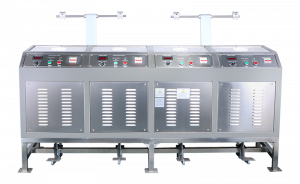

Three Furnace Melting Furnace

China leading smelting furnace manufacturer, SuperbMelt, has recently developed a triple smelting furnace.

SuperbMelt Three Furnace Melting Furnace is capable of melting 2-8kg of three different metals, including platinum, palladium, gold, silver, copper, and stainless steel in a single operation.

The three-furnace induction melting furnace utilizes a German original IGBT+CPU variable frequency induction heating power supply, capable of reaching up to 2600°C at any time. This feature allows the machine to complete all metal melting within two minutes, enhancing production efficiency and reducing labor costs for jewelry making or smelting industries.

SuperbMelt Three Furnace Melting Furnace is the optimal choice for small to medium-sized jewelry workshops, jewelry stores, educational research, and assay laboratories.

For more information about induction melting furnaces, please contact us immediately!

| Model number | SPB-BF3 | SPB-BF4 |

| Power source | 3 phase 380V, 50/60Hz | 3 phase 380V, 50/60Hz |

| Power | 15 kw*3 | 15 kw*4 |

| Applicable metal | Gold, Silver, Platinum, Palladium, K gold and Their alloys | Gold, Silver, Platinum, Palladium, K gold and Their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 1-10kg customized*3 | 1-10kg customized*4 |

| Max temperature | 2600℃ | 2600℃ |

| Temperature control k-type | Optional | Optional |

| Weight | 272 kg | 330 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

- Equipped with a German original IGBT+CPU variable frequency induction heating power supply, ensuring strong stability in equipment operation.

- Safety is guaranteed with built-in functions for overcurrent, overvoltage, and water shortage protection.

- Easy operation with one-key startup for melting, eliminating the need for specialized personnel;

- Simplified power structure with water and electricity separation, significantly enhancing equipment lifespan.

- Temperature can reach up to 2600°C, allowing for the melting of metals such as platinum, palladium, gold, and stainless steel.

- Jewelry and Jewelry Manufacturing Industry: Used for melting and casting precious metals such as gold, platinum, palladium, silver, etc., for the production of jewelry and ornaments.

- Metallurgy and Metal Processing Industry: Employed for smelting and melting various metals such as copper, stainless steel, etc., to meet the production requirements of metal materials.

- Education and Research Institutions: Provides a convenient and rapid smelting tool for academic research, laboratory work, and research in metal materials.

- Laboratory and Quality Inspection Industry: Utilized for sample preparation, material analysis, and metal quality testing to ensure products meet standards.

- Small and Medium-Sized Metal Processing Enterprises: Suitable for small and medium-scale metal processing enterprises, enhancing production efficiency and reducing labor costs.

Each batch melts 3 kinds of metal raw materials extremely quickly within 2 minutes, and works continuously for 24 hours, greatly improving production efficiency.

Three-furnace simultaneous smelting machine for refining 2-8 kilograms of gold, capable of melting 6-24 kilograms of metal raw materials in a single operation.

Capable of reaching a high temperature of 2600°C at any time, achieving rapid melting and enhancing production efficiency.

Why SuperbMelt Three Furnace Melting Furnace

Any Question About SuperbMelt Three Furnace Melting Furnace

Any Question About SuperbMelt Three Furnace Melting Furnace

Ultimate Three Furnace Melting Furnace Buying Guide

Introduce

The furnace is equipped with the most advanced German original IGBT+CPU variable frequency induction heating power supply to ensure unparalleled stability in equipment operation. Safety is a top priority, with built-in features providing overcurrent, overvoltage and water shortage protection.

Start melting with one click, easy and simple operation, no need for professionals. The power structure is simplified and water and electricity are separated, which significantly improves the service life of the equipment.

One of its outstanding features is its excellent temperature capabilities and the ability to smelt three metals at once. Capable of reaching 2600°C at any time, the furnace can quickly melt a variety of metals including platinum, palladium, gold and stainless steel, with the entire process taking just two minutes. This not only improves production efficiency but also helps significantly reduce labor costs, making it ideal for the jewelry manufacturing and smelting industries.

Composition

This machine, named the “Three Furnace Melting Furnace,is composed of various components to ensure its efficient functioning. Here is a breakdown based on the provided information:

Power Supply System:

German Original IGBT+CPU Variable Frequency Induction Heating Power Supply (for stable equipment operation).

Power Input: 380V Three-phase.

Power Consumption: 15KW.

Heating Technology:

Induction Heating.

Temperature Control:

Maximum Temperature: 2600°C.

Physical Characteristics:

Machine Weight: 272KG.

Melting Time: 2 minutes.

Metal Compatibility:

Suitable for melting metals such as platinum, palladium, gold, silver, copper, and stainless steel.

Safety Features:

Overcurrent Protection.

Overvoltage Protection.

Water Shortage Protection.

Operational Ease:

Simple Operation with One-Key Startup for Melting.

No Specialized Personnel Required.

Power Structure:

Streamlined Power Structure.

Separation of Water and Electricity (for enhanced equipment lifespan).

In summary, the Three Furnace Melting Furnace (BF-ST1) is a sophisticated piece of equipment that includes components such as the German IGBT+CPU variable frequency induction heating power supply, safety features, temperature control systems, and physical attributes like weight and melting time. This combination of features ensures its effectiveness in melting a variety of metals while prioritizing safety, operational simplicity, and durability.

Conclusion

In terms of metal smelting, the Three Furnace Melting Furnace represents the height of sophisticated technology and practicality. This furnace’s advanced German original IGBT+CPU variable frequency induction heating power supply ensures unparalleled equipment operating stability. Safety is still the first priority, and the integrated features—which include protection against overcurrent, overvoltage, and water shortage—attest to its dedication to a safe working environment.

One of the furnace’s main selling points is how easy it is to use. With one click, melting can begin, making it a convenient and approachable option that doesn’t require professional staff. The equipment’s service life is greatly extended by the streamlined power structure and the separation of water and electricity, guaranteeing long-term dependability and efficiency.

Its remarkable temperature capabilities—which may reach as high as 2600°C—allow for the rapid melting of a wide variety of metals, such as gold, platinum, palladium, and stainless steel. Three metals may be smelted at the same time, which speeds up production—the whole process takes only two minutes. This is a great option for the smelting and jewelry making sectors since it not only proves significant labor cost reductions but also increases production efficiency.

To sum up, the Three Furnace Melting Furnace is a cutting-edge solution that combines modern technology, safety features, and ease of use. This makes it a dependable and effective option for a range of metal smelting applications.

FAQ Guide of Three Furnace Melting Furnace

- 1. How many types of melting furnaces are there?

- 2. What is the Three Furnace Melting Furnace?

- 3. What is the power supply requirement for the furnace?

- 4. What is the heating technology used in this furnace?

- 5. What safety features does the furnace have?

- 6. How easy is it to operate the Three Furnace Melting Furnace?

- 7. What is the maximum temperature this furnace can reach?

- 8. What metals can be melted using this furnace?

- 9. How long does it take to melt metals in this furnace?

- 10. Can the furnace be used for jewelry manufacturing?

- 11. Is specialized training required to operate the furnace?

- 12. How does the separation of water and electricity in the power structure enhance equipment lifespan?

- 13. Can the furnace be used in educational and research institutions?

- 14. What is the weight of the Three Furnace Melting Furnace?

- 15. Is the furnace suitable for small and medium-sized metal processing enterprises?

1. How many types of melting furnaces are there?

- Cupola Furnace: Foundries use this to melt cast iron.

- An induction furnace, which is frequently used in the foundry and metallurgy sectors, melts metal using electromagnetic induction.

- Arc Furnace: Used in steelmaking, this device melts metals using an electric arc.

- Crucible Furnace: Designed for small-scale operations, this furnace has a refractory crucible to hold the metal as it melts.

- Electric Resistance Furnace: This type of furnace, which is frequently used in small-scale metalworking and jewelry making, melts metal using electric resistance heating components.

- Gas-powered Furnace: Used in many industrial applications, it generates heat through the combustion of gas to melt materials.

- An oil-fired furnace produces heat by using oil as a fuel source. These furnaces are frequently used in the forging and heat-treating of metal.

- Microwave Furnace: This device uses microwave radiation to melt metal and is frequently employed in specific applications and research.

- Solar furnaces: mostly employed in research and certain commercial uses, they concentrate sunlight to reach high temperatures.

- Foundries frequently utilize tilting furnaces, which are constructed with a tilting mechanism to make pouring molten metal simple.

- The kind of metal to be melted, the volume of production, the need for energy efficiency, and particular industrial uses all influence the choice of furnace.

2. What is the Three Furnace Melting Furnace?

The Three Furnace Melting Furnace is an advanced industrial equipment designed for the simultaneous smelting of three different metals, including platinum, palladium, gold, silver, copper, and stainless steel.

3. What is the power supply requirement for the furnace?

The furnace requires a 380V three-phase power supply for optimal operation.

4. What is the heating technology used in this furnace?

The furnace utilizes German original IGBT+CPU variable frequency induction heating power supply for efficient and stable operation.

5. What safety features does the furnace have?

The furnace is equipped with overcurrent, overvoltage, and water shortage protection features to ensure a secure operational environment.

6. How easy is it to operate the Three Furnace Melting Furnace?

The furnace is designed for user-friendly operation with a one-click startup for melting, eliminating the need for specialized personnel.

7. What is the maximum temperature this furnace can reach?

The furnace can reach a maximum temperature of 2600°C.

8. What metals can be melted using this furnace?

The furnace is suitable for melting various metals, including platinum, palladium, gold, silver, copper, and stainless steel.

9. How long does it take to melt metals in this furnace?

The furnace has a rapid melting capability, completing the entire process within two minutes.

10. Can the furnace be used for jewelry manufacturing?

Yes, the Three Furnace Melting Furnace is an optimal choice for jewelry workshops and stores due to its versatility in melting precious metals.

11. Is specialized training required to operate the furnace?

No, the furnace is designed for easy operation with a one-key startup, eliminating the need for specialized personnel.

12. How does the separation of water and electricity in the power structure enhance equipment lifespan?

The separation of water and electricity in the power structure significantly improves the durability and service life of the equipment.

13. Can the furnace be used in educational and research institutions?

Yes, the furnace serves as a convenient and rapid smelting tool for academic research, laboratory work, and research in metal materials.

14. What is the weight of the Three Furnace Melting Furnace?

The furnace weighs 272 kilograms.

15. Is the furnace suitable for small and medium-sized metal processing enterprises?

Yes, the furnace is tailored for the needs of small to medium-scale metal processing enterprises, enhancing production efficiency and reducing labor costs.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited