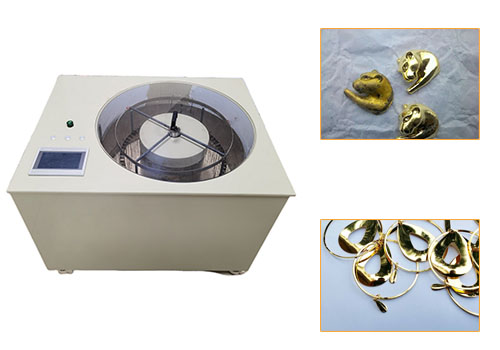

Electro Polishing Machine For Gold Jewellery

SuperbMelt possesses the world's top jewelry electropolishing equipment

SuperbMelt Electro Polishing Machine for Gold Jewellery helps customers solve the polishing issues of gold, silver, and copper jewellery. This gold electro polish machine is used for polishing and surface treatment of gold jewellery, removing minor irregularities and oxide layers from the metal surface, thereby making the gold jewellery surface smoother, more uniform, and glossy.

- This electrolysis equipment is compact in size, affordable in price, and suitable for small-scale jewellery businesses and individual jewellery shops.

- The machine can achieve 360° no-dead-angle polishing, ensuring the integrity of the jewellery appearance compared to traditional polishing methods.

Electro Polishing Machine For Gold Jewellery can complete the electrolytic polishing of 20 jewellery rings or bracelets at a time, making it very suitable for small jewellery processing factories and DIY jewellery enthusiasts.

| Model number | SPB-GR3 | SPB-GR2 | SPB-GR1 |

| Power supply | AC 220V/DC 0-15V | AC 220V/DC 0-15V | AC 220V/DC 0-15V |

| Power | 1kw Max 50A | 2.3kw Max 150A | 4.5kw Max 300A |

| Machine hook | 20pcs | 60pcs | 138pcs |

| Batch productioncapacity | Silver: 6.5kg Copper:6.5kg K gold:5kg | Silver: 52kg Copper:52kg K gold:40kg | Silver: 97.5kg Copper:97.5kg K gold:75kg |

| Electrolyte capacity | 5L | 40L | 75L |

| Metal electrolyte ratio | Copper: 1.7L electrolyte: 3.4L water Silver: 1.3L electrolyte: 2.6L water K gold: 4L electrolyte (No water) | Copper: 10L electrolyte 20L water Silver: 10L electrolyte: 20 water K gold: 30L electrolyte (no water) | Copper: 25L electrolyte/ 50L water Silver: 25L electrolyte/ 50L water K gold: 75L electrolyte (no water) |

| Size | 465mm*335mm*41mm /28kg | 81mm*1010mm*700mm /70kg | 810mm*600mm*70mm /120kg |

| Abrasive dosage | 3 kg | 15 kg | 25 kg |

| Applicable metal | copper , silver, K gold, (No pure gold, platinum) | copper , silver, K gold, (No pure gold, platinum) | copper , silver, K gold, (No pure gold, platinum) |

- Superior Electrolytic Polishing: The apparatus offers proficient and superior electrolytic polishing, successfully eliminating corrosion, grime, and flaws from the metallic exterior.

- Restoration of Luster: The device brings back the sheen and luster of jewelry, including pieces made of gold, silver, copper, and K gold, by employing certain electrolytes.

- Versatility: It may be used for many different kinds of jewelry made of different metals, such as rings, necklaces, bracelets, earrings, and more.

- Enhanced Appearance: The jewelry seems cleaner, glossier, and more brand-new thanks to the machine, which raises its market value.

- Batch processing: This technique polishes several jewelry items at once, increasing productivity and saving time.

- Flexibility of Application: In addition to jewelry, it can be used to polish various metal items and parts, including coins, watch parts, metal crafts, and metal tools.

- Tailored Solutions: SuperbMelt guarantees client satisfaction by providing tailored solutions to satisfy certain jewelry processing and polishing needs.

- Jewelry Manufacturing: This process is used to polish a variety of jewelry pieces, including pendants, earrings, rings, necklaces, bracelets, and earrings made of copper, silver, and K gold, among other metals.

- Jewelry repair shops: Used to bring worn or tarnished jewelry items in for repair or refurbishing back to their original brilliance and sheen.

- Retail stores that sell jewelry: Used to improve the way jewelry is presented for sale, drawing buyers in and raising the price of the item.

- Used in the watchmaking industry to polish metal parts and components to preserve their luster and visual attractiveness.

- Metal Crafts Industry: Used to polish ornaments, sculptures, and other ornamental metal objects to improve their aesthetic appeal.

- Numismatics and coin collecting: Used to preserve the value of metal coins and other numismatic artifacts as collections by polishing them.

- Workshops for metalworking: required to polish different metal parts, tools, and components required in industrial production operations.

working principle of the electrolytic polishing machine is mainly based on electrochemical principles. During the electrolytic polishing process, the workpiece acts as the anode, connected to the positive terminal of a DC power source, while a material resistant to electrolyte corrosion, such as lead or stainless steel, serves as the cathode, connected to the negative terminal of the power source. Both are immersed in an electrolyte solution containing basic components such as sulfuric acid and phosphoric acid, and subjected to a certain temperature, voltage, and current density (typically below 1 ampere per square centimeter) for a specific period (e.g., several seconds to minutes).

Under the influence of the electric current, dense bubbles form on the metal surface, creating an oxide film. This oxide film slows down the dissolution rate of the metal, putting the metal surface in a passivated state. During the polishing process, the metal surface undergoes both dissolution and passivation reactions simultaneously. Due to the larger contact area of the rough metal surface with the electrolyte, surface defects are dissolved more rapidly. Electrolytic polishing can improve the external geometric structure of the metal surface, reduce surface roughness, and make it progressively smoother, thereby achieving the polishing effect.

Why SuperbMelt Electro Polishing Machine For Gold Jewellery

Any Question About SuperbMelt SuperbMelt Electro Polishing Machine For Gold Jewellery

About SuperbMelt Electro Polishing Machine For Gold Jewellery

Introduction to Jewelry Polishing

The technique of treating jewelry’s surface to improve its brilliance and look quality is known as jewelry polishing. Jewelry that has been polished should be free of flaws, oxidation layers, grime, and unevenness to give it a brighter, smoother, and more exquisite appearance.

Jewelry polishing is important since it has a direct impact on the jewelry’s look, quality, and perception. The jewelry’s texture and attractiveness are enhanced when it is polished, giving the surface a smoother, finer, brighter, and more even reflection of light appearance. Furthermore, polishing can restore small surface blemishes and scratches, restoring the jewelry’s shine.

Conventional jewelry polishing is usually carried either by hand or by machine. But as technology develops, the jewelry polishing industry is using an increasing amount of CNC machinery and automated procedures to increase productivity and quality. Whether done by hand or with contemporary technology, polishing is an essential phase in the jewelry-making process.

1.1, Previous Polishing Methods

Jewelry was formerly polished by hand with the use of grinding tools, grindstones, polishing chemicals, and other supplies. This method mostly depended on the artistry of craftspeople, who required extraordinary talent and perseverance. The skill and experience of the craftsman determined the quality of the polishing, which led to inconsistent results and a labor-intensive procedure.

1.2, A modern way to polish

Modern jewelry polishing techniques use automated procedures and cutting-edge technologies to provide consistently high-quality results quickly. These methods erase surface flaws and improve the sheen and luster of jewelry items by using specialized tools such polishing machines with revolving brushes, abrasive wheels, or polishing chemicals.

Modern technologies like electrochemical polishing and ultrasonic polishing have arisen in addition to conventional mechanical polishing techniques. While ultrasonic polishing uses high-frequency vibrations to provide accurate and consistent polishing results, electrochemical polishing uses electrolytic solutions and electrical currents to eliminate surface flaws and enhance surface smoothness.

1.3, The commercial value of exquisite jewelry

Exquisite jewelry has a high market value because it appeals to consumers looking for status symbols, elegance, and beauty. Beautiful jewelry is frequently made of precious metals like platinum, silver, and gold and embellished with gemstones like sapphires, rubies, and diamonds. These items serve as expressions of cultural importance, social standing, and personal style in addition to being accessories. They are quite popular and sought after in the market since they have sentimental significance and may be passed down through generations. Exquisite jewelry items also have a higher market value as they are frequently connected to milestone events like weddings, anniversaries, and festivities.

What jewelry polishing machines are on the market now?

To meet the different demands of jewelry producers and artists, a range of jewelry polishing machines, including fully automatic, semi-automatic, and manual versions, as well as specialty equipment like magnetic tumbling machines and ultrasonic cleaners, are available on the market.

2.1, Electrolytic Polishing Machine

- A tool for electrochemically polishing metal surfaces is an electrolytic polishing machine. Using an electrochemical reaction, material is removed from a metal workpiece’s surface in this procedure. Metal items can have their surface finishes improved via electrolytic polishing, which leaves the metal glossy, smooth, and free of flaws.

- Electrodes, an electrolyte solution, and a power source are the standard components of an electrolytic polishing machine. One electrode is the metal workpiece that has to be polished, while the other electrode is either a conductive pad or another electrode. The electrolyte solution is submerged in both the workpiece and the electrode.

- Metal ions are removed from the workpiece’s surface when an electric current flows through the electrolyte solution between the electrodes. This procedure improves the overall surface polish, smooths out surface imperfections, and eliminates tiny burrs. To obtain the intended polishing effect, variables like voltage, current density, electrolyte composition, and temperature are carefully regulated.

- In industries where high-quality surface finishes are necessary for practical or aesthetic reasons, such as the automotive, aerospace, electronics, and medical device sectors, electrolytic polishing is frequently utilized. It has benefits including repeatability, homogeneous material removal, and the capacity to polish intricate forms and challenging-to-reach places.

- It’s important to remember, though, that because electrolytic polishing uses chemical solutions and electric currents, safety measures must be closely followed. To avoid mishaps and guarantee worker safety, proper ventilation, safety gear, and observance of regulations are crucial.

2.2, Mechanical Polishing Machine

- A mechanical polishing machine is a tool used to mechanically remove material from a workpiece’s surface in order to give it a more polished, smooth finish. With mechanical polishing, the workpiece surface is physically abrasiveened using rough materials, as opposed to electrolytic polishing, which depends on electrochemical processes.

- The general operation of a mechanical polishing machine is as follows:

- Workpiece Mounting: The workpiece is firmly fixed to the polishing machine. It may be composed of ceramic, metal, plastic, or another material. Depending on the size and shape of the workpiece, this might be accomplished with the use of clamps, chucks, or other holding devices.

- Application of Abrasive Materials: The workpiece’s surface is treated using abrasive materials, which can include wheels, discs, polishing compounds, abrasive belts, brushes, and discs. The material of the workpiece, the desired finish, and the particular needs of the polishing process all play a role in the selection of abrasive material.

- Polishing Procedure: The workpiece is subjected to mechanical force by the polishing machine, which causes the abrasive material to abrasively remove material from the surface. This procedure improves the overall surface polish by removing burrs, scratches, and other flaws from the surface.

- Controlled factors: During mechanical polishing, a number of factors may be adjusted, such as the polishing machine’s speed, the pressure used on the workpiece, the kind and grit size of the abrasive material, and the polishing process’ length. The particular needs of the workpiece and the intended finish are taken into consideration while adjusting these parameters.

- Cleaning and Inspection: To get rid of any last bits of dirt and abrasive material, the workpiece is usually cleaned after polishing. To make sure the intended finish has been reached and that no flaws or blemishes remain, it could also go through inspection.

- In many industries, including industrial, automotive, aerospace, electronics, jewelry, and optics, where flawless surface finishes are necessary for both practical and esthetic reasons, mechanical polishing equipment are employed extensively. They have benefits including adaptability, scalability, and polishing a broad spectrum of materials and workpiece shapes. To efficiently obtain the intended outcomes, the procedure might be laborious and need skill.

2.3, Platinum resistance furnaces

- A vibratory polishing machine is a sort of mass finishing equipment used for deburring and polishing ceramic, metal, plastic, and other materials. It is sometimes referred to as a vibratory tumbler or vibratory finisher. It works by introducing a batch of workpieces into a container or chamber that is filled with high-frequency vibrations coupled with abrasive material and often a liquid solution.

- The general operation of a vibratory polishing machine is as follows:

- Load Workpieces and Abrasive Media: The vibratory polishing machine is filled with the workpieces to be polished as well as abrasive media, such as metal shot, plastic pellets, or ceramic chips. Depending on the unique needs of the polishing process, the workpiece to medium ratio may change.

- Add Liquid Compound: To lubricate the operation, remove debris, and aid in distributing the abrasive media evenly over the workpieces, a liquid compound—typically water-based—may be introduced to the machine.

- Start the Vibration: The machine’s motor produces high-frequency vibrations that start the oscillation of the chamber or container. As a result of the abrasive media’s interaction with the workpieces caused by these vibrations, burrs and other irregularities are removed from the surface.

- Polishing Procedure: The workpieces’ surfaces are continually in touch with the abrasive media while the vibratory motion continues, progressively polishing them to the required finish. The material of the workpieces, the required level of finish, and the abrasive media’s aggressiveness are some of the variables that might affect how long the polishing process takes.

- Unload and Clean: The workpieces and abrasive media are taken out of the machine when the polishing procedure is finished. To leave behind a smooth, polished surface, the workpieces can be cleaned and dried to get rid of any remaining abrasive media and compound.

- For finishing purposes, vibratory polishing machines are widely utilized in a variety of sectors, such as metalworking, automotive, aerospace, jewelry manufacture, and medical device fabrication. They have a number of benefits, including as the capacity to process big batches of workpieces at once, reliable and uniform finishing outcomes, and the capacity to polish intricate forms and challenging-to-reach places. Furthermore, vibratory polishing is gentler than other mass finishing techniques, which makes it appropriate for delicate or breakable workpieces.

2.4, Platinum resistance furnaces

- For the purpose of polishing and deburring tiny metal components, a magnetic polishing machine—also referred to as a magnetic finisher or magnetic tumbling machine—is a form of mass finishing apparatus. It works on the basis of using magnetic force to induce motion and agitation in a chamber or container, which polishes the workpieces.

- The general operation of a magnetic polishing machine is as follows:

- Load Workpieces and Abrasive Media: The magnetic polishing machine is filled with the workpieces to be polished as well as abrasive media, such steel pins or balls. Within the container, the workpieces and abrasive media are combined.

- Turn on the Magnetic Field: The device creates a magnetic field that rotates inside the box or chamber. The abrasive medium moves and circulates around the workpieces as a result of this magnetic field, causing a tumbling movement.

- Polishing Process: The abrasive media come into touch with the workpiece surfaces as they tumble around them in the magnetic field. This abrasive action removes burrs, surface defects, and other irregularities from the workpieces. The surfaces of the workpiece are polished as a result of the continuous movement and agitation.

- Controlled Parameters: To obtain the appropriate polishing effect and finish quality, the parameters of the magnetic polishing process may be changed. These include the size and shape of the abrasive media, the rotational speed, and the strength and duration of the magnetic field.

- Unload and Clean: After polishing is finished, the machine’s workpieces and abrasive media are taken out. To achieve smooth, polished surfaces, the workpieces can be cleaned by rinsing and drying them to get rid of any remaining abrasive media and debris.

- In sectors where small, complicated metal parts require high-quality surface treatments, such jewelry production, watchmaking, dental equipment fabrication, and electronics manufacturing, magnetic polishing machines are frequently utilized. Their benefits include processing tiny components in big batches, uniform and reliable finishing outcomes, and the ability to polish intricate forms and challenging-to-reach regions. Furthermore, magnetic polishing is rather soft when it comes to mass finishing techniques, which makes it appropriate for delicate or breakable workpieces.

Why do jewelry pieces need polishing?

Beause Melting metal to mend or re-work your jewellery pieces will help you to expand on the style of jewellery you offer and the variation of jewellery pieces you supply. At Cooksongold, we supply all the metal melting equipment you need to successfully liquefy metal.

From hand torches to scorifiers, tongs and butane gas lighter fuel – we really are the one-stop shop for all your metal melting equipment. Browse our range of metal melting equipment and find our quality melting tools in a selection of shapes and sizes.

3.1, The surface aesthetics

Jewelry’s surface aesthetics include its texture and visual appeal. This covers elements including its color, form, gloss, texture, and workmanship. In order to guarantee a pleasing look and exquisite design, high-quality jewelry usually places an emphasis on surface aesthetics. Surface design improves a piece of jewelry’s worth and appeal while also enhancing the charm and self-assurance of the wearer. Because of this, jewelry makers frequently use premium materials and precise craftsmanship to guarantee that the outside appearance of their creations meets the greatest standards.

3.2, Improve comfort

Rough surfaces may cause discomfort when wearing jewelry and even lead to skin irritation. Jewelry surfaces that have been polished are smooth and even, making them more comfortable to wear and less likely to cause discomfort.

3.3, Enhanced durability

Electrolytic polishing enhances durability by smoothing out surface imperfections and strengthening the metal structure, making the jewelry less prone to corrosion and wear over time.

How to obtain exquisite and durable jewelry

4.1, Smelting

The gold raw material is placed into a vacuum melting furnace for smelting, producing high-quality liquid gold, laying a solid foundation for crafting exquisite jewelry. The vacuum melting furnace can melt liquid with no surface bubbles and uniform fineness.

4.2, Casting

Using a vacuum casting machine for casting is a device that injects molten metal into casting molds. SuperbMelt’s casting machine features precise control systems, ensuring accuracy and consistency in metal filling into the molds.

4.3, Polishing

Removing surface imperfections such as oxides and contaminants through the electrolytic process enhances the fineness of jewelry. This process helps reveal the inherent brilliance and purity of the metal, thereby improving its color and luster.

Conclusion

Polishing jewelry is crucial for enhancing its aesthetics, comfort, and durability. Whether through traditional methods like manual polishing or modern techniques employing advanced machinery, the goal remains the same: achieving flawless, dazzling surfaces to elevate the beauty and value of the jewelry. From electrolytic polishing to mechanical, vibratory, and magnetic polishing, each method offers unique advantages tailored to specific industry needs. With cutting-edge equipment like the Jewellery Liquid Polish Machine from SuperbMelt, jewelers can confidently craft exquisite, durable, captivating, and inspirational pieces. Whether achieving perfect surface aesthetics, improving wearer comfort, or extending the jewelry’s lifespan, the processes of melting, casting, and polishing are paramount in creating truly stunning and high-quality jewelry.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited