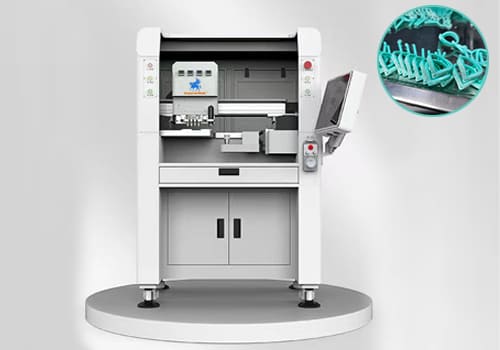

Automatic Jewelry Stone/Diamond Setting Machine

Professional Manufacturer in China

The automatic diamond setting machine is a fully automatic jewelry machine based on intelligent vision, which can set stones on jewelry such as rings, necklaces and earrings. The automatic stone setting machine integrates gluing and stone setting. The machine can set 7 diamonds in one second. The spray gun is above the stonehole. After the crystal nozzle takes the stone from the glue hole, it is quickly set on the wax mold.

This machine helps customers to realize the technology of setting diamonds in different shapes of molds, such as single channel, double channel, plate, tube, etc., and can also synthesize gemstones.

| Equipment nam | Flexible-Five-axis automatic spot drilling machine |

| Equipment Model | SPB-5DZ1000 |

| Table structure | flat table & double rotary axis table structure |

| Drilling speed | 6000-10000 drills / hour |

| Number of suction drill head | 4 suction nozzles |

| Drill plate fixing method | movable force magnet on the upper side of the platform |

| Spot drilling accuracy | ±0.02mm |

| Control system | industrial grade five-axis motion controller |

| Main operating system | SuperbMelt self-developed system |

| Drive system | High-end servo |

| Transmission method | high precision screw guide |

| Z*Y*Z/A/C effective stroke | 300*250*120mm/180 degrees/360 degrees |

| Working power | AC220V/50Hz |

| Rated voltage | 1.5kw |

| Working air pressure | 80psi(0.5Mpa |

| Equipment size | length 1150 * width 800 * height 1530mm |

| Equipment weight | about 500KG |

High Precision

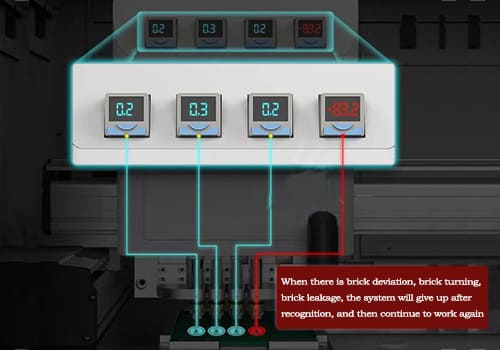

The intelligent grading system can 100% avoid omissions and wrong drilling, and ensure high-quality manufacturing.

High Speed

Four suction drill bits, reaching 6000-10000 pieces per hour, realize fast and high-precision drilling, and improve production efficiency.

Fully Automated

Automatic identification system, 540-degree rotating diamond setting, can realize various three-dimensional, curved and flat diamond setting, fully automatic.

100% Manual Restoration

Use flexible point drills to imitate hand-pressed point drills, 100% to achieve the same effect as hand-set diamonds. It also saves labor costs while improving production quality.

Easy to Use

It only needs to simply install the mold, change the mold, and press the powerbutton to complete the operation. No professional training is required, so training time and cost are saved.

High Quality Machine Body

One-piece cast iron body, high rigidity, ultra-stable, not easy to deform, ensuring stability and precision for long-term use.

Reduce Metal Loss

Using the jewelry wax inlay casting process, the diamonds are first spotted onthe wax mold, and then the jewelry is cast by casting the mold to achieve no metal loss.

Various Specifications

Supports #0.9-3mm size diamonds, and supports diamonds of various colors.

Flat Diamond

Like some flat pendants, earrings etc,can be more direct engraved.

Curved Diamond

Like some curved animal shape pendants, can be inserted easily and precisely.

Multi-faceted Diamond

Like some complex shaped rings, bracelets, etc.

100% Restoration of The Handmade Wax Setting Process:

Flexible point drill head, imitating hand pressed point drill, manual effect, but faster than manual.

High Precision, Super Stable:

Selfdeveloped highly intelligent spot drilling system, intelligent identification ofempty and missing drills during process, to achieve high intelligence, high speed, high finished products, and high automatic processing.

6000~10000 Drills Per Hour:

Easy and fast operation, fast drill pointing speed, up to 10,000 drill points hourly, increase productivity.

Why SuperbMelt Automatic Jewelry Stone/Diamond Setting Machine

Any Question About SuperbMelt Automatic Jewelry Stone/Diamond Setting Machine

Guide of SuperbMelt Automatic Jewelry Stone/Diamond Setting Machine

What is the SuperbMelt Automatic Jewelry Stone Setting Machine Comprising

The diamond setting machine adopts AC servo drive system plus a precision guide rail and a precision planetary reducer to ensure the accuracy of spot drilling.

It is driven by high-precision servo motor, and the spot drilling speed is up to 10000CPH, the dispensing speed is up to 20000CPH, and the machining accuracy is ±0.05mm.

The integrated upper and lower frame welding high-precision alloy processing table is used to ensure long-term stability of processing accuracy, and precision guide rail + TBI lead screw is used to ensure high-speed movement accuracy and reduce equipment operating noise.

ey specifications of the SuperbMelt Automatic Stone Setting Machine for Jewelry:

High precision and multiple types

The fully automatic diamond setting machine can manufacture and set all types of diamond jewelry with 100% precision

Highly restored manual craftsmanship

Not only does it operate 24 hours a day, but it is also 100% handcrafted and 20 times faster than an experienced diamond setter.

Super fast and increases productivity

An experienced diamond setter can achieve 90,000 to 120,000 diamonds per year, whereas our automatic diamond setting machines can accomplish 1.5 million diamonds per year.

Save costs and gain profits

The diamond setting price in the market is US$0.068 per piece, and our diamond setting machine can set 10,000 diamonds in one hour, resulting in a monthly income of US$489,600.

Very intelligent and high quality

It can also be used for multiple diamonds of different sizes, and its work quality and efficiency are much better than manual work.

Therefore, this is undoubtedly a product that can bring great benefits to leading jewelry manufacturers worldwide.

Technology and Software of the SuperbMelt Automatic Stone Setting Machine for Jewelry

Software System:

- User-friendly operating interface, easy to operate and navigate.

- Supports Chinese/English language switch to meet different user language requirements.

- Equipped with an in-house developed industrial-grade motion control system, which is feature-rich and enables precise monitoring of various process parameters.

Artificial Vision Motion Control Platform:

The software’s visual recognition positioning and stone hole processing can effectively reduce processing errors and achieve high-precision spot drilling.

Visual System:

Supports CCD programming, saving the cost of manual teaching time.

Automatic needle alignment system, effectively improving the positioning accuracy of the machine head.

How Does SuperbMelt Automatic Jewelry Stone Setting Machine Work

The Superbmelt diamond setting machine has very simple operation steps:

- Step 1: Set the stone setting programming on the touch screen in advance.

- Step 2: Put the wax mold on the platform, the mold can be placed at will.

- Step 3: Press the start button on the right side of the machine to start working.

FAQ Guide of SuperbMelt Automatic Jewelry Stone/Diamond Setting Machine

- 1. Can Any Shape Of Diamond Be Used On This Machine?

- 2. What Material Of Drill Is This Machine Suitable For?

- 3. Can Diamonds of Different Sizes and Colors Be Set in the Same Mold?

- 4. Can A Mold And Programming Only Be Used On One Machine?

- 5. How many Colors Can be Set at One Time

- 6. How Long Does It Take to Program a Mold Style?

- 7. If I Need to Switch Wax Designs on the Same Machine, How Long Does It Take to Set Up?

- 8. Will Your Company Provide Technical Guidance?

- 9. How to Do the Setting Program of Designs?

- 10. How many Suction Heads are Equipped?

- 11. What is The Consumable Parts Need to Prepare?

- 12. What Is the Max Wax Size could Set in the Machine?

- 13. How Many pcs of Stones could Set in one Hour in SuperbMelt Auto Stone Setting Machine?

- 14. How Many pcs of Stones could Set in One Plate?

- 15. How Does the Machine Make Sure the Diamond is Face-up and can't Go Wrong?

- 16. How Efficient are Machines Compared to Humans?

1. Can Any Shape Of Diamond Be Used On This Machine?

Currently only round drills are accepted, if you have other shape requirements, please tell us in detail, we will recommend a more suitable machine for you.

2. What Material Of Drill is This Machine Suitable For?

Rhinestones, glass drills, acrylic drills, plastic drills, small beads, etc.

3. Can Diamonds of Different Sizes and Colors Be Set in the Same Mold?

Yes, diamonds of size #0.9-3.0mm and various colors are supported.

4. Can a Mold and Programming Only Be Used On One Machine?

Our machines support file copying and multi-machine sharing to achieve rapid mass production.

5. How many Colors Can be Set at One Time

Max 6 colors or sizes can be set at one time. And the specific number of colors depends on the style.

6. How Long Does It Take to Program a Mold Style?

Depending on the number and size of diamonds, the time varies from 10 minutes to 2 hours, depending on the complexity of the design.

7. If I Need to Switch Wax Styles on the Same Machine, How Long Does It Take to Set Up?

It only takes a few seconds to switch the program, and you need to change the position of the inlay head and wax tool to be consistent with the inlay program.

8. Will Your Company Provide Technical Guidance?

Every machine we sell will provide detailed technical guidance to each customer according to the needs of customers, and this diamond setting machine is easy to operate, and it only takes less than an hour to fully grasp the operation method.

9. How to do the setting program of Designs?

There are two ways, the first is to manually find the point and program, align each point and program one by one. The second is to scan the wax model and the chassis together with a 3D scanner, and then match the whole to the conformal model for overall auxiliary adjustment. When the machine receives the scanned file, it only needs to manually confirm each point and make fine adjustments. Normal production can be achieved, which can save a lot of time and cost.

10. How many Suction Heads are Equipped?

8 suction heads are standard, 4 pcs of No.502 nozzles which suck 0.9 to 1.3 stone, 4 pcs of No. 503 nozzles which can suck 1.4 to 1.7 stones.

11. What is The Consumable Parts Need to Prepare?

Suction heads, Molding rubbers, Stone plates

13. How Many pcs of Stones could Set in one Hour in SuperbMelt Auto Stone Setting Machine?

It could set 6000-10000 pcs of stones per hour.

14. How Many pcs of Stones could Set in One Plate?

One plate size is 44*85mm. It could set 11220pcs of stones. Machine could place 3 plates or 6 small plates which are half size of big plate.

15. How Does the Machine Make Sure the Diamond is Face-up and Won't Go Wrong?

First of all, before the diamonds are put into the tray, a Sieve diamond machine will be used. This step can ensure that each diamond is face-up. Secondly, our stone setting machine is also equipped with an automatic identification function. The suction nozzle can identify whether there are errors or missing diamonds through suction.

16. How Efficient are Machines Compared to Humans?

It could do setting job instead of 10-15 workers.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited