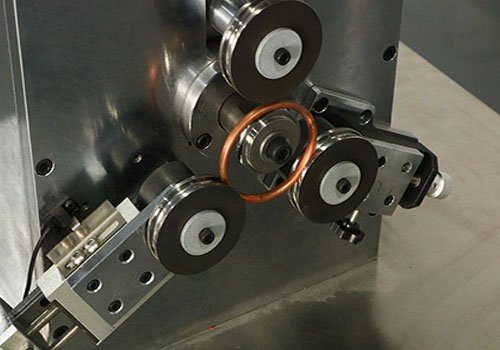

Round Bending Machine

SuperbMelt Precious Metal Ring Forming Machine for Gold, Silver, Platinum, Alloy, and Other Precious Metals

SuperbMelt circular bending machine can produce 4-8 gold, silver, platinum, K gold, and alloy jewelry bracelets, rings, or other round artworks per minute in a fully automatic manner.

The circular bending machine is a mechanical equipment used for metal processing, primarily for bending metal sheets or metal tubes into curved shapes.

It is also applicable for manufacturing pipelines, bent parts, curved metal frames, and various other shapes of metal components. This type of machine is widely used in the metal processing and manufacturing industries, applicable for producing structural components, automotive parts, ship parts, furniture, and various other products.

| Model number | SPB-BSM8 |

| Power source | 220V |

| Power | 800w |

| Applicable metal | Gold, Silver, Platinum, Palladium, and their alloys |

| Integrated production capacity | 4-8 pieces/ minutes |

| Max capacity | Platinum, gold, silver, copper, K gold and their alloys |

| Control System | PLC intelligent control |

| Dimension | 690*1200*1100mm |

| Weight | 220 kg |

- Fast Speed: With a production capacity of 4-8 pieces per minute.

- Tight Tolerance: Controlled within 5 threads, suitable for direct CNC operations.

- PLC Control System: Capable of storing 100 sets of data for convenient access (illuminated control panel).

- Uniform Thickness: Ensures smooth inner and outer rings, reducing the need for post-polishing (shiny finished bracelets).

- Versatile: Capable of producing bracelets with various shapes by simply changing the molds (display of finished products in platinum, gold, silver, copper, etc.).

- Integrated Bracelet and Ring Machine: Saves costs and space.

- Precision Bending: Ensures accurate and consistent bending angles, contributing to the overall quality of the finished products.

- User-Friendly Interface: Equipped with an intuitive interface, making it easy for operators to set parameters and monitor the production process.

- Durable Construction: Built with high-quality materials and components, ensuring longevity and reliability in operation.

- Safety Features: Incorporates safety mechanisms to prevent accidents and ensure the well-being of operators during use.

- Low Maintenance: Requires minimal maintenance efforts, reducing downtime and operational costs.

- Customizable Options: Offers flexibility in customization, allowing users to tailor the machine according to their specific requirements and preferences.

- Metalworking Industry: Used for manufacturing metal pipes, fittings, metal frames, etc.

- Construction Industry: Utilized in fabricating building structures, stair handrails, railings, etc.

- Automotive Manufacturing: Employed in producing automotive parts like car body frames, door frames, etc.

- Shipbuilding Industry: Used for fabricating metal components for ships, such as hull structures, ship handrails, etc.

- Furniture Manufacturing: Utilized in making structural components of metal furniture, such as table and chair frames.

- Craftsmanship Industry: Applied in manufacturing metal crafts, decorations, jewelry, etc.

Why SuperbMelt Round Bending Machine

Any Question About SuperbMelt Round Bending Machine

FAQ Guide of Round Bending Machine

- 1. What is the bending machine called?

- 2. What equipment is used to bend metal?

- 3. What is a Round Bending Machine?

- 4. How does a Round Bending Machine work?

- 5. What are the main purposes of a Round Bending Machine?

- 6. What materials are suitable for Round Bending Machines?

- 7. What is the range of thicknesses of materials that a Round Bending Machine can handle?

- 8. What are the operating methods of a Round Bending Machine?

- 9. What are the safety precautions for using a Round Bending Machine?

- 10. What are the maintenance and care requirements for a Round Bending Machine?

- 11. What are the advantages of Round Bending Machines?

- 12. What are the disadvantages of Round Bending Machines?

- 13. How does a Round Bending Machine differ from other types of bending equipment?

- 14. How to choose the right model of Round Bending Machine for specific needs?

- 15. What is the price range of Round Bending Machines?

- 16. In which industries are Round Bending Machines commonly used?

- 17. What is the history and development of Round Bending Machines?

- 18. What are some well-known manufacturers of Round Bending Machines?

- 19. How is the accuracy and repeatability of Round Bending Machines?

- 20. What are common problems with Round Bending Machines and their solutions?

- 21. What type of control system do Round Bending Machines use?

- 22. What are the environmental requirements for operating a Round Bending Machine?

1. What is the bending machine called?

It is a machine tool with a die and punch combination for bending plate and sheet metal. The workpiece is bent to the required angle by applying force with the press brake. These devices are frequently employed in the fabrication and metalworking sectors for a variety of tasks, including the shaping of metal parts for building, cars, machinery, and other purposes.

2. What equipment is used to bend metal?

equipment used to bend metal is called a bending machine or a press brake. It applies force to deform the metal, allowing it to bend into the desired shape.

3. What is a Round Bending Machine?

A Round Bending Machine is a type of machine tool designed to curve or bend metal rods, tubes, or sheets into various rounded shapes or arcs.

4. How does a Round Bending Machine work?

A Round Bending Machine works by feeding the metal workpiece between three adjustable rollers (two bottom rollers and one top roller), which rotate and apply pressure to gradually bend the metal into the desired shape.

5. What are the main purposes of a Round Bending Machine?

The primary purposes of a Round Bending Machine include forming metal rods, tubes, or sheets into curves, arcs, circles, or cylindrical shapes for various applications in industries such as construction, manufacturing, and fabrication.

6. What materials are suitable for Round Bending Machines?

Round Bending Machines are suitable for bending various materials, including but not limited to steel, stainless steel, aluminum, copper, and brass.

7. What is the range of thicknesses of materials that a Round Bending Machine can handle?

The thickness of materials that a Round Bending Machine can handle depends on the specific model and design. However, they typically handle a wide range of thicknesses, from thin sheets to thicker rods or tubes.

8. What are the operating methods of a Round Bending Machine?

Round Bending Machines are operated by adjusting the position and pressure of the rollers manually or through automated controls, depending on the machine’s features.

9. What are the safety precautions for using a Round Bending Machine?

Safety precautions for using a Round Bending Machine include wearing appropriate personal protective equipment, ensuring proper machine guarding, following proper operating procedures, and receiving adequate training.

10. What are the maintenance and care requirements for a Round Bending Machine?

Maintenance and care requirements typically include regular lubrication of moving parts, inspection for wear and tear, cleaning of debris, and periodic adjustments to ensure optimal performance.

11. What are the advantages of Round Bending Machines?

Advantages of Round Bending Machines include versatility in bending various shapes, relatively simple operation, and the ability to achieve precise bends with consistent results.

12. What are the disadvantages of Round Bending Machines?

Disadvantages may include limitations in bending certain complex shapes, the need for skilled operators to achieve desired results, and the potential for material distortion or deformation during bending.

13. How does a Round Bending Machine differ from other types of bending equipment?

Round Bending Machines differ from other types of bending equipment such as press brakes or tube benders in their capability to form rounded shapes or arcs, rather than linear bends or folds.

14. How to choose the right model of Round Bending Machine for specific needs?

When choosing a Round Bending Machine, factors to consider include the required capacity (size and thickness of materials), the desired bending radius, available features (such as digital controls or additional tooling), and budget considerations.

15. What is the price range of Round Bending Machines?

The price range of Round Bending Machines varies depending on factors such as size, capacity, features, and brand. Prices can range from a few thousand dollars for smaller models to tens of thousands for larger, more advanced machines.

16. In which industries are Round Bending Machines commonly used?

Round Bending Machines are commonly used in industries such as metalworking, construction, automotive, aerospace, and shipbuilding for various applications involving curved or rounded metal components.

17.What is the history and development of Round Bending Machines?

The history of Round Bending Machines dates back to the early 20th century, with continuous advancements in design, technology, and automation leading to more efficient and versatile machines over time.

18. What are some well-known manufacturers of Round Bending Machines?

Well-known manufacturers of Round Bending Machines include companies such as Haeusler, Faccin, MG, Davi, and AKYAPAK, among others.

19. How is the accuracy and repeatability of Round Bending Machines?

Round Bending Machines can achieve high levels of accuracy and repeatability, especially when equipped with precise digital controls and quality tooling. However, factors such as material properties and operator skill also influence results.

20. What are common problems with Round Bending Machines and their solutions?

Common problems with Round Bending Machines may include material slippage, wrinkling, or springback during bending. Solutions may involve adjusting roller pressure, using proper tooling, or optimizing machine settings.

21. What type of control system do Round Bending Machines use?

Round Bending Machines may use manual controls, hydraulic controls, or CNC (Computer Numerical Control) systems for precise and automated operation, depending on the machine’s design and capabilities.

22. What are the environmental requirements for operating a Round Bending Machine?

Environmental requirements for operating a Round Bending Machine typically include providing adequate ventilation to remove fumes or dust generated during the bending process and ensuring compliance with relevant safety and environmental regulations.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited