Vertical Continuous Casting Machine

Enhance Jewelry Production with a Reliable Continuous Casting Machine

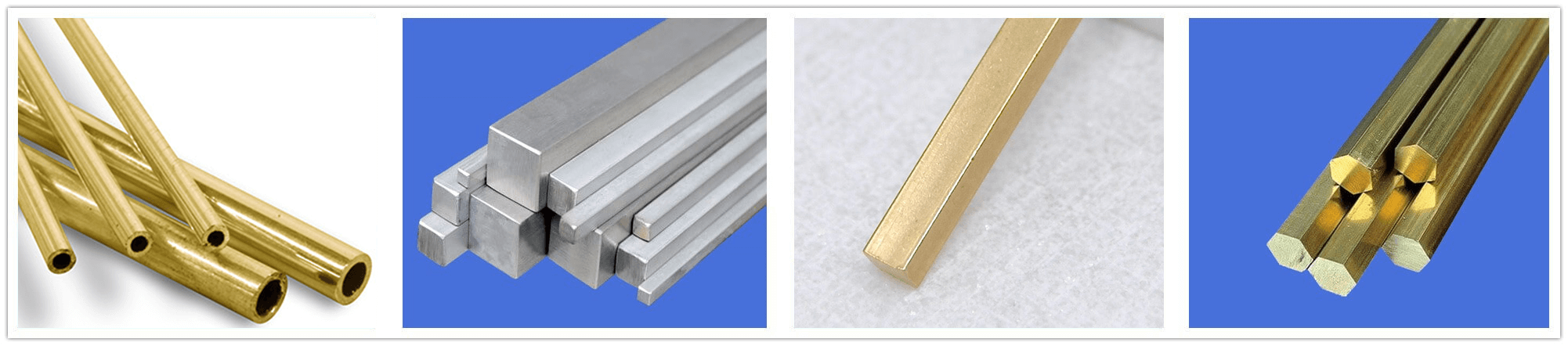

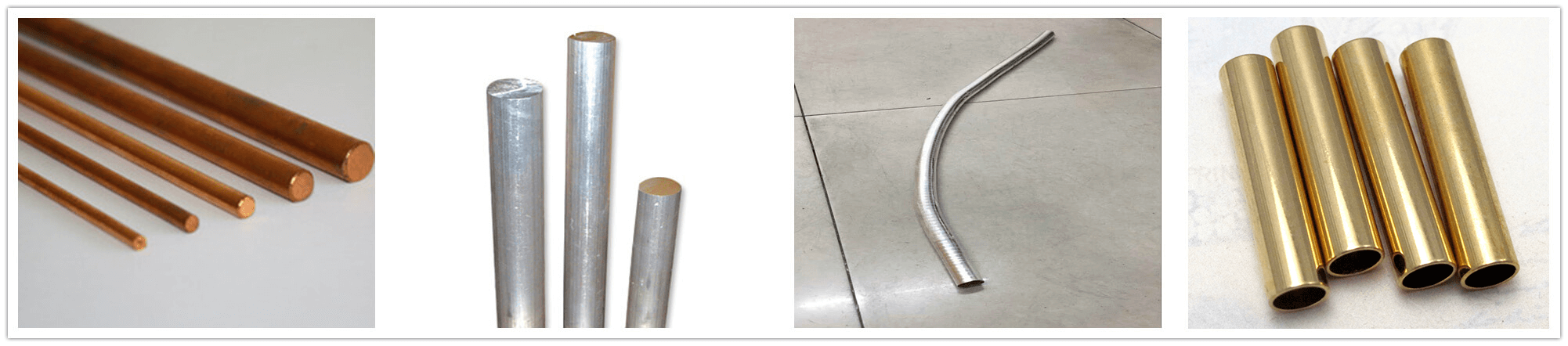

SuperbMelt vertical continuous casting machine can cast various shapes of jewelry materials, such as gold, silver, copper, and K gold, in a single operation, with a capacity of 50kg. It is designed for the production of high-quality raw materials for metal jewelry, including tubes, sheets, plates, and bars.

Equipped with precise and automated temperature control and stirring mechanisms, this vertical continuous casting machine ensures high-quality finished products. Its simple operation and high-quality output make it the optimal choice for jewelry businesses.

If you need more information about the jewelry continuous casting machine, please contact us immediately!

| Model number | SPB-LS4 | SPB-LS8 | SPB-LS50 |

| Power source | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 15 kw | 25 kw | 45kw |

| Max Current | 15A | 26A | 120A |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloysa |

| The Max capacity | 24K Gold: 5.0 kg 18K Gold: 3.5 kg 925 Silver: 2.5 kg | 24K Gold: 8.0 kg 18K Gold: 6.0 kg 925 Silver: 4.0 kg | Gold: 50 kg |

| Melting time | 5 min | 8 min | 15min |

| Casting Application | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm | Rod: φ4-φ20mm Tube: Min φ9*12mm Max φ52*60mm Bar: Min T5*W5mm Max T20*W70mm |

| Max temperature control R-type | 1600℃ | 1600℃ | 1600℃ |

| Max temp control k-type | 1100℃ | 1100℃ | 1100℃ |

| Max drawing speed | 40 cm/minute | 40 cm/minute | 40 cm/minute |

| Dimension | 1120×840×1560 mm | 1120×840×1560 mm | 1100x1350x1830 mm |

| Weight | 195 kg | 205 kg | 300kg |

| Protective gas | Nitrogen or argon | Nitrogen or argon | Nitrogen or argon |

| Heating system | Induction heating | Induction heating | Induction heating |

| Control of temperature | By PID | By PID | By PID |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius | ±2 degrees Celsius |

- The SuperbMelt Jewelry continuous casting machine can be operated 24 hours round the clock without any system malfunction. This feature saves you time and help you achieve more productivity.

- Automatic control of all process variables and parameters is achievable with the SuperbMelt Jewelry continuous casting machine

- It can be used for casting of alloys and semi alloys into different sizes and shapes in the shortest amount of time possible. This feature does not only save you time, it saves a lot of money as well.

- You can as well cast your gold tubes or silver tubes with this machine.

- This equipment is also capable of automatically stirring any melted metal. This feature helps you improve your production efficiency as well as the quality of your final piece.

- It can heat up to a maximum temperature of 1600℃ . This is a temperature range in which most metals melts.

- Unlike other traditional metal casting furnaces. This machine is equipped with a very powerful Proportional Integral and Derivative Controller. The installed PID controller unlike PI controller or any other controller in the market is capable of automating your whole melting operation without any error.

- The PID controller is also capable of detecting temperature up to an accuracy of ±2 degrees Celsius

Are you looking at making a purchase for a jewellery casting machine? Well, the SuperbMelt Jewelry continuous casting machine is very economical and easy to use. It is also highly efficient compared with the traditional and gas resistances furnaces. With this machine, you be rest assured of massive reduction in your process wastes. With this machine, flexible casting operations is highly achievable.

Why SuperbMelt Vertical Continuous Casting Machine

Helpful Resource For Your Reference ( An expert about SuperbMelt Continuous Casting Machine )

SuperbMelt Jewelry Casting Machines for Precise and Efficient Production

Any Question About SuperbMelt Vertical Continuous Casting Machine

Continuous casting is a manufacturing process used to cast metals and alloys with high precision and consistency. It is an efficient method for producing large quantities of high-quality materials and is widely applied across various industries.

During the continuous casting process, molten metal is poured into a casting machine’s pouring box. The metal flows through a nozzle into a mold where it begins to solidify. The mold is continuously cooled, and the solidified metal is pulled out from the bottom of the mold using rollers or water-cooled plates.

One of the primary advantages of continuous casting is its ability to produce materials with consistent properties. Compared to traditional casting methods, this process yields products with uniform quality and improved mechanical performance.

Continuous casting finds extensive applications in the production of materials such as steel, aluminum, copper, gold, and silver. These materials are used in diverse industries including automotive, construction, aerospace, and jewelry.

In the consumer goods industry, continuous casting is employed to manufacture various products, including aluminum cans, kitchenware, and jewelry. These products are highly regarded by consumers for their superior quality and consistency.

Monaca's evaluation of continuous casting machines

On-site evaluation of Belgian customers

Second repurchase for Mumbai customers

Nicolai, Operations Manager, Azer Gold Factory.

User Guide for Vertical Continuous Casting Machine

Metal Casting Basics

Metal casting is a common manufacturing process used to pour molten metal into a mold, allowing it to solidify and form the desired parts or products. Metal casting is a complex manufacturing process that involves considerations such as material selection, mold design, melting control, casting process, and post-processing. Proper operation and control are crucial to ensure the quality and performance of the castings.

1.1, Metal casting processes

Metal casting is a frequently used manufacturing process that uses a number of techniques, such as:

When using a sand mould to make a casting, molten metal is poured into the mould once it has been prepared. The casting is taken from the mould after solidification.

Metal Mould Casting: Using a metal mould to create the casting.

Die Casting: Rapid solidification is achieved by injecting molten metal under high pressure into a metal mould.

Using the power of gravity, molten metal is poured into a mould.

Continuous Casting: Continuous manufacturing involves continuously pouring molten metal into moulds using a variety of continuous casting tools.

Low-pressure casting is the process of casting molten metal at low pressure.

1.2, What are the common machines used in jewelry casting

- Wax Injector

- Burnout Furnace

- Casting Machine

- Melting Furnace

- Polishing Machine

- Continuous Casting Machine

- Centrifugal Casting Machine

How to Choose a Continuous Casting Machine

When selecting a continuous casting machine, you must consider the following factors: production capacity, materials to be cast, equipment quality, technical support, and cost-effectiveness.

2.1, Advantages of Continuous Casting Machines

Casting in a vacuum environment helps to improve casting quality by reducing the impact of gas and contaminants. It is frequently employed for producing high-performance casHigh Productivity: Compared to batch casting techniques, continuous casting machines enable the continuous casting process, which boosts manufacturing productivity.

High-Quality Products: Continuous casting improves product quality and consistency by allowing for better control over the solidification process, producing castings that are more consistent and free from flaws.

Cost savings: Continuous casting machines minimise the quantity of moulds needed for each casting, minimising material waste and cutting material prices, ultimately resulting in cost efficiency.

Enhancement of safety: By eliminating physical handling of molten metal, continuous casting lowers the danger of accidents and injuries associated with conventional casting techniques.

Increased Flexibility: Continuous casting machines can produce castings of different shapes and sizes, allowing for customisation and production flexibility.

Resource Conservation: Continuous casting reduces waste production, which encourages resource conservation and environmental sustainability. It also reduces material waste.tings.

2.2, Why is continuous casting machine used in jewelry casting?

Continuous casting machines have been widely applied in the jewelry industry. They enable efficient production and cost savings while producing high-quality jewelry castings. Additionally, continuous casting machines offer excellent safety performance.

2.3, Benefits of a Vertical Continuous Casting Machine

Vertical Continuous Casting Machine offers high flexibility, allowing for the production of castings in different shapes and sizes. It provides production flexibility and customization options. The machine produces castings of high and consistent quality, making it particularly suitable for the production of fine jewelry.

SuperbMelt Continuous Casting Machine Manufacturers

With our Vertical Continuous Casting Machine, which is made exclusively for making high-quality jewellery, SuperbMelt serves jewellery producers. To satisfy all of your jewellery processing requirements, we provide a variety of jewellery casting machines, including melting furnaces, chain-making equipment, and vacuum casting machines.

In addition to our state-of-the-art equipment, we offer flawless after-sales support, including round-the-clock customer care and on-site technical support.

Choose SuperbMelt for your jewellery production needs to enjoy the ideal fusion of cutting-edge technology, dependable equipment, and first-rate customer service.

About SuperbMelt Continuous Casting Machine FAQ

- 1. Why use a continuous casting machine?

- 2. What can a continuous casting machine do?

- 3. What role does the continuous casting machine play in the jewelry industry?

- 4. Continuous casting machines offer several advantages over traditional gold melting machines, including?

- 5. What is the function of the temperature measurement function of the continuous casting machine?

- 6. Is the mold loss large? Is there any way to make the mold more durable?

- 7. What is a continuous casting machine crucible? Why can't a quartz crucible be used? What consumables are available?

- 8. What supporting equipment is needed?

- 9. What kind of material is best to add strong stirring function? Why?

- 10. What is vertical casting?

1. Why use a continuous casting machine?

Continuous casting machines offer many advantages over traditional casting methods. It allows the production of high-quality materials with consistent performance, high volumes and high precision. This makes it a popular choice in a variety of industries including automotive, construction, aerospace and jewelry consumer goods. The ability to produce a variety of materials with consistent properties, such as steel, aluminum, copper and gold, has made continuous casting an essential process in many industries. Furthermore, continuous advancements in technology are expected to increase the efficiency and reliability of continuous casting, further cementing its role in modern manufacturing.

2. What can a continuous casting machine do?

Continuous casters are capable of converting molten metal into solidified form in a continuous and automated manner. This technology has revolutionized the way metals are produced, increasing the efficiency and precision of the manufacturing process.

The machine works by pouring molten metal into a water-cooled mold, which gradually solidifies the metal into the desired shape. As the metal solidifies, it is continuously pulled through the die and cooled by circulating water, forming a fully solidified product at the end of the process.

Continuous casting machines are used in a variety of industries, including gold jewelry production.

3. What role does the continuous casting machine play in the jewelry industry?

The continuous casting machine has a significant role in the jewelry industry. It allows for the production of high-quality, consistent jewelry pieces in a cost-effective and efficient manner.

Jewelry manufacturers use continuous casting machines to create a wide range of products, from simple rings to intricate pendants. The machine’s ability to produce large quantities of uniform and high-quality jewelry pieces quickly makes it a crucial part of the manufacturing process.

Continuous casting machines also offer precise control over the metal’s cooling rate, which can affect the final product’s quality. The machine’s computerized controls allow manufacturers to customize the cooling rate for each product, ensuring that the metal is cast precisely to the desired specifications.

Moreover, the continuous casting machine is an ideal choice for creating delicate pieces of jewelry. Since the machine allows for precise control over the metal’s flow and cooling rate, manufacturers can create intricate jewelry pieces that would be impossible to produce using other methods.

In summary, the continuous casting machine plays an essential role in the jewelry industry, enabling manufacturers to create high-quality, consistent, and intricate jewelry pieces efficiently and cost-effectively.

4. Continuous casting machines offer several advantages over traditional gold melting machines, including?

Improved efficiency: Continuous casting machines have a higher production rate compared to traditional melting machines. This means that more material can be produced in a shorter period of time, leading to increased productivity and reduced manufacturing costs.

Consistency: Continuous casting machines produce materials with consistent quality and properties, which is not always possible with traditional casting methods.

Reduced waste: Continuous casting machines produce less waste material compared to traditional methods, which is beneficial both from an economic and environmental standpoint.

Increased safety: Continuous casting machines have built-in safety features that prevent accidents and injuries, making them a safer option for manufacturing.

5. What is the function of the temperature measurement function of the continuous casting machine?

The temperature measurement function of the continuous casting machine serves an important role in ensuring the quality of the cast product. By measuring the temperature of the molten metal in the tundish and the mold, the machine operator can make adjustments to the casting speed and cooling rate to ensure that the metal solidifies correctly and uniformly.

If the temperature is too high or too low, it can result in defects such as cracks or porosity in the finished product. Therefore, the temperature measurement function helps to ensure that the casting process runs smoothly and that the final product meets the required quality standards.

6. Is the mold loss large? Is there any way to make the mold more durable?

Proper cooling: Cooling plays a critical role in the durability of the mold. The cooling system must be designed to maintain the mold at an optimal temperature, which can prevent thermal fatigue and wear.

Mold material: The mold material should be carefully chosen to withstand high temperatures and stresses. Materials such as copper, steel, and ceramic are commonly used for continuous casting molds.

Coatings: Coatings can be applied to the mold surface to improve its durability. Coatings such as ceramic, chrome, and other materials can enhance the surface hardness and resistance to wear and corrosion.

Maintenance: Regular maintenance of the mold is essential to ensure its longevity. The mold should be inspected and cleaned regularly to prevent the build-up of debris and to maintain proper cooling.

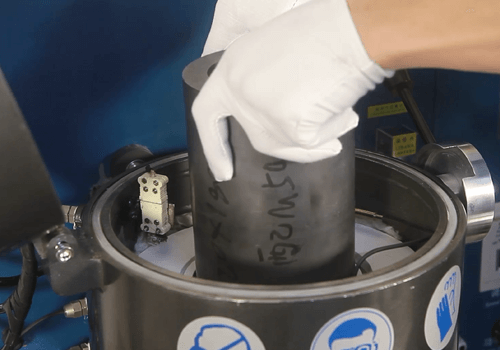

7. What is a continuous casting machine crucible? Why can't a quartz crucible be used? What consumables are available?

A continuous casting machine crucible is a container used to hold the molten metal during the casting process. It is typically made of graphite or other high-temperature materials that can withstand the extreme heat and thermal shock of the casting process.

Quartz crucibles cannot be used in continuous casting machines because they are not able to withstand the high temperatures and thermal shock that occur during the casting process. Quartz has a low thermal shock resistance, and it will crack or break when exposed to rapid temperature changes, such as those that occur during casting.

Consumables that are commonly used in continuous casting machines include:

Mold lubricants: These are used to reduce friction between the mold and the solidifying metal to improve the surface quality of the cast product and extend the life of the mold.

Mold fluxes: These are used to protect the molten metal from oxidation and promote a smooth flow of metal into the mold.

Cooling water: Continuous casting machines require a continuous supply of cooling water to keep the mold and other components cool during the casting process.

Graphite electrodes: These are used to provide electrical current to melt the metal in the furnace and maintain the molten state during the casting process.

8. What supporting equipment is needed?

Tundish: It is a reservoir that holds the molten metal and feeds it into the casting machine.

Mould: It is the component that shapes the metal into the desired shape during the casting process.

Cooling system: Continuous casting machines require a cooling system to maintain the temperature of the mould and ensure proper solidification of the metal.

Cutting machine: It is used to cut the continuous casted metal into desired lengths.

Conveyors: These are used to move the metal from one stage of the process to another.

Control system: Continuous casting machines require a sophisticated control system to ensure the proper functioning of the machine and to monitor the casting process.

Safety equipment: Safety equipment such as fire protection systems and personal protective equipment (PPE) are necessary to ensure the safety of workers and prevent accidents.

Consumables: Consumables such as mould powders, lubricants, and refractory materials are necessary to maintain the machine and ensure its proper functioning.

9. What kind of material is best to add strong stirring function? Why?

Adding a material with good thermal conductivity and strong stirring function, such as graphite, is often recommended to improve the performance of a continuous casting machine. Graphite has a high thermal conductivity, which helps to maintain a consistent temperature in the mold and prevent hot spots. Additionally, graphite has a strong stirring function, which helps to distribute the molten metal evenly and prevent the formation of defects. Overall, using graphite in a continuous casting machine can lead to improved product quality and higher efficiency in the casting process.

10. What is vertical casting?

Molten metal is poured into a mould that is vertically orientated in the vertical casting process, which is sometimes referred to as upward casting. With this technique, the metal is put into the mould from the bottom and rises as it sets. As a result, it is possible to produce vertically cast metal items like bars, rods, tubes, and other long forms.

Improved grain structure, less impurities, and superior mechanical qualities in the finished product are just a few benefits of vertical casting. For applications that demand exceptional quality and consistency, it is frequently utilised in businesses including those that produce steel, aluminium, copper, and precious metals.

Vertical casting machines may create high-quality castings with fewer flaws and better dimensional accuracy by managing the cooling and solidification process. This approach is favoured for applications where accuracy, sturdiness, and integrity are essential, making it a well-liked option across different production industries.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited