Vacuum Metal Granulator

China Professional Precious Metals Casting Equipment Supplier

Vacuum metal granulators are used to granulate various precious metals such as gold, silver, copper and alloys. It works by first heating the metal material to its melting point in a vacuum chamber, then passing through a multi-hollow crucible as a current breaker, and finally flowing into a circulating water groove to cool into regular metal particles without oxidation.

SuperbMelt vacuum metal granulator performs smelting work under the environment of full vacuum inert gas, and is equipped with an electromagnetic automatic stirring device, so that the finished product of the metal particles can not be oxidized and has uniform spherical shape and luster.

It is most commonly used in precious metal refinery and jewelry manufacturing plants with high quality requirements.

Parameter of vacuum granulator

| Model number | SPB-VS5P | SPB-VS10P | SPB-VS20P |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 15 kw | 25kw |

| Casting system | Vacuum casting system | Vacuum casting system | Vacuum casting system |

| Applicable metal | Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, K-Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 5-6 min | 5-6 min | 5-6 min |

| The Max capacity | 24K Gold: 5.0 kg 925 Silver: 2.5 kg | 24K Gold: 10.0 kg 925 Silver: 5.0 kg | 24K Gold: 20.0 kg 925 Silver: 10.0 kg |

| Max heating temperature | 1600℃ | 1600℃ | 1600℃ |

| Max. temp control k-type | 1100℃ | 1100℃ | 1100℃ |

| Casting chamber size | D275*H1100mm | D330*H840mm | D385*H1000mm |

| Dimension | 730*935*1600mm | 800*1020*1700mm | 850*1050*1800mm |

| Weight | 175KG | 235KG | 265KG |

| Protective gas | Argon | Argon | Argon |

| Vacuum pump (Optional) | 63 m³/hour | 63 m³/hour | 63 m³/hour |

| Control of temperature | by PID | by PID | by PID |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius | ±2 degrees Celsius |

| Vacuum filter | Y | Y | Y |

| Vacuum leakage detector | Y | Y | Y |

| Casting chamber lift | Y | Y | Y |

Details of vacuum granulator

Insulating Heating

The equipment adopts the coil designed by low voltage, so that the equipment can work in a state of insulation and heating, so the operation risk can be better avoided, and the safety of workers is ensured.

Electromagnetic Stirring

When the metal is melted, the machine will perform electromagnetic stirring, which can make the final product color more uniform and shiny.

PID Temperature Control

The machine accurately controls the temperature through PID intelligent digital. The temperature difference is within ± 2 degrees. The corresponding temperature is set for different metals, and the melting speed is faster and more efficient.

Inert Gas Environment

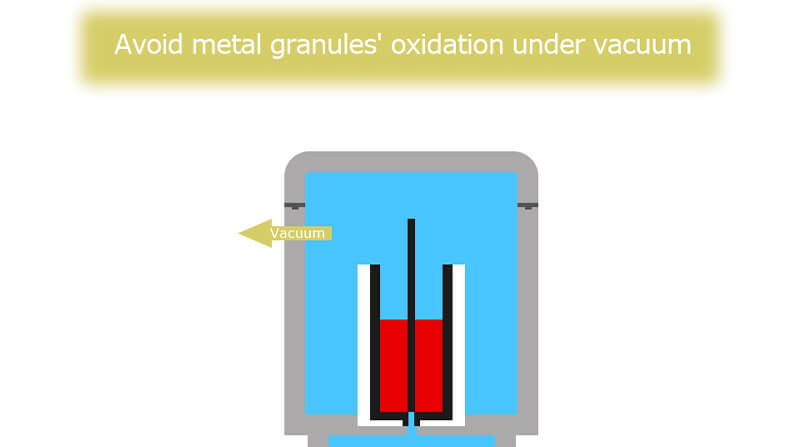

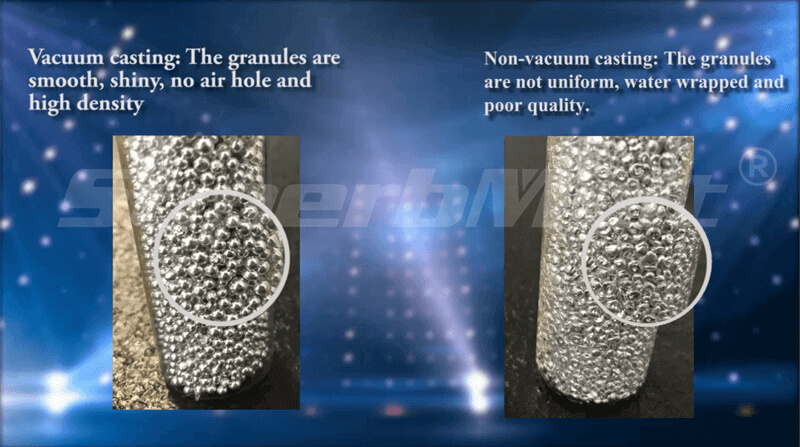

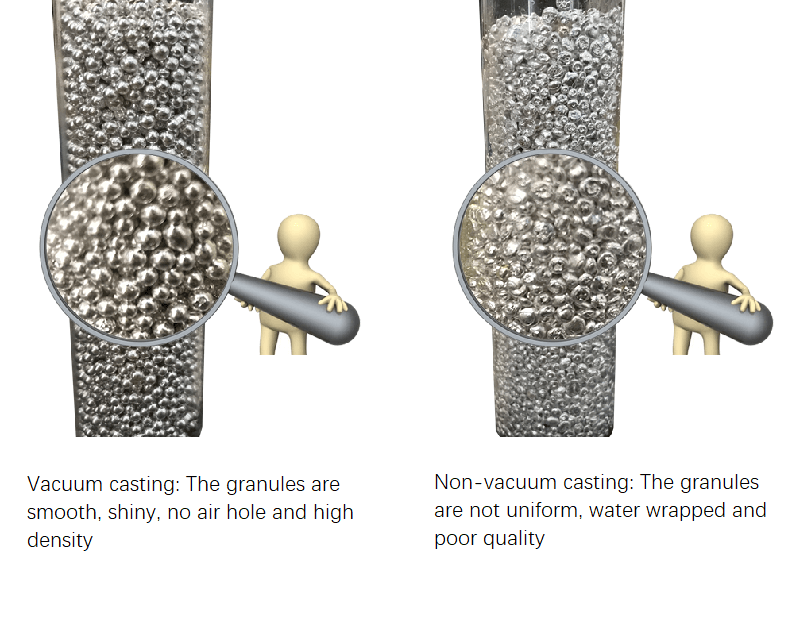

smelting the smelted metal under the protection of inert gas, thereby avoiding the phenomenon of alloy oxidation. and granulating under vacuum environment, the oxygen content of the finished product is reduced, the water content is low, and the sphericity of the finished product is better and more uniform.

PLC Screen Control

The machine is equipped with a 7-inch high-definition touch screen, the interface is simple, and it is more convenient to use. If the parameters are set, it can work automatically, which reduces the training cost of workers.

Convenient Material Fetching

A water locking device is installed under the machine, which can better isolate excess water, and a finished product can be easily obtained by simply unscrewing it, so the work is simpler and more convenient.

Water Circulation System

Water in the tank is continuously circulating and it is cooled by a powerful chiller to keep the finished grain uniform and highly spherical.

Water Pump Device

The vacuum metal granulator is equipped with a water pump in the water tank. The vortex is generated by the water pump to keep the water flowing, which prevents the particles from sticking together during the granulation process and ensures the granules more independent.

A vacuum metal granulator is a device used in the recycling industry to process blocks, flakes, or other irregular shapes metal into small, uniformly sized particles.

The main function of a vacuum metal granulator is to process scrap metal into small, usable pieces that can be melted down and reused in the production of new metal products. This helps to reduce waste and conserve resources, as recycled metal requires less energy to process than raw metal.

The applications of vacuum metal granulators are widespread in the metal recycling industry. Usually used in some metal refineries, metal processing and jewelry manufacturing plants

The whole process is completed under vacuum to avoid metal oxidation

Through induction heating metal, no flame, to ensure safety

Vacuum casting the granules are smooth, shiny, no air hole and high density

Why SuperbMelt Vacuum Metal Granulator

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Any Question About SuperbMelt Vacuum Metal Granulator

Guide of SuperbMelt Vacuum Metal Granulator

How to use the Vacuum Metal Granulator?

Step 1: Place metal material in smelting cavity

Step 2: Close vacuum furnace and start smelting

Step 3: Press the casting button when the temperature reaches the melting point for 2 minutes

Step 4: After the granulation step, turn off the heating power and exhaust the gas

Step 5: Finally, the water separation and material taking device is opened to obtain the finished product.

How to Choose a Suitable Vacuum Metal Granulator?

Material Type

The type of metal you will be processing will impact the type of metal granulator you need. Some granulators may only be suitable for certain metals, such as aluminum or copper, while others can handle a wider range of materials.Capacity

Consider the volume of material you will be processing and choose a metal granulator that can handle the required capacity. For example, 24K Gold: 5-20 kg and 925 Silver: 2.5-10 kg.Energy Efficiency

Consider the energy consumption of the granulator, as well as the cost and availability of the power source.Maintenance Requirements

Consider the ease of maintenance and replacement of wear parts, as well as the availability of spare parts. Our vacuum metal granulator is designed in one piece for easy maintenance.Price

The cost of the granulator is an important factor, but it should not be the only consideration. The most expensive option may not be the best choice if it does not meet your specific needs.Comparison between Vacuum Metal Granulator and Non-vacuum Granulator

Structure

Vacuum metal granulators typically have a more complex structure compared to ordinary granulators, as they are designed to operate under a vacuum. This helps to reduce minimize the oxidation of the metal being processed. Ordinary granulators, on the other hand, do not have a vacuum system and may be more straightforward in design.

Operation

The operation of vacuum metal granulators is more controlled and precise compared to ordinary granulators, as they are designed to minimize the oxidation of the metal being processed and prevent the formation of dust. Ordinary granulators, on the other hand, may produce oxidation during the granulation process.

Energy Efficiency

Vacuum metal granulators tend to be more energy-efficient than ordinary granulators, as they are designed to operate under a vacuum and thus require less energy to granulate the metal.

Application

Vacuum metal granulators are typically used in applications where a high degree of metal purity is required, such as in the recycling of electronic waste or precious metal scrap. Ordinary granulators may be more suitable for less demanding applications, such as granulating metal scrap for use in other manufacturing processes.

FAQ Guide of Vacuum Metal Granulator

Vacuum granulating machine is what you need to invest in when looking to make some fine gold, silver or other granules of precious and non-precious metals. Suppose you are looking for some of the most frequently asked questions about the vacuum granulating machine, then you have come to the right place.

In this piece, we have tried to be as comprehensive as possible with our responses about the vacuum granulating machine. However, if you have a question that you feel we have not addressed in this piece, be sure to let us know in the comments. Our experts will make sure you get the most professional response possible.

- 1. What does the term granulating means when working with gold?

- 2. How do you do gold granulation?

- 3. How to choose the right non-ferrous metal melting furnace?

- 4. What can you use as a crucible for non-ferrous metal melting?

- 5. Can you melt gold and silver off electronics?

- 6. What Kind of Metal Granulation can the Machine Make?

- 7. What is the Melting Capacity of the Machine?

- 8. What Consumables Need to be Prepared for a Long Time?

- 9. What Particle Size can be Achieved?

- 10. How Long is the Lead Time of the Machine?

- 11. What is the Footprint of the Machine

- 12. What Type of Gas can be used?

1. What does the term granulating means when working with gold?

When granulating gold with vacuum granulating machine, you will be using our machine to turn your gold into grains that you can easily handle work. With the machine, you will get high quality and homogenous grains. Once you have the grains, you will pour them into a water tank with the help of a multi-hollowed crucible.

There are so many things you can do with the grains. Remember, you will have to begin from the raw material that has been molten with the help of induction heating. If you ask any jeweler, they will tell you that the master grains must have certain level of quality to meet the industrial standard.

However, the machine we have at Superbmelt is best for alloys and metals that have been easily oxidized. Note that you don’t have to be the best jeweler to know what clients or customers are looking for when producing the master grains and alloys.

2. How do you do gold granulation?

Granulation might be an old process, but the machines used to complete the process have undergone major transformation. With the help of technology, Superbmelt has formulated a powerful induction furnace that you can use to complete the granulation process. Provided you have the right materials, granulation should not take a lot of your time to complete.

To begin the process, take your induction furnace and put the crucible in place. Remember, the crucible should be made of a material with a higher melting point compared to that of gold. Unless you do that, you the crucible will melt and the granulation process will not be successful one.

Place a large piece of gold on the crucible and turn on your induction furnace to commence the heating process. Heat the gold to its melting point and right below the crucible, there will be some holes. Your liquid gold will go through the hold at the bottom of the crucible to drop inside water.

Since the water is cold, it will force the liquid or molten gold to form granules. Note that our induction furnace will complete the process in a matter of minutes based on the amount of gold you are trying to melt.

3. How to choose the right non-ferrous metal melting furnace?

Would you like to have the best non-ferrous metal melting furnace? There are things you must have in mind before you begin looking. For instance, when you want the best, think about its power efficiency.

It is vital to consider using our induction furnace or vacuum granulating machine since it comes with a wide range of features for the most pleasurable application process. It does not consume a lot of power and is also perfect for environment.

Our induction furnace doesn’t require a lengthy learning curve to operate. If you choose our induction furnace, you will save a lot of money since it doesn’t consume a lot of power.

4. What can you use as a crucible for non-ferrous metal melting?

Graphite or silicon carbide are the best materials to use for crucible meant for heating non-ferrous metals. If you are not sure why that is the case, silver and gold have very high melting points.

Silicon carbide and graphite have melting points of around 1600 degrees centigrade. If you heat up to that level, you shall have melted most of your gold. You don’t have to keep heating your non-ferrous metal to 1600 because they have way lower melting points.

But if you must heat metals with melting temperatures higher than 1600 degrees centigrade, then you might have to reconsider the material used to make your crucible.

5. Can you melt gold and silver off electronics?

Yes, just like you can remove gold and silver from their natural ores, you can easily get them off electronics. The problem with this technique is that you will spoil the electronics, but it makes sense if you all you need is to get silver and gold from electronics.

6. What Kind of Metal Granulation can the Machine Make?

Gold, Silver, Copper, and their Alloys.

7. What is the Melting Capacity of the Machine?

24K Gold: 5-20 kg and 925 Silver: 2.5-10 kg.

8. What Consumables Need to be Prepared for a Long Time?

Graphite crucible, graphite mold and stopper.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited