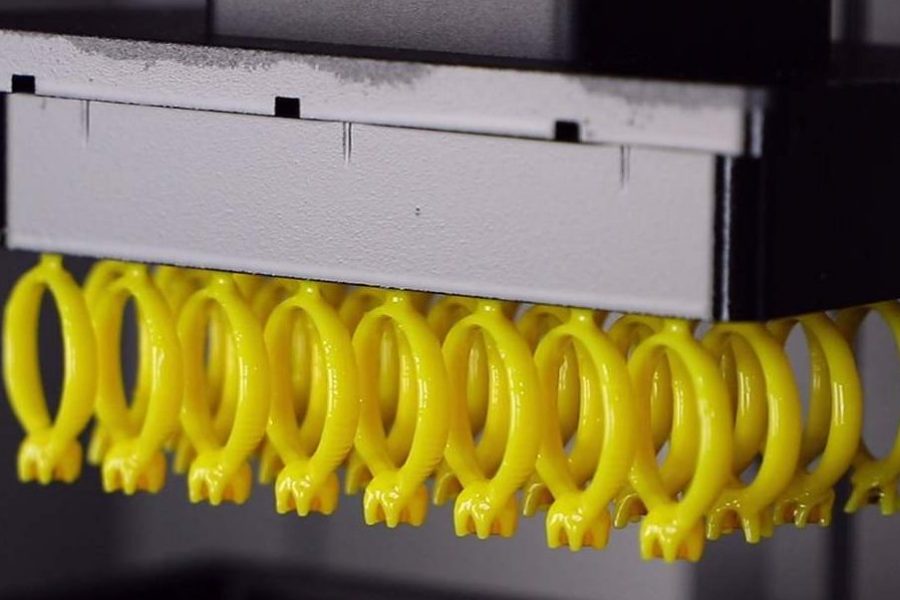

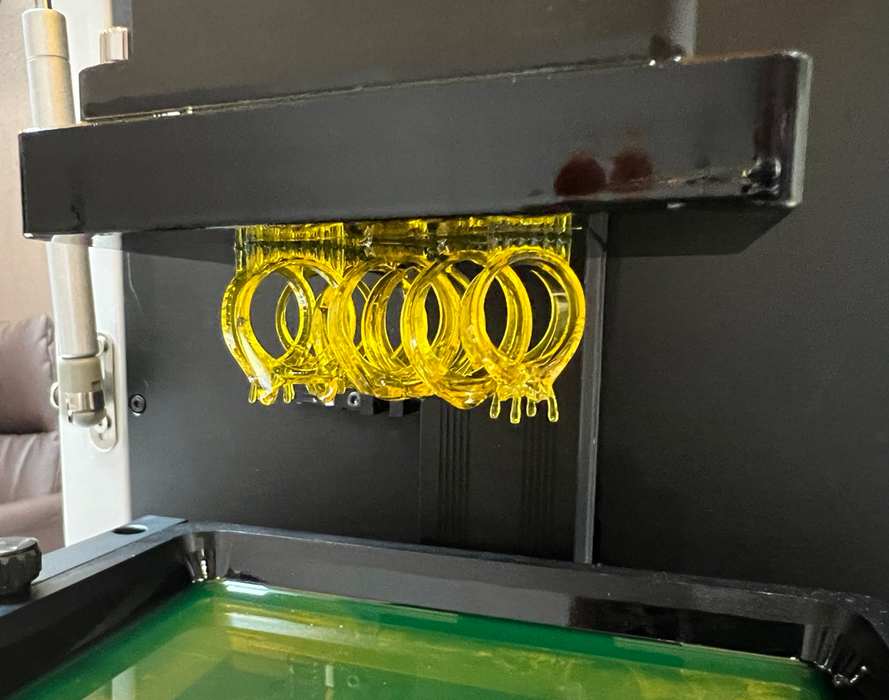

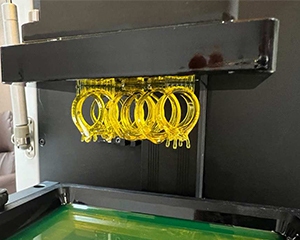

The complete production of a ring (gold, platinum or silver) needs to go through the process of starting design, making wax mold, burning wax, casting, polishing, etc. Superbmelt has developed high-tech equipment for each step to help jewelers shorten production time and improve production efficiency.

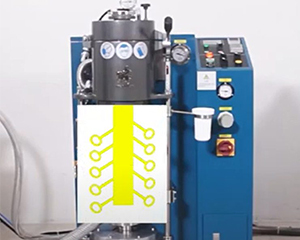

Many wedding rings on the market today are basically made of platinum, which has a high melting point and is almost impossible to achieve by hand.

The mini jewelry casting kit from our company can solve this problem,

It can be used to make 300g platinum and 150g silver,which is very practical for some studios engaged in high-end wedding ring customization.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited