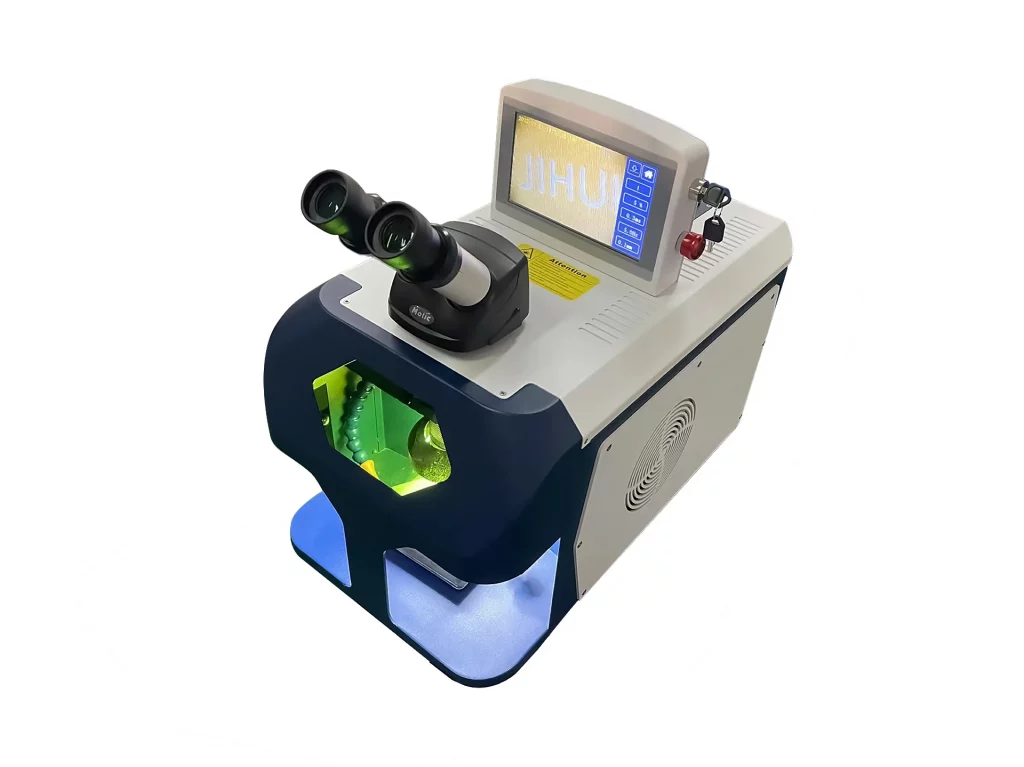

Laser soldering machine for gold jewellery

SuperbMelt’s laser soldering machine for gold jewelry is specifically designed for welding gold, silver, platinum, and other jewelry bracelets.

The welding process of SuperbMelt’s soldering machine achieves high precision and flawless welding results. Parameters such as frequency, pulse, and spot size can be automatically adjusted. The dual-eye microscope and camera device allow users to observe the welding process and prevent errors.

The laser soldering machine for gold jewelry is not only suitable for jewelry welding but also applicable to industries such as medical, electronics, tool manufacturing, and automotive.

SuperbMelt is a leading manufacturer of laser welding machines, offering a range of models, including 80W, 150W, and 200W.

| Model | SPB-200WB |

| Wavelength | 1064nm |

| Maximum output power | 200W |

| Maximum pulse energy | 80J |

| Pump source | Single lamp |

| Pulse width | 0.1-20ms |

| Pulse frequency | ≤50Hz |

| Aiming and positioning | Microscope + camera system |

| Application | Welding and repairing various precious metal trinkets |

| Host power consumption | ≤7KW |

| Electricity demand | AC220V±5%/50Hz |

| Cooling system | Water cooling |

| Host size | L: 1050mm, W: 620mm, H: 1250mm |

| Chiller size | L: 620mm, W: 480mm, H: 710mm |

| Total weight | 193kg |

- Superbmelt laser welding machine operates without contact to weld together metal parts. So, there is no risk of wear and tear on your laser machine. There is also no need to change welding tools which means that our laser machine helps to reduce waste production.

- The laser welding machine is suitable for welding the same metal types, different metal types and also broken jewellery items. It is particularly suitable for welding small parts.

- This type of welding machine is particularly popular in the dental and jewellery industry because it provides aesthetic welding.

- Supermelt automatic laser welding machine has a water chiller measuring 620*480*710mm that is responsible for cooling the host machine, which prevents overheating.

- The inbuilt microscope and camera system allows for proper aiming and positioning when welding. This means that you can clearly view the metal pieces being welded and reduces the chances of making errors.

- The welding spots are neatly done which causes little to no discolouration. This is made possible through the wavelength of 1064nm and the pulse width of 0.1-20ms.

- The automatic laser marking machine is easy to use, it is equipped with different switches and buttons and an LCD display screen that allows you to control the parameters.

- Parameters such as current (controls welding power), frequency (speed), pulse (depth) and spot (controls the weld area) can easily be set on the LCD screen.

- The welding process is noiseless, therefore, it is environmentally safe.

- The high level of automation makes it possible to detect and solve and quality problems.

- The maximum power output required by the automatic laser machine is 200W while the host machine requires ≤7KW. The total electricity demand is about AC220V±5%/50Hz.

- The compact size of the Superbmelt laser welding machine means that it requires minimal space. The total weight is 193kg with easy to transport features.

Numerous sectors, including those that produce jewelry, cars, aircraft, medical equipment, electronics, and more, frequently employ laser welding devices. Laser welding equipment is utilized in the jewelry industry for delicate and complex tasks like repairing fragile parts, resizing rings, and attaching clasps. They are used to weld high-strength steels and aluminum alloys in the automobile sector. They are employed in aerospace to weld the structures of the aircraft and the engine parts. They are employed in the medical device sector to solder delicate wires and tiny components. They are employed in the electronics sector to solder small components and build circuits with a high component density.

Jewelry Spot Welding Machine

The method of soldering jewelry involves utilizing filler metal and heat to connect two or more metal parts. By putting many metal pieces together, the soldering technique may be utilized to make elaborate designs, such as the necklaces, bracelets, and other jewelry items that are made. For a finished result that is of excellent quality and durability, soldering calls for expertise, endurance, and attention to detail.

- Prepare the jewelry to be soldered.

- Clean the area to be soldered and apply flux.

- Adjust the equipment parameters and power according to the metal material of the jewelry.

- Use the laser of the welding machine to weld the jewelry to create or repair the jewelry.

Why SuperbMelt Laser Soldering Machine for Gold Jewellery

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

About SuperbMelt Laser Soldering Machine for Gold Jewellery Related Products

80W Jewelry Laser Welding Machine

SuperbMelt Laser Soldering Machine for Gold Jewellery

What does the SuperbMelt Automatic Laser Welder include?

1.1, Including

- Chiller

- Display screen

- Magnifier

1.2, 200W Automatic Laser Welder Key Specifications

Automatic Laser Welder offers a compact and space-saving design, comprising essential components such as a laser, power supply and control system, chiller, beam delivery and focusing system, and a binocular stereomicroscope. Its advanced features include a coaxial micro-coordinate indicator, enabling effortless workpiece positioning without the need for specialized fixtures. With adjustable laser power, pulse frequency, and pulse width settings accessible through the user-friendly control panel, precise customization is at your fingertips.

This versatile machine finds its primary application in the jewelry industry, specifically for tasks like spot welding sand holes, hole filling, seam repairing, and welding claw positions in gold and silver jewelry. The welding spot size can be easily adjusted to meet specific requirements. Notably, it boasts a minimal heat-affected zone, resulting in meticulously crafted and aesthetically pleasing weld spots. Furthermore, the Automatic Laser Welder minimizes the need for extensive post-welding treatments.

With its exceptional precision and accuracy, this advanced welding solution ensures precise positioning without causing any damage to the surrounding jewelry during the welding process. Experience the efficiency and effectiveness of the Automatic Laser Welder, designed to elevate your jewelry manufacturing and repair capabilities.

1.3, Working Principle of Automatic Fiber Laser Welding Machine

A powerful fibre laser serves as the machine’s energy source for automated fibre laser welding. The laser beam is produced and sent to the welding head through an optical fibre. A highly concentrated heat source is produced when the laser beam is directed onto the workpiece at the welding head.

The material at the weld junction melts under the tremendous heat produced by the laser beam, creating a molten pool. The molten pool solidifies as the laser beam travels along the weld path, producing a reliable and accurate weld.

Advanced control systems that enable exact control of variables including laser power, pulse frequency, and welding speed are installed in the autonomous fibre laser welding equipment. This guarantees top-notch weld quality and excellent welding performance.

Due to its great effectiveness, precision, and adaptability, the fibre laser welding machine is extensively employed in a variety of sectors, including the production of jewellery, automotive, aerospace, and electronics.

Gold Jewellery Welding Machine

gold jewelry welding machine is used for the production and repair of high-quality gold, silver, and jewelry bracelets.

2.1, Bracelet welding process

Discover the superior strength and design flexibility of welding in gold jewelry production. Compared to riveting, bolted connections, casting, and forging, welding offers distinct advantages that can revolutionize your jewelry manufacturing process.

Experience Unmatched Strength: Welded joints exhibit exceptional strength, surpassing even the base material itself. While riveting and bolted connections weaken the working section by drilling holes, resulting in a 20% strength reduction, welding ensures joints that match or exceed the strength of the base material.

Embrace Design Freedom: Welding opens up endless design possibilities. Unlike riveting and casting methods, welding is not limited by geometric shapes, allowing you to create intricate and hollow structures that captivate the eyes of jewelry enthusiasts.

Break Free from Thickness Constraints: Welding transcends limitations on structural thickness. Irrespective of significant variations in wall thickness, welding effortlessly brings together components, enabling seamless connections and empowering your creativity.

Scale Up with Ease: Welding empowers you to handle large-sized joints effortlessly. Dividing components and welding them on-site, an arduous task with forging or casting, becomes a seamless process. Embrace standard or non-standard profiles to achieve the desired structures, reducing weight and minimizing welds.

Unleash Fusion: Welding seamlessly integrates with other processes, facilitating endless possibilities. Explore combinations like casting-welding, forging-welding, or welding-bolting to unlock the potential of diverse material connections within a single structure, ensuring optimal performance and resource utilization.

Elevate Your Jewelry Manufacturing: Style and quality are paramount in the jewelry industry. Embrace the simplicity, versatility, and transformative capabilities of jewelry welding. From connecting metal molds to setting and repairing jewelry, welding proves its worth at every step, empowering your success.

Harness the power of welding in gold jewelry manufacturing today. Maximize strength, unleash creativity, and elevate your craftsmanship to new heights with this timeless technique.

2.2, How to Use Laser Welding for Bracelets?

Laser welding is a highly precise method commonly used in the manufacturing of bracelets.

Ensure that the bracelet components are clean and neatly arranged.

Set appropriate laser welding parameters such as power, frequency, and pulse width based on the bracelet material and design requirements.

Properly position and secure the bracelet components on the welding machine using suitable positioning tools to ensure accurate alignment for welding.

Activate the welding machine with the parameters set, and the laser beam will generate a highly focused beam of high-energy light in the welding area, connecting the bracelet components together.

After the welding process is completed, inspect the quality and strength of the weld seam.

Laser welding is a precise and efficient welding method suitable for various bracelet materials such as gold, silver, and platinum. It enables seamless welding, preserving the appearance and texture of the bracelet while ensuring welding strength and reliability.

Conclusion

SuperbMelt 200W Automatic Laser Welder offers exceptional capabilities for welding gold, silver, platinum, and other jewelry bracelets. With its high precision and flawless welding results, this machine delivers superior performance. It provides adjustable parameters such as frequency, pulse, and light spot, ensuring optimal customization. The inclusion of a binocular microscope and camera unit allows for accurate observation and error prevention during the welding process.

Beyond the jewelry industry, the Automatic Laser Welder finds applications in the medical, electronics, tool manufacturing, and automotive sectors. SuperbMelt, a renowned laser welding machine manufacturer, offers various models, including 80W, 150W, and 200W options.

The Automatic Laser Welder package includes essential components such as a chiller, display screen, and magnifier. This compact and space-saving machine consists of a laser, power supply and control system, beam delivery and focusing system, and a binocular stereomicroscope. Its advanced features, including a coaxial micro-coordinate indicator, allow for effortless positioning without the need for specialized fixtures. The user-friendly control panel enables precise adjustment of laser power, pulse frequency, and pulse width.

Primarily used in the jewelry industry, the Automatic Laser Welder excels in spot welding sand holes, hole filling, seam repairing, and welding claw positions in gold and silver jewelry. It provides flexibility in adjusting the welding spot size and produces minimal heat-affected zones, resulting in aesthetically pleasing weld spots. Additionally, it reduces the need for extensive post-welding treatments while ensuring precise positioning without damaging surrounding jewelry.

The working principle of the Automatic Fiber Laser Welding Machine involves the use of a powerful fiber laser that generates a highly concentrated heat source. The laser beam melts the material at the weld junction, creating a molten pool that solidifies to form a reliable and accurate weld. With advanced control systems, precise adjustment of laser power, pulse frequency, and welding speed is achievable, guaranteeing top-notch weld quality and performance. The versatility of fiber laser welding makes it widely used in jewelry production, automotive, aerospace, and electronics industries.

In summary, the SuperbMelt 200W Automatic Laser Welder is a state-of-the-art solution for welding gold, silver, and platinum jewelry bracelets. Its precision, efficiency, and adaptability make it an essential tool in the jewelry manufacturing process. Embrace the strength, design flexibility, and superior craftsmanship that welding offers to elevate your jewelry production capabilities.

FAQ Guide of Automatic Laser Welder

- 1. How To Weld Gold Chain?

- 2. How Can I Weld Tungsten?

- 3. How Does A Jewelry Laser Welder Work?

- 4. Can Your Welding Machines Be Used To Fill Air Holes Or Fill Gaps?

- 5. How Frequently Does The Water In The Welding Machine'S Water Tank Need To Be Changed?

- 6. How Long Can I Use The 150w Welding Machine Continuously?

- 7. What Metals Should Not Be Welded?

1. How To Weld Gold Chain?

- Cleaning and preparing the area to be fused is the first stage in laser welding gold chain jewelry. The area must be clear of any oil or grease and clean of any dirt, dust, or debris.

- The jewelry is then positioned such that the region that has to be welded is exposed and convenient to deal with.

- The laser welder is then configured with the appropriate settings, including power level, pulse duration, and frequency.

- When the laser welder is prepared, the user turns on the laser and points it at the jewelry to be welded. The metal melts due to the laser beam’s extreme heat, which also causes it to solidify into a tight bond. Up till the entire region is welded, the procedure is repeated.

- Cleaning the weld area: The jewelry is cleaned to get rid of any particles or residue that could have collected during the welding process. After welding, the area is polished to bring it back to its former glory.

- The weld is then examined to make sure it is of the highest quality and complies with all requirements. Any imperfections or faults are located and fixed as necessary.

2. How Can I Weld Tungsten?

Tungsten steel is very hard and is a brittle material. It needs to be welded with silver wire, and the welding seam of the product needs to be very small to be firmly welded.

3. How Does A Jewelry Laser Welder Work?

High intensity lasers are used by jewelry laser welding devices to accurately melt and fuse metals together. A pool of molten metal is created when the laser beam is focused on the piece of metal that has to be connected and melts it due to the laser’s extreme heat. The two pieces of metal immediately cool and solidify once they have melted together, forming a solid and long-lasting link. Jewelry laser welding is a non-contact procedure, which means the metal is not touched by the laser and there is no need for pressure or physical force to bind the metal pieces together. As a result, it is feasible to attach tiny, fragile, or complicated elements without endangering the vicinity or creating deformation. As a result, it is feasible to attach tiny, fragile, or complicated elements without endangering the vicinity or creating deformation.

4. Can Your Welding Machines Be Used To Fill Air Holes Or Fill Gaps?

Yes, metal pores or gaps may be filled using welding equipment. To create a connection between two pieces of metal, the base metal is melted while filler material is added. Filling voids or pores in the metal is feasible with the right welding procedure and filler material. It is crucial to remember that the type of metal, its thickness, and the welding technique all have a role in how successfully the welding process goes. Please email the after-sales address on our website if you experience any issues while welding.

5. How Frequently Does The Water In The Welding Machine'S Water Tank Need To Be Changed?

Usually the water inside the tank needs to be replaced within 1-2 months but this ultimately depends on how often you weld. If your welding frequency is very high, we recommend that you change it once a month.

6. How Long Can I Use The 150w Welding Machine Continuously?

For regular use, there is no problem for 5 hours working; if an external water pump is connected, it can be used for 12 hours.

7. What Metals Should Not Be Welded?

- Lead and zinc are two metals that are challenging to weld without emitting harmful fumes due to their low boiling point and high vapor pressure.

- Due to their various melting temperatures and rates of thermal expansion, aluminum and stainless steel are difficult to weld without cracking or deformation.

- Copper and steel can produce brittle, weak welds due to their vastly different melting points.

- Cast iron: Due to its high carbon content and propensity for cracking during welding, cast iron has a high carbon concentration.

- Steel and titanium both have distinct rates of expansion, which might result in a brittle, weak weld. Furthermore, titanium can react with oxygen during the welding process, resulting in the formation of a brittle oxide layer on the weld’s surface.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited