Automatic Rolling Mill

SuperbMelt is a professional manufacturer of precious metal sheets and strips.

SuperbMelt Automatic Rolling Mill is a large-scale jewelry rolling mill that provides a wider pressure shaft and wider capacity for metal products.

Designed with high power, this Automatic Rolling Mill is suitable for manufacturers requiring wider sheet metal products, capable of rolling metal to thicknesses ranging from 5 to 0.2 centimeters in a single pass.

Featuring simplified operation, automatic oil supply, and high durability of the press shaft with zero loss, this equipment is a crucial asset for gold and silver jewelry manufacturers to enhance work efficiency and creative design.

| Model number | SPB-YP50P |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 37.5 kw |

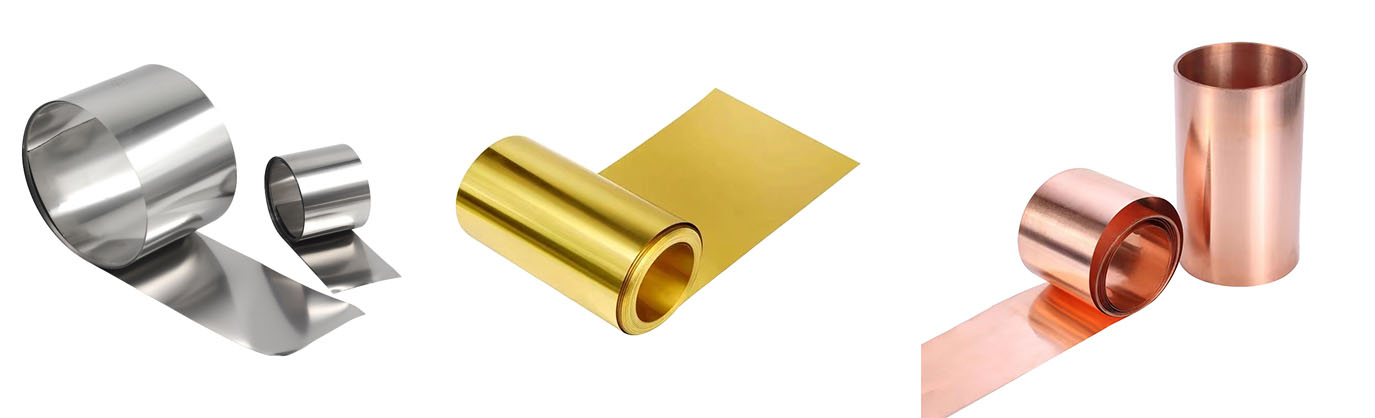

| Applicable metal | Gold, Silver, Platinum, Palladium, and their alloys |

| Sheet Thickness | 5-0.2cm |

| Pressing width | Within 40cm |

| Rolling mill dimensions | (D*L)250*500mm |

| Rotation Speed | 0-15 rpm adjustable speed |

| Dimension | 3200*1650*1900mm |

| Weight | 68000KG |

| Air switch | 63A or above |

- High Efficiency and Precision: This rolling mill’s powerful construction enables it to flatten metals to exact thicknesses of between 5 and 0.2 cm in a single pass, which makes it ideal for the production of high-precision jewelry.

- Automatic Lubrication System: This system ensures smooth and effective rolling operations while reducing wear and maintenance requirements. It also extends the equipment’s lifespan.

- High Hardness Pressure Shaft: This mill’s high-hardness pressure shaft ensures both the mill’s longevity and the quality of the metal processing by withstanding increased operating pressures.

- Zero Loss Technology: This rolling mill maximizes material utilization and lowers costs by achieving zero material loss during metal processing through optimized design and production processes.

- Versatility: It can process other metal materials in addition to precious metals including gold, silver, and platinum, meeting a range of jewelry-making requirements.

- Operational Simplicity: The machine’s straightforward control interface, which is easy for operators to learn and operate, contributes to its user-friendly design and increased productivity.

- High Safety: The design of the equipment places a high premium on safety, protecting users while they work and lowering the possibility of workplace accidents.

Making Jewelry:

Metal Sheet Production: Produces thin sheets of platinum, silver, and other precious metals that are used as the base for jewelry such as necklaces, earrings, and rings.

Metal Wire Making: This process creates exquisite metal wires that can be used in jewelry designs, such as necklaces and bracelets, or for weaving.

Texture and Pattern Creation: Adds distinctive patterns and textures to metal surfaces to improve the jewelry’s appearance and individuality.

Crafts and the Arts:

Metal sheets and wires are used in the creation of decorative artworks, such as decorative panels and metal paintings.

Custom Metal Crafts: Tailors distinctively shaped metal crafts to the specifications of clients or designers.

Industrial Uses:

Metal Component Processing: This technique is used to create precise metal components in more general manufacturing industries like electronics and automobile parts.

Metal prototypes are created for new product development, enabling speedy design and functionality validation.

Instruction and Practice:

Teaching and Experiments: Used in educational settings to give students practical experience while teaching them the fundamentals of jewelry design and metalworking.

Repair and Replenishment:

Restoration of antique or traditional jewelry involves fixing and recreating it to return it to its original form and functionality.

Why SuperbMelt Automatic Rolling Mill

Any Question About SuperbMelt Goldsmith Rolling Mill

1. How does a rolling mill work?

A rolling mill is a type of industrial machine used mostly for shaping and decreasing the thickness of metal stock. This is achieved by using revolving cylindrical rollers that are placed in different ways based on the particular needs of the task. The metal experiences elongation, compression, and occasionally texturing as it travels through these massive rolls. Rolling mills are essential in the manufacturing, automotive, and aerospace industries for producing everything from sheet metal to complex components with uniform properties and precise dimensions. This is because adjustments to the distance between the rolls allow for precise control over the final thickness and width of the metal.

2. What is a Jewellery rolling mill?

A jewelry rolling mill is a specialized tool used in the jewelry-making process to modify the dimensions and form of metal components. Scaled down to suit jewelers’ demands, it runs on the same mechanical principles as industrial rolling mills.

Rolling mills for jewelry are necessary in any locati0n where jewelry is made because they can turn metal into structural, decorative, or functional elements for stunning, elaborate jewelry. They improve the quality of the final result as well as the creative process by enabling jewelers to fully customize metal work.

3. What products are produced on a rolling mill?

Material Efficiency:

By converting bulk metal into forms and proportions that are useful, rolling mills drastically minimize material waste. By maximizing material consumption, this procedure lowers the cost of production.

Production of a Wide Range of Materials: Rolling mills are adaptable devices that can handle a variety of metals, including non-ferrous materials like brass, copper, and aluminum as well as ferrous materials like steel and iron. Because of its adaptability, a wide range of metal products utilized in various industries can be produced.

Improved Material characteristics:

Rolling mills can improve the mechanical characteristics of metals by rolling them hot or cold. For example, by introducing flaws into the crystal structure of the metal, cold rolling improves surface finish and dimensional accuracy while simultaneously increasing the metal’s strength and hardness. In order to shape larger parts and achieve better ductility, hot rolling is necessary.

Scalability and Mass Production:

Systems for mass production require rolling mills. Compared to conventional forming techniques, they can create vast quantities of metal items with consistent thickness and width more quickly. For businesses like packing, construction, and the automotive industry—which have tremendous demand—this efficiency is essential.

Customization:

For unique uses, modern rolling mills can be set to produce particular shapes, thicknesses, and surfaces. This includes designing distinctive profiles for complicated jewelry designs, automobile components, and building beams.

Energy Efficiency:

Rolling uses less energy than other metal forming processes like as forging or casting, especially when continuous rolling techniques are applied. This lessens the negative effects of metal production on the environment while simultaneously lowering operating expenses.

Infrastructure Development:

The building sector depends heavily on the steel rebar, beams, and sheets that rolling mills manufacture. They supply the elements required to construct infrastructure, including skyscrapers, railroads, bridges, and highways.

4. What are the characteristics of a rolling mill?

Using a variety of configurations, such as several rolls and computerized control systems, rolling mills precisely reduce the thickness of metal, modify its shape, and improve its qualities. They are vital, sophisticated industrial tools that play a significant role in the metalworking industry. Due to their versatility and adaptability, these machines can process a wide range of metals into a variety of shapes and sizes, from thin sheets to intricate profiles, meeting a wide range of production needs in sectors including jewelry making, construction, and the automotive industry.

5. What are the differences between manual rolling mills and electric rolling mills?

1. Mode of Operation

Manual rolling mills: In order to move the rollers, the operator must physically turn a handle. This approach works well in situations where large-scale, continuous production is not required. Although it requires the operator to exert physical effort, it also gives them more control over the pressure and pace of the processing.

Electric Rolling Mills: These mills operate more quickly and easily by using an electric motor to drive the rollers. Electric mills greatly increase production efficiency and are ideal for processing thicker, tougher metals or for continuous manufacturing.

2. Efficiency of Production

Manual rolling mills: These mills are less efficient since they rely heavily on human labor, but they are more adaptable for small batches or customized projects. As a result, production pace is relatively slow.

Electric rolling mills: These are perfect for large-scale production settings since they can handle materials far more quickly than manual mills.

3. Utilization Cost

Manual rolling mills: These are typically less expensive, don’t need extra energy, and have fewer running and maintenance expenses.

Electric rolling mills: Due to their great productivity and efficiency, these machines may end up being more economical in the long run, even though their initial setup and purchase prices may be higher.

4. User Control Manual Rolling Mills: Provide extremely precise control, enabling users to assess the metal pressing procedure through their sense of touch and familiarity—a crucial skill in fine craftsmanship.

Electric rolling mills: Although simpler to operate, certain types could not have the same level of precision as manual mills. On the other hand, many contemporary electric mills are equipped with sophisticated control systems that enable accurate adjustments and pressing process monitoring.

5. Physical Labor Intensity: Manual rolling mills need more work and can wear you out over time.

Electric rolling mills: Lessen manual labor, which eases operation’s difficulty and physical strain.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited