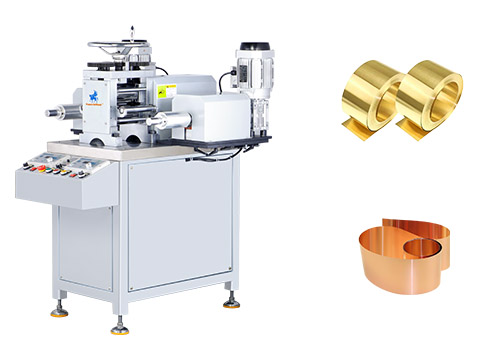

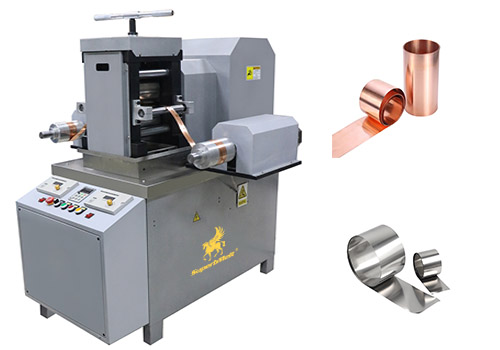

Gold Sheet Rolling Machine

SuperbMelt, China top metal sheet rolling mill, revolutionizes your metal processing techniques

The most prominent feature of the SuperbMelt Gold Sheet Rolling Machine is its automatic coiling function. This feature helps provide tension during the rolling process, ensuring that the material is rolled more uniformly, and the resulting material is coiled neatly rather than scattered, saving collection time and thus enhancing production efficiency.

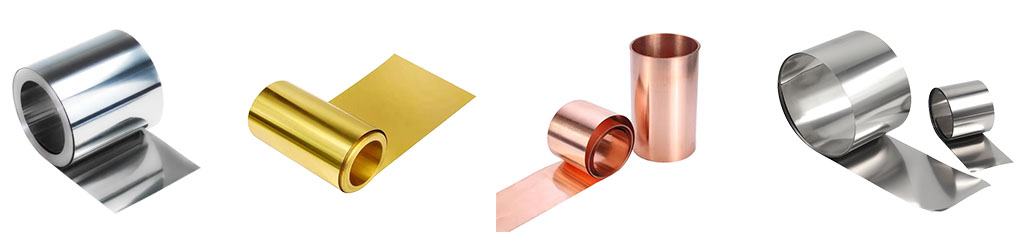

This machine is primarily used for processing platinum, gold, silver, alloy billets, or metal sheets by rolling them into metal foils of the desired thickness and width.

These metal foils can be used for making jewelry, crafts, metal parts, and various other products. The SuperbMelt Gold Sheet Rolling Machine is renowned for its high precision, efficiency, and reliability, meeting the diverse needs of metal foil processing across different industries.

The Gold Sheet Rolling Machine is suitable for various metalworking industries. If you need more information about our rolling machines, please feel free to contact us for customized solutions.

- High precision, with finished products reaching up to 0.04mm (tin).

- High hardness, using imported rollers with a shaft hardness of 60-62HRC.

- Dual-sided coil handling significantly enhances production efficiency and product qualification rate.

- Precise downward pressure adjustment, with roller gap easily adjustable by rotating the turntable, ensuring accuracy.

- Adjustable coil tension, employing highly sensitive adjustable magnetic powder tensioner to prevent breakage due to excessive tension.

- Easy operation, featuring a concise panel design for clear and straightforward operation.

| Model number | SPB-YP-3PZQ | SPB-BF-YP10P | SPB- |

| Power supply | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Power | 2.2 kw adjustable | 7.5 kw adjustable | kw adjustable |

| Applicable metal | Platinum, palladium, gold, K-gold, silver and copper | Platinum, palladium, gold, K-gold, silver and copper | Platinum, palladium, gold, K-gold, silver and copper |

| Rolling sheet thickness | 0.1-28mm(gold) | 0.1-28mm(gold) | 0.1-28mm(gold) |

| Rotating speed | 20 rpm (adjustable) | 18 rpm (adjustable) | |

| Lubrication method | Automatic oil supply | Automatic oil supply | Automatic oil supply |

| Dimension | 800x800x1500mm | 1030*715*1350mm | |

| Weight | 450KG | 700KG | |

| Final shaft size (D*L) | 100x150mm | 140*180mm | |

| Rolling sheet width | Within 60mm | Within 60mm | Within 60mm |

- Jewelry manufacturing: This process creates sheets of gold, silver, platinum, and alloys that are used to make jewelry such as necklaces, bracelets, earrings, and rings.

- Craftsmanship: Used in the production of metal sheets for a variety of ornamental and artistic applications, including decorations, sculptures, and artwork.

- Metalworking: Used in sectors where exact metal sheet manufacture is necessary to create assemblies, parts, and components for machinery, equipment, and buildings.

- automobile: Used to create metal sheets for body panels, trim pieces, and ornamental features, among other automobile components.

- Aerospace: Used in the manufacturing of metal sheets for use in structural parts, avionics enclosures, and interiors of airplanes.

- Electronics: Used in the production of metal sheets for circuit boards, electrical enclosures, and electronic gadgets.

- Utilized in the production of metal sheets for roofing, building facades, architectural features, and structural components in construction projects.

Why SuperbMelt Gold Sheet Rolling Machine

Any Question About SuperbMelt Gold Sheet Rolling Machine

FAQ Guide of Gold Sheet Rolling Machine

- 1. What is the process of rolling gold?

- 2. What is the use of sheet rolling machine?

- 3. How long does it take to roll a sheet of gold using a Gold Sheet Rolling Machine?

- 4. How long does it take to roll a sheet of gold using a Gold Sheet Rolling Machine?

- 5. What are the common issues faced when using a Gold Sheet Rolling Machine and how to troubleshoot them?

- 6. Can a Gold Sheet Rolling Machine be customized for specific sheet sizes and thicknesses?

- 7. Are there safety precautions to be followed while using a Gold Sheet Rolling Machine?

- 8. What are the advantages of using a Gold Sheet Rolling Machine over manual methods?

- 9. Can a Gold Sheet Rolling Machine be used for materials other than gold?

1. What is the process of rolling gold?

A rolling mill, often referred to as a sheet rolling machine, is a device that reduces or shapes metal sheets or plates by running them between two rollers. This machine is widely used to create thin metal sheets with uniform thickness and shape in a variety of sectors, including jewelry production. Additional uses for the rolled metal sheets include the production of jewelry, metal parts, and ornamental objects.

2. What is the use of sheet rolling machine?

A sheet rolling machine is used to process metal sheets by passing them between a pair of rollers to reduce their thickness or change their shape. This machine is commonly used in industries such as metalworking, manufacturing, and jewelry making to produce thin metal sheets of consistent thickness and shape. The rolled metal sheets can be further used for various applications, including fabrication of components, jewelry production, and construction materials.

3. What are the different types of Gold Sheet Rolling Machines available in the market?

- Hand-operated gold sheet rolling machines: ideal for small-scale production.

- Electric gold sheet rolling machines: Using electricity to power them increases precision and efficiency.

- Hydraulic Gold Sheet Rolling Machines: For heavy-duty gold sheet rolling, use hydraulic systems.

- Rolling, flattening, and shaping are just a few of the tasks that combination gold sheet rolling machines can do.

- CNC Gold Sheet Rolling Machines: Using computer numerical control, these machines are very accurate and automated.

- Gold sheet rolling machines that are gear-driven: These machines include gear systems that allow for regulated and smooth rolling.

- Bench-top gold sheet rolling machines: These are small, convenient machines that are meant to be set up on workbenches.

- Industrial gold sheet rolling machines: Sturdy equipment for processing and producing gold sheets on a big scale.

- Rolling machines for precision gold sheets: designed to roll gold sheets with accuracy and dexterity.

- Gold sheet rolling machines with motors: These machines include motorized rollers that enable reliable and effective sheet rolling.

4. How long does it take to roll a sheet of gold using a Gold Sheet Rolling Machine?

3-5min

5. What are the common issues faced when using a Gold Sheet Rolling Machine and how to troubleshoot them?

- Uneven Rolling: Verify and modify the roller alignment.

- Slipping Sheets: Verify that the machine’s tension is adjusted correctly.

- Sheets jammed: Clean out any dirt or impediment within the rollers.

- Overuse of Rollers: Replace worn-out components on a regular basis.

- Uneven Thickness: Verify and correct the machine’s calibration.

- Overheating: In between rolling sessions, let the machine cool down.

- Motor Malfunction: Look for problems with the electrical connections and motor.

- Overbearing Noise: Check for loose parts and lubricate moving parts.

- Bad Rolls: Use superior gold sheets and modify the pressure settings.

- Safety Concerns: Make sure operators are properly trained and adhere to the correct safety procedures.

6. Can a Gold Sheet Rolling Machine be customized for specific sheet sizes and thicknesses?

Indeed, it is possible to tailor gold sheet rolling machines to accommodate particular sheet thicknesses and sizes. In order to handle different sheet dimensions, manufacturers may provide choices for altering roller widths, diameters, and pressures. Furthermore, some machines include replaceable rollers or settings that let users tailor the rolling procedure for various sheet thicknesses and sizes. Options for customization might increase the machine’s adaptability and flexibility to satisfy certain manufacturing needs.

7. Are there safety precautions to be followed while using a Gold Sheet Rolling Machine?

- Yes, when operating a gold sheet rolling machine, there are a few safety measures to take:

- To avoid injury, put on the proper personal protection equipment, such as gloves and safety glasses.

- Make sure your hair, jewelry, and loose clothing are fastened to prevent becoming tangled up in moving parts.

- Read the operation handbook for the equipment carefully and abide by all manufacturer-provided safety instructions.

- To avoid mishaps, keep your hands and fingers away from the rollers when the machine is operating.

- Before doing any repairs or maintenance, turn the equipment off and disconnect it.

- To ensure safe operation, periodically check the machine for wear or damage, and take quick action to fix any problems.

- In order to avoid stressing any parts or creating any risks, avoid overloading the equipment.

- For ideal balance when operating, place the machine on a level, sturdy surface.

- To reduce hazards, instruct operators on the safe and efficient usage of the machine.

- Stop using the equipment right once and get expert assistance for repairs if you hear any strange noises, vibrations, or malfunctions.

8. What are the advantages of using a Gold Sheet Rolling Machine over manual methods?

- Precision: Compared to human methods, machines yield rolling results that are reliable and accurate.

- Efficiency: Compared to manual work, gold sheet rolling machines can process sheets more quickly and effectively.

- Versatility: Machines are more versatile since they may frequently be changed to accept different sheet sizes and thicknesses.

- Decreased Labor Intensity: When workers use a machine, their physical strain is lessened, which increases output.

- Quality Control: To maintain better standards of quality, machines make sure that the rolled gold sheets are consistent.

- Automation: By automating the rolling process, Gold Sheet Rolling Machines lessen the requirement for continuous operator involvement.

- Speed: By rolling gold sheets more quickly, machines can raise total production rates.

- Consistency: Machines produce more consistently since human mistake is less likely to occur.

- Safety: Machines increase operator safety by reducing the amount of manual handling involved in the rolling process.

- customisation: To accommodate certain sheet sizes and thicknesses, several machines provide customisation choices that enhance production flexibility.

9. Can a Gold Sheet Rolling Machine be used for materials other than gold?

Indeed, a gold sheet rolling machine is useful for a variety of materials besides gold. Other metals including silver, copper, brass, and other alloys may be acceptable for rolling, depending on the design and requirements of the machine. To guarantee the best outcomes, it is crucial to take into account the machine’s compatibility with various materials and modify the parameters appropriately. To find out if the machine is appropriate for using with materials other than gold, always consult the manufacturer’s instructions.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited