Silver Melting Pot

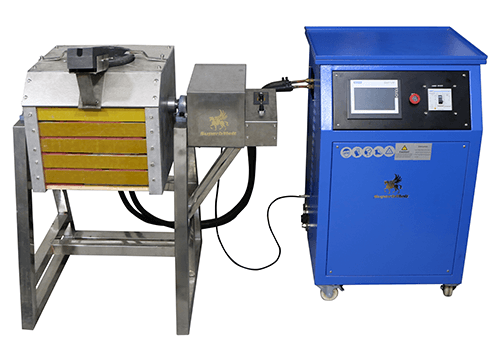

The most popular SuperbMelt 1-2kg gold and silver melting pot on the market

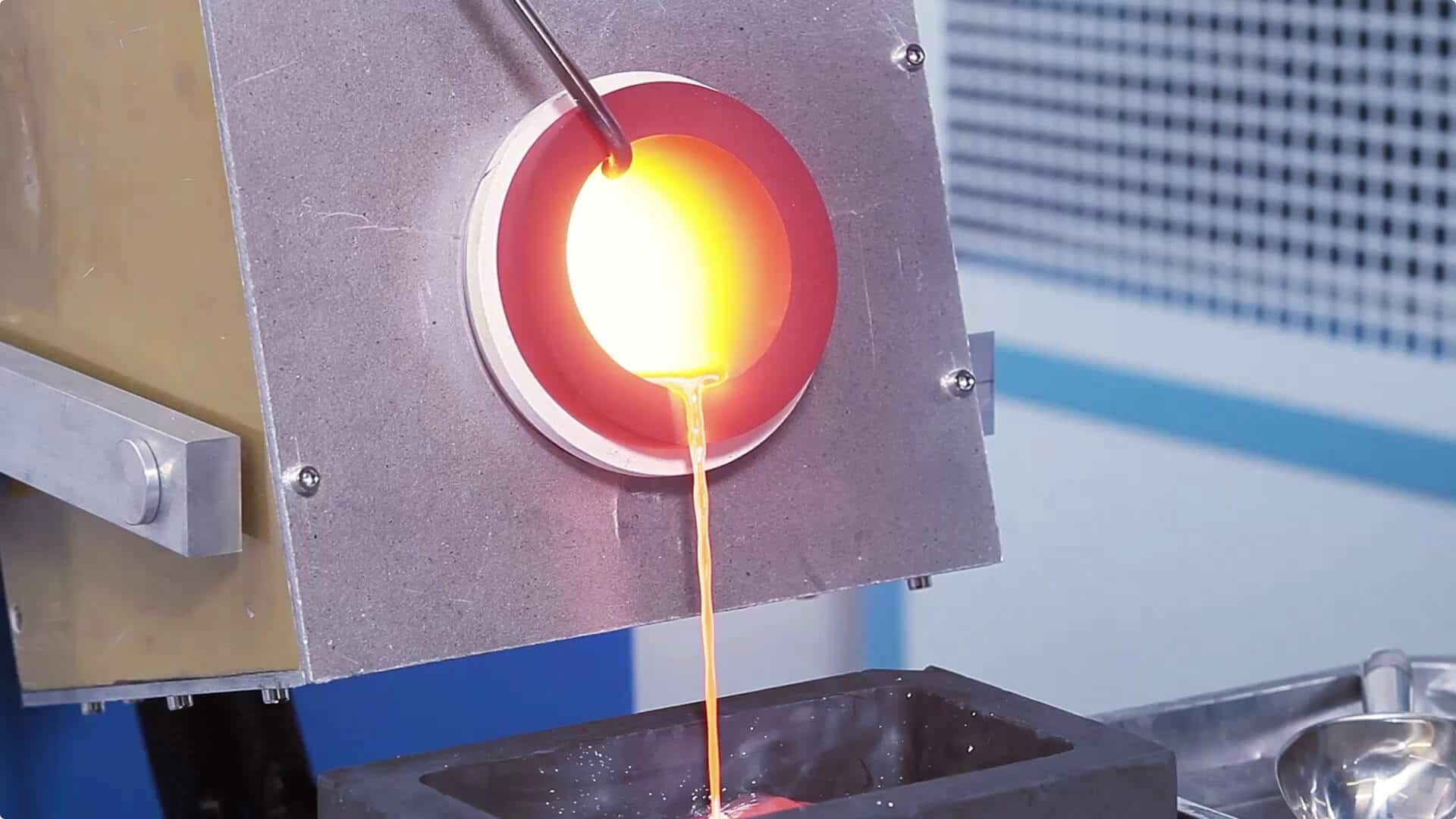

Superbmelt silver melting pot is used for melting metals up to 2kg. Metals such as silver, copper, aluminium, gold, brass, bronze, etc, can be melted with a crucible melting pot.

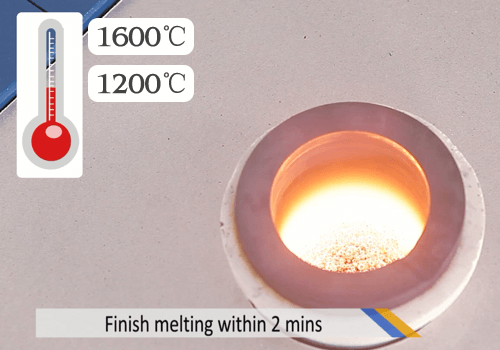

You can melt your metals at a maximum temperature of 1600 degree celsius within 2 minutes.

Supermelt silver melting pot uses induction heating for an efficient melting process that saves time and energy use. You can melt continuously for 24 hours using a Superbmelt crucible melting pot, without affecting the quality of melting.

The silver melting pot is applicable for use in metal recycling, jewelry making, personal use. We are a silver melting pot manufacturer that also produces electric silver melting pots for larger applications.

We have a support team and technology experts that are ready to respond to your inquiries and guide you through the process of owning your electric melting pot. Contact us today for your affordable and high-quality silver melting pot.

If you wanna check silver melting pots with bigger capacity, Please click here.

- Superbmelt electric silver melting pot allows you to melt silver, gold, copper, brass, bronze, and their alloys with a maximum temperature of 1600 degree celsius.

- With a Superbmelt crucible melting pot, you can melt up to 2kg of your metals within 2 minutes. Therefore, allowing you to melt 30kg of metals within an hour.

- Superbmelt silver melting pot is equipped with a water cooling unit that prevents overheating of the electric melting pot, after continuous use. Therefore, you can melt for 24 hours.

- Superbmelt silver melting pot is equipped with induction heating technology. The induction heating technology has the following benefits to your crucible melting pot; save melting time and energy use, conserve energy for heating only, therefore, heat does not escape the silver melting furnace to cause an unpleasant working condition.

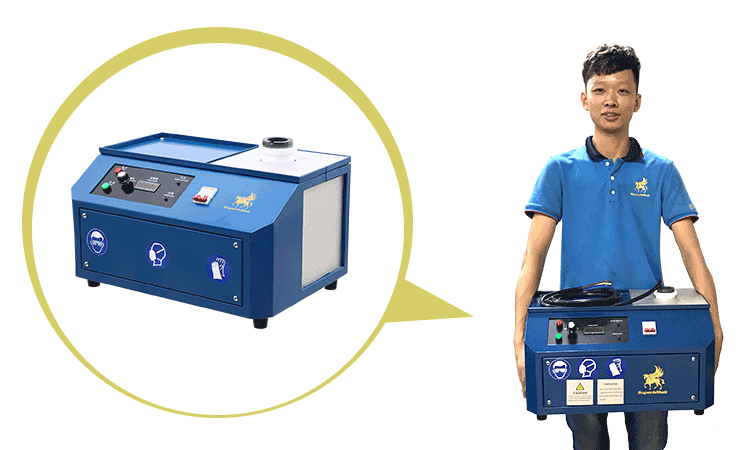

- The gold and silver melting pot is a compact size that is easy to use, transport and maintain. The compact size allows you to melt in your garage, porch or laboratory.

- The power required for melting with a Superbmelt electric melting pot is between 3.5 and 3.8kg, which means your small silver melting pot is cost-effective for production.

- The PLC control system makes the operation of the electric silver melting pot highly automatic. Therefore, improving efficiency.

- Superbmelt silver melting pot is designed for safety. Melting takes place in an enclosed chamber, therefore, you are not exposed to molten metal during the melting process.

- Superbmelt crucible melting pot is safe for the environment, the electric melting pot does not emit smoke, fumes or noise when it’s in use.

- With the Superbmelt electric silver melting pot, you can choose the best crucibles for melting your metals. Superbmelt crucible melting pot can melt metals in graphite and silicon carbide crucibles.

- Superbmelt electric silver melting pot has induction heating technology that allows a consistent molten metal. It also prevents oxidation, shrinkage and porosity of metals after casting. Therefore, you have an excellent production process.

- Superbmelt gold and silver melting pot prevent the loss of precious metals compared to the traditional melting process.

- Superbmelt electric melting pot has a video tutorial and an installation guide to facilitate a smooth installation process and use.

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

Small 1-2kg gold and silver smelting pot is portable size design, light weight, easy to carry and fix.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Gold and Silver Melting Pot

Any Question About SuperbMelt Gold and Silver Melting Pot

Silver Melting Pot Buying Guide

Application Fields of Gold and Silver Melting Pot

1.1, Smelting the Gold and Silver Ores

If you don’t know much about smelting gold and silver ores, this is the process of extracting silver and gold from their ores. The ores come included with a substantial amount of impurities. After smelting, you can get gold and silver with 90 percent purity value. But you can’t use those metals to make jewelry. The reason is that the gold or silver may contain a few amounts of silver, iron, or aluminum.

While smelting gold and silver ores, you need to make sure that you are doing it correctly. Otherwise, you may not extract all the golds from the ore. The profit will depend on the weight and purity level. So, ensure that you have the purest form of gold.

During the smelting process, the ore is heated at around 1064-degree C or 1000-degree C based on the type of ore you are smelting. The smelting process is conducted at high pressure, and some chemicals are also used. If you are looking for the best way to smelt ores, you can use a silver melting pot and gold silver melting machine.

This is where you can use a jewelry melting furnace. Such furnaces are designed to produce the required amount of heat and melt the ore within 10 to 15 minutes, based on the size.

1.2, For Recycling Old Gold and Silver

Is it possible to recycle your silver and gold jewelry? Yes, and you can do this by melting your old or unused gold jewelry pieces. Most people, those who want to re-use gold for some sentimental reason, melt the gold and create new jewelry pieces from that.

For this, you can use a silver smelting pot and a gold silver melting machine. Even though you can take the help of a professional metal refiner to do this task, using a melting machine can be a cost-effective way. Using these machines, you can melt the gold and silver within 15 minutes, based on the quantity. Get the machine now.

1.3, For Jewelry Casting

Jewelry casting is a form of art where experts used melted gold or silver to create different types of ornaments. With time, the technology for melting and casting gold has changed, and now most jewelers use lost-wax methods.

The jewelry models are created through the wax carving method, and then, in the case of the jewelry design investment, it is then heated at an extreme temperature. The cavity is properly filled with melted gold or silver.

For jewelry casting, one of the most important things that you will need is melted metals. This is where you can use an induction furnace. For safer and faster melting of silver, gold, and other precious metals for casting, you can go for silver melting equipment.

The machines are designed to meet your low-volume and high-volume melting requirements perfectly. With this, to melt 2kg to 5kg of gold or silver, you will only need around 10 minutes.

Besides, these machines are easy to use and come with various impressive features. Just get a good quality metal melting pot and an induction furnace, and you are all set to go.

1.4, For Industrial Applications

A silver melting pot and furnace melting machine are not just limited to the jewelry application. These devices can be used for some other essential applications. Some prominent example of industrial applications for these machines are:

- Investment casting

Companies or jewelers are now widely using induction furnaces and melting pots for investment casting. They work perfectly and let the users get the job done within a few minutes.

- Precious metals melting

As discussed above, one can use these devices to melt different precious metals properly without losing the purity level of the metals. Besides, they don’t have to worry about contamination. When it comes to refining gold and silver, this method is very efficient and effective.

- Alloy manufacturing

A silver melting furnace can also be utilized for alloy manufacturing. Due to the optimal uniformity and maximum level of flexibility, these machines work great in the manufacturing industry.

Besides, a silver melting pot can be useful in aluminum smelting and copper melting. Well, it can be said that no matter what type of precious metal you have, you will witness a safe and faster melting and smelting process with this. Check the silver smelter for sale and place your order now.

What is Gold and Silver Used For

2.1, Karat Gold Manufacturing

You all know that gold that is used for making jewelry pieces is not pure. One hundred percent pure gold is very soft. To make it harder for jewelry production, jewelry manufacturers add a small portion of other metals, such as palladium, copper, platinum, or silver.

So, to mark the purity level of the gold jewelry, they use karat marking. This shows the actual amount of gold and other elements used in that particular piece of jewelry. In the jewelry industry, gold is widely used to produce karat gold that can be used for gold casting, jewelry making, and more.

2.2, Making Gold and Silver Grains and Chips

Silver and gold are also used to make electronic items and chips. Why? Well, these two materials demonstrate a good level of electrical conductivity and resistance. Another reason is that the material is pliable. So, these materials are elementary to use. Besides, both silver and gold are highly resistant to tarnishing.

2.3, Gold Bar & Coin Making

Pure gold coins and bars are quite popular across the world. Gold bars are used for different purposes, and some use this for investment. These products are made of high-quality pure gold. For this, gold and silver are extracted carefully from the ores. This is also called mining. After introducing the gold and silver melting machine, the mining process has become a lot easier and faster.

The metals are melted using a melting pot or crucible and an induction furnace, and then the melted metals are used to make coins and bars. Different types of dies are used for this. A casting machine produces long sheets, and from those sheets, gold coins are made.

2.4, Gold Bar & Coin Making

Why gold and silver are widely used for jewelry making? Well, these materials don’t tarnish, and the workability level is also very good. So, instead of other metal, there is great demand for gold and silver-made jewelry pieces. As per some studies, around 10 percent gold is used in different industries, 40 percent for investment, and 50 percent for jewelry making.

Gold is perfectly refined, malleable, and ductile. By combining other precious metals with gold, jewelers make it easy to use. Besides, gold doesn’t react with the skin. So, those who have sensitive skin can even use gold jewelry.

If you are planning to set up your jewelry-making business, you will need a machine to melt gold. This is where you can buy a mini gold melting machine and a silver or gold melting pot.

How to Smelt Gold and Silver Nowadays

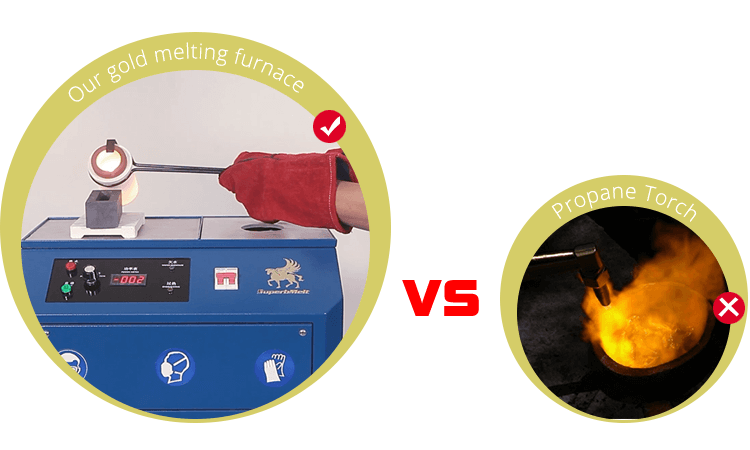

3.1, How to Smelt Silver by Propane Kiln

Smelting silver using a propane kiln is a traditional smelting process. Through this, you can melt silver ore faster. All you need to do is to put the silver into a silver melting pot and place the pot on a fire-proof surface. Now, heat the pot using the propane kiln by lighting a torch. That’s it. After a few minutes, you will get melted silver.

Not just silver, this method can also be used to melt other metals, for example, copper or gold. But for better results, use borax. For more heat, go for an oxy-acetylene torch.

However, you should be very careful while performing the method. Besides, keep in mind that creating a constant level of heat using a propane kiln can be a little challenging, and the process is manual.

3.2, How to Smelt Silver by Resistance Furnace

A resistant furnace is used for different mining applications. However, compared to an induction furnace, this can be very time-consuming. But with the best and high-quality resistant furnace, you can use that at different temperatures; for example, it can sustain around 1600-degree C of temperature.

This is enough to melt silver, gold, copper, and other precious metals. Some resistant furnaces come with the automatic temperature-controlling feature.

These machines use a gaseous medium, and that may affect the user’s health. Besides, such machines are not ideal for melting a large quantity of metal. For that, an induction furnace would work great.

3.3, How to Smelt Silver in Induction Furnace

One of the modern methods of smelting silver and gold is using an induction furnace. The machine is environmentally friendly and offers faster smelting results. Here, the alternative magnetic current produces the required heat.

The heat is directly transferred to the melting pot or crucible. The machines don’t need combustion. So, the room will not heat up while using the machine. With these machines, you can use a nonconductive silver melting pot. The pot will be surrounded by copper wire. Then the current moves through that copper wire, producing heat.

The induction machines can create the desired level of heat to melt different types of metals. Besides, equipped with advanced technologies and features, an induction machine can produce constant heat during the melting process. This is also called an electric silver melting furnace.

3.4, Why You Should Choose Induction Furnace

Based on your requirements, the type of melting furnace you buy will create a significant difference in terms of efficiency as well as costs. No matter what is your metal melting requirements, an induction furnace will be a perfect option for you.

Induction furnaces are pretty common in steel plants, mining industries, and foundry. The reason behind this is, such furnaces are very efficient and offer a cleaner melting process. Besides, the process is also very fast. On the other hand, it also provides you with a controlled melting process. The best induction furnaces can demonstrate a greater level of thermal uniformity.

Most of the iron factories are now replacing their cupolas with modern induction furnaces. While cupolas produce different pollutants, like dust, induction furnaces are designed to offer you a cleaner way to melt metals.

Another essential thing to consider is that induction furnaces don’t need combustion or arc. So, the working temperature will be safe. When using these machines, all you need is to reach the required temperature for melting the metals.

This way, you can prevent the loss of alloying elements. Using this, you can also lower the oxidation burn loss. The lower level of frequencies lowers the burning rate. So, there will be less oxidation of melted silver and gold.

With these machines, the melting operation will be fast, and the electromagnetic string will produce a homogenous mixture of melted metals. So, you can use one sample to represent the entire batch.

Choosing the suitable machine can help your company witness increased production at minimized losses and reduced cost.

| Propane Torch | Resistance Furnace | Induction Melting Equipment |

| For melting small quantity of gold | Melt in small quantity | Can melt large quantity |

| Inexpensive | Inexpensive | Expensive |

| Not environmentally friendly | Not environmentally friendly | Environmentally friendly |

| Not energy saving | Not energy saving | Energy saving |

| Can cause bodily damage | Can cause bodily damage | Smooth and efficient smelting process |

The process attached to the usage of the induction furnace gold melting equipment is straight forward. No hectic schedules or extra energy is needed. Its energy conserving mode of operation have made it the most sought out smelting method available. Regarded as the best choice for every business.

What Kinds of Silver Melting Pots that SuperbMelt can Provide

4.1, Mini 1-2kg Silver Melting Furnace

For any of your small-scale gold production, the mini silver melting pot (SPB-DH) is suitable. It is capable of melting any piece of gold whose weight falls in the range of 1-2Kg.

This small gold smelting machine can reach a maximum temperature of 1600℃ in no time. These features also make it this machine easy for melting other metals. Metals such as silver, aluminium, and copper, just to mention a few.

Mini gold and silver melting furnace also finds application in jewellery recycling, and SuperbMelt can be a good choice. For gold diggers or miners in deals in collecting gold and its alloys can also very suitable.

4.2, Integrated 3-10 kg Silver Melting Pot

Silver Melting Pot (SPB-TB) can reach up to a maximum temperature of around 1800℃ (the maximum temperature of platinum tilting smelter is 2600℃) with a power rating of around 15kw. This provides an ultra-high heating effect capable by the silver melting equipment of melting either 4kg of platinum or 6kg of silver (and similarly commensurate weights of other metals) 12kg of gold or within a period of 2-5 minutes.

SuperbMelt gold and platinum melting equipment can heat your raw metals very fast and rapid. With the effect of increasing the profit ultimate margin, it speeds up your operations. The gold melting machine is suitable for jewellery foundry and old jewellery refining plants.

Based on advanced induction technology or IGBT, the gold smelting equipment is a highly effective solution for gold smelting.

- Over time due to its superior action, it has come to be trusted by operators and business owners, which is.

- Designed with efficiency and convenience as the core targets.

- The melted metals can easily be poured into the mould by the tilting furnace, whose design ensures that. This prevents splashing or spillage from hot liquid metal splashes reduces the risk of operator injuries.

- To operator convenience, another proof of the commitment is the use of a replaceable crucible for easy maintenance.

- Also, a strong electromagnetic stirring system ensures the homogeneity of the liquefied metal. This comes in handy, especially for alloys.

- The silvermelting equipment or furnace is also equipped with an omnidirectional warning system. When potentially harmful operating conditions, this alerts the operator so that they are being approached.

- Induction silvermelting equipment or furnace is manufactured with the capability of operating for 24 hours at full capacity. Except for scheduled maintenance, this considerably lowers downtime.

- An advantage is present due to the use of induction technology. It is owing to the absence of electric arcs and electrodes, which can form impurities deposits.

Finally, preventing the production of unsafe gases like oxides of carbon and nitrogen due to no combustion takes place. The induction gold melting equipment has the edge over other forms of a furnace. Gases that are unsafe for the environment are often given off by Resistance and gas furnace.

4.3, 20kg-30kg Manual Tilting Melting Pot

This silver melting furnace comes with awesome specifications, unlike any other product on the market. It can melt almost 20-30kg of non-ferrous metals like copper, aluminium, gold, and silver etc. Based on an induction supply of power of 25-35kw, up to a temperature of about 1800℃, it can melt any metal. All within a short time frame of 7 to 9 minutes.

Induction gold melting equipment or furnace split design enhances easy tilting. This feature gives room for the pouring of liquefied metal without splashing or spillage.

4.4, 10-50kg Chain Tilting Silver Melting Machine

Superbmelt silver melting pot (SPB-CMF) can be used to melt any choice of metal. Both your non-ferrous and ferrous metals such as gold, lead and silver in no time can easily be processed. This small induction furnace (SPB-CMF) can accommodate metals in the weight range of 10kg to 50kg.

SuperbMelt small induction furnace (SPB-CMF) comes with a digital Simen control system (PLC) and is a good option. It gives more accuracy and precision to your readings.

4.5, 10-100kg Motor Tilting Melting Furnace

This motor-tilting gold melting pot is designed for the ferrous and non-ferrous metal of 10-80kg melting based on the technology of induction.

Motor tilting silver melting pot by SuperbMelt is constructed for one-man pouring action. Onto a steel frame, its body is mounted. By manual control, when tilting, the furnace body can be set in any position.

According to non-ferrous or ferrous melting, the crucibles will be taken use of different material. Graphite crucible is special for non-ferrous metal like copper, gold, silver, aluminium. For ferrous metal, silicon crucible is suitable.

The small land occupied, energy-saving and fast melting are its obvious features. For metal casting with a small capacity, that is the cost performance choice.

4.6, 50-250kg Hydraulic Tilting Melting Furnace

One of gold and silver melting furnace that comes from one of the leading induction furnace manufacturers in Asia is the SuperbMelt Electric Induction Furnace (SPB-HMF). It is capable of melting any non-ferrous metals and ferrous such as gold, silver, copper, zinc, aluminium, steel and lead. Minimum and maximum weight requirement of 50Kg and 250kg, respectively, are considered suitable benefit from an output power rating of 45kw ~160kw.

The Electric Induction Furnace is incorporated with a Simens controls system (PLC). This gives accuracy, precision and better control to your melting process.

How to Choose the Right Gold and Silver Melting Pot

5.1, Capacity of The Gold and Silver

The first factor that you need to consider is the size of the melting pot as well as the machine’s capacity. Well, it will significantly depend on the quantity of metal that you will melt per day. You can buy a silver melting pot having a capacity of 5Kg or 300kg based on your requirements.

Always buy a pot that can meet the daily production requirement. Well, you can always go for SuperbMelt’s induction furnace machine and melting pot for better results.

5.2, Power Usage of The Gold and Silver Melting Pot

You need to check the energy requirement by the induction furnace to melt the metals. While using a melting pot with an induction furnace, the overall power consumption level will be very low. However, based on the capacity, the power consumption level will increase.

For a low-capacity induction furnace, the power consumption level can be around 2Kw to 10Kw. In the case of a large-capacity pot and machine, it will consume around 160Kw of power.

5.3, Temperature Range Provided by the Gold and Silver Melting Pot

The capacity of a melting pot to handle the temperature changes is as crucial as the pot’s maximum and minimum temperature limits. If your melting process includes frequent cooling and heating cycle and rapid changes in the temperature, then you should choose a melting pot that is resistant to a higher level of thermal shock.

Some melting pot can easily handle rapid temperature changes than others crucible, for instance, a crucible with a higher level of the carbon content of the graphite. The pot will demonstrate better non-wettability and high thermal conductivity.

Besides, make sure that the melting pot can be used at different temperatures as each metal has a different melting point. This is where you can go for SuperbMelt’s silver melting pot.

5.4, Safety Provided by The Gold and Silver Melting Pot

As you will be using the melting pot with an induction melting furnace, make sure that the machine has all the required safety features. Furthermore, choosing a machine with a temperature control feature will be very useful.

On the other hand, buy a melting pot that is made of high-quality material, like graphite. Check the body density level. What’s more? You need to choose a crucible that is resistant to corrosion and better heat conductivity, and comes with a longer melting life. High-quality graphite-made melting pots are energy-efficient and can work perfectly by consuming less energy.

As per the experts, one should buy a silver melting pot from the manufacturer that is ISO, CE and SGS Approved. Well, you can trust SuperbMelt for this.

5.5, Variety of Metals That Can be Used in The Gold and Silver Melting Pot

Understanding the types of metal you want to melt will help you in choosing the right melting pot. For metals like nickel, chromium, brass, and copper, you can go for a pot made of silicon carbide graphite. Don’t forget to understand the melting temperature of the metals as you need to heat the pot at that particular melting point.

Graphite-made melting pot can easily sustain around 1600-degree of higher temperature. You can also use a melting pot made of silicon carbide crucibles, aluminum-bronze alloy, nickel-bronze alloy, coper-based alloys, and more. With the best melting pot, you will witness a better shock resistance feature and constant heat to melt the metals.

FAQ Guide of Silver Melting Pot

How hot can induction heating get?

Based on multiple studies, it can be said that the induction heating level can range from 100-degree C to 3000-degree C. Another thing to keep in mind that the silver melting furnace’s temperature can go up 1000-degree C as this is the melting temperature of the silver. In the case of a gold melting furnace, it can reach 1600-degree C. If you are looking for a high-quality melting furnace that can work appropriately at different temperature levels, then go for SuperbMelt’s gold and silver melting machine. Our furnace can attain 2000-degree C. The machines are designed to create constant heat during the melting process.

What are the advantages of electric heating over other types of heating?

After witnessing some fantastic benefits, most jewelers have now started using electric heating instead of other types of heating machines to melt silver, gold, and other precious metal. Some significant advantages are:

- Our metal melting furnaces have the constant stirring of charge and can provide you with a perfectly melted meta composition.

- The furnace uses electricity, but we would like to tell you that the machine will not consume more electricity. In some tests, by using the machine, you can save 15 to 25 percent of energy.

- Another best part about the machine is, you can also monitor the temperature while using it without opening the unit. So, it is very safe to use.

- The machines are designed to meet the production of different types of metals faster; as a result, you will enjoy faster production.

- Besides, SuperbMelt’s machines don’t produce much noise, and there is no risk of any harmful gas. Our melting machines are environment friendly.

- Using an electric melting machine, you can enjoy a faster and clean melting process.

- With a constant heat generation system, there will be no fluctuation in the melting temperature.

- They come equipped with a unique water-cooling system to keep running for hours.

Can I get 9999 gold and silver from your melting pot?

When it comes to buying the best quality silver melting pot, you can always trust SuperbMelt. These pots can sustain a higher level of temperature and perfect for smelt silver, gold, and different non-ferrous metals. However, these pots are not for purifying the silver. It can only be used to melt silver and gold so that you can remove the impurities. To purify the metals, you will have to get good quality and professional refining system.

How does an Induction melt pot work?

The primary principle of the induction melting pot or furnace is that a higher voltage of electrical source produced to form a primary coil induces a high current and a lower level of voltage in the metals. It is all about transferring the heat energy into the metals that you want to melt. Once the metal is melted, the high-frequency magnetic field can be utilized to perfectly stir the metal. As a result, the alloys will be properly mixed. In the induction furnace, if the current power is around 60Hz AC, then the magnetic field will switch the direction around 60 times.

How to melt different kinds of metals?

After the introduction of advanced melting machines that have replaced the manual process, melting metals has become a lot easier than before. Compared to the traditional process, now you can melt metal within 10 to 15 minutes. You can use SuperbMelt’s gold and silver melting machine to melt any types of metal you want. For the melting process, you will need a powerful melting furnace, and you can go for electric arc, cupola, and induction furnaces. For the best result, you can go for electric furnaces made by SuperbMelt. Using this, you can melt gold, aluminum, platinum, copper, gold, and more. While producing a constant level of heat, these machines offer a faster melting process.

How to choose the induction melting pot you need?

It is a fact that choosing a perfect and quality induction melting pot to melt gold and silver can be a very challenging task. However, to make it a little easier for you, we have mentioned down some important points:

- First of all, you need to understand the melting point of different metals because different pots can reach up to a specific temperature. You need to make sure that the induction melting pot can sustain a higher level of heat.

- On the other hand, you should consider the melting pot’s melting capacity. Choose a size based on your daily metal melting requirements.

- You need to check the induction heating machine in which you will place the melting pot.

How efficient is induction heating?

There is no doubt that induction heating is a super-efficient process for melting different metals. Because induction heating uses less energy as it directly transfers the energy to the part. As a result, you will save power as well as money. If you compare induction heating with oven or torch heating, this offers a lot of benefits; for example, no ramp-up and doesn’t heat up the room. Besides, it transfers more power to the part and more. So, go on and buy the best gold silver melting machine from SuperbMelt now.

What is the difference between an electric arc pot and an induction pot?

Talking about an electric arc pot, it can be used for the electric furnace where heat is produced from a powerful arc that melts the metal. However, in the case of an induction pot, it is widely used in the induction furnace machine where the head is produced from electromagnetic induction. An induction pot can heat up much faster, and the thermal efficiency level is also quite impressive. The electric arc pot gets the required heat to melt the metals through slag, and this is an indirect heating process. To know more about this and to buy the best silver melting pot, you can get in touch with SuperbMelt now.

What is the difference between smelting and melting?

Both smelting and melting are used to melt solid materials in metallurgy. Talking about melting, it is a process of converting solid metals into liquid by heating in a melting machine. This process is also known as fusion. Under this process, the substance’s internal energy is increased through heating. On the other hand, smelting not just melts the material but also removes impurities from the ore to keep the meta 100 percent pure. In the case of smelting, it has two major requirements, i.e., reducing agent and heat treatment.

Can you melt gold and silver off electronics?

Well, silver and gold can be obtained from electric boards and other electrical equipment, and the entire process is straightforward. However, you should not take the process lightly as the chemicals that you will use here are very dangerous. Make sure that you have all the required tools, such as a gas mask, glass apparatus, goggles, gloves, and more. Besides, use a well-ventilated space for this. First, break the circuit boards into smaller pieces, and then put those pieces in a durable glass container that can handle a high level of heat. Now, add concentrated nitric acid into the container. After that, burning fumes will produce, and they will come from the glass container. You need to keep stirring the mixture until it becomes fluid. Gold melts with stronger chemicals, so nitric acid will only melt the plastic and metal parts without damaging the gold. Once done, carefully drain the nitric acid using a filter and separate the gold. That’s it.

What is the best way to melt gold and silver?

One of the best ways to melt silver and gold metal is the induction furnace or gold and silver melting machine from SuperbMelt. These metals are melted at different temperatures using different types of chemicals. The melting point of silver and gold is 1000-degree C and 1046-degree C, respectively. Our machines can easily attain this level of temperature, and they are effortless to use. Try this out now.

How fast can gold and silver melt?

This will significantly depend on the material quantity and types of machines you will be using. But for a faster and efficient melting process, you can use an induction furnace offered by SuperbMelt. With this machine, melting 12kg of gold or silver will take only 5 to 15 minutes. Don’t worry about the power consumption level as the machine is energy-efficient.

How many types of induction melting pots can Superbmelt provide?

As a leading supplier of metal melting machines, SuperbMelt offers different types of induction melting pots and machines. You can go for manual tilting machines, hydraulic and chain tilting machines, mini induction melting furnaces, stationary platinum induction furnaces, and more. For more detail about our products, please visit our official website and check the product section now.

How do you smelt gold with borax?

In order to smelt gold using borax, you need to create a perfect mixture of sodium carbonate and disodium tetraborate. After that, the application of flux on the gold metal before heating will increase the chances of the impure elements that are attached to the gold. Borax is a famous oxidizing agent for gold smelting. Keep in mind that when using borax with the gold, you should be very careful with the gold having rough surfaces. Borax is very affordable and used in various mining operations across the world.

How do you separate gold from other metals by melting?

This process is quite easy. By melting at the right temperature, you can do this. However, the process is:

- First, heat the furnace that you are using at around 1200-degree C to 1300-degree C.

- After getting at the right temperature level, mix silica and borate chemicals solutions in the furnace. This will create the slag.

- After a few minutes, the metal will begin to dissolve and move down to the smelting pot or vessel.

- Let the melted gold cool down and remove the gold from the pot and separate the slag.

How do you melt gold jewelry?

Unwanted and old gold jewelry can be melted and again used to create new pieces of gold jewelries. You can melt gold using a 1200-watt microwave oven, a propane torch, a resistance furnace, or a gold melting machine. From all the methods, the melting machine method is very effective, and we recommend you to use the machines. These machines are very efficient for large size as well as small size gold production. It is also efficient as the heat is generated from the altering magnetic current and instantly directed to the melting pot without losing a small portion of energy. Just heat up the gold melting furnace and put your gold jewelry. Now, wait for a few minutes. In the end, you will get melted gold.

How do you get gold from gold ore?

The process of separating gold from the ore is called Cupellation. Under this process, the ore is treated under a high temperature in order to separate the metal. The ore comes with different types of base metals, for example, lead, zinc, and copper. When heated at a high temperature, those metals oxidize. However, this process doesn’t affect the noble metals. The gold ore is heated at a temperature of more than 960-degree C. If you are using a gold and silver melting machine, you can need to heat the furnace at 1064-degree C to elevate the gold beyond than the melting point. When you have the best precious metal melting furnace, like SuperbMelt’s induction furnace machine, you can complete the process within an hour.

How do you get impurities out of gold?

When you heat the ore or gold, most impurities will burn off in the gold or silver melting furnace. In general, gold is extracted from mines, and the ore includes a considerable amount of impurities, like traces of different metals. To separate gold from those metals, different chemicals, such as Cyanide or mercury, are introduced. However, using chemicals can create coagulate and develop clumps. Well, there is another effective method that you can try. First, you need to put the gold into a melting pot or crucible. After that, put that in a gold silver melting machine. Now, heat it at 1100-degree C. After a few minutes, the dross created by the heat will rise to the surface. You need to skim the impurities from the crucible periodically. After each removal, properly stir the gold. You need to keep repeating the steps until the formation of the dross stops.

What flux do you use to smelt gold and silver?

There are different types of fluxes that you can use to smelt silver and gold using a silver smelting furnace. These are Silica, Sodium Nitrate, Sodium Carbonate, Borax, Hydrochloric Acid, Ammonium Chloride, Zinc Chloride, and more. By using flux for the smelting process, you can enjoy the following benefits:

- Lower energy cost

- Better profit margin

- Easy removal of mercury

- Pure separation process.

How much borax is required to melt gold?

When it comes to melting silver or gold in a harmless and pure way, you can always use borax. Well, the quantity of borax that you will need to use while melting silver or gold using a silver melting machine will significantly depend on the quantity of silver or gold you want to melt. Using a sufficient level of heat and borax, you can easily extract gold from the ore. When borax melts, it can reduce the melting temperature. In general, for gold melting, you will need a small amount of borax. As per the experts, the flux mixture for gold melting should contain around 40 percent to 50 percent of borax, 1 to 5 percent of silica, and around 10 to 15 percent of soda.

How do you melt gold dust?

Remember that melting gold is a complex process. If the temperature is not adequate, and the process is no fast, you may not get the finest quality gold. Well, we would love to help you with this and tell you the process of gold dust melting. For this process, you can use different technologies, for example, a coal furnace, an electric silver melting furnace, a gas torch, or a coal furnace. We will not suggest you to use a gas torch as gild dust can waste with this. A practical option is a gas furnace. Follow these steps to melt the gold dust.

- Place a few amounts of borax inside the melting pot for the crucible. You should add the borax before adding the gold dust.

- Utilize a flux, a combination of borax and sodium carbonate. You need to mix the flux with the gold dust before melting it.

- The crucible should be pre-heated.

- After pouring the gold dust into the crucible, you can use aluminum chloride.

- The last step is selecting a portion of gold and then melting the gold and fixing it for melting.

Conclusion

Using a good quality gold silver melting machine, you can now quickly melt different types of precious metals within a few seconds. Besides, the process is safe. When you have these machines and a perfect melting pot or crucible, you can lower the cost while improving productivity.

Our advanced induction furnaces demonstrate a good level of thermal efficiency and consume less power. Furthermore, the maintenance cost is also very low. It can be said that, in the coming days, these machines may replace the traditional metal melting process. Don’t think much and get out induction furnaces and melting pots now if you want to witness a smooth, faster, and safe metal melting procedure.

According to gold capacity, one could always choose from 1kg to 500kg gold melting equipment or furnaces; the most common goldsmith and gold miner could use mini gold melter, which is the most popular among small business and factory. The refinery refines range varies from 10kg to 1000kg gold to melt. We will recommend the 5kg gold melting furnace up to 500kg hydraulic tilting melting furnace.

According to customers’ business model like goldsmith, small gold miners, small dealers, and jewellery shops, we will recommend the mini gold melter. It is the most cost-saving and portable size, with fast melting, introducing the advantages of the small gold melting machine.

For Refinery purposes, we recommend an advanced chain tilting gold melting furnace. PLC control with tilting and the High tech design always benefits any size of work. If One’s work is over 50kg, then the hydraulic tilting melting furnace would the best choice. For some big miners, motor tilting melting furnace hydraulic tilting melting furnace.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited