Electric Rolling Mill

Top Manufacturer in China

- 5.5-50p widely used rolling mill to choose

- Provide wire and sheet rolling machines for different product requirements

- Provide single and double-head equipment for factories with different output requirements

- Suitable for many precious metals, such as gold, brass, silver, etc

- The upgraded model has a rewinding function to reduce human resources

Electric Rolling Mill For Industrial Jewelry Manufacturing

SuperbMelt Electric Rolling Mill can be customized to meet customers’ specific requirements for sheet or wire rolling mills.

The SuperbMelt Electric Rolling Mill series offers equipment ranging from 5p to 30p, with options for single-head or double-head machines. The sheet thickness can be processed from 0.01mm to 33mm, and the wire thickness can be processed from 12mm to 1mm.

Our machines are driven by high-quality single power motors, allowing for variable frequency speed control. Additionally, the sturdy construction ensures stable operation. The rollers are made of the highest hardness material, with the movable rollers linked to the upper and lower mechanisms, ensuring uniform thickness and precision of the metal products.

The simple and robust design takes up minimal space, operates almost noiselessly, and is easy to use. With low material loss and precise grooving based on accurate data, the machine is also equipped with an emergency stop button to ensure worker safety.

Jewelry Rolling Mill With Different Horsepower

This machine has two types of 5.5p and 7.5p, of which 5.5p mainly rolls the sheet, and the maximum thickness of the applicable sheet is 9mm. There is also 7.5p, which can roll sheets and wires.

The maximum thickness of the sheets that can be applied to rolled sheets is 11mm, and the thickness that can be applied to rolled wires is 14-0.8mm.For gold bars or wire, and smaller factories can choose this machine.

SPB-YX-5P/SPB-7.5P-S250/SPB-7.5P-S200 Rolling Mill

This machine has two types of 5.5p and 7.5p, of which 5.5p mainly rolls the sheet, and the maximum thickness of the applicable sheet is 9mm. There is also 7.5p, which can roll sheets and wires. The maximum thickness of the sheets that can be applied to rolled sheets is 11mm, and the thickness that can be applied to rolled wires is 14-0.8mm.

For gold bars or wire, and smaller factories can choose this machine.

Parameter

- Max Thickness:9-11mm

- Max Rolling Width: 50mm

- Power: 4-5.5KW

SPB-YP-10PZQ Enhanced Sheet Rolling Machine

This equipment is mainly used for rolling metal sheets with a width of less than 50MM.The size of the finished product is stable, the deviation of both sides of rough pressing is within 0.004mm, and the deviation of front and rear is within 0.005. The deviation of precision pressing will be smaller.

The machine comes with a precision dial, and the reading is accurate. One circle of the handle is 1mm, and a small grid is 0.01mm. The material of the rollers of the machine is made of high hardness materials, and its hardness can be above HRC65 degrees, which is enough to meet the processing and rolling requirements. Material.

Parameter

- Thickness:0.1-28mm

- Max Width:60mm

- Power:7.5KW

Automatic 12P Sheet Rolling Machine SPB-YP-PZQ-B

The machine operates very steadily and produces minimal noise. It features an automatic lubrication system that helps prevent bearing damage due to human error.

It has an advanced appearance, with painted metal sheets and all exterior parts electroplated, providing excellent anti-rust properties and making it easy to clean. Equipped with an automatic winding function, the machine offers a high level of automation, saving both time and effort. The finished product is uniform and flat.

Parameter

- Thickness:0.05-25mm

- Max Width:80mm

- Power:9KW

SPB-YP-20A Sheet Rolling Machine

The machine adopts multi-stage transmission, with moderate speed, which can prevent jamming, without manual lubrication, and automatic refueling system, which is more user-friendly.

Our machines are strictly controlled for the manufacturing accuracy of equipment parts. Each mechanical part is processed according to the drawing accuracy. The same type of machine parts can be interchanged, which is more convenient and time-saving when maintenance is required.

The 8 bearings are imported from the German brand INA, which guarantees high precision and durability.

Parameter

- Thickness:30mm

- Max Width:200mm

- Power:15KW

SPB-YP-30A Sheet Rolling Machine

The equipment is made of the current high-hardness roll material, and the tableting precision is high, and the deviation of the 120mm wide tablet is within 0.005mm. The 8 bearings of the machine are imported from the German brand INA to ensure high precision and durability.

The stainless steel oil pan for desktop is oil-proof and rust-proof, no oil leakage, the parts are electroplated or blackened, and the emergency stop safety device is installed.

The large vector frequency converter is used to realize variable frequency speed regulation and grating measurement, which can display the real-time thickness of the tablet without frequent manual measurement.

Parameter

- Thickness:33mm

- Max Width:200mm

- Power:22KW

50P Large Jewelry Rolling Mill

The SuperbMelt 50P Sheet Rolling Mill has high precision. The 650mm wide roll can roll out the finished gold sheet within 0.003mm, which can achieve a uniform thickness that cannot be achieved manually. It can be pressed like 24K gold, K gold, 925 silver and other products with high hardness and good elasticity

The chassis is equipped with a ventilation and cooling device to protect the equipment from running continuously for 24 hours, so as to avoid the failure of the equipment due to overheating caused by long-term operation, to ensure smooth processing, and the processing effect is very perfect.

Parameter

- Max Thickness:50mm

- Max Width:550mm

- Power:30KW

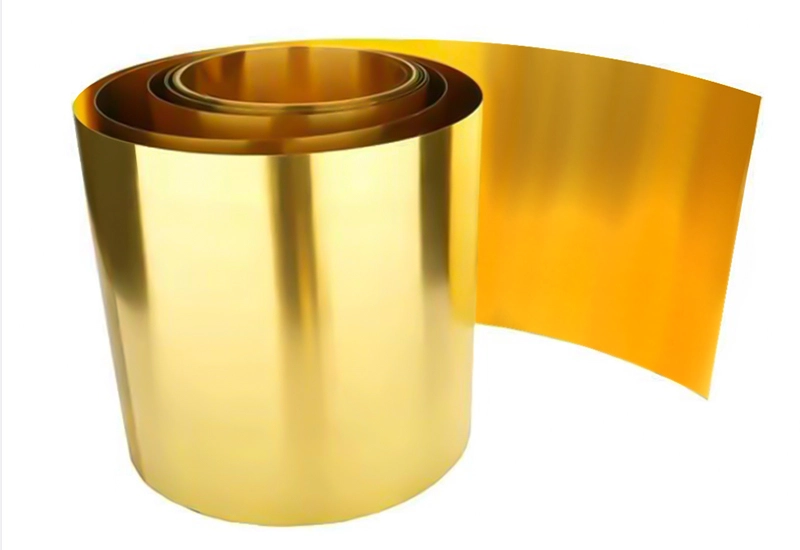

Tungsten Steel Electric Rolling Mill Jewelry

SuperbMelt Electric Rolling Mill Jewelry uses tungsten steel rollers to roll metal sheets, producing surfaces that are smoother and more uniform in thickness to achieve a mirror effect. It is suitable for high-quality jewelry manufacturing and metalworking industries.

with thicknesses ranging from 9mm to 0.1mm, helping jewelry manufacturers meet various design and manufacturing needs.

Parameter

- Max Thickness:9mm

- Max Width:30mm

- Power:4KW

Rolling mill with coiling function

SuperbMelt Sheet Rolling Machine Manufacturer help clients customize rolling mills with special requirements such as online thickness measurement, coiling, and correction functions. These features enable clients to meet complex metal processing needs.

- Coiling: Provides tension during the rolling process, ensuring that the material is rolled more uniformly, and the resulting material is coiled neatly rather than scattered, saving collection time.

- Correction: Prevents material misalignment, which can cause issues with coiling and layer displacement.

- Thickness Measurement: Thickness is measured during the rolling process, reducing the need for manual measurements.

Parameter

- Max Thickness:60mm

- Max Width:25mm

- Power:9KW

Silver Rolling Machine

SuperbMelt Four-Axis Silver Rolling Machine is specially designed for rolling various types of metal sheets and can press sheets into thicknesses ranging from 120-0.03mm including gold, silver, and platinum. This machine can apply pressure from multiple directions, significantly improving the flatness and uniformity of the material, while also greatly enhancing production efficiency.

The Four-Axis Silver Rolling Machine can handle a wider range of materials, making it suitable for large-scale production, especially in applications requiring high precision and high-quality finished products, such as in jewelry, automotive, aerospace, and precision engineering sectors.

Parameter

- Max Thickness:1mm

- Max Width:180mm

- Power:15KW

Jewelry Rolling Mill By Single & Double Sided

Supermelt’s rolling mills are basically single-head, which is very practical. We also have a double-head rolling mill that is also popular with medium and large jewelry factories.Double heads can greatly increase production efficiency.

Double Sided Jewelry Rolling Mill 10P

The double-head rolling mill can realize dual-use of one machine. According to the production needs of customers, the characteristics of two-sided plate pressing/two-sided wire pressing/one sided plate pressing and another wire pressing can be ordered. The roller is made of high hardness material, the machine structure is simple and firm, and the space is small. Synchronized connecting rod gears ensure uniform metal thickness, stable dimensions and high finished product accuracy.

Parameter

- Thickness:0.1-11mm

- Max Width:50mm

- Power:7.5KW

Jewelry Rolling Mill By Finale Design

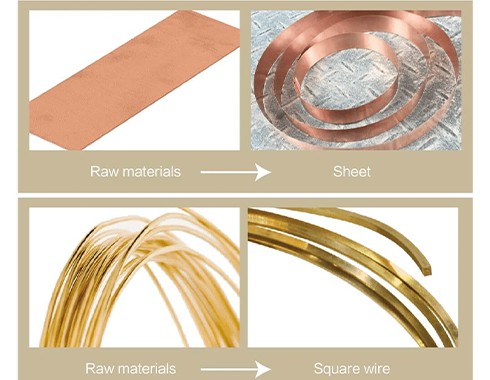

Our rolling mills have individual sheeting and wire pressing, as well as combined sheeting and wire pressing. The design of the groove determines the type of crimping wire, which can be made into a round wire and a square wire.

The use of different materials for the finale will also affect the effect and accuracy of the finished product.

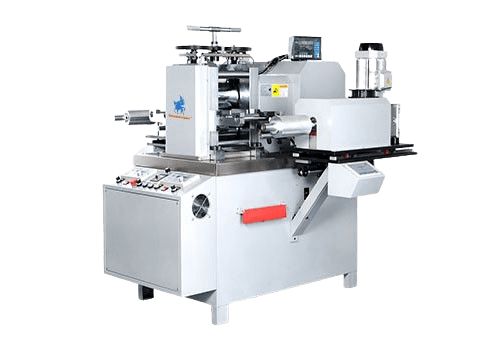

5.5P/7.5P Tungsten Steel Sheet Rolling Machine

This device uses a high-quality tungsten steel shaft that can roll on metal surfaces to achieve a mirror-bright finish.The accuracy of finish products is also very high. The thickness of the applicable material is 0.03-11mm.And the rolling mill is adjustable for jewelry making.

5.5p roller size is 110*80mm, 7.5p roller size is 120*100mm.

Parameter

- Thickness:0.03-11mm

- Max Width:70mm

- Power:4-5.5KW

7.5P Wire Rolling Machine

The wire crimping machine is used for rolling wire, it grinds corresponding circular and square grooves on the surface of the upper and lower pressure rollers, and extrudes metal wires of different shapes and sizes. The applicable pressure line size is 14-0.8mm, and it can also process the corresponding text and trademark patterns on the upper and lower pressure rollers to achieve the desired effect.

Parameter

- Max Thickness:11mm

- Max Width:50mm

- Power:5.5KW

Jewelry Rolling Mill By Continuous Press

Our Rolling Mill have always been upgraded and innovated to meet the needs of our customers. We have also introduced sheet and wire continuous pressing machines, which can realize one-shot molding, reduce time costs and greatly improve production efficiency.

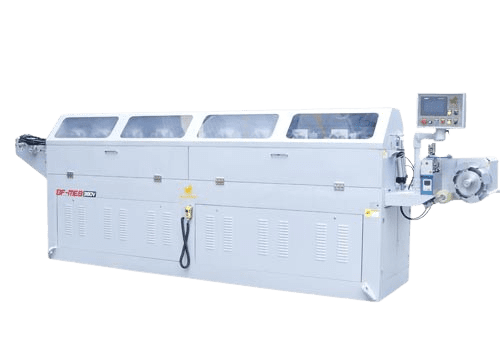

5/6-lane Continuous Sheet Rolling Mill

This machine has 5 and 6 sets of rollers to roll at the same time. You only need to press once to get the desired thickness. The thickness can be customized between 3mm-0.5mm. The equipment is equipped with an infrared sensing device, which will automatically stop rolling when it senses that there is no material.

The hardness of the pressing roller reaches HRC63 degrees, and gold, silver, copper and aluminum can be pressed to produce a beautiful finished product.

With automatic winding function, it is convenient to collect finished products and realize high automatic production.

The machine is controlled by the plc system, the operation is simple and convenient.

Parameter

- Max Thickness:3mm

- Max Width:60mm

- Power:45KW

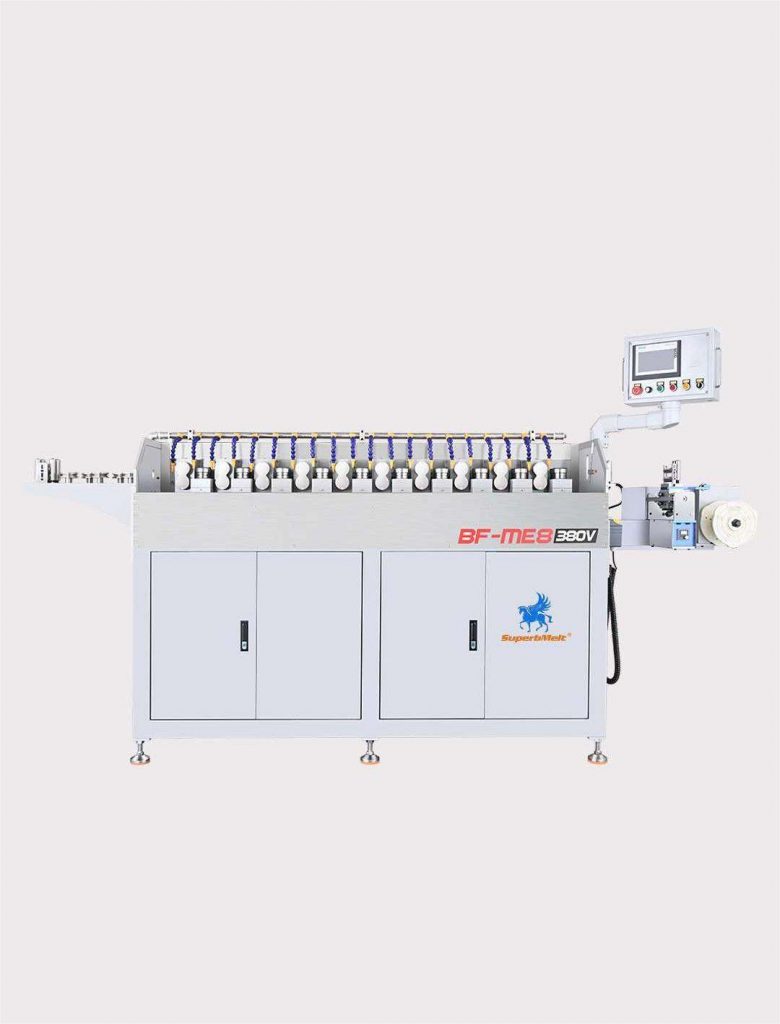

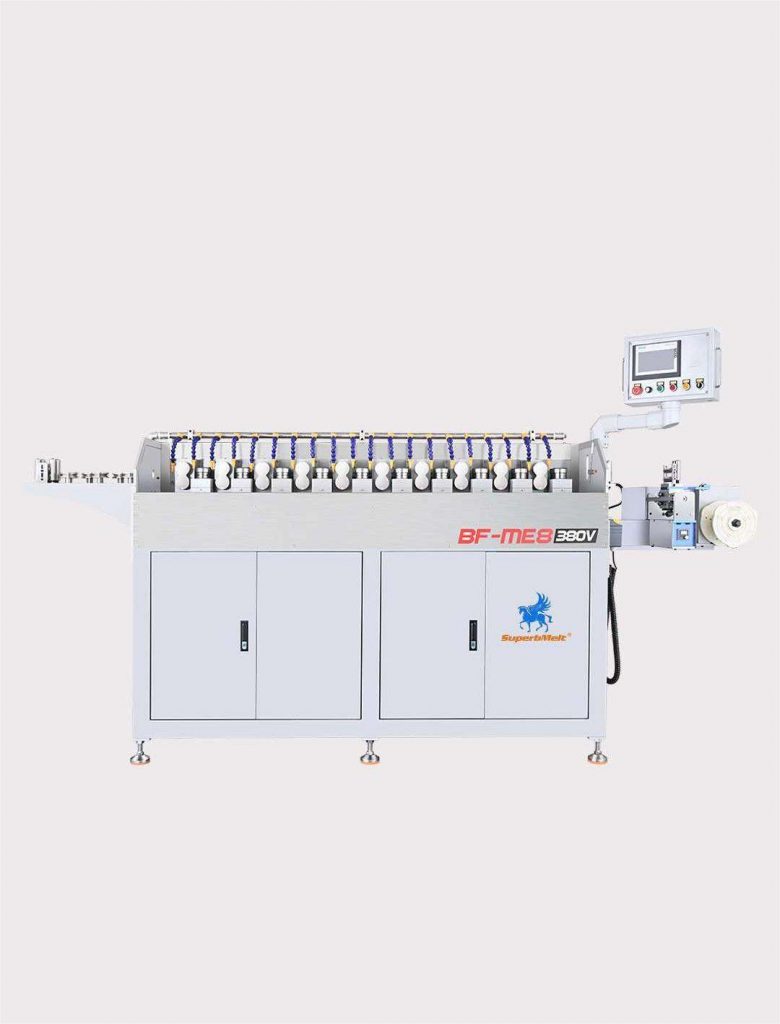

Continuous Wire Rolling Machine

Our continuous crimping machine has 20 sets of pressing rollers, which can realize one-time rapid prototyping, and the final product will not be lost, with smooth surface and high quality. The machine protects the wires and will not hurt the wires.

The device also has the function of automatic arranging and reeling, which is very flexible in operation and simple and quick in reeling. The machine is equipped with a 7-inch high-definition touch screen, which is simple and convenient to operate. There is also a jog threading function, and you can start precise work by simply pressing the remote control button. No need to worry about continuous work. The machine is equipped with a spray cooling system to protect the machine rolls.

Parameter

- Finale Diameter:60mm

- Number of Pressing Rollers:20 Group

- Power:11KW

Continuous Wire Drawing Machine

SuperbMelt Continuous Wire Drawing Machine is used for producing metal wires such as gold, silver, and copper. This machine is capable of pressing wires into the range of 12-3.2mm in one go, which is several times faster than ordinary wire pressing machines, effectively addressing production issues for large-scale chain manufacturers.

- Compared to ordinary wire pressing machines, the Continuous Wire Drawing Machine offers faster wire pressing speed and higher precision, capable of pressing 0-50 meters per minute in one go.

- The Continuous Wire Drawing Machine is suitable for large-scale jewelry chain processing plants, helping factories increase production capacity and reduce labor costs.

Parameter

- Finale Diameter:60mm

- Number of Pressing Rollers:16 Group

- Power:30KW

Custom Jewelry Rolling Mill

Combined with the effect requirements that the finished product needs to achieve, we also have a professional R&D team that can customize it for customers. For example, if you have high requirements on the effect and precision of the finished product, then we will meet your needs by using different materials of pressure rollers.

If you have dual needs for sheet and wire pressing, then we can also help you design the pressing roller into a dual-purpose type according to the thickness of the finished product you need, which is more cost-effective and can achieve rapid production.

For rollers, we also have relatively rare textures, pattern designs, and use roll printing technology to print embosser patterns and textures on the surface of metal materials. You can tell us your ideas and designs, and our R&D team will try our best to help you.

Jewelry Rolling Mill Application

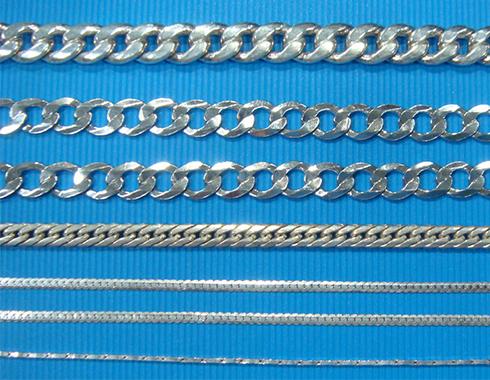

Sheet and wire rolling are both very important links in forging jewelry. Through sheet Pressing, a hollow tube can be made, and then the hollow tube can be hammered into jewelry beads that we are familiar with.

And use the wire pressing machine to make the required thickness, and then you can also make the corresponding jewelry chain.

Our rolling mills are suitable for a wide range of metals, including gold, karat gold, 925 silver, copper, aluminum, platinum, etc. It is very practical for large and medium-sized jewelry factories, jewelry stores, accessories processing, metal handicraft processing, etc.

Using Rolling Mill to Make Metal Sheet & Wire

Making to Gold Beads

Making to Bracelet

Making to Necklace

FAQ Guide of SuperbMelt Jewelry Electric Rolling Mill

1. How Many Types of Rolling Mills Do You Have?

Sheet Pressing

The applicable thickness of our sheet rolling mill is 0.008-33mm, which can meet the needs of different customers.

Suitable for a wide range of metals, such as gold, silver, copper, aluminum, etc.

Wire Pressing

The applicable metal size of the wire is 14-0.8mm, and the grooves of different sizes can be customized according to the needs of customers, which can be made into very small and exquisite square lines.

Pattern Pressing

We also have embossed design rollers, such as patterns, textures, etc., which can be customized according to customer needs.

Combination Models

The combined design can be customized according to your needs to maximize the use value of the machine.Slot according to the required width, rationally distribute the area of pressing wire and pressing sheet.

2. How To Use SuperbMelt Rolling Mill?

- Adjust the pressing seam of the pressing roller of the rolling mill and then turn on the machine

- Insert the metal plate or wire to be processed into the pressing seam and pass through the pair of rollers

- Then further adjust the pressing seam, and pass the metal plate or wire through the machine again.

- Repeat several times until desired thickness is achieved.

3. How To Take Care of A Rolling Mill?

- The machine should be placed far away from the source of the earthquake, avoid sunlight and radiation, and try to place it in a dry place to avoid the influence of humidity and airflow.

- Check whether the electrical system of the cold rolling mill and the oil level of the oil tank are normal before use.And check whether enough coolant in the cooling tank.

- Check whether the oil of the automatic lubricating device of the machine reaches the position specified by the oil level indicator.

- The electrical parts of the cold rolling mill should always be cleaned of dust and debris.

- The movement shaft part should be checked frequently for looseness.

- During the use of the cold rolling mill, avoid excessive use, otherwise it will easily cause damage to the mechanical parts of the cold rolling mill. It should be rolled according to the rolling standard.

4. How to Select An Electrical Rolling Mill For Industrial Jewelry Making?

The following points should be considered:

Whether the Stability is Consistent

The stability of each output section of the whole machine, such as vibration, noise, precision, etc., is consistent

The Superbmelt rolling mill has almost no vibration and no noise in the work process, and the deviation of the finished product is only within plus or minus 0.005mm, and the working performance is very stable.

Whether the Output Can Meet the Demand

In addition to the most commonly used single-end models, our machines also have double-end models, as well as continuous models with many upgrades, which can be selected by customers with different needs.

Our current customers are basically medium and large jewelry manufacturers, and they all recognize the output of our machines.The material and machining accuracy of key components

Spare Parts Interchangeability

Our equipment has strict control over the manufacturing accuracy of equipment parts, and the machine parts of the same model manufactured by our factory are interchangeable, which is convenient and time-saving for maintenance.

5. How To Change Oil?

- Check the fuel tank at the bottom of the machine

- Remove the screws on both sides

- Remove the fuel tank and pour out the oil

- Reinstall it, and pour in new oil

6. Will Your Rolling Mill Leak Oil?

Our machines are all sheet metal design, the sheet metal is painted, the exterior parts are all electroplated, and the fuel tank is also the same, so it is very tight, so there is no need to worry about oil leakage

SuperbMelt Jewellery Rolling Machine Guide

Utilizing the SuperbMelt Sheet Rolling Mill

- Proper Material Selection: Choose high-quality metal sheets or wires for your jewelry projects. The success of your rolling largely depends on the material you use.

- Safety Measures: Always prioritize safety. Wear protective gear like safety glasses and gloves to prevent accidents while operating the sheet rolling mill or jewelry rolling machine.

- Machine Calibration: Set the jewelry rolling machine to the desired thickness and texture for your jewelry pieces. Precise calibration is key to achieving the desired results.

- Material Preparation: Ensure your metal is clean and annealed. Annealing makes the metal more malleable and easier to roll.

- Roll Gradually: Feed the metal into the machine slowly and evenly. Gradually reduce the thickness, making multiple passes if necessary for fine-tuning.

- Proper Lubrication: Keep the rollers and moving parts of the machine well-lubricated to ensure smooth operation and extend the machine’s life.

- Routine Maintenance: Follow the maintenance schedule outlined in the machine’s manual to keep it in top working condition.

- Cooling Process: Allow the rolled metal to cool slowly after each pass to prevent warping or deformities.

- Quality Inspection: After rolling, carefully inspect the metal for imperfections. If needed, you can reroll it to achieve the desired finish.

- Experiment and Learn: Don’t be afraid to experiment with different textures and thicknesses. Continuous practice will enhance your jewelry-making skills.

- Troubleshooting: If you encounter any issues, consult the machine’s manual or contact SuperbMelt’s customer support for guidance.

How to Maintain Your SuperbMelt Sheet Rolling Mill

To maintain your SuperbMelt Sheet Rolling Mill effectively and ensure its longevity, follow these key steps:

- Regular Cleaning: Clean the rollers and surfaces before and after every use. Use a soft, lint-free cloth and a mild solvent if necessary to remove any debris or residue.

- Lubrication: Lubricate the rollers and moving parts according to the manufacturer’s recommendations. Proper lubrication helps prevent friction and excessive wear and tear.

- Adjustment: Ensure that the mill is correctly adjusted for the thickness of the sheet you’re rolling. Regularly check and calibrate the mill to maintain precision.

- Storage: Store the rolling mill in a dry, cool place. If you don’t plan to use it for an extended period, consider coating the rollers with a rust inhibitor.

- Maintenance Schedule: Establish a maintenance schedule, including inspection of parts for wear, damage, and loose bolts. Follow the manufacturer’s guidelines for replacing worn parts.

- Safety Precautions: Always observe safety precautions, and avoid overloading the mill to prevent damage.

- Professional Servicing: Consider professional servicing and inspection of your rolling mill periodically to ensure optimal performance.

Remember, proper maintenance not only extends the life of your SuperbMelt Sheet Rolling Mill but also ensures the quality of the jewelry sheets it produces.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited