Gold Jewelry Making Machine

China professional gold jewelry equipment supplier.

- One-stop solution for users' jewelry processing needs.

- Advanced equipment technology.

- User-friendly operation process.

- 24-hour after-sales service

Apply Our Best Quotation

To better manage the core business of precious metal jewelry manufacturing, SuperbMelt offers fully automated Gold Jewelry Making Machines that enable the mass production of complex jewelry, thereby improving production line efficiency.

We have established extensive collaborations with multiple domestic and international technology institutions. SuperbMelt’s technical team will carefully configure efficient and comprehensive system equipment for your jewelry store or jewelry manufacturing plant. We also provide the following main auxiliary facilities for jewelry making:

If you have additional requirements for your factory, please feel free to contact us at any time.

Main Auxiliary Facilities for Jewelry Manufacturing

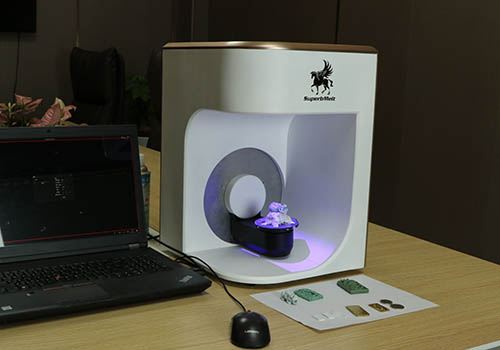

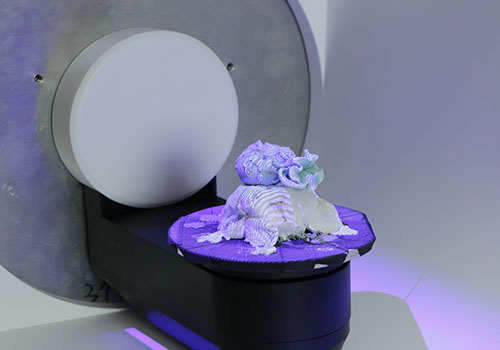

High Resolution Jewelry 3D Scanner

Superbmelt Jewelry 3D scanner is the perfect solution for anyone looking to capture high-precision data with ease. Our scanner records and stores beautiful 3D jewelry data, saving time in jewelry design, modification and production. By digitizing the jewelry industry with our cutting-edge technology, we can help promote innovation and upgrade the quality of jewelry products.

Parameter

- Scanspeed: ≤3s

- Scan accuracy: ≤0.01mm

- Single capturerange: 100X80X80mm

Coin Die

Coin dies are important stamping tools in the production of gold, silver, copper, zinc or other types of metal coins. Various customized logos, texts and shapes are embossed on coin dies which will in turn appear on both sides of the metal coins.

A coin die is a steel rod with a face that is the same size as the coins that it will be striking and for custom coin engraving. Two of these coin dies are needed to strike metal coins; one has the obverse (front) design while the other has the reverse (back) design.

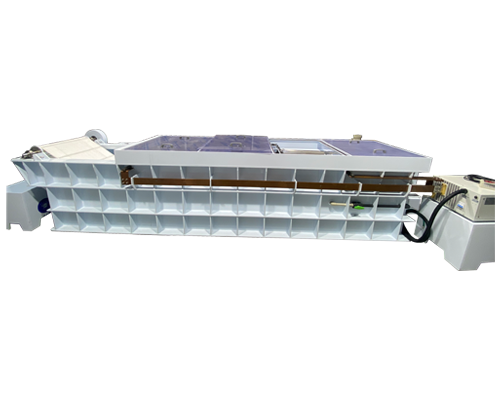

Jewelry Investment Mixer

SuperbMelt’s Jewelry Investment Mixer integrates vacuuming, powder mixing and powder injection, high automation and greatly increased efficiency. Compared with other complex processes of investment powder vacuuming machines, it is more simple and convenient, saving time and effort.

The mini powder mixer is compact and practical, the maximum capacity can reach 800g, and the size of the flask is 100x120mm. This equipment is more suitable for small and medium-sized jewelry manufacturing studios.

Parameter

- Applicable: Mix investment powder

- Flask chamber size : φ350*H300

- Max Capacity: 5 pcs of 4*10 inch flask

Silver Refining Electrolysis

SuperbMelt Silver Refining Electrolysis machine can refine and purify up to 100kg of silver in a single operation, achieving a purity level of typically over 99.99% by removing impurities.

Compared to traditional refining methods, the automated Silver Refining Electrolysis machine from SuperbMelt can accelerate the refining process, improve production efficiency, and consistently maintain purity levels above 99.99%, resulting in the production of high-purity silver and enhancing the quality and performance of the final products.

Parameter

- Capacity:300-500kg

- Production volume:24h*100kg silver

- Application: gold, silver, copper

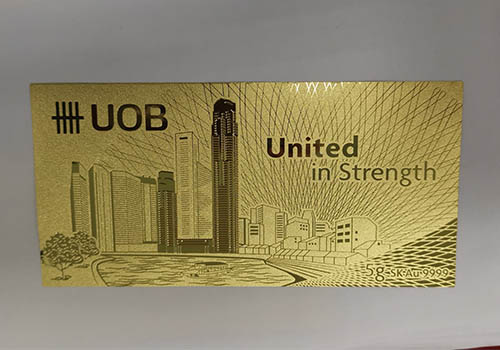

Printers That Print on Metal

SuperbMelt Printers That Print on Metal allows seamless coloring on various metal surfaces, suitable for applications such as coin processing, intricate gold bar coloring, and coloring of metal artworks.

- Features:Compared to traditional printing, it is more resistant to fading, corrosion, and oxidation.

- Compatibility: Besides metal coin printing, it can also print on various materials such as wood, glass, ceramic tiles, rubber, PVC, and acrylic.

- Contrast:Compared to traditional printing, SuperbMelt UV printers have a faster printing speed, capable of printing 4m² per hour, which increases production efficiency and reduces labor costs.

Parameter

- Printing Speed:4M²/H

- Printing Material Height: 150MM

- Printing Size: 1600*1200MM

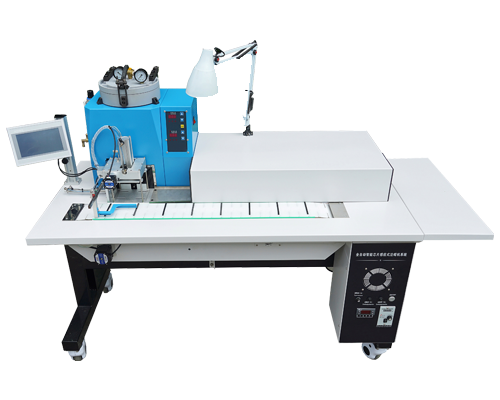

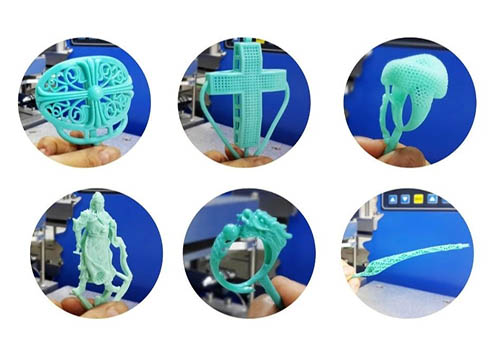

Automatic Wax Injector Machine

The automatic wax injector machine is used to make various types of jewelry wax molds, such as bracelets, rings, pendants, earrings, etc., also the mold of clocks and watches can be made.

It can be directly used to cast gold, silver, copper, platinum and other materials. As well as be made into a style that can be set with diamonds, and can be used with a wax setting machine to achieve rapid mass production.

Parameter

- Tamaño del molde(L*W*H):116*116*96mm

- Temperature Accuracy:±0.2℃

- Wax Precision:1%

Wax burnout oven

SupebMelt Is A Professional Manufacturer Of Wax Melting Machines, Focusing On Melting Wax Flowing In Plaster Molds. A Hollow Plaster Mold Is Obtained During Jewelry Casting.

Special Design For Secondary Combustion; Re-Collect The Incomplete Combustion During The Dewaxing Process, Let It Burn Again And Fully Burn It, And Reduce The Wax Smell In The Environment As Much As Possible.

Parameter

- Operation temperature: 850℃

- Power: 11.5kw (9kw+2.5kw)

- Capacity: 24 pcs of 4*9 inch flask

Tube Making Machine

The hollow tube forming machines from SuperbMelt are created to make it simple and effective for you to produce tubes of all different shapes and sizes. SuperbMelt hollow tube forming machines specialize in creating various metal hollow tubes, including hollow gold, silver, copper, and aluminum tubes.

Metal tubing may be produced using SuperbMelt’s tubing equipment for a variety of uses, such as manufacturing, construction, and jewelry. Our equipment is made to last, with long-lasting components and meticulous engineering to guarantee reliable results each and every time.

Parameter

- Diameter: 3.2mm (Personalized)

- Power: 4KW

- Efficiency :1000 – 2000mm/min

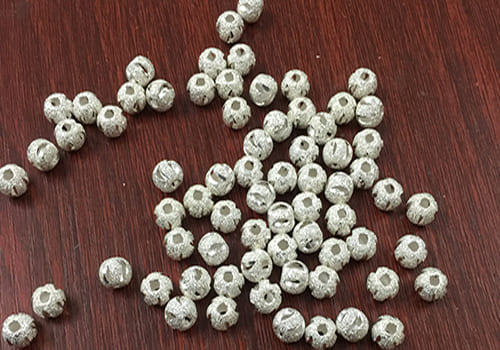

Hollow Ball Making Machine

Superbmelt hollow ball making machine is used for making different shapes of hollow balls. The hollow bead making machine performs an automatic ball making operation by making up to 2mm to 14mm size balls. The bead making machine transforms the flat sheet metal into different shapes of balls such as olive balls, abacus balls, tear-drop balls, special-shaped balls, and so on. The automated ball making machine produces 120 pieces of balls within a minute. Materials such as gold, karat gold, silver and copper can be used in the hollow ball making machine.

Parameter

- Hole size: 2mm: 0~0.8mm 6mm: 0~2.7mm

- Power: 2.2kw

- Application: Special for K gold

Ball Diamond Cutting Machine

Superbmelt ball diamond cutting machine is designed for cutting precious metals hollow balls get diamond shiny effect. The diamond cutting machine uses diamond technology that cuts the metal balls automatically using a 360-degree rotation. Superbmelt diamond cutting machine is able to cut ball sizes ranging from 2mm to 18mm. Metals like gold, silver and brass can be used for making jewellery balls by the ball cutting machine.

Parameter

- Spindle speed:7500r/min

- Processing specifications:Ø3.0- Ø10.0mm (round beads/olive)

- Work efficiency: 1-2 knives/S

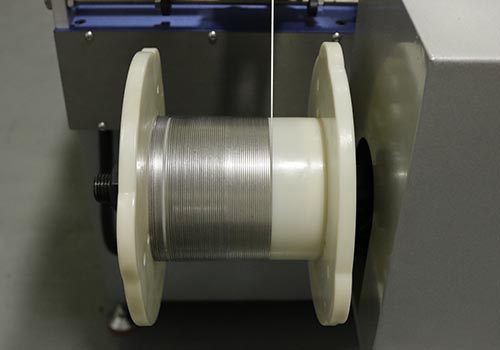

Wire Drawing Machine

The primary function of the wire drawing machine, also known as the gold wire machine, is to reduce the diameter and shape of a wire using a series of dies. It achieves this by passing the wire through consecutive dies, each with a smaller hole diameter than the previous one.

As the wire is pulled through the dies, it becomes longer and thinner, resulting in improved tensile strength and a smoother surface finish. The gold wire machine finds applications in various industries, including jewelry production, for working with different metals such as copper, gold, silver, and more.

Parameter

- Wire diameter range:2.2mm→0.2mm

- Drawing speed: 0-50 m/min

- Application: Au, Ag, Cu wire shrinkage

Dot Peen Marking Machine

SuperbMelt dot peen marking machine is software-controlled marking peen that moves according to a specific guide rail in the X, Y two-dimensional plane. The marking peen performs high-frequency impact motion under the action of electric power, thereby engraving a mark with a certain depth on your product surface.

Superbmelt desktop metal marking machine is integrated design, extremely stable and easy to use, a good engraving depth, high speed direct parts marking, marking result clear, support some uneven surface marking.

Parameter

- Marking Speed:40mm~50mm/s

- Usage:Metal machine for etching, marking, engraving – Stylus printer, dot peen header

- Marking Materials: Metal or nonmetals with hardness under HRC 60

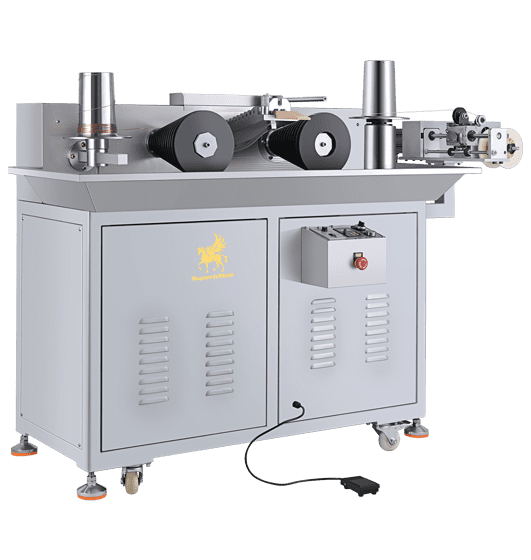

Coin Rimming Machine

The coin rimming machine is used for rolling the edges of various sizes of gold, silver, copper, platinum and other coin blanks before pressing coins. The machine forms an arc with a uniform diameter by extruding and rolling. The use of this step can well avoid the generation of gold coin edge capes and burrs, thereby saving subsequent processing steps and making the finished product smoother.

Parameter

- Molding speed :80-100 pcs/min adjustable

- Power:1.5Kw

- Mold diameter: Ф300mm

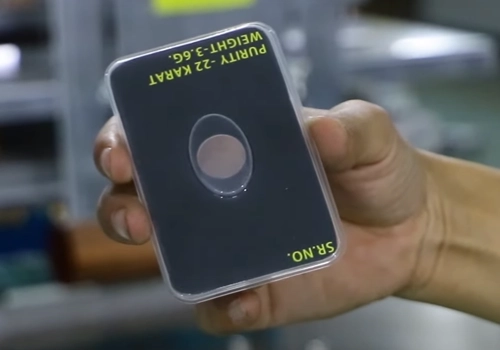

Gold Coin Packing Machine

Gold coin packaging is the last important process in the sale of gold coins and bars, and the gold coin packaging machine plays a big role in this link. It not only displays supplier information and product specifications clearly, but also prevents wear and tear during transportation.

In the production and processing industries such as gold, silver coins and bars, the protective panel of the machine can reduce the safety hazards of employees during operation. The fully automatic machine greatly increases the production and reduces labor input.

Parameter

- Oscillation Tube:7T69RB

- Electrode Stroke:150mm

- Electrode Size:250*350mm

Air Cooled Water Chiller

Under different cooling methods, the chiller can be divided into two types: air-cooled and water-cooled. The air-cooled chiller directly takes away the heat of the refrigerant through the forced air flow of the fan. The model is small and movable.

SuperbMelt’s air-cooled chiller is compact, easy to move, and the whole machine has been treated with anti-rust, easy to install and use. Connect to the equipment that needs cooling and start working directly.

Parameter

- Cooling capacity:8.99KW (7742kcal/h 50hz)

- Water tank capacity :40L

- Pump power:0.37KW

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Gold Jewelry Making Machine

What equipment do I need to make gold jewelry?

1. Melting and Casting Equipment

- Induction Melting Furnace: Melts gold at high temperatures for casting.

- Crucibles: Containers that can withstand high temperatures for melting gold.

- Casting Machine: Machines like a centrifugal or vacuum casting machine are used to pour molten gold into molds.

2. Rolling and Forming Equipment

- Rolling Mill: Reduces the thickness of metal sheets or wires to the desired dimensions.

- Wire Drawing Machine: Creates gold wire of specific thickness.

3. Molding and Shaping Equipment

- Jewelry Molds: Used for shaping molten gold into desired designs.

- Wax Injection Machine: For creating wax models for the lost-wax casting process.

- Press Machines: For stamping designs into gold sheets.

4. Cutting and Soldering Tools

- Jeweler’s Saw: For cutting metal into intricate shapes.

- Soldering Equipment: Torches, soldering blocks, and other tools for joining metal pieces.

5. Polishing and Finishing Equipment

- Polishing Machine: For smoothing and shining the jewelry pieces.

- Ultrasonic Cleaner: Removes dirt and polishing compounds from finished jewelry.

- Tumbling Machine: For polishing bulk items in a more automated process.

6. Engraving and Setting Tools

- Engraving Machine: For adding intricate designs and personalization.

- Stone Setting Tools: Tools like prong pushers and bezel rollers for setting gemstones.

7. Safety and Support Equipment

- Ventilation System: To safely remove fumes and dust from the workspace.

- Protective Gear: Gloves, safety glasses, and masks to protect against heat, chemicals, and metal shards.

8. Auxiliary Equipment

- XRF Analyzer: For analyzing and verifying the purity of gold.

- Hydraulic Press: For tasks like coin minting or stamping larger pieces.

How can I start my own gold jewelry business?

- 1. Surveys of markets

Determine Your Specialization: Decide whether you want to concentrate on personalized pieces, wedding bands, or expensive luxury pieces when it comes to gold jewelry. Look into consumer preferences and current trends.

Recognize Your Audience: Determine your target market by taking into account factors like age, gender, income, and purchasing patterns.

Examine the Competition: Examine the offerings, pricing policies, and product marketing tactics of competing jewelry companies.

- 2. Development of Business Plans

Describe Your Brand: Choose the goals, values, and purpose for your brand. Create a USP (unique selling proposition) that sets you apart from the competition.

Make a Business Strategy: Describe your target market, pricing strategy, budget, target market, and marketing approach. This strategy will direct your company’s activities and is essential if you want to apply for funding.

- 3. Lawful Points to Remember

Select an Organizational Structure: Choose whether your business will be run as a corporation, LLC, partnership, or sole proprietorship.

Acquire the Required Licenses and Permits: Make sure you possess all the permits needed to do business lawfully, such as a seller’s permission, business license, and, if relevant, a precious metals license.

Brand Your Brand: Register trademarks to safeguard your brand’s name and emblem.

- 4. Safe Finance

Personal Loans or Savings: Establish your capital requirements and look at finance sources including investors, bank loans, and personal savings.

Crowdfunding: If you’re making distinctive or avant-garde jewelry, think about using websites like Kickstarter.

- 5. Locating Equipment and Material Providers

Build ties with trustworthy vendors of gold, jewels, and other resources.

Tools: Invest in tools that are necessary for creating jewelry, such rolling mills, melting furnaces, casting machines, and polishing machines.

- 6. Choosing Between In-House and Outsourced Production

Make the decision to either create the jewelry yourself or contract with a manufacturer.

Quality Control: To guarantee consistency and high standards in your goods, put quality control procedures into place.

- 7. Establishing an Online Identity

Establish a Website: Create an online store including high-quality images of your jewelry, thorough product details, and an intuitive user experience.

Social media marketing: Showcase your goods, interact with consumers, and establish your brand on sites like Facebook, Pinterest, and Instagram.

Investing in search engine optimization (SEO) and online advertising may help you become more visible online.

- 8. Sales and Distribution Retail Channels

Choose whether you want to sell on the internet, via physical shops, or through both. Think about selling on independent websites like Etsy or Amazon.

Wholesale and Partnerships: Take into consideration going out to wholesale other shops with your jewelry or partnering with department stores and boutiques.

- 9. Promotion and Marketing

information marketing: To draw in new clients, produce information about gold jewelry, such as blog entries, tutorials, or films.

Email marketing: Create an email list to notify clients about events, specials, and new items.

Engagement in Trade Shows: Participate in jewelry exhibits and trade shows to meet specialists in the field and present your goods.

- 10. After-sale support and customer service

Allow Customization: To boost attractiveness, let buyers add their own touches to their jewelry.

Ensure quick and professional handling of customer questions and concerns to provide excellent customer service.

After-Sales Services: To foster enduring client connections, provide services including cleaning, resizing, and repairs.

- 11. Keep an eye on and adjust

Monitor Sales, Customer Satisfaction, and Marketing Effectiveness with Metrics to Track Performance.

Adapt to Changes: Remain adaptable and modify your plans in response to consumer input, market developments, and industry shifts.

What machine is used to make jewelry?

1. Centrifugal Casting Machine

- Purpose: Used for casting jewelry, especially in creating detailed designs by spinning molten metal into a mold through centrifugal force.

- Applications: Suitable for casting rings, pendants, and other intricate jewelry items.

2. Rolling Mill

- Purpose: A machine used to shape metal into sheets, wires, or other forms by passing it between rollers.

- Applications: Essential for making metal sheets and wires of specific thicknesses and shapes, which are then used to create various types of jewelry.

3. Laser Engraving Machine

- Purpose: Used for engraving intricate designs, logos, or text onto metal surfaces with high precision.

- Applications: Popular for personalizing jewelry pieces with names, dates, or patterns.

4. Hydraulic Press

- Purpose: Applies pressure to shape metal, form patterns, or set gemstones.

- Applications: Often used in coin making or to create textures and shapes in metal sheets.

5. Polishing Machine

- Purpose: Buffs and polishes jewelry to give it a shiny, finished appearance.

- Applications: Final step in jewelry making to enhance the visual appeal by removing scratches and imperfections.

6. Laser Welding Machine

- Purpose: Used for joining metal parts together with precision, often without needing soldering material.

- Applications: Ideal for repair work or assembling small, delicate jewelry pieces like rings and chains.

7. 3D Printer (Resin or Metal)

- Purpose: Creates detailed jewelry prototypes or direct metal printing for jewelry production.

- Applications: Used for creating custom designs, intricate patterns, and complex shapes that might be difficult to achieve with traditional methods.

8. Induction Melting Furnace

- Purpose: Melts metals such as gold, silver, or platinum for casting or refining purposes.

- Applications: Essential for preparing metal for casting or alloying in jewelry production.

What is the difference between handmade and machine made gold jewellery?

1. Production Process

- Handmade Gold Jewelry: Crafted by skilled artisans using traditional tools and techniques. Each piece is individually worked on, involving processes like hammering, soldering, and engraving by hand. This method is time-intensive and requires a high level of craftsmanship.

- Machine-Made Gold Jewelry: Produced using automated machines that can quickly create multiple pieces in a uniform manner. Techniques like casting, stamping, and CNC (Computer Numerical Control) machining are common, which allow for faster production and higher volumes.

2. Quality and Detail

- Handmade: Often offers superior quality in terms of craftsmanship and attention to detail. Artisans can work on intricate designs, make adjustments on the fly, and add unique touches that are difficult to replicate with machines.

- Machine-Made: Typically more uniform and consistent in appearance. However, intricate and delicate designs may not be as detailed as those crafted by hand. Machine-made pieces might lack the personal touch found in handmade items.

3. Uniqueness and Customization

- Handmade: Each piece is unique, with slight variations that reflect the artisan’s individual style and skill. This uniqueness adds to the charm and value of handmade jewelry. Customization is also easier, allowing for personalized designs based on customer preferences.

- Machine-Made: Mass-produced and identical in design, making it difficult to distinguish one piece from another. Customization options are limited to predefined templates, though advancements in technology are allowing for more customization possibilities.

4. Cost

- Handmade: Generally more expensive due to the time, effort, and skill required to produce each piece. The cost also reflects the artistry and uniqueness of the jewelry.

- Machine-Made: Usually more affordable because of the efficiency and speed of production. The economies of scale in mass production allow for lower costs per piece.

5. Durability

- Handmade: Tends to be more durable because artisans can ensure the integrity of each piece, paying close attention to joints and settings.

- Machine-Made: While still durable, machine-made jewelry might have weaker points where mass production compromises on precision and quality control.

6. Market Perception

- Handmade: Often seen as more valuable and prestigious, especially when crafted by well-known artisans or designers. It’s associated with luxury and exclusivity.

- Machine-Made: Viewed as more practical and accessible, catering to a broader market due to its affordability and availability.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited