Home / Jewelry vacuum pressurized casting machine

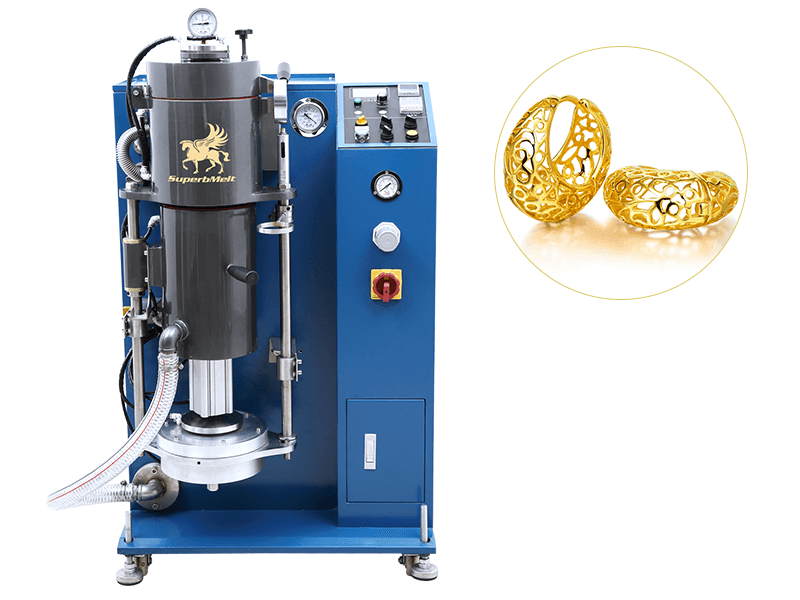

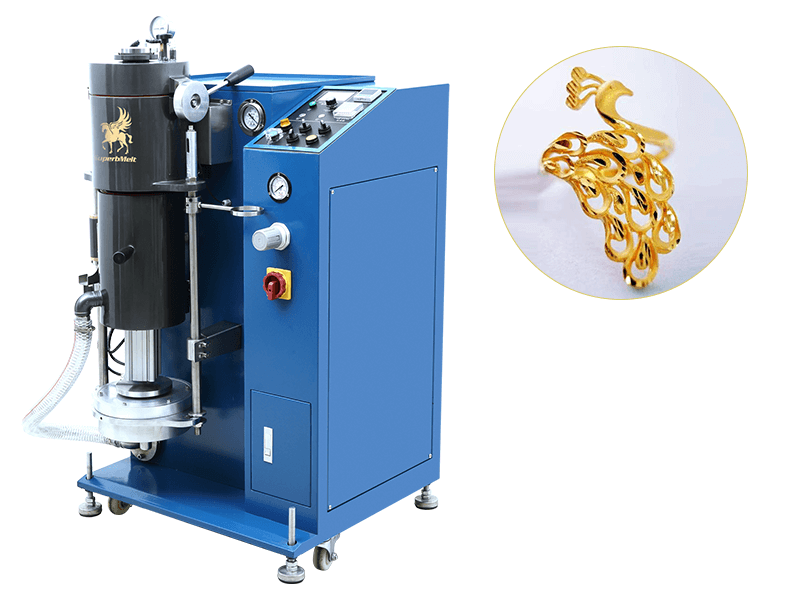

Jewelry vacuum pressurized casting machine

Jewelry vacuum pressurized casting machine

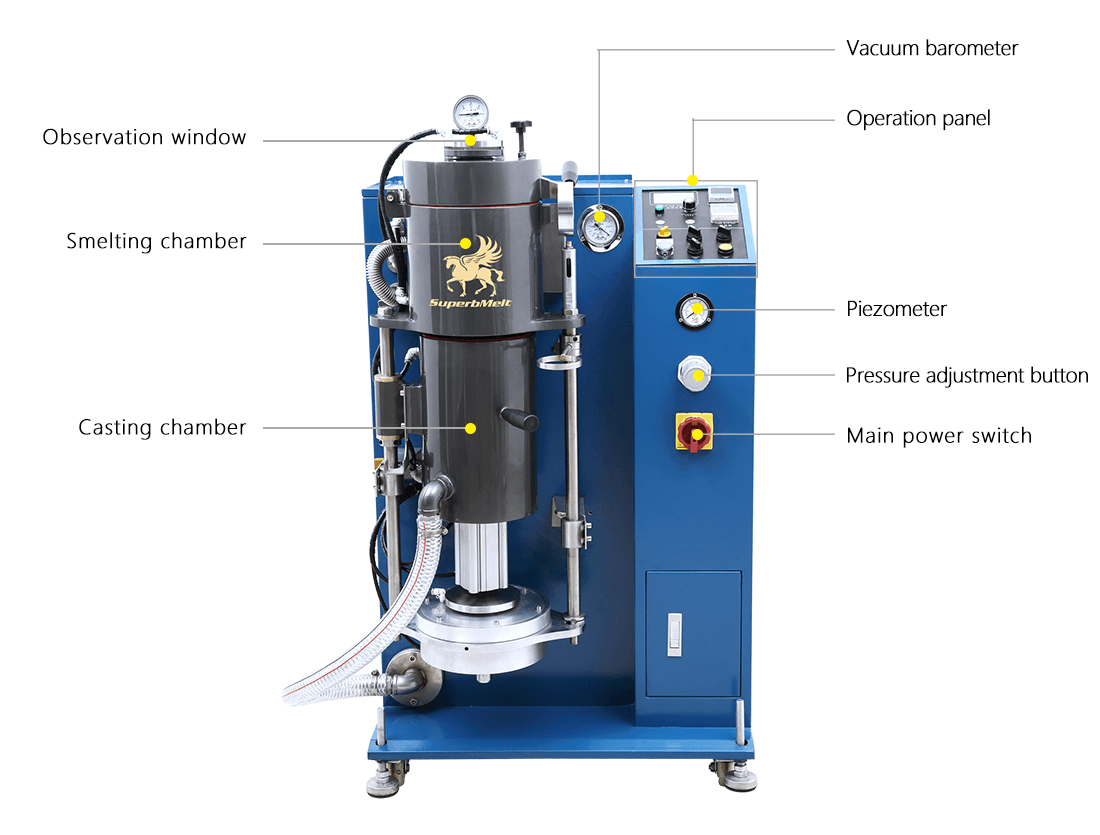

The jewelry vacuum pressurized casting machine is customized to melt and cast 1-6 kg jewelry gold, silver and other precious metal.

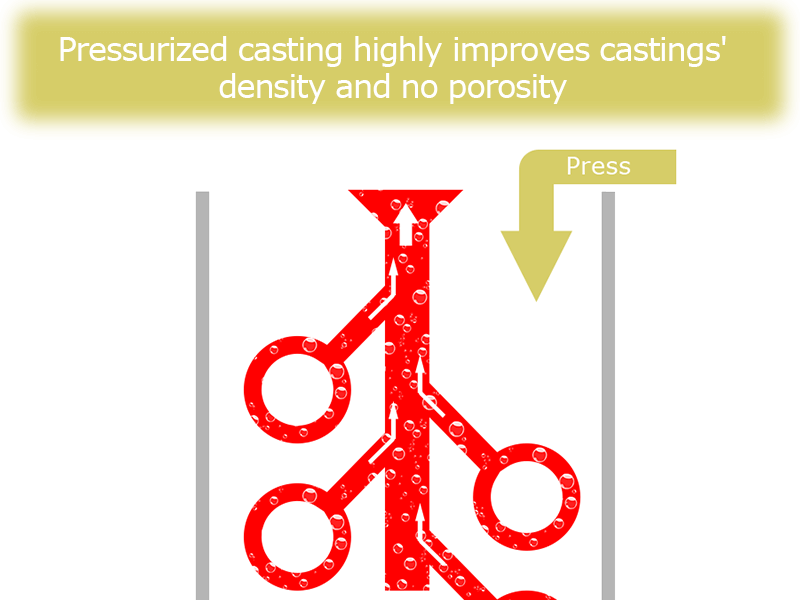

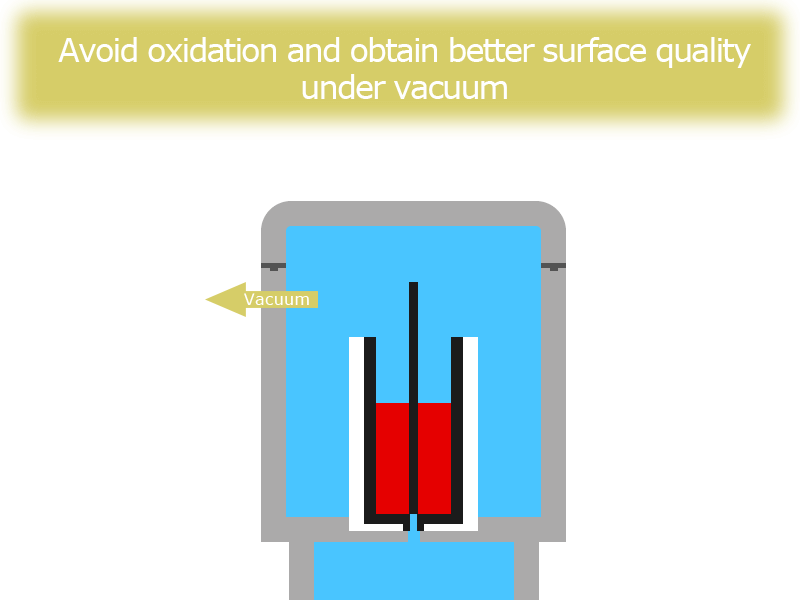

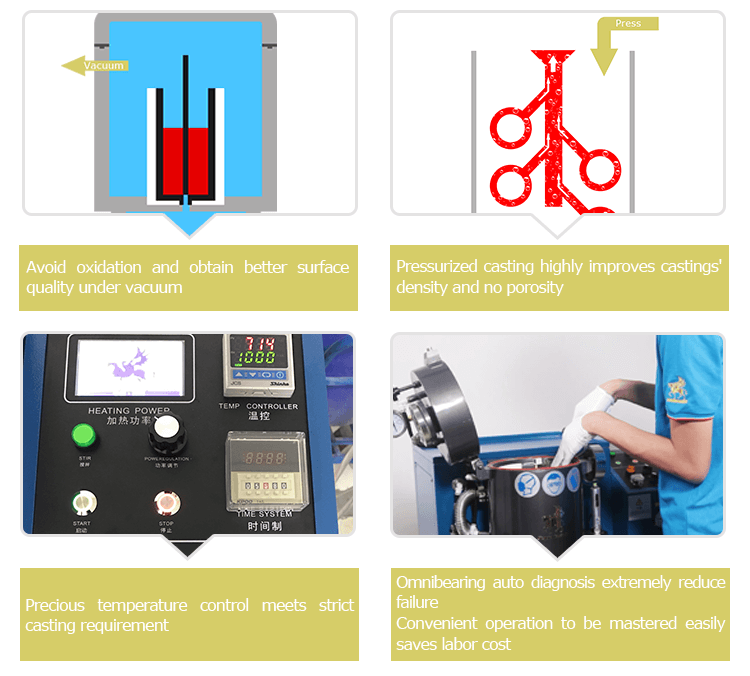

The jewelry melting and casting is under vacuum with argon pressure to protect your precious jewelry from oxidation. It achieves high density, high compactness, with almost no air bubble and reaches basically non-shrinkage cavity casting.

Has an accurate digital temperature control system with the temperature control errors of ±2°C.

Any precise jewelry and metal artworks could be perfectly done by Superb vacuum pressurized casting machine. We also provide full year warranty and worldwide onsite training service.

Jewelry Vacuum Pressurized Casting Machine Parameter

| Model number | SPB-DM2 | SPB-DM4 | SPB-DM6 |

| Power source | Three phase 380V±10%, 50/60Hz | Three phase 380V±10%, 50/60Hz | Three phase 380V±10%, 50/60Hz |

| Power | 15 kw | 15 kw | 25kw |

| Max Current | 15A | 15A | 26A |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 3-5 min | 3-5 min | 3-5 min |

| The Max capacity | 24K Gold: 2.0 kg 18K Gold: 1.5 kg 925 Silver: 1.0 kg | 24K Gold: 4.0 kg 18K Gold: 3.0 kg 925 Silver: 2.0 kg | 24K Gold: 6.0 kg 18K Gold: 4.0 kg 925 Silver: 3.0 kg |

| Max temperature control R-type | 1500℃ | 1500℃ | 1500℃ |

| Max. temp control k-type | 1100℃ | 1100℃ | 1100℃ |

| Dimension | 720×700×1150 mm | 720×700×1150 mm | 720×800×1150 mm |

| Weight | 150 kg | 155 kg | 170 kg |

| Casting system | vacuum pressure casting system | vacuum pressure casting system | vacuum pressure casting system |

| Pressure applied | Max. 0.1 Mpa | Max. 0.1 Mpa | Max. 0.1 Mpa |

| Protective gas | single gas (Argon) | single gas (Argon) | single gas (Argon) |

| Vacuum pump | 63 m³/hour | 63 m³/hour | 63 m³/hour |

| Oscillation | induction heating | induction heating | induction heating |

| Max flask size | D5*H10 inch | Normal D5*H10 inch (Customized) | Normal D6.3*H10 inch (Customized) |

| Control of temperature | by PID | by PID | by PID |

| Accuracy of temperature | ±2 degrees Celsius | ±2 degrees Celsius | ±2 degrees Celsius |

| Ultimate vacuum | 10hPa | 10hPa | 10hPa |

| Vacuum filter | Y | Y | Y |

| Vacuum leakage detector | Y | Y | Y |

| Flask check before casting | Y | Y | Y |

| Flask and chamber lift | Y | Y | Y |

| Pressure differential casting | Y | Y | Y |

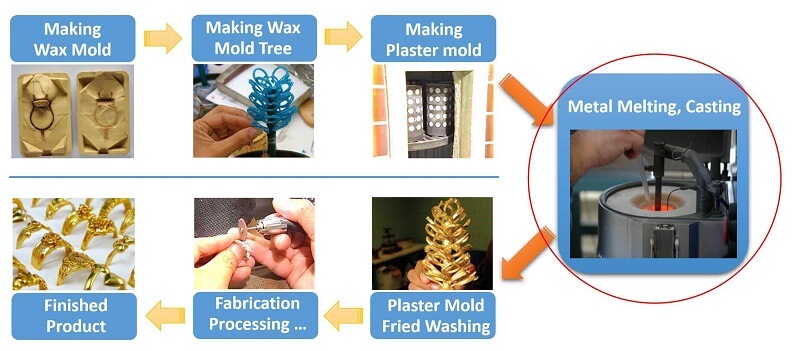

Process of Jewelry Vacuum Pressurized Casting Machine

Application of Jewelry Vacuum Pressurized Casting Machine

- Comparatively more space for metal casting

- Vacuum melting and casting both performed in one machine

- Provides quality metal casting

- Strong stirring to ensure even colour

- Unique casting cylinder separated from vacuum device

- Compact design

- Alarm system

- Faster casting process

- PID temperature control system

- Auto and semi-auto options available

You Will Get Reply within 24 Hours

Contact Us

- 0086-755-28838424

- 0086-755-28883730

- 0086-18857719978

- sales@superbmelt.com

We Are Here

- No.55 Anhua Road, Henggang Town, Longgang District, Shenzhen City, China