Sheet Metal Slitting Machine

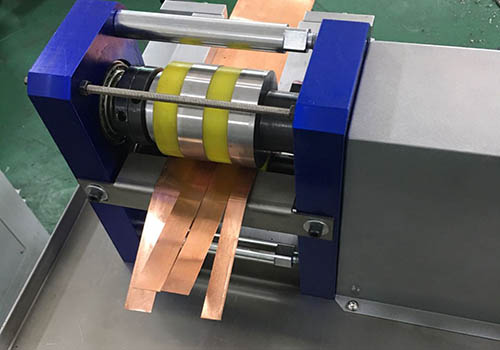

SuperbMelt slitting machine cuts metal sheets of gold, silver, platinum, and other metals into strips for convenient subsequent processing, casting into rings, bracelets, necklaces, and more.

Sheet Metal Slitting Machine is used to cut metal sheets into narrower strips to meet the processing needs of various crafts in the jewelry industry, including rings, earrings, necklaces, bracelets, and jewelry accessories.

The SuperbMelt Sheet Metal Slitting Machine can cut metal sheets of gold, silver, platinum, rhodium, copper, etc., into strip products within one minute. It has a length range of 1-25m, thickness of 0.1-1.3mm, and width of 3-200mm.

SuperbMelt offers three different models of the slitting machine, including the basic model and those with features like edge alignment and winding functions, catering to the diverse production needs of jewelry businesses.

Sheet Metal Slitting Machine

| Model number | SPB-SCM | SPB-SCM-C | SPB-SCM-P | SPB-SCM-W |

| Photo |  |  |  |  |

| Power source | Single phase 220V, 50Hz | Single phase 220V, 50Hz | Three phase 220V, 50Hz | Three phase 220V, 50Hz |

| Power | 1.1 kw | 2.2 kw | 1.1 kw | 1.1 kw |

| Applicable metal | Gold, gold, silver, copper, platinum and their alloys | Gold, gold, silver, copper, platinum and their alloys | Gold, gold, silver, copper, platinum and their alloys | Gold, gold, silver, copper, platinum and their alloys |

| Slitting speed | 0-20 meters per minute (variable frequency speed regulation) | 0-20 meters per minute (variable frequency speed regulation) | 0-20 meters per minute | 0-20 meters per minute |

| Slitting precision | 0.001mm | 0.001mm | 0.001mm | 0.001mm |

| Slitting width | 2-100mm | 2-200mm | 2-100mm | 2-100mm |

| Slitting thickness | 0.05-0.6mm | 0.05-0.6mm | 0.05-0.6mm | 0.05-0.6mm |

| Dimension | 1200x600x1200mm | 2100*900*1230mm | 1200*600*1200mm | 1420*1030*1300mm |

| Weight | 150KG | 420 kg | 150 kg | 350kg |

| Features | * | With correction function | With pallet function | With winding function |

- High Efficiency: Simultaneously slits multiple metal strips, ensuring swift and efficient production.

- High Precision: Achieves precise cutting with a tolerance of within ±0.02mm, guaranteeing uniform width without burrs or loss.

- Durable Blades: Equipped with high-hardness blades that are sharp and long-lasting, with no material jamming issues.

- Automatic Metering: Provides real-time length display and customizable length settings for accurate cutting.

- Easy Blade Replacement: Simplifies the process of blade replacement, ensuring quick and hassle-free maintenance.

- User-Friendly Operation: Features intuitive interface design for easy and straightforward operation.

- Edge Alignment : Pre-aligns the material before feeding to prevent material deviation, ensuring accurate cutting.

- Coil Collecting Device : Incorporates a coil collecting device with high sensitivity and constant force mechanism to prevent coil breakage and facilitate waste collection.

- Tension Control: Maintains constant tension during coil winding, minimizing material breakage and ensuring smooth operation.

- Jewelry Manufacturing: Used to efficiently and precisely cut metal strips for the creation of rings, earrings, necklaces, bracelets, and other jewelry components.

- Metalworking Industry: Used to cut metal strips to the appropriate widths for further forming, shaping, or assembling in metal production operations.

- Craftsmanship: Used to make metal parts or accents for sculptures, decorations, art pieces, and other products.

- Industrial Production: Used in a variety of industrial industries to cut metal strips to precise measurements needed for producing parts, components, or finished goods.

- Automotive & Aerospace: Used to ensure precision and consistency in manufacturing processes while producing metal parts or components for automotive and aerospace applications.

- Cutting metal strips for circuit boards, connections, and other electronic components is one of the jobs done by employees in the electronics manufacturing sector.

- Architectural Design: This process creates metal strips for use as architectural accents, trims, or structural components in buildings and other structures.

- Medical Device Manufacturing: This technique is used to ensure accuracy and high quality in manufacturing operations when producing metal parts or components for use in medical devices, instruments, or equipment.

Cutting multiple gold strips simultaneously reduces costs, with built-in correction function to prevent material deviation before feeding.

Equipped with coiling device, high-sensitivity constant force mechanism ensures continuous coiling without breakage, featuring scrap material collection for edge trimming.

Straight material placement with the addition of a support plate ensures straight and non-deviated material discharge.

Why SuperbMelt Sheet Metal Slitting Machine

Any Question About SuperbMelt Sheet Metal Slitting Machine

About SuperbMelt Sheet Metal Slitting Machine Guide

What is a Slitting Machine

An industrial piece of machinery called a slitting machine is used to cut broad rolls or sheets of material into thinner strips. It is frequently used to treat materials including metal, plastic, paper, textiles, and more in a variety of industries. The material is fed through a series of rotating blades or knives in the machine, which slice it into the required thickness or breadth. Because of its adaptability, slitting machines may be made to fit a variety of materials and cutting needs. They are essential to the manufacturing process because they make it easier to produce smaller, more manageable strips that may be used in final products or for additional processing.

1.1, Types of Slitting Machines

Using revolving circular blades, a rotary slitter may cut materials into thinner strips. It works well with a wide range of materials, including metal, plastic, and paper.

Razor Slitter: Equipped with precisely sharp blades that slice through materials. It is frequently used to thin, fragile materials, such as foils and films.

Crush Cut Slitter: Slicing materials involves combining crushing and cutting. It works well with heavier materials like fabrics and rubber.

Shear Slitter: This tool makes accurate, clean slices in materials using shear blades. It is frequently used on metals and robust materials.

Score Slitter: Makes score lines on fabrics so that they may be folded or torn easier. Paper and cardboard are frequently used with it.

1.2, Slitting Machines Offered by SuperbMelt

1.Multi-channel slitting machine with coiling

High efficiency, capable of simultaneously slitting multiple metal strips.

High precision, with smooth cutting edges, no burrs, and no material loss.

High-hardness blades, sharp and durable, with blade cushioning to prevent material jamming.

Equipped with a coiling device, featuring a high-sensitivity constant force mechanism to ensure continuous coiling without interruption, and with scrap collection for edge materials.

Automatic meter counting, real-time display of length, and customizable length settings.

Intuitive interface design for easy and user-friendly operation.

- Slitting speed: 0-20 meters per minute

- Applicable metals: Gold, K gold, Silver, Copper, Platinum, and their alloys

- Slitting precision: 0.001mm

- Slitting width: 2-100mm

- Slitting thickness: 0.05-0.6mm

2.Multi-channel slitting machine with edge alignment

Edge alignment function, pre-alignment before feeding to prevent material deviation;

High efficiency, capable of simultaneous slitting of multiple metal strips;

High precision, finished width tolerance within ±0.02mm;

High-hardness blades, sharp and durable, cushioned to prevent material jamming;

Automatic metering, real-time display of length and customizable settings;

Expandable mandrel for coil winding, adjustable tension for convenient material handling;

Constant tension control ensures uniform winding force, preventing material breakage.

Slitting speed: 0-20 meters per minute (variable frequency speed regulation)

- Applicable metals: Gold, K gold, Silver, Copper, Platinum, and their alloys

- Slitting precision: 0.001mm

- Slitting width: 2-200mm

- Slitting thickness: 0.05-0.6mm

3.Multi-channel slitting machine with support plate

Straight material feeding, high efficiency

High precision, high hardness, capable of simultaneous slitting of multiple metal strips

Newly added support plate ensures straight material feeding without deviation

Automatic metering, easy blade replacement

- Slitting speed: 0-20 meters per minute

- Applicable metals: Gold, K gold, Silver, Copper, Platinum, and their alloys

- Slitting precision: 0.001mm

- Slitting width: 2-100mm

- Slitting thickness: 0.05-0.6mm

Applications of Slitting Machines in Various Industries

Because of their adaptability and ability to cut precisely, slitting machines are essential to many different sectors around the globe. These machines are widely utilized in several industries such as packaging, textiles, printing, metallurgy, electronics, converting, automotive, and medical. They effectively process materials into thinner rolls or strips to satisfy industry standards. Slitting machines are essential for increasing productivity and guaranteeing the quality of final products in a variety of applications, including processing medical tapes in the healthcare sector, cutting metal coils in manufacturing, and converting big rolls of paper in the printing industry.

2.1, Jewelry Industry

Slitting machines are crucial in the jewelry business because they cut metal sheets into thin coils or strips that are then used to make a variety of jewelry pieces, including necklaces, bracelets, earrings, and rings. The stringent design specifications of jewelry producers are satisfied by these machines, which guarantee precise cutting of metal materials such as gold, silver, platinum, and alloys. Slitting machines make manufacturing processes more effective by precisely cutting metal sheets into the required dimensions. This allows jewelry makers to produce magnificent items with fine finishes and detailed detailing.

2.2, Medical Device Industry

Slitting machines are essential to the medical device industry’s manufacturing process because they accurately cut metal sheets into coils or narrow strips. These strips are used to make a variety of medical equipment and gadgets, including implants, surgical instruments, and diagnostic tools. Slitting machines suit the exacting quality and dimensional standards of medical device makers by ensuring accurate and consistent cutting of metal materials such as titanium, stainless steel, and other alloys. Slitting machines facilitate the efficient manufacturing of precise metal components, which is crucial for the creation of safe, dependable, and superior medical equipment used in healthcare applications.

2.3, PHandicrafts Industry

Slitting machines are used in the handicrafts sector to accurately cut metal sheets into thin strips or coils, meeting the various requirements of craftsmen and artists. These metal strips are vital building blocks for the intricate metalwork patterns, ornamental components, and decorative elements used in a variety of handcrafted goods, including decorations, sculptures, and artwork. With the use of slitting machines, craftspeople may quickly and precisely shape and size metal materials such as copper, brass, and aluminum into desired forms and sizes, resulting in the creation of superior handcrafted goods. Slitting machines improve the artistry and inventiveness of craftspeople by providing diversity and accuracy in metal processing, which helps to produce beautiful and aesthetically pleasing handcrafted goods.

Conclusion

SuperbMelt Sheet Metal Slitting Machine Guide Conclusion

In conclusion, the SuperbMelt Sheet Metal Slitting Machine stands out as a versatile and efficient tool for various industries, particularly in jewelry manufacturing, metalworking, craftsmanship, industrial production, automotive, aerospace, electronics, architectural design, and medical device manufacturing. With its high efficiency, precision cutting capabilities, durable blades, automatic metering, easy blade replacement, user-friendly operation, edge alignment feature, coil collecting device, and tension control, this machine caters to a wide range of production needs.

Whether it’s for creating intricate jewelry components, shaping metal strips for industrial applications, crafting decorative pieces, or manufacturing precise parts for medical devices, the SuperbMelt Sheet Metal Slitting Machine offers a reliable solution for achieving accurate and consistent results. By following proper maintenance practices, troubleshooting common issues, and utilizing the machine’s features effectively, businesses can enhance their productivity, quality, and efficiency in metal processing operations.

With its multiple models tailored to different requirements and applications, the SuperbMelt Sheet Metal Slitting Machine provides a comprehensive solution for cutting metal sheets into precise strips, making it an indispensable asset for businesses seeking to streamline their metal processing operations and achieve superior results in their respective industries.

FAQ Guide of Sheet Metal Slitting Machine

- 1. What is a sheet metal slitter?

- 2. How does a slitting machine work?

- 3. What are the different types of slitting?

- 4. What is the difference between slitting and cutting?

- 5. What types of sheet metal materials can be processed with a Slitting Machine?

- 6. What are the advantages of using a Sheet Metal Slitting Machine?

- 7. How precise is the cutting accuracy of a Sheet Metal Slitting Machine?

- 8. How can I maintain and troubleshoot common issues with a Sheet Metal Slitting Machine?

1. What is a sheet metal slitter?

Sheet metal slitters are essential tools in metalworking. They are designed to cut thin sheet metal into narrower strips with precision. The machine’s adjustable circular blades allow for cuts of varying widths, catering to the specific needs of different industries and applications.

Function: Cuts thin sheet metal into strips

Components: Multiple circular blades

Adjustability: Blades can be adjusted for precise cuts

Industry Use: Various applications requiring specific strip sizes

2. How does a slitting machine work?

A slitting machine is essential in the manufacturing industry for cutting materials into narrower strips. Here’s how it functions:

Material Feeding: A continuous sheet of material is fed into the machine.

Cutting Action: Rotating circular blades make longitudinal cuts.

Adjustable Blades: The positions of the blades are adjustable to set the strip width.

Rewinding/Stacking: After cutting, the machine rewinds or stacks the strips.

Applications: Used for metal, paper, plastic, or fabric.

3. What are the different types of slitting?

Types of Slitting Techniques

Different slitting techniques are employed in the industry to cut materials with precision and care. Each technique has its unique application and is suited for specific types of materials.

Razor Slitting: For precise cutting with sharp, circular blades or razors.

Shear Slitting: Uses two rotary knives, ideal for paper, plastic, or metal.

Crush Cutting: Combines a hardened anvil roll with a rubber-covered blade, suitable for foam or rubber.

Score Slitting: Makes a partial cut for easy tearing, often used in packaging.

Razor Blade Slitting: Involves razor blades for sharpness and precision across various materials.

Log Slitting: Transforms large rolls into narrower ones, prevalent in paper and converting industries.

4. What is the difference between slitting and cutting?

Slitting vs. Cutting

Slitting and cutting are two processes used in material fabrication. While they share similarities, they serve different purposes and involve distinct techniques.

Slitting:

Involves cutting material into long strips or narrow pieces.

Typically done along the length of the material.

Used for preparing materials in roll form for further processing.

Cutting:

A more general term for dividing material.

Can result in various shapes and sizes.

Encompasses different methods like shearing, laser cutting, and waterjet cutting.

5. What types of sheet metal materials can be processed with a Slitting Machine?

Gold, silver, copper, gold, platinum, rhodium

6. What are the advantages of using a Sheet Metal Slitting Machine?

Efficient and precise cutting of materials into strips

High production speeds for increased throughput

Reduced material waste, contributing to cost savings

Capability to handle a variety of sheet metal thicknesses and widths

7. How precise is the cutting accuracy of a Sheet Metal Slitting Machine?

Sheet metal slitting machines typically cut with high accuracy, with the level of accuracy depending on the machine’s design and settings. SuperbMelt machines can achieve tight tolerances for consistent strip widths.

8. How can I maintain and troubleshoot common issues with a Sheet Metal Slitting Machine?

Regular Cleaning: Keep the machine parts free of debris and dust.

Lubrication: Apply lubricant to moving parts to reduce friction.

Blade Alignment: Check and adjust the blades to prevent uneven cuts.

Wear and Tear Inspection: Look for signs of damage or deterioration.

Tension Settings Monitoring: Ensure the tension is set correctly for the material being slit.

Sound and Vibration Checks: Be alert to changes in machine noises or vibrations.

If these steps do not resolve the issues, further action may be required:

Professional Assistance: Contact a qualified technician if the problem is beyond basic maintenance.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited