3D Resin Printer For Jewelry

Jewelry resin 3D printers are specialized machines used for creating intricate designs on jewelry. Using resin 3D printers in jewelry making not only enhances the precision and quality of the final products but also streamlines the production process, making it more efficient and versatile.

Simplifying the Production Process Using Resin 3D Printers

In today’s jewelry manufacturing industry, customers have increasingly higher expectations when it comes to the complexity of designs, production speed, and personalized customization for pieces such as rings, necklaces, and earrings. Traditional hand-carved wax modeling and mold-making methods can no longer meet the demand for such precision and flexibility.

To address this, we have introduced Resin 3D Printing technology, which fully upgrades the jewelry production process and ushers jewelry design and manufacturing into the era of digital intelligent manufacturing.

Resin 3D printing not only enhances the flexibility and precision of jewelry production, but also provides jewelry brands, studios, and designers with a more efficient and competitive production path.

From initial sketches to final delivery, the entire process is digitized and automated, allowing you to focus more on creativity rather than time-consuming manual processes.

If you’re looking to meet custom orders faster, improve product precision, and reduce production costs, a 3D Resin Printer for Jewelry is the ideal solution to revolutionize your manufacturing workflow.

Our Resin 3D Printers for Jewelry Making

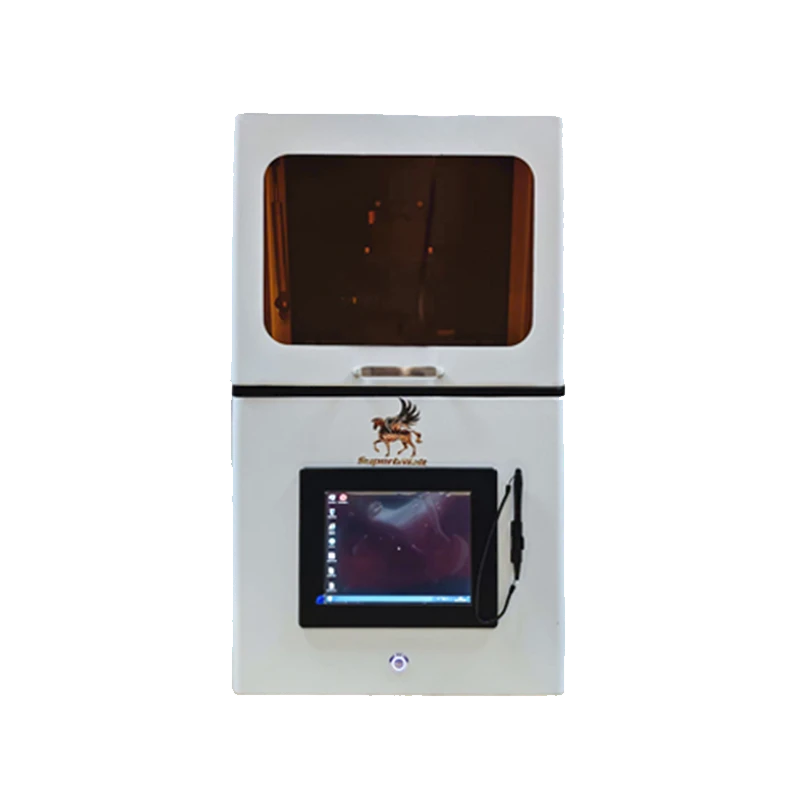

SPB-4K192 for Jewelry Casting

Compared with the wax 3d printer, this machine is more cost-effective, and some simple styles of finished products can achieve the effect of the wax printer. Therefore, the cost can be greatly reduced.

The material is castable resin, which simplifies the process, makes the production cycle shorter, and can respond to market demands faster.

The surface of the finished product is smooth, because it is a high-quality casting resin, with strong stability, and the finished product will not be deformed during pouring, and the finished product can achieve a delicate effect.

Diversification of available materials, in addition to castable resins, ceramic resins, dental mold resins and other materials can also be used to meet the needs of different products.

It is easy to use, and it only takes a few easy steps to quickly print out the model. First, import the designed pattern into the computer, and then start printing after setting the program.

SPB-DLP64/SPB-DLP144/SPB-DLP96 for Jewelry Prototyping & Molds

The system is very stable, the molding process is highly automated, and the molding process can be automated until the prototype is completed.

Traditionally outsourced prototyping often takes weeks, but with resin 3D printers, prototyping can be completed within hours, greatly saving production time.

Small, compact and powerful, the machine is ideal for jewelry studios, not only saving production time, but also offering designers more possibilities for their creative jewelry.

Accurate printing accuracy and support for continuous and stable printing can realize rapid iteration of design prototypes and rapid production in small batches, saving time for tedious processes in the later stage and greatly improving production efficiency.

Some 3D printers only allow users to use special resin materials, which is a very big limitation, while our 3D printers have an open system that can be compatible with more third-party materials.

| Model number | SPB-J100 | SPB-J150 |

| Power source | 110/220v 50/60Hz 200w | 110/220v 50/60Hz 200w |

| Build envelope | L108*W60*H120mm | L144*W81*H120mm |

| Native Pixel | 43 µm | 56 µm |

| Resolution | 2560*1440 | 2560*1440 |

| Light Source | Industrial UV LED | Industrial UV LED |

| Layer thickness | 1-50 µm | 1-50 µm |

| Printing speed | 10mm/h | 10mm/h |

| File formate | STL/SLC | STL/SLC |

| Interface | USB | USB |

| Materials | Resin Wax | Resin Wax |

| Software | WIN7 | WIN7 |

| Dimension | 380×380×660mm | 380×380×660mm |

| Weight | 35kg | 35kg |

Here's What Our Satisfied Customers Have to Say

Applications of SuperbMelt Jewelry Resin 3D Printers

Direct Casting (Castable Resin)

Now some exquisite jewelry on the market, such as European style, American style, Middle East and other styles, can be quickly printed with resin 3D printers, and present high-precision, smooth and detailed effects to meet customers’ high requirements for jewelry.

In traditional crafts, jewelers would engrave or shape patterns into the wax, making many intricate designs impossible. 3D resin printers solve this problem nicely and use castable resins in 3D that have nearly the same properties as wax. Cumbersome manual processes are simplified.

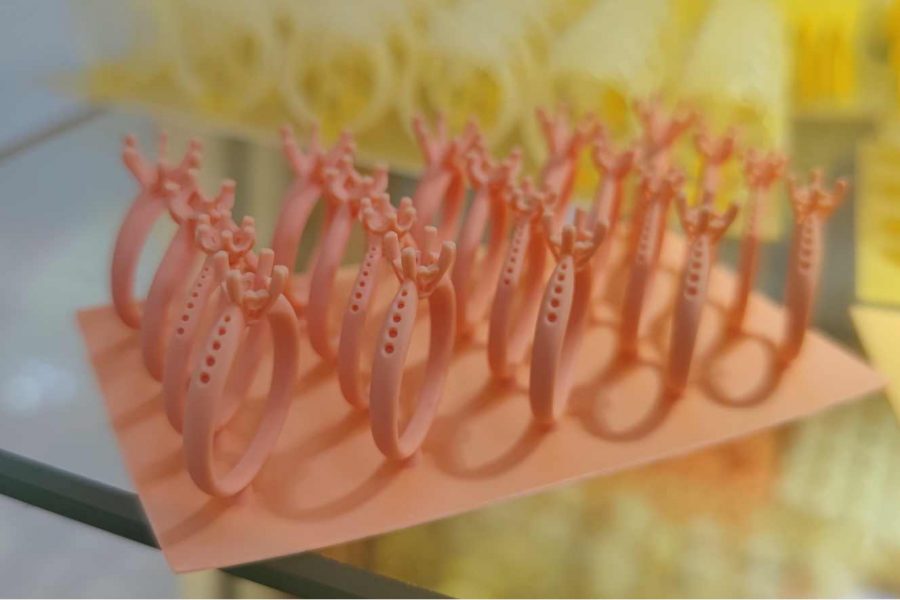

With castable resin materials and efficient 3d printers, it is no longer necessary to spend a lot of time and manpower to manually shape wax models, and dozens of design models can be printed at one time in a short period of time, such as common exquisite rings, pendants .

Using resin 3D printers is not only fast, but also achieves various fine and high-quality designs that cannot be achieved by traditional processes.

This resin is still a direct casting material, the casting process will burn out, and the finished product will be very fine and smooth, with strong stability and not easy to shrink, so that the final product will not deform or change size.

Prototyping (Uncastable Resin)

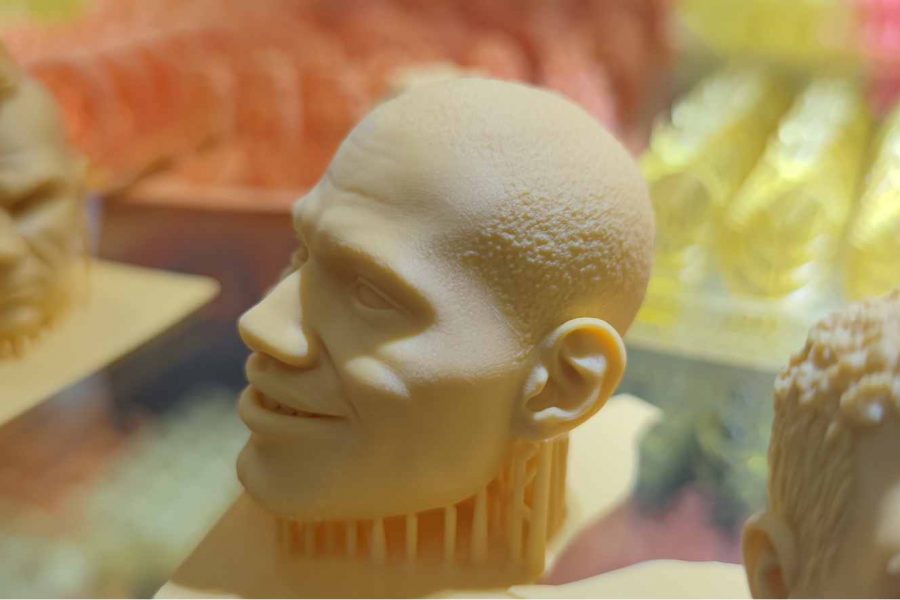

The model resin has the material properties of washable, low viscosity, and can make the printed model have a smooth, fine textured surface, and is widely used in figure toys, educational and medical models.

In addition, many designs in the jewelry industry are used as models before casting, which can be used with 3D printing technology to find problems in product modeling and structural design as soon as possible, reduce frequent design changes, rework and cumulative losses caused by other so that improve production efficiency, and insure finished product perfection.

Rubber Molds (Uncastable Resin)

Rubber mold, which is a printed resin prototype, placed in liquid glue or low-temperature rubber, vacuumed, and solidified or heated for several hours to form a crystal plastic mold or a low-temperature plastic mold, cut with a blade to take out the prototype, The contour shape exposed in the plastic mold is the style of the prototype, which can be mass-produced by the wax injection machine later.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

User Guide 3D Resin Printer For Jewelry

Fundamentals: What Is Resin 3D Printing for Jewelry?

1.1, The Role of Resin 3D Printing in the Jewelry Industry

Resin 3D printing is a cutting-edge digital manufacturing technology that uses photopolymer resins to produce ultra-precise jewelry prototypes. Compared to traditional hand-carved wax or rubber molds, resin 3D printing significantly speeds up production, improves precision, and enhances design flexibility for rings, pendants, earrings, bracelets, and more.

As demand for custom jewelry and rapid production continues to grow, more and more jewelers are adopting resin 3D printers to meet these evolving needs.

- 1. High Precision for Complex Designs

Resin 3D printers offer layer resolutions as fine as 25 microns, allowing for unmatched detail in every curve, gemstone setting, and filigree pattern.

- 2. Faster Production, Shorter Lead Time

Unlike traditional wax carving or mold making, resin 3D printing allows you to turn your CAD designs into physical prototypes within hours, not days.

- 3. Cost-Effective for Small-Batch and One-Off Production

No expensive molds are needed. Resin 3D printing is ideal for short-run manufacturing and custom orders, reducing material waste and tooling costs.

- 4. Seamless Integration with Lost-Wax Casting

Castable resins are specially formulated for clean burnout, making them fully compatible with traditional lost-wax casting processes using gold, silver, platinum, and other precious metals.

Applications of Resin 3D Printing in Jewelry

- Custom engagement rings

- Personalized name necklaces

- Lightweight, artistic earrings

- Fashion jewelry prototypes

- Small-batch artisan jewelry collections

Whether you’re a boutique brand or a production facility, jewelry 3D printing empowers you to experiment freely and iterate quickly.

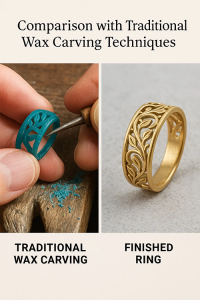

1.2, Comparison with Traditional Wax Carving Techniques

Which is better for modern jewelry design and production?

1. Production Process

| Aspect | Traditional Wax Carving | Resin 3D Printing |

|---|---|---|

| Workflow | Hand-sculpted by artisans using tools | Designed in CAD, printed digitally |

| Skill Dependency | Highly reliant on manual skill and craftsmanship | Relies on digital modeling and printer calibration |

| Repeatability | Difficult to reproduce identical models | Digital files ensure precise replication |

| Aspect | Traditional | 3D Printing |

|---|---|---|

| Time per model | 4–10 hours depending on complexity | 2–6 hours for multiple parts printed simultaneously |

| Iteration speed | Slow (re-sculpt needed) | Fast (edit CAD file and reprint) |

| Batch production | Inefficient | Efficient – multiple parts in one print job |

| Feature | Traditional Carving | Resin 3D Printing |

|---|---|---|

| Design Complexity | Limited by hand tools and skill | Excellent for intricate, organic, and hollow designs |

| Symmetry and Accuracy | Hard to perfect by hand | CAD ensures perfect symmetry and dimensional accuracy |

| Micro-detailing | Challenging for fine structures | Supports high-resolution (25–50 microns) features |

4. Cost & Materials

| Factor | Traditional Wax | Resin 3D Printing |

|---|---|---|

| Labor Cost | High (requires trained artisan) | Low (single operator can run multiple printers) |

| Tooling/Molds | May require silicone/rubber molds | No mold needed unless mass-producing |

| Material Waste | Often more waste during carving | Efficient material use; unused resin can be filtered and reused |

5. Customization & Flexibility

| Capability | Wax Carving | Resin Printing |

|---|---|---|

| Personalized Orders | Time-consuming to modify | Easy to edit CAD and reprint |

| Mass Customization | Impractical | Ideal for small-batch variations |

| Prototyping | Slow and costly | Rapid and cost-effective for A/B testing |

6. Conclusion: Which Should You Choose?

Use Traditional Wax Carving if:

You’re creating a one-of-a-kind artisan piece

You want a handmade touch or antique feel

You have master-level carving skills in-house

Use Resin 3D Printing if:

You need to scale production or increase design speed

You offer customized jewelry or frequent design changes

You want higher detail and faster turnaround

Many modern workshops combine both: using 3D printing for base forms, then adding hand finishes for uniqueness

1.3, Types of Jewelry That Can Be Printed

Types of Jewelry That Can Be Printed with Resin 3D Printers

Resin 3D printing enables the creation of highly detailed and customized jewelry prototypes and casting models. Below are the most common types of jewelry that benefit from this technology:

Rings

Engagement rings, wedding bands, signet rings

Intricate filigree, micro-pavé settings, and inner engravings

Ideal for personalized, one-off, or pre-casting prototypes

Pendants & Necklaces

Name necklaces, zodiac symbols, initials, religious icons

3D sculpted pendants with hollow or organic structures

Lightweight and complex shapes made easy with digital design

Earrings

Studs, hoops, danglers, and statement earrings

Matching symmetrical pairs ensured through CAD design

Perfect for lightweight designs with extreme detail

Bracelets & Charms

Chain links, charm bracelet components, engraved bangles

Can be designed as modular parts for assembly

Custom motifs or repeating patterns printed with precision

Brooches & Pins

Fashion pins, lapel pins, or gemstone-based brooches

Multi-layered or interlocking geometries printed with ease

Thin structures supported effectively during printing

Jewelry Components & Findings

Settings, prongs, bezels, links, jump rings

Crown settings for stones, hollow beads

Printed in batches for rapid assembly and casting

Custom & Artistic Pieces

Abstract art jewelry, cultural or conceptual designs

One-of-a-kind prototypes for exhibitions or limited editions

Highly personalized commissions for clients

Bonus: Multi-Part Assemblies

Hinged parts, stackable rings, or kinetic elements

CAD modeling allows precise tolerances for post-casting assembly

Whether you’re a jewelry designer, custom manufacturer, or artist, resin 3D printing opens the door to freedom of form, detail, and speed that traditional methods struggle to match.

1.4,Material Types: Standard Resin vs. Castable Resin

Material Types: Standard Resin vs. Castable Resin

Choosing the right resin for 3D printed jewelry production

1. Standard Resin

Definition:

Standard resin is a general-purpose photopolymer used in 3D printing for prototyping and visual models.

Best For:

Non-casting prototypes

Design previews

Fitting tests

Master models for mold duplication

Key Features:

Good surface finish

High dimensional accuracy

Available in multiple colors (gray, white, transparent, etc.)

Not suitable for direct burnout casting

Limitations:

Cannot be used in lost-wax casting

Leaves ash/residue during high-heat burnout

More brittle than castable resins

Use Cases:

Jewelry design validation

Presentation samples

Mold master for rubber or silicone duplication

2. Castable Resin

Definition:

Castable resin is specially formulated for clean burnout during lost-wax casting, leaving minimal ash or residue.

Best For:

Direct casting of gold, silver, platinum, bronze, etc.

High-precision jewelry molds

Custom and production-ready parts

Key Features:

Burns out cleanly (ash-free)

Compatible with investment casting

Excellent for micro-detail and smooth surfaces

Often has a wax-like feel or color (purple, green, blue)

Considerations:

Slightly more expensive than standard resin

Requires proper curing before burnout

Specific burnout schedule must be followed (850–900°C max)

Use Cases:

Rings, pendants, earrings, and other final-use jewelry parts

Small-batch production

One-off custom commissions

Comparison Summary:

| Feature | Standard Resin | Castable Resin |

|---|---|---|

| Burnout Compatibility | ❌ Not suitable | ✅ Designed for lost-wax casting |

| Use Purpose | Prototyping, fit checks | Final production parts |

| Surface Finish | Smooth | Very smooth (suitable for casting) |

| Cost | Lower | Slightly higher |

| Ash Residue | High (not recommended for kilns) | Near-zero (clean burnout) |

Conclusion: Which One Should You Choose?

Use Standard Resin if you need to test or showcase your jewelry design before casting.

Use Castable Resin if you’re going directly to metal casting — it’s the industry standard for precious metal production.

Casting Integration: How to Use Prints for Metal Casting

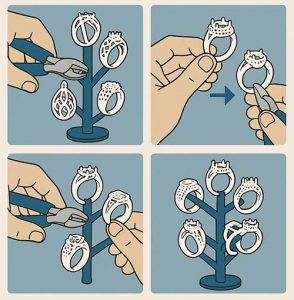

2.1, How to Assemble Printed Models into a Casting Tree

For Resin 3D Printed Jewelry Patterns

Materials Needed:

Fully cured resin-printed jewelry models (preferably castable resin)

Wax sprues (2–4 mm diameter)

Wax pen or heated spatula

Main wax trunk (central sprue)

Rubber sprue base or casting flask base

Tweezers, gloves, and alcohol wipes

Step-by-Step Assembly Process

1. Inspect and Clean Printed Models

Ensure all models are fully UV cured

Clean them gently with alcohol to remove dust or residue

Choose appropriate attachment points (usually flat, thick areas)

2. Prepare the Central Sprue (Tree Trunk)

Use a straight wax rod as the main trunk

Cut it to match the height of the flask, leaving space at the top and bottom

Fix it upright into a rubber sprue base

3. Attach Wax Sprues to Each Model

Use a wax pen or heated metal spatula to melt and weld one end of a wax sprue to the model

Keep sprues short and direct—angled 30–45° upwards is ideal

Avoid sharp bends or long, unsupported sprue paths

4. Assemble the Tree Structure

Attach models around the main trunk, starting from the bottom and spiraling upward

Ensure even spacing to allow investment to flow freely between parts

Avoid crowding—leave 2–3 mm between models

Keep weight balanced to avoid leaning during casting

5. Final Check and Stability

Gently tap the tree—nothing should wobble

Double-check for:

Weak connections

Colliding models

Unclean joints

Secure the trunk tightly into the base for a vertical hold during investment

Best Practices & Tips

Use thicker sprues (3–4 mm) for heavier models to improve metal flow

Position heavier pieces at the bottom of the tree

Label tree levels if printing multiple designs for tracking

Keep the tree as compact and balanced as possible

Minimize the total number of connections to reduce metal waste

What Comes Next?

Once your casting tree is assembled:

Place it in a metal flask

Pour investment plaster to fully cover the tree

Dry and burn out in a kiln to remove the resin

Pour molten metal (gold, silver, etc.) into the cavity

2.2, Investment Molding & Vacuum Mixing Process

How to properly embed resin-printed models in investment material for lost-wax casting

Purpose:

Investment molding is the process of surrounding your resin casting tree with a heat-resistant plaster (called investment) that will form a mold cavity after burnout. Vacuum mixing removes air bubbles to ensure a smooth, detailed mold surface.

Materials & Tools Needed:

Fully assembled casting tree

Casting flask (metal cylinder)

Investment powder (gypsum-based, for high-temp casting)

Deionized/distilled water

Vacuum investment mixer

Rubber sprue base and flask ring

Scale and mixing container

Timer, gloves, spatula

Step-by-Step Procedure:

1. Seal the Flask to the Rubber Base

Insert your wax/resin tree into the rubber sprue base.

Fit the casting flask securely on top.

Make sure the seal is tight to prevent leaks when pouring investment.

2. Measure and Mix the Investment

Follow the ratio recommended by the investment powder manufacturer (e.g., 100g powder : 35–40ml water)

Pour water first, then gradually add the powder while stirring

Use a vacuum mixer to blend for 3–5 minutes under vacuum.

This removes bubbles that could cause mold defects.

3. Pour Investment into the Flask

After mixing, gently pour the investment into the flask from the side (not directly on the model)

Pour in a slow, steady stream to avoid trapping air

Fill to about 1–2 cm below the top of the flask

4. Vacuum De-Bubbling (Optional but Recommended)

Place the filled flask under a bell jar vacuum chamber for another 60–90 seconds

Watch for bubbles rising to the surface and collapsing

This step ensures a bubble-free surface around delicate jewelry features

5. Initial Set & Curing

Let the investment sit undisturbed for at least 60 minutes at room temperature

Avoid vibration or moving the flask during this stage

After curing, the mold is ready for burnout in a kiln

Tips for Best Results:

Use deionized water to avoid chemical reactions that can weaken the investment

Don’t over-mix or introduce excessive air during manual mixing

Use a timer for consistency between batches

Ensure room temperature is stable (~20–25°C) to avoid premature setting

Next Step:

Once the investment is cured, proceed to the burnout cycle to remove the resin and prepare the mold cavity for metal casting.

2.3, Burnout Schedule (Temperature Curve)

Recommended temperature curve for complete resin elimination without ash or damage to the mold

Purpose:

The burnout process gradually heats the investment mold to vaporize and eliminate the resin 3D printed model, leaving behind a clean, detailed cavity for molten metal.

Standard Burnout Temperature Curve (12–14 Hours)

| Stage | Temperature | Duration | Notes |

|---|---|---|---|

| 1. Drying Phase | 150°C (300°F) | 2 hrs | Slowly dries out residual moisture in investment |

| 2. Transition | Ramp up to 350°C (660°F) | 2 hrs | Begins resin softening & thermal expansion |

| 3. Resin Burnout | Ramp up to 700–750°C (1290–1380°F) | 3–4 hrs | Fully burns out the resin (critical stage) |

| 4. Soak | Hold at 730–780°C (1345–1435°F) | 2 hrs | Ensures all resin and ash are eliminated |

| 5. Cooldown | Reduce to casting temp (~500–550°C / 930–1020°F) | 2 hrs | Stabilize mold before metal pouring |

Best Practices:

Ventilation is crucial: Always use a burnout kiln with a good fume exhaust system (resin produces vapor and gas).

Avoid stacking flasks too tightly—leave space for airflow between molds.

Preheat the kiln before inserting flasks to avoid condensation.

Ensure resin is completely cured before burnout, or it may leave residue.

Use an ash-free castable resin designed for lost-wax/resin casting.

Optional Fast Burnout (For Emergency Use Only – Not Recommended for High Detail)**

| Temp | Hold Time |

|---|---|

| 150°C → 350°C → 750°C | Ramp over 3 hours, hold at 750°C for 3 hours |

| Cool to 550°C for casting |

This should only be used when time is constrained, and detail loss is acceptable.

After Burnout:

Once cooled to the appropriate casting temperature, proceed to metal melting and casting (gold, silver, bronze, etc.).

2.4, Metal Melting & Casting: Gold, Silver, Copper

Purpose:

To pour molten metal into the investment mold cavity (created by burning out the resin model), resulting in a detailed jewelry piece in gold, silver, or copper.

Required Equipment & Materials:

Fully burnt-out investment mold (still hot, 500–550°C)

Induction melting furnace or torch/tilt furnace

Crucible (graphite or ceramic)

Casting metal:

Gold (Yellow/White/Rose)

Silver (Sterling or Fine)

Copper

Casting machine:

Vacuum casting machine

Centrifugal casting machine

Protective gear (gloves, shield, apron, tongs)

Step-by-Step Melting & Casting Process

1. Prepare the Mold for Casting

After burnout, let the flask cool to casting temperature (typically 500–550°C)

Do not let the flask reach room temp unless you’re doing cold mold casting (not typical for resin casting)

Keep the flask in the kiln at casting temperature until ready

2. Melt the Metal

| Metal | Melting Point |

|---|---|

| Gold (24K) | ~1064°C (1947°F) |

| Silver | ~961°C (1762°F) |

| Copper | ~1085°C (1985°F) |

Place the required amount of metal in the clean crucible

Use an induction furnace for speed and even melting

Add flux (borax or commercial metal flux) to prevent oxidation and improve flow

Stir gently if needed with a carbon rod for uniformity

3. Casting the Metal

Once molten and fluid, pour the metal into the flask using one of the two methods:

a) Vacuum Casting

Place the flask into the vacuum casting chamber

Engage the vacuum to draw the molten metal into the mold cavity

Ideal for high-detail parts and minimizing porosity

b) Centrifugal Casting

Load the mold and crucible into the spinning arm

Heat until the metal is fully molten

Release the arm; centrifugal force forces metal into the mold

Suitable for small to medium batch sizes

4. Cooling & Mold Breakout

Let the metal-filled mold cool for 30–60 minutes

Quench in water (optional based on investment type)

Carefully break the mold using water pressure or manual tools

Retrieve the raw metal cast jewelry tree

Post-Casting Steps (Overview):

Cut off the sprues

Surface filing and cleaning

Polishing and buffing

Electroplating (if required)

Stone setting (optional)

Tips for Better Casting Results:

Use fresh or high-quality recycled metal to avoid impurities

Preheat crucible to reduce thermal shock

Avoid over-melting the metal (risk of oxidation or evaporation)

Ensure proper ventilation and safety at all times

2.5, Post-Casting Finishing

1. Sprue Removal

Tool: Jeweler’s saw, rotary tool, or cutting disc

Cut off the casting sprues (branches from the casting tree) as close to the part as possible

Take care not to damage the surface of the piece

Leave a small nub for further grinding and smoothing

2. Surface Grinding & Filing

Tool: Needle files, carbide burrs, sanding wheels

Smooth the area where sprues were removed

Eliminate surface irregularities, visible layer lines (if any), or minor casting defects

Start with coarser abrasives and progress to finer ones

3. Pre-Polishing

Tool: Rubber wheels, sanding drums, or abrasive papers (400–1000 grit)

Refine the surface evenly to prepare for final polishing

At this stage, you aim to remove any scratches or texture from previous steps

4. Polishing

Tool: Buffing motor with polishing compounds (Tripoli, Rouge, etc.)

Use a two-step process:

Tripoli (brown compound) for cutting and smoothing

Rouge (red compound) for high-gloss finish

Apply gentle, even pressure to avoid losing sharp detail

5. Ultrasonic Cleaning (Optional)

Tool: Ultrasonic cleaner with jewelry solution

Removes polishing compound and micro-debris from crevices

Enhances cleanliness and sparkle, especially before plating or stone setting

6. Electroplating (Optional)

Use Case: Gold vermeil, rhodium finish, or anti-tarnish coating

Apply a thin layer of metal (e.g., rhodium over silver, gold flash plating over copper)

Enhances corrosion resistance, appearance, and skin compatibility

7. Stone Setting (Optional)

Tool: Prong pushers, burnishers, microscopes for fine detail

Set gemstones manually or with pneumatic tools

Secure stones based on design (prong, bezel, pavé, etc.)

8. Final Inspection & Packaging

Inspect the piece for symmetry, polish quality, and structural integrity

Clean fingerprints or polishing residue

Package in a box or display case for delivery or sale

Pro Tips:

Always wear a dust mask during polishing (metal dust is hazardous)

Use appropriate polishing compound for the metal type

Avoid polishing too hard on filigree or fine detail to prevent losing features

For high-volume production, consider using tumbling machines for initial polish

Summary:

Post-casting finishing turns a raw metal piece into a refined, high-value jewelry product, ready for customer presentation. Each step adds value—precision and care here reflect directly in the quality and price of the final piece.

Applications & Target Users: Who Is This For?

3.1, Small Jewelry Studios

For tiny jewellery studios looking to increase creative possibilities, save expenses, and simplify production, resin 3D printing has revolutionised the industry. In contrast to conventional wax carving, which requires a great deal of work and expert workmanship, 3D printing enables designers to precisely manufacture intricate, personalised items straight from digital CAD files. Detailed rings, earrings, pendants, and charms may now be made in-house by small studios without the need for outsourcing or mold-making. In addition to significantly reducing lead times, the ability to print castable resin models that are compatible with lost-wax casting allows craftsmen complete control over the whole process, from design to metal casting. Resin 3D printers enable independent jewellers and boutique studios to increase their creativity and efficiency, meet customer demands more quickly, and compete more successfully in the custom jewellery market because they reduce material waste, eliminate the need for costly tooling, and enable quick iteration or customisation of designs.

3.2, Custom Jewelry Brands

Resin 3D printing provides unparalleled design, speed, and personalisation flexibility for custom jewellery manufacturers, perfectly complementing the fundamental principles of customised crafting. Brands can now convert consumer concepts into high-resolution 3D printed models in a matter of hours rather than depending on antiquated hand-carved wax moulds, facilitating quicker prototyping, client approvals, and final manufacturing. Without the high expenses or constraints of mold-making, designers may create one-off pieces, intricate geometries, and ultra-fine details using castable resin, which is ideal for lost-wax casting. Resin 3D printing guarantees accuracy, consistency, and creative freedom whether creating personalised name necklaces, unique engagement rings, or limited-edition collections. While keeping control over quality and manufacturing schedules, it enables organisations to provide quick design iterations, adapt to changing trends, and create really one-of-a-kind items that tell distinct customer stories.

3.3, Educational Institutions (Jewelry Design Programs)

Resin 3D printing is an essential tool for educational institutions that provide jewellery design programmes because it connects traditional craftsmanship with contemporary digital production. Students may turn their CAD drawings into physical prototypes and have practical experience with technologies that are relevant to the business by including resin 3D printers into the curriculum. In addition to improving their comprehension of form, proportion, and utility, this method gets students ready for lost-wax casting and other real-world manufacturing processes. Students are able to accomplish the whole design-to-finish cycle by using castable resin to create intricate rings, pendants, and earrings that are appropriate for metal casting. In contrast to the years-long process of mastering conventional wax carving, 3D printing allows novices to rapidly envision and improve their works, encouraging confidence and inventiveness. Schools that have resin 3D printing provide students a competitive advantage as the jewellery industry continues to use digital technologies. This ensures that students graduate with the abilities necessary to innovate in both bespoke design and commercial production situations.

3.4, Craft Brands & Independent Designers

Resin 3D printing gives independent designers and handmade jewellery firms more creative freedom, manufacturing control, and market flexibility. Whether it’s a small-batch earring line, a personalised pendant, or a one-of-a-kind sculpture ring, designers may create complex, unique items straight from their digital designs without the need for extensive production infrastructure. Resin printers, particularly those that use castable resins, enable the production of intricate, casting-ready models that work in unison with conventional lost-wax techniques. This eliminates the time and expense limits associated with hand carving or mould fabrication, allowing designers to rapidly test, alter, and refine their designs. Craft companies may adapt more quickly to consumer input or design trends while maintaining complete control over quality and uniqueness by managing prototype and manufacturing in-house. Independent designers are able to grow at their own speed by producing distinctive, fine jewellery that expresses their own style and narrative, whether they want to sell online, at art fairs, or in boutiques.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited