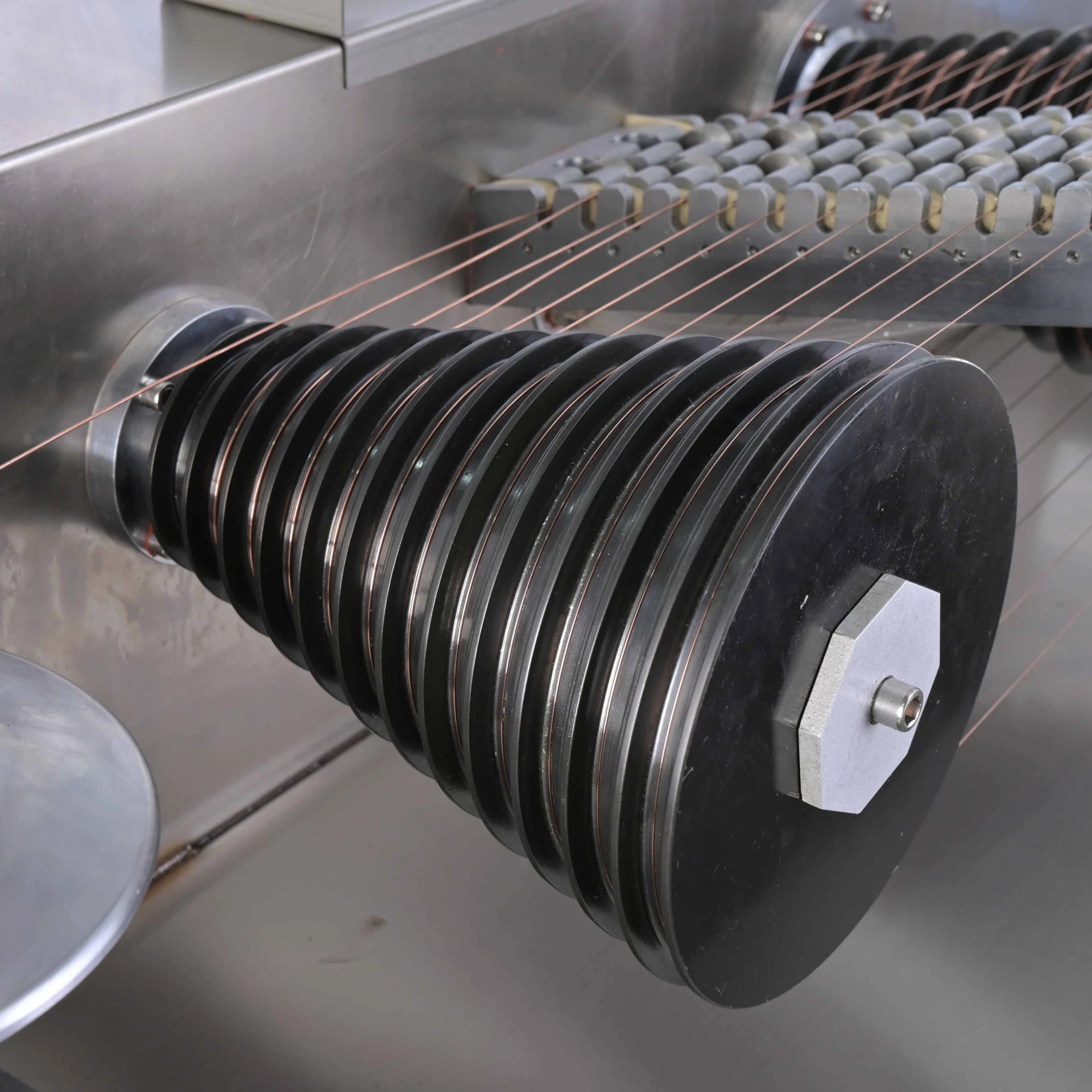

1.Winding cone pulley

lmported materials from precision machining, surfacecarburzing.durable wear

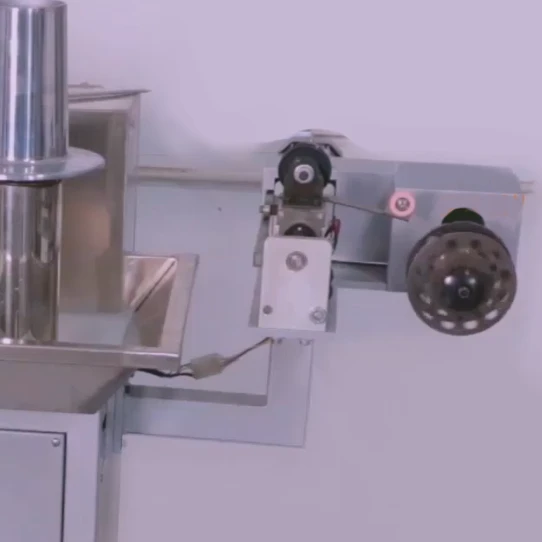

2.Wire wheel

Automatic take-up wire andpay-off wire, convenient andquick

3.Cooling device

Adopt spray design to cool the wire

4. Wire take-up device

Automatic collection,convenient and quick

5.Wire eyes arrangement frame

Each wire eyes are staggered separately

Gold Wire Making Machine

The jewelry business depends heavily on wire drawing machines, which pull precious metals like gold and silver into wires of various thicknesses. In order to create elaborate shapes and patterns, jewelers need constant, high-quality wire, which the machine makes possible.

The metal’s surface polish is also improved by brushing, increasing its durability and resistance to wear and strain. Jewelers can produce fine wire with the use of a wire drawing machine for use in a range of jewelry-making processes, such as weaving, weaving, and beading. Drawing machines are essential equipment for jewelers who want to create complicated, high-quality jewelry.

The 12-hole wire drawing machine from SuperbMelt is more productive than the majority of single-hole devices on the market. It can pull wire at a speed of 0 to 50 meters per minute and with a size of 2.2 to 0.2 millimeters.

Best Gold Drawing Machine

Why SuperbMelt Wire Drawing Machine

Any Question About SuperbMelt Wire Drawing Machine

SuperbMelt Wire Drawing Machine Guide

What is a wire drawing machine?

A wire drawing machine is a device used for metal processing. It is primarily utilized to stretch metal billets (such as gold, silver, copper, etc.) into fine wires. During this process, the metal billets are fed into the wire drawing machine and undergo a series of pulling forces and friction, gradually reducing their cross-sectional area, resulting in thinner wire-like materials. Wire drawing machines typically consist of multiple consecutive dies or modules, with each die reducing the diameter of the metal wire step by step until the desired specifications are achieved.

Wire drawing machines are widely used in various industrial fields, especially in the jewelry manufacturing industry. Through these machines, high-quality metal wires can be produced, which are used for making rings, necklaces, bracelets, and other jewelry products. Additionally, wire drawing machines are also employed in the production of wires for electrical cables, steel ropes, springs, and other metal products, providing essential metal processing solutions for modern industry.

1.1, Types of Wire Drawing Machines

- Single-Channel Wire Drawing Machine: This kind processes metal wires that meet a single standard and has just one drawing die.With its numerous successive drawing dies, the multi-channel wire drawing machine enables continuous stretching of metal wires to various diameters in a single pass. Metal wires with different characteristics are produced using it.

- Steel wire rope drawing machine: Created specifically to process and stretch the high-strength metal wires used for steel wire ropes.Utilising laser technology, the laser wire drawing machine can produce high-precision, ultra-fine metal wires by stretching metal at a micron-scale.

- Coating Wire Drawing Machine: This device is used to coat metal wires, changing their properties and potential uses.A device that twists several metal wires together to create wire ropes is a wire rope stranding machine.A spring wire drawing machine is used to create metal spring wires, giving users control over the wires’ tensile strength and hardness.

- Metal wire drawing machine: Used for the precise stretching and processing of metal wires, it is similar to a wire drawing machine.

How to Choose a Wire Drawing Machine?

- Material Processing: Determine the metal material to be processed, such as gold, silver, copper, etc. Different metals may require different types of wire drawing machines to achieve the best results.

- Specifications and Diameter: Based on the required specifications and diameter of the metal wire, choose a suitable model and specification of wire drawing machine.

- Production Capacity: Consider the daily or hourly demand for metal wire production and select a wire drawing machine that can meet the production requirements.

- Processing Precision: If high-precision metal wire production is needed, select a high-precision wire drawing machine capable of providing the required accuracy.

- Power and Energy Consumption: Take into account the power and energy consumption of the wire drawing machine to ensure it meets the factory’s power supply and energy-saving requirements.

- Automation Level: Depending on the production process and requirements, choose between manual operation or a wire drawing machine with higher levels of automation.

- Brand and Quality: Choose a reputable brand and a high-quality wire drawing machine to ensure long-term stable production operations and lower maintenance costs.

- Service and Support: Understand the manufacturer’s after-sales service and technical support offerings to ensure timely assistance and maintenance during usage.

2.1, Wire drawing machine provided by SuperbMelt

SuperbMelt manufactures wire drawing machines specialized in the processing of precious metal wires such as gold wire, silver wire, alloy wire, etc. These processed wires are used in the production of exquisite jewelry items like rings, bracelets, necklaces, and other fine jewelry pieces.

Applications of wire drawing machine

The wire drawing machine is mainly used for the production of metal wire, stretching metal billets such as gold, silver, copper, etc., into fine wires for manufacturing jewelry items like rings and bracelets. The wire drawing machine plays a significant role in modern industry, providing efficient and precise metal processing solutions for various sectors.

Why Jewelry Casting Requires Wire Drawing Machine

- Material Refinement: The wire drawing machine can stretch metal billets into finer metal wires, making the material smoother and more uniform, suitable for crafting exquisite jewelry pieces. The machine can process thicker metal wires into fine wires that meet the requirements, fulfilling the needs of jewelry casting.

- Production of Metal Wire Material: In jewelry casting, metal wires are essential materials. The wire drawing machine can produce high-quality metal wires used in the jewelry casting process.

- Custom Jewelry Production: The wire drawing machine allows for adjusting the diameter and shape of metal wires, catering to the design requirements of various jewelry pieces. Through the machine, metal wires of different diameters and styles can be produced, facilitating the creation of customized jewelry.

- Increased Production Efficiency: Using the wire drawing machine enables bulk production of metal wires, thus enhancing production efficiency and reducing the time and labor costs associated with manual wire drawing.

- Improved Quality and Consistency: The wire drawing machine enables precise control of metal wires, ensuring consistent product quality and avoiding variations that may occur in manual operations.

4.1, Craftsmanship

The prepared metal billet is fed into the wire drawing machine. The wire drawing machine uses a series of dies or modules to gradually reduce the diameter of the metal billet, stretching it into fine metal wire of the desired thickness and length. The drawn metal wire may undergo annealing, which is a heating process used to relieve internal stress and increase ductility, making the metal wire easier to work with and preventing it from becoming brittle. The metal wire is then shaped, twisted, and formed into various jewelry components such as rings, bracelets, necklaces, pendants, or earrings.

Conclusion

If you are a jewelry manufacturer, you must have a metal wire drawing machine, which can provide you with a perfect solution for making rings, bracelets, earrings, and other jewelry items.

FAQ Guide of Wire Drawing Machine

- 1. What Is Wire Drawing Machine?

- 2. How About The Feeding Size For 6 Eyes And 12 Eyes ?what Is The Minimum Output Size?

- 3. How Does The Drawing Machine Work?

- 4. What Is The Price of The Gold Wire Drawing Machine?

- 5.How many types of wire drawing machines are there?

- 6. What is wet wire drawing machine?

1. What Is Wire Drawing Machine?

A wire drawing machine is a tool used to reduce the diameter of metal wire from a thick one to a thin one. The procedure entails dragging a metal wire through many dies while progressively lowering its diameter and lengthening it. manufacturing wire for a range of sectors, including as jewelry manufacturing, building, and wire, is frequently done with the use of wire drawing equipment. Wire drawing machines are employed in the jewelry industry to produce fine metal wires, which are subsequently utilized in a variety of jewelry-making procedures.

2. How About The Feeding Size For 6 Eyes And 12 Eyes ?what Is The Minimum Output Size?

The maximum drawline is 2.2mm for 6 eyes, the maximum drawline for 12 eyes is 1.5mm; and the final drawline can be up to 0.2mm

3. How Does The Drawing Machine Work?

The process of drawing a wire through a sequence of progressively smaller dies to decrease its cross-sectional area and increase its length is known as wire drawing. A roller or capstan drags the wire through a set of dies, a spool or coil holds the wire, and a motor powers the entire apparatus.

Before being fed through the first die with the greatest aperture, the wire is first cleaned and lubricated. The diameter and length of the wire change as it is pulled through the die. To get the appropriate diameter and length, the wire is next sent through a sequence of smaller dies, each with a smaller aperture.

Depending on the level of reduction needed, drawing machines can be single or multi-pass. The wire is pulled through a set of dies only once in a single-pass process. To obtain a higher diameter reduction, the wire is passed through the same set of dies more than once in a multi-pass machine.

The drawing process can generate wire in a variety of forms and surface finishes, depending on the layout of the die and the lubricant employed. The resultant wires are employed in several industries, including as industrial production, jewelry creation, and electrical wiring.

4. What Is The Price of The Gold Wire Drawing Machine?

Depending on features like quality and functionality, the cost of a gold wire drawing machine typically ranges from several thousand to tens of thousands of dollars. The wire drawing machine under the SuperbMelt name satisfies market demands. Whether it is valuable metals like gold, silver, copper, or another type, it can swiftly and effectively finish the wire drawing.

5. How many types of wire drawing machines are there?

- Single wire drawing machine: Used to stretch a single metal wire into various diameters of fine wire.

- Multi-wire drawing machine: Can simultaneously stretch multiple metal wires, improving production efficiency.

- Steel wire rope drawing machine: Used to manufacture steel wire ropes by weaving multiple wires together.

- Metal tube drawing machine: Stretches metal tubes into different diameters and wall thicknesses.

- Copper wire drawing machine: Specifically designed for drawing copper wires, used in power transmission, electronics, and other industries.

- Aluminum wire drawing machine: Used for producing aluminum wires commonly used in wire and cable manufacturing.

- Metal strip drawing machine: Stretches metal strip material into thinner and wider strips.

- Non-ferrous wire drawing machine: Suitable for drawing non-ferrous metal wires like copper, aluminum, steel-copper, etc.

6. What is wet wire drawing machine?

A wet wire drawing machine is a device used for the production of metal wires. In the wet wire drawing machine, the metal wire is lubricated during the drawing process with a lubricant (usually water or oil) to reduce friction and make it easier to stretch the metal wire into finer diameters. This lubrication method helps to reduce heat and friction losses during the drawing process, thus improving the quality and production efficiency of the metal wire. Wet wire drawing machines are widely used in the manufacturing of various metal wires, such as gold wire, silver wire, copper wire, and aluminum wire.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited