Tube Drawing Machine

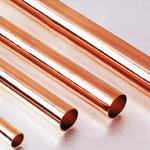

SuperbMelt is a leading machinery manufacturer in China, specializing in the production of round tube manufacturing machines for gold, silver, alloy, and other metals.

SuperbMelt Tube Drawing Machine has the capability to reduce the thickness of the tube wall and adjust the diameter of the wire, facilitating the production of various jewelry items such as rings, bracelets, necklaces, jewelry components, as well as decorative crafts, assisting jewelry industry factory owners in achieving high-quality jewelry processing and production.

The machine produces cylindrical hollow tubes made of materials such as gold, silver, K gold, alloys, etc., with lengths ranging from 0 to 8 meters every 8 minutes. These tubes are utilized in various applications.

Furthermore, the Tube Drawing Machine is not limited to the jewelry industry; it also finds extensive applications in other sectors. For example, it is utilized in the aerospace industry for manufacturing precision tube components, in the medical industry for producing surgical instruments and implants, and in the electronics industry for manufacturing electronic components and connectors. This versatility helps customers address high-quality production challenges across different industries.

If you wish to learn more about other metal tube manufacturing machines offered by SuperbMelt, please feel free to contact us for customized solutions!

| Model number | SPB-DHW-3 |

| Power | 4kw |

| Voltage | 3 phase 380V, 50/60Hz |

| Diameter | 10mm (Personalized) |

| Thickness | 0.32 -0.5mm (Frequency control) |

| Efficiency | 0-8M/8min |

| Control method | Switch control |

| Size | 890*1000*1380mm |

| Weight | 520kg |

| Large tube diameter | 10MM |

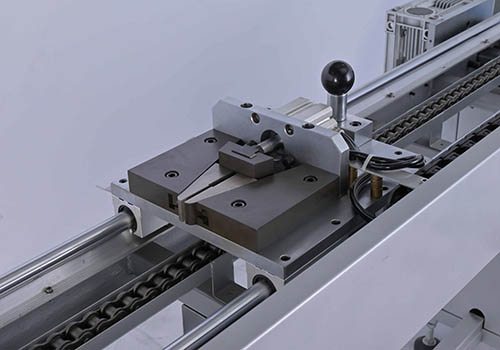

| Pipe clamping method | Automatic pneumatic clamp |

| Operation mode | linear guide sliding |

- High-speed Operation: Capable of producing tube materials at a rate of 8 meters per minute, with adjustable speed settings to accommodate various production needs.

- Unparalleled Precision: Achieves a minimum wall thickness of 0.15mm for hollow tubes and a minimum diameter of 1.0mm for solid wire, ensuring the highest standards of product quality.

- Versatile Options: Suitable for a wide range of specifications for hollow tubes and solid wires, catering to diverse customer requirements.

- Stable Drawing: Utilizes pneumatic clamping mechanisms to ensure stability and smoothness during the drawing process, enhancing production efficiency.

- User-Friendly Operation: Featuring a simple mechanical switch design for easy and straightforward operation, reducing operational complexity and improving work efficiency.

- Jewelry Industry: Used to make solid wires and hollow tubes for making jewelry components like rings, bracelets, and necklaces. It makes accurate sculpting and scaling of metal materials easier, which makes it easier for jewelry producers to create complex designs.

- Precision tube components needed in airplanes and spacecraft are manufactured by those employed in the aerospace industry. The machine guarantees the manufacturing of parts with precise dimensions and excellent quality, which are essential for the safety and functionality of aircraft systems.

- Medical Industry: Used in the production of surgical tools, implants, and other medical components that need to have exact tube dimensions. It contributes to the production of medical devices that fulfill strict quality criteria for healthcare applications and are remarkably accurate and consistent.

Why SuperbMelt Tube Drawing Machine

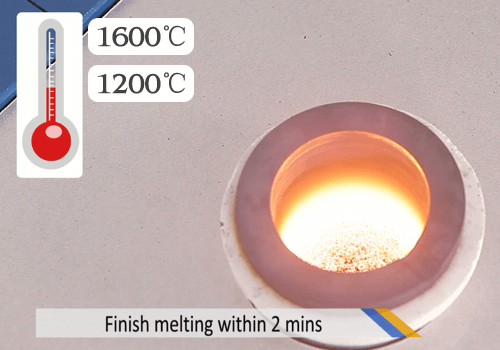

More Gold Melting Furnace and Gold Casting Machines for Your Choice

Any Question About SuperbMelt Tube Drawing Machine

FAQ Guide of Tube Drawing Machine

- 1. What are the advantages of tube drawing process?

- 2. Why is tubing better than solid material?

- 3. What is the difference between wire and tube drawing process?

- 4. What is a Tube Drawing Machine?

- 5. How does a Tube Drawing Machine work?

- 6. What materials can be processed using a Tube Drawing Machine?

- 7. What are the typical applications of Tube Drawing Machines?

- 8. What are the advantages of tube drawing over other manufacturing methods?

- 9. What factors determine the quality of tubes produced by a Tube Drawing Machine?

- 10. What types of tubes can be produced with a Tube Drawing Machine?

- 11. How does tube drawing contribute to material efficiency and waste reduction?

- 12. What maintenance is required for a Tube Drawing Machine?

- 13. Is operator training necessary for operating a Tube Drawing Machine?

1. What are the advantages of tube drawing process?

- Precision: The ability to precisely regulate dimensions through tube drawing yields exact diameters and homogeneous wall thicknesses for the drawn tubes or wires.

- Customization: To accommodate diverse uses, manufacturers can modify the tube drawing process to fit specific needs, such as changing the wall thickness, diameter, and length of the tubes.

- Improved Mechanical Properties: The drawing process can improve the material’s tensile strength and surface smoothness, among other mechanical qualities that make the drawn tubes appropriate for demanding applications.

- Material Savings: Tube drawing effectively reduces waste and maximizes material use by converting larger diameter tubes or bars into smaller diameter tubes or wires.

- Versatility: A wide range of materials, including metals like gold, silver, platinum, copper, and alloys, may be drawn into tubes. This allows for the production of varied components for a variety of sectors.

- Cost-Effectiveness: Because tube drawing may save material and has efficient production processes, it can be a cost-effective manufacturing method in the long term, especially for high-volume production, despite the startup expenses.

- Consistency: For applications needing accuracy and dependability, tube drawing guarantees consistency in tube dimensions and quality, producing homogenous results with little fluctuation.

2. Why is tubing better than solid material?

- Weight reduction: Tubing may be used to create components that are lighter than solid materials, which is helpful in areas like the aerospace and automobile industries where weight is a crucial consideration.

- Material Savings: When creating components in large quantities, tubing utilizes less material than solid components, which reduces waste and costs expenses.

- Flexibility & Versatility: When it comes to design and application, tubing is more versatile than solid material. It is ideal for a variety of purposes since it can readily molded, bent, and curved into different forms.

- Enhanced Strength-to-Weight Ratio: Tubing has a stronger strength-to-weight ratio than solid materials, which makes it perfect for uses like structural components where strength is needed without adding extra weight.

- Enhanced Fluid Flow: Because tubing has a hollow interior that permits the flow of gasses or fluids, it is perfect for applications that need to transfer fluids, such hydraulic, HVAC, and plumbing systems.

- Heat Dissipation: Hollow tubing has superior heat dissipation than solid material, which makes it appropriate for uses in cooling systems and heat exchangers where thermal control is essential.

- Decreased Cost: Tubing may frequently be produced at a lower cost than solid material, particularly for complicated designs or big numbers, which results in cost reductions overall.

3. What is the difference between wire and tube drawing process?

A metal workpiece’s diameter can be decreased using one of two metal forming techniques: wire drawing or tube drawing. They vary, meanwhile, in how they are applied and how the workpiece being treated is shaped:

Procedure for Wire Drawing:

Application: The main purpose of wire drawing is to make metal workpieces with wire or rod shapes smaller in diameter.

Procedure: When drawing wire, a metal rod or wire is drawn through a sequence of dies that get smaller and smaller in diameter. This causes the wire to become longer and less wide while growing in length.

Result: A long, continuous wire or rod with a smaller diameter and a better surface polish is what wire drawing ultimately produces.

Process of Drawing Tubes:

Use: Hollow cylindrical metal pipes or tubes can have their diameter reduced by using tube drawing.

Method: In the tube drawing process, a hollow, cylindrical metal tube or pipe is drawn through a sequence of dies that get smaller and smaller in diameter. This results in a tube with a smaller diameter and thinner walls by decreasing the outer diameter of the tube and also decreasing the thickness of its walls.

Result: A hollow cylindrical tube with a smaller outer diameter and maybe thinner walls, depending on the required criteria, is what is produced when a tube is drawn.

4. What is a Tube Drawing Machine?

A Tube Drawing Machine is a piece of equipment used in metalworking industries to reduce the diameter and thickness of hollow cylindrical metal tubes through a process called tube drawing.

5. How does a Tube Drawing Machine work?

The machine pulls a hollow cylindrical metal tube through a series of dies with progressively smaller diameters. As the tube passes through these dies, its outer diameter and wall thickness are reduced to the desired dimensions.

6. What materials can be processed using a Tube Drawing Machine?

Tube Drawing Machines are capable of processing various metals, including steel, stainless steel, copper, aluminum, brass, and alloys thereof.

7. What are the typical applications of Tube Drawing Machines?

Tube Drawing Machines are commonly used in industries such as manufacturing, automotive, aerospace, medical devices, and construction for producing tubes used in applications ranging from fluid transport to structural components.

8. What are the advantages of tube drawing over other manufacturing methods?

Tube drawing offers advantages such as precise dimensional control, improved surface finish, and the ability to produce tubes with complex geometries and tight tolerances.

9. What factors determine the quality of tubes produced by a Tube Drawing Machine?

Tube Drawing Machines can produce a wide range of tubes, including seamless tubes, welded tubes, round tubes, square tubes, and rectangular tubes, depending on the machine’s capabilities and tooling.

10. What types of tubes can be produced with a Tube Drawing Machine?

Tube Drawing Machines can produce a wide range of tubes, including seamless tubes, welded tubes, round tubes, square tubes, and rectangular tubes, depending on the machine’s capabilities and tooling.

11. How does tube drawing contribute to material efficiency and waste reduction?

Tube drawing enables manufacturers to produce tubes with precise dimensions, reducing material waste compared to traditional machining methods where excess material is removed.

12. What maintenance is required for a Tube Drawing Machine?

Regular maintenance tasks for Tube Drawing Machines include lubrication of components, inspection of dies for wear, alignment checks, and cleaning to prevent buildup of debris.

13. Is operator training necessary for operating a Tube Drawing Machine?

Yes, operators should receive training on machine operation, safety protocols, maintenance procedures, and troubleshooting to ensure safe and efficient operation of the Tube Drawing Machine.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited