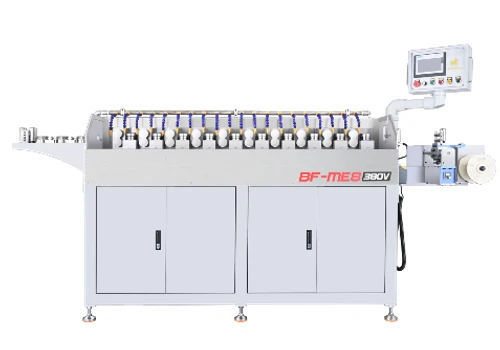

Gold Wire Rolling Machine

Professional Precious Metal Jewellery Rolling Mill Supplier in China

Gold wire rolling machine is used in the production of various metal wires in the jewelry industry, such as gold, silver, copper and other chains, and is also an important processing process for wires in the electronics industry.

SuperbMelt jewelry wire roller are available on request from 5.5p to 30p. Adopt automatic lubrication system, automatic winding and unwinding, one-time molding and other technologies to achieve high automatic operation, improve production efficiency and realize mass production.

Our equipment is thick and heavy, and the important parts are all imported brands, which ensures the smooth operation of the wire cold rolling machine and prolongs the life of the machine.

Clere here to see more Jewelry Rolling Mill Machine with different Horsepower

Gold Rolling Machine Parameters

| Model number | SPB-YX-7.5P-S250 | SPB-YX-7.5P-S200 | SPB-2YXP-10P | SPB-20WDM |

| Photo | |  |  | |

| Type | 7.5P Wire Rolling Machine | 7.5P Winding Wire Rolling Machine | 10P Double-head Rolling Machine | Continuous Wire Rolling machine |

| Power source(V) | 380 | 380 | 380 | 380 |

| Power(kw) | 5.5 | 5.5 | 7.5 | 11 |

| Roller Size(D*L mm) | 120*250 | 120*200 | 120*200 | Tungsten Steel 110*80 |

| Max Thickness(mm) | 11 | 11 | 11 | 7 |

| Revolving Speed(rpm) | 22 | 22 | 0-22 double speed | 0-75(Adjustable) |

| Lubricating System | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply | Automatic Lubricating Oil Supply |

| Wire Rolling Size(mm) | 14-0.8mm(Customized) | 14-0.8mm | 14-0.8mm (Customized) | 6-1.1mm |

| Max Rolling Width | 50 | 100 | 50 | 60 |

| Dimensions(mm) | 520*620*1470 | 520*620*1470 | 980*650*1450 | 3300*830*1800 |

| Weight(kg) | 480 | 480 | 980 | 2200 |

Customizable Rollers

The roller can be customized into a specific shape and size according to the customer’s finished product requirements, which is more flexible in use and helpful for the creation of personalized products.

Automatic Lubrication System

The machine is equipped with an oil pump, which can realize automatic oil supply without manual oiling, making the work more efficient and more humane.

High Hardness Roll

The machine adopts HC63-HC65 hardness rollers, which are very hard and suitable for pressing most precious metals. The finished product is pressed and more secure.

Low Loss

The rollers of the gold wire rolling machine are smooth, and the grooves are grooved according to precise data, thus greatly reducing the loss rate of finished products.

Good Finished Product

The finished product is smooth, the diameter can be uniform, and the precision is as high as 0.1mm

Easy to Use

The control panel is simple and concise, and it is easy to operate. Some machines are equipped with PLC intelligent control, and it can be operated easily after setting parameters.

A gold wire rolling machine is a piece of equipment used in the production of gold wires. It is used to compress and reduce the diameter of gold rods or wires through a series of rolling processes. The machine uses a series of rollers, which gradually decrease the diameter of the wire, while increasing its length.

The application of a gold wire rolling machine is primarily in the jewelry industry, where gold wires are used for a variety of purposes, including the creation of intricate designs, chain making, and as a decorative element in jewelry pieces. The machine is also used in the electronics industry to produce fine gold wires for use in bonding electronic components.

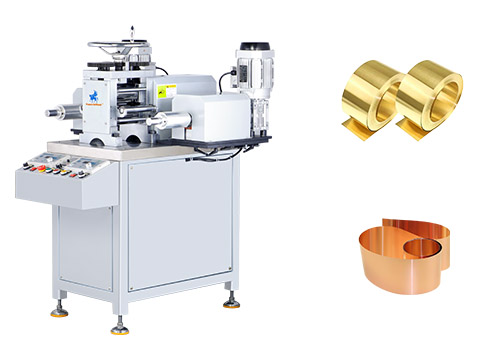

In addition to gold, wire rolling machines can be used to produce wires of other precious metals, such as silver and platinum. The resulting wires can be used in a range of applications, from jewelry making to industrial manufacturing.

Why SuperbMelt Gold Wire Rolling Machine

Any Question About SuperbMelt Gold Wire Rolling Machine

Here's What Our Satisfied Customers Have to Say

SuperbMelt Gold Laser Engraving Machine FAQ

Square, round/hexagonal, etc. Square is the most commonly used, because the finished line of pressing square has no loss.

Almost no loss, 0.2 per thousand.

When the finished wire is thin and long, it is recommended to install a wire take-up. The effect will not be scattered on the ground.

The wire drawing function can be added, which is convenient for drawing the wire with low output.

Yes, you need to provide the width and thickness of the sheet, and the minimum size of the finished product (thinness).

Jumping rolling means that the gap between the pressing shaft and the pressing shaft needs to be adjusted every time the wire is pressed. There is no need to adjust the gap for continuous pressing, and the two pressing shafts are pressed directly after pressing. 7.5p can be changed into a wire pressing machine.

SuperbMelt Gold Rolling Machine Buying Guide

Let’s dive right in:

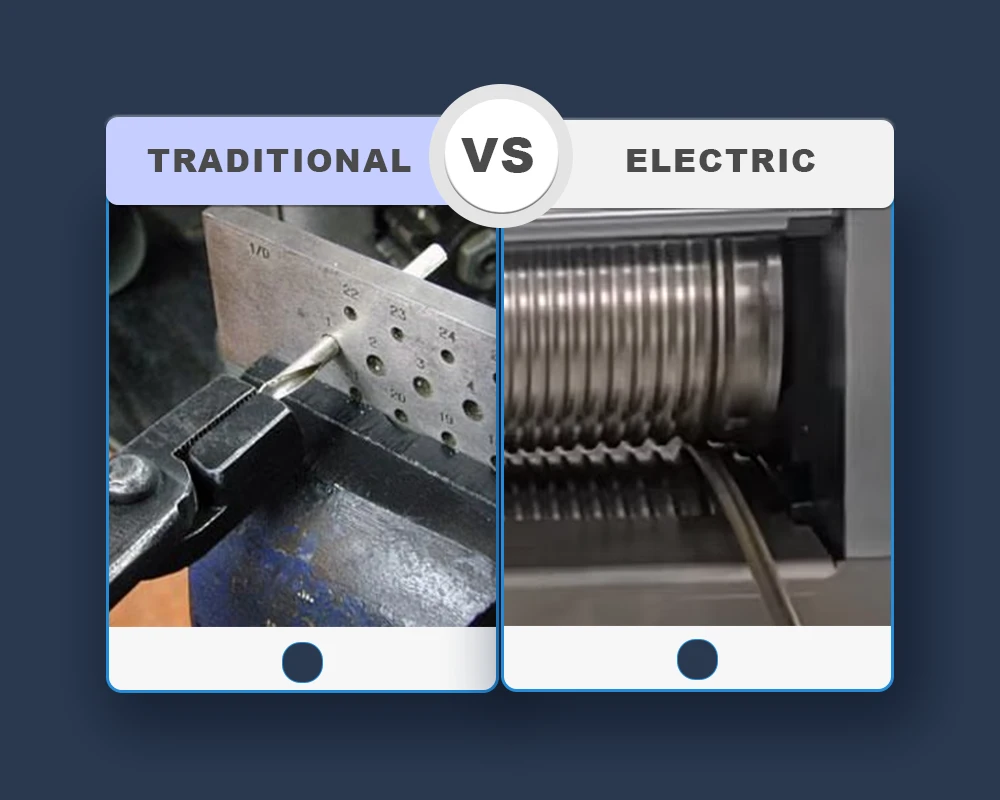

Traditional Metal Wire Production VS SuperbMelt Wire Rolling Machine Production

The production of traditional gold wire and the production of electric wire rolling mill both involve shaping gold into a wire form, but they differ in their processes and techniques.

Traditional gold wire production involves the use of manual labor and hand tools to draw gold bars through a series of progressively smaller holes in a draw plate, until the desired wire diameter is achieved. This process is repeated multiple times, with annealing (heating and cooling) the wire in between each drawing pass to prevent it from becoming too brittle or breaking. The resulting wire is then cut to the desired length and shape using hand tools.

In contrast, gold wire rolling machine use automated machinery and a continuous rolling process to produce gold wire. The process starts with a cast gold bar that is passed through a series of rollers that gradually reduce the thickness and shape of the metal. The wire is then pulled through a series of additional rollers to create the desired diameter, and cut to length using automated cutting tools.

While traditional gold wire production can produce high-quality wire with a distinct handcrafted look, it is a labor-intensive process that can be time-consuming and expensive. Electric rolling mills offer faster production times, greater consistency, and can produce wire in larger quantities, making it a more efficient and cost-effective option for many applications.

What Should be Paid Attention to When Rolling Gold Wire with Electric Rolling Mill?

Rolling gold wire with an electric rolling mill requires attention to several important factors to ensure that the process is safe and successful. Here are some things to keep in mind:

Cleanliness

Before beginning the rolling process, make sure the rolling mill and the gold wire are clean and free of any debris or impurities. Any contamination could affect the quality of the wire.

Lubrication

In order to prevent the gold wire material from sticking to the roller, it is necessary to add lubricating oil regularly when using the gold wire rolling machine, and the SuperbMelt equipment has an automatic oil supply system, which can effectively prevent the roller from damaging.

Annealing

Gold wire has different hardness and purity. Pure gold is the most ductile and does not need annealing. However, when rolling K gold, it is best to press for a period and then anneal for a period to make it softer and easier to roll.

Tension

Apply the appropriate tension to the gold wire as it passes through the rolling mill. Too much tension can cause the wire to break, while too little tension can result in uneven thickness and surface defects.

Our equipment can adjust the retractable tension under the action of high-sensitivity magnetic powder device, so as to avoid the situation of disconnection due to too much tension.

Rollers

Use rollers that are properly sized and aligned to ensure consistent wire thickness and a smooth surface finish. Make sure the rollers are securely mounted and adjusted to the desired gap width.

We have HC63-65 high-hardness rollers, and tungsten steel rollers with a smoothness of Ra0.02, which can make the finished product achieve a mirror effect.

Gradual Reduction

Roll the wire gradually, reducing its thickness in small increments. This helps to prevent the wire from breaking and allows for better control over the final thickness and shape.

Monitoring

Pay close attention to the rolling process and monitor the gold wire carefully as it passes through the rolling mill. This can help to detect any issues or defects early on and prevent damage to the wire or the rolling mill.

We can configure the visual screen to keep an eye on the size of the material in real time.

Safety

Always wear appropriate safety gear, including eye protection and gloves, when working with an gold wire rolling machine. Be aware of the risks associated with working with metal and moving machinery, and take appropriate precautions to ensure your safety.

Our rolling mills are also equipped with emergency stop long plates, which can be stopped quickly in an emergency and more effectively protect the safety of workers.

What are the Important Components of the Electric Rolling Machine?

Rollers

The rollers are the main component of the machine and are responsible for shaping the wire. They can be made from a variety of materials such as steel, tungsten and so on.

Motor

The motor provides the power for the machine to operate. It can be a single-phase or three-phase motor, depending on the size and capacity of the machine.

Gearbox

The gearbox is used to transfer the power from the motor to the rollers. It is important to ensure that the gearbox is properly lubricated to prevent wear and tear.

Control Panel

The control panel is used to operate and control the machine. It may include buttons, switches, and digital displays to adjust the speed and other settings of the machine.

Rewinding and Unwinding Device

When the wire reaches a certain length, the material can be fixed on the rewinding and unwinding roll, so as to realize automatic production and higher production efficiency.

High Sensitivity Adjustable Magnetic Powder Device

It is used to adjust the tension on the wire as it passes through the machine. This is important to ensure that the wire is properly formed and to prevent it from breaking or becoming damaged.

Safety Features

Electric wire rolling machines include various safety features such as emergency stop buttons, protective guards, and sensors to detect malfunctions or irregularities in the machine’s operation.

The Application of Gold Wire

Jewelry Industry

Gold wire can be used to make various jewelry chains. With a wire drawing machine, the wire can be drawn to 0.15mm in size for necklaces and bracelets. Different styles of gold chain making machines can also be used for mass production, such as cuban chains, box chains, rope chain and cable chain and so on.

Electronics Industry

In the electronics industry, gold wires are often used as conductive materials such as microcircuits of electronic equipment, through local gold plating, or gold powder is used to make required components.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited