Chain Hammering Machine

Superbmelt provide a one-stop service to solve any problems with your jewelry chain manufacturing line

In the creation of jewelry, chains do play the most pivotal role here. The Superbmelt jewelry chain hammering machine is generally utilized for the recognizable template designs that can be worn by many.

They are quite expensive when it comes to the gold and silver chains. With the hammering techniques, the chains can be given the most distinctive shapes that can make them hard or even lengthen or shorten in terms of the repairs that are being made.

The hammering process may also involve other metals such as platinum, palladium as well as steel. The chains can be redone as well as undone with the help of the smaller lever mechanisms that are considered as the findings that serve as fastenings.

- Superbmelt chain hammering machine is extremely easy to be employed, considering the durable nature that can make them quite cohesive.

- Various shapes of the chains can be done here with the free forms of different sizes that are being mixed with the solid sections with smaller rings that connect the larger round as well as the square sections of the wire, making it user-friendly.

- It generally depends on the imagination of the craftsman that is making them. The ones made from the jump rings are the commonest kinds of chains that are involved here.

- They are extremely affordable in their prices with designs that are extremely compact.

- This process can help with a greater amount of durability that can help it against the shock loads with tensile strengths and are easily recognizable.

- The hammered pins and bushes can also be reduced in their sizes, with materials being selected specifically for their durability in mind.

- The hammering process of the chain hammering machine is maintained in greater control with the proper temperature and the use of energy, making the process of chain-making easier.

- Superbmelt chain hammering machine offered here are mainly manufactured on the basis of using high-quality equipment along with the components being sourced through the trusted and reliable vendors out there in the market as the machines come equipped with the speed controller as well as the automatic chain puller.

- Greater improvement in the method of chain-making

- Light and pre-set of the side plates

- Greater breaking loads

- Improved endurance over the fatigue strength.

| Model | SPB-ZC016 |

| Item | Parameter |

| Max. working pressure | 15 tons |

| Speed | 1000 rpm/min |

| Voltage | 3-phase 380V 50Hz |

| Power | 500W |

| Size | 70x75x162 cm |

| Weight | 610kg |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Jewelry Chain Making Line Solution

Any Question About SuperbMelt Jewelry Chain Making Line Solution

FAQ Guide of Chain Hammering Machine

- 1. What is the jewelry chain hammering machine used for?

- 2. How to produce jewelry chains nowadays?

- 3. How does SuperbMelt jewelry chain hammering machine work?

- 4. How do you make a flat chain?

- 5. What is the production capacity of the chain hammering machine?

- 6. What machines are used to make jewelry chain?

- 7. How durable is a jewelry chain hammering machine?

- 8. Does a jewelry chain lose gold hammering?

- 9. What are safety features of chain hammering machine?

- 10. Do operating SuperbMelt jewelry chain-making machine require special training?

- 11. How to choose the best jewelry chain hammering machine manufacturer?

1. What is the jewelry chain hammering machine used for?

In general, a chain hammering machine is used to at attaining a perfect shape through the hammering process. The machine is fully automatic, and you can process the chains with more than 15 tons of power. You can also use this machine to make flat gold or silver chains.

2. How to produce jewelry chains nowadays?

Nowadays, all the jewelers use machines to make chains as using them; they can make multiple chains within a few hours. No matter what type of material you want to use, these machines can be a great option for you. Now, speaking about the modern process of making chains:

- First, pure gold is obtained by smelting gold ore in a furnace. An induction furnace works best.

- Next, durable gold rods are created from the gold using a powerful continuous casting machine. You can give any shapes, like a cylinder, circular and more.

- Once done, a rolling machine is used to make gold wires from the gold rod.

- Then thin gold wires are created by utilizing a wire drawing machine.

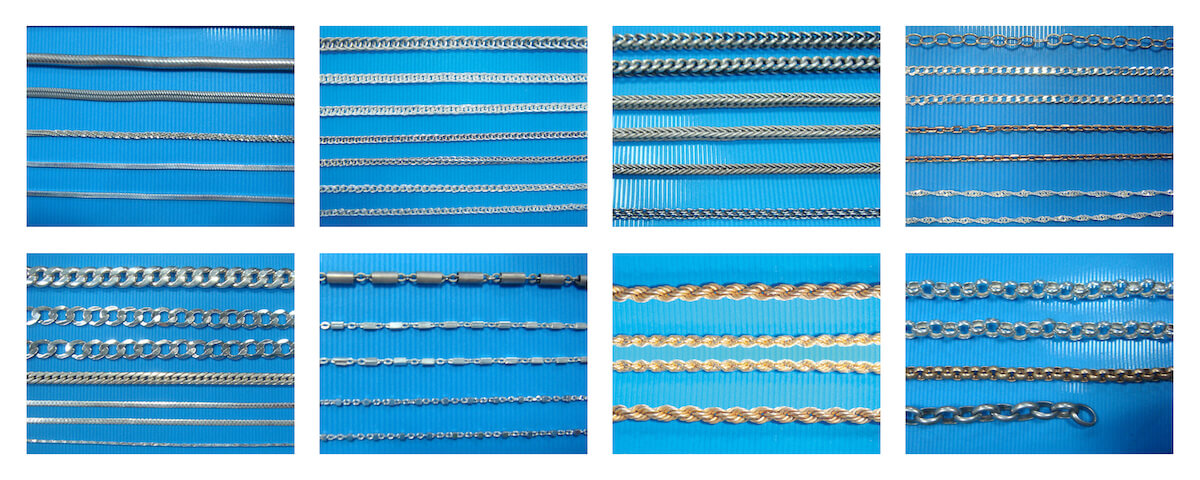

- After making the wires with the desired diameter, jewelers use a chain-making machine to manufacture chains in different shapes. The machine can create different types of gold chains, such as double curb, snake, Figaro, link chains, and more.

- A chain hammering machine is later used to give those chains a perfect shape. This will make sure that the parts are perfectly connected to each other.

- In the end, to give a shiny look to the gold chains, they use a chain faceting machine.

If you are looking for a reliable platform to buy these machines and start your own jewelry manufacturing unit, then visit SuperbMelt now. We offer durable machines under your budget.

3. How does SuperbMelt jewelry chain hammering machine work?

SuperbMelt offers good-quality chain hammering machines that can easily handle the hammering process. All you need to feed the wire into the machine, and it will start hammering the parts. Our machine can make various designs from a basic chain. Well, you can also use a squaring die, universal die, or block-on-block die for hammering. Contact our executives now to know everything about this machine.

4. How do you make a flat chain?

Well, the introduction of advanced machines, including chain hammering machines, has made it a lot easier to make flat chains. In fact, there is no need to manually create gold rods, welding, and hammering. Every task can be done using a machine. To make a flat chain, create a chain using a jewelry chain-making machine and then process that through a chain hammering machine to give that a flat shape. Once done, use a faceting machine for finishing. That’s it. Your flat chain is ready to wear.

5. What is the production capacity of the chain hammering machine?

These machines are automatic press machines designed for the hammering process of compacted chains. Well, you can use them for non-compacted chains also. The machines can create up to 30 tons of high-precision hammering. You will find them extremely versatile and of high precision. So, there will be no chances of error. Some machines can offer a capacity of 5-ton blow per min.

The machine comes with a powerful traction system that will pull the chain through the stamping unit when the blocks are open and that will not block the chains. As a result, you can easily avoid any uncontrolled and excess stretching of your gold chain.

On the other hand, the toggle system-based hammering mechanism will make sure that the machine produces total and controlled power at every stroke with a sufficient amount of force on the internal mechanisms, thus reducing wear. Tool change is very fast, and its blocking system works very effectively. The machine is very silent and comes with a powerful pneumatic brake and clutch system. To get a free quote and to know more about our machine, feel free to get in touch with us now.

6. What machines are used to make jewelry chain?

Earlier, jewelers used to make jewelry chains by hand, which is a very time-consuming task. Besides, there is no guarantee that you will get an accurate result. However, the process of jewelry making has changed a lot, and now you can use different machines to make the chain-making process faster, accurate, and efficient. Let’s discuss the type of machine you can use in the process. Have a look.

- Gold casting machine

Using a continuous gold casting machine, you can create a gold rod or bar from the melted gold. Some machines come with melting protection technology so that you can get accurate temperature throughout the casting process.

- Chain roll mill

The primary task of this machine is to transform gold rods into gold wires. Equipped with advanced technology, this machine will roll the hard gold rod and convert them into thin wires.

- Gold wire drawing machine

Our gold chain wire drawing machine can easily create thin wire from the thick gold wire. Applying the right pressure will create the desired standard of gold wire.

- Chain making machine

After creating a thin gold wire, you can use our chain-making machine to start making chains. This one machine can handle multiple tasks like winding, welding, cutting, and more so that you can make a chain faster.

- Chain hammering machine

To bring the chains into the desired shape, jewelers use a chain hammering machine. With the best machine, you can complete the hammering processes within a few hours.

- Chain faceting machine

In the end, you can use a faceting machine to give your chain a perfect finish. This machine can make lapping, chamfers cut, plain cut, and more.

SuperbMelt is a reliable jewelry chain production solution provider and has years of experience in this. We have machines to make belcher chains, trace chains, bead chains, Figaro chains, flat chains, and more. Get in touch with us now to get a free quote.

7. How durable is a jewelry chain hammering machine?

The advanced technologies have made it possible to make quality and durable chain hammering machines. No matter what is your daily production requirements, such machines will easily meet that. Whether you have a large jewelry shop or a small one, you can always trust these machines. Well, today’s hammering machines are designed to carry out the task automatically. So, you just need to insert the chain, and the rest of the task will be handled by the machine.

These machines are so durable that they can process chains made of silver, copper, gold, platinum, and more. At SuperbMelt, we manufacture machines using quality material and advanced technology. They meet the required production standard so that you can use them safely. If you want to know more about our machines, then please feel to get in touch with us now. Our experts can explain to you every detail of the machine and how it can help you in product improvement.

8. Does a jewelry chain lose gold hammering?

Gold hammering now has become a common method among jewelers to make hammered chains. Such chains look beautiful and durable. Those who want to buy a hammering machine have a common question, i.e., will they lose gold during hammering? Well, the answer is now. The modern gold hammering machines are very powerful and efficient. They are designed to carry out the process without affecting the gold quality. They are so efficient that you will not lose any amount of gold during the hammering process.

9. What are safety features of chain hammering machine?

No matter what types of machines you are using, you will have to use them properly, following all the safety instructions to enjoy a safe hammering process. Besides, it is always important to choose a chain hammering machine that comes with maximum safety features. So, what are the features you should look for in a hammering machine? Some common safety features are the working pressure of the machine, maximum ram stroke, strokes per minute, electrical power supply capacity, throat depth, and more.

Besides, choose a machine with a robust structure so that it can last for years. SuperbMelt’s hammering machine comes with a perfectly welded steel machine structure and powerful roller bearing as well as automatic lubrication so that it can work smoothly under severe working conditions.

10. Do operating SuperbMelt jewelry chain-making machine require special training?

When it comes to choosing a reliable brand for your chain hammering machine, most jewelers prefer to opt for SuperbMelt. Why? Well, SuperbMelt, has years of experience and expertise in offering the best quality machines that can take your production process to the next level. SuperbMelt is your one-stop solution for buying different machines to make jewelry chains, such as roll mill machines, casting machines, drawing machines, faceting machines and hammering machines, and more.

All our machines are made of durable materials and advanced technologies. Besides, they have a lot of features. In terms of usability, SuperbMelt’s machines are super easy to use. The machines are easy to set up and program. All you need to feed the chain into the machine to start the hammering process. One can easily operate it without developing any special skills.

11. How to choose the best jewelry chain hammering machine manufacturer?

When it comes to buying a good quality chain hammering machine, it is always advisable to choose a reputed manufacturer so that you can enjoy maximum benefits. As the market is full of many manufacturers, choosing the best one can be a challenging task. However, to help you out with this, we have mentioned down some major factors to keep in mind.

- Manufacturer’s experience

One is the most important things that you need to consider while choosing a chain hammering machine manufacturer is the total years of experience of the company. It is always advisable to choose a manufacturer with more than ten years of experience in manufacturing and supplying good quality machines. This is where you can always trust SuperbMelt.

- Manufacturer’s reputation

Don’t choose a company that has a bad reputation in the industry. As a result, you may face poor services and machines. How to know your reputation? Well, the best way to do that is by checking the reviews posted on the manufacturer’s site by the old clients who are using the machine.

If the company has positive reviews, then go for it. If you are finding it challenging to locate a company with a good reputation, you can choose SuperbMelt. We have been working in this industry for more than ten years and have a good brand reputation among our clients.

- Technical support provided by the company

Always check the after-sale service quality of the chain hammering machine manufacturer before finalizing any deal. Such machines can develop technical issues without any notice. But you need to resolve them as soon as possible. And for that, the company should be able to offer prompt technical support. At SuperbMelt, we really care about our clients and always try our best to respond within 24 hours against your issues.

- Quality of the machine

To enjoy a smooth chain hammering process, it is important to buy a quality machine. A good quality machine can hammer multiple chains within a few hours. SuperbMelt’s machines are equipped with advanced electric components from the top brand and can satisfy your daily production requirements.

- Check for the registration certificate

Always choose a manufacturer that is fully licensed and certified. This way you can make sure that all the machines are up to the mark and developed following the international standards. Well, SuperbMelt is an ISO CE SGS approved company. The professional certification bodies have certified the quality of the machine.

- Consider the delivery time

Make sure that the manufacturer offers faster delivery services so that you can get the machine as soon as possible and start your production. SuperbMelt maintains sufficient stock of the machine, and once you place the order, you will get the machine within seven working days.

These are some of the major factors that you need to keep in your mind while choosing a chain hammering machine manufacturer. However, you can opt for SuperbMelt whenever you need to buy a machine.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited