Jewellery Laser Soldering Machine

Top Manufacturer in China - With the power is 150-200w optional - Convenient power supply: AC 1-P 220V±5%/50Hz

The laser soldering machine uses a light energy to weld noble metals to themselves. In other words, the laser soldering machine is used to repair jewelry pieces in the jewelry making industry. It is also used for recreating unique jewelries.

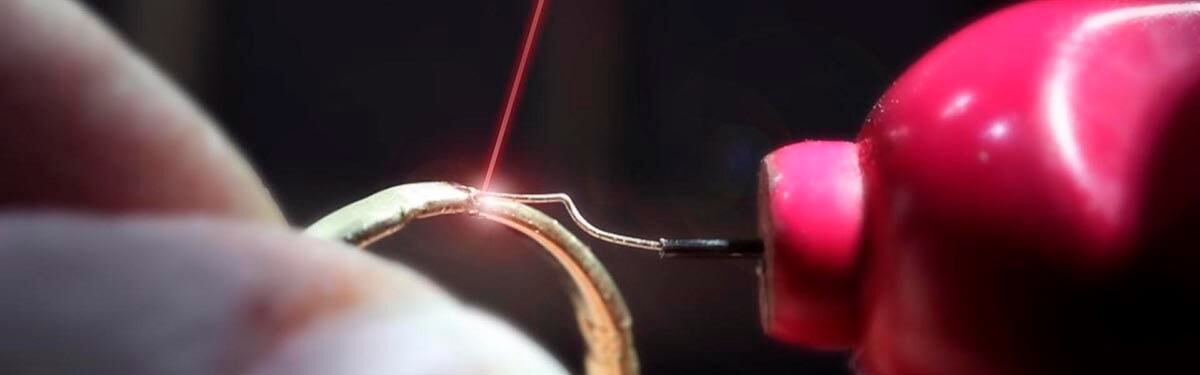

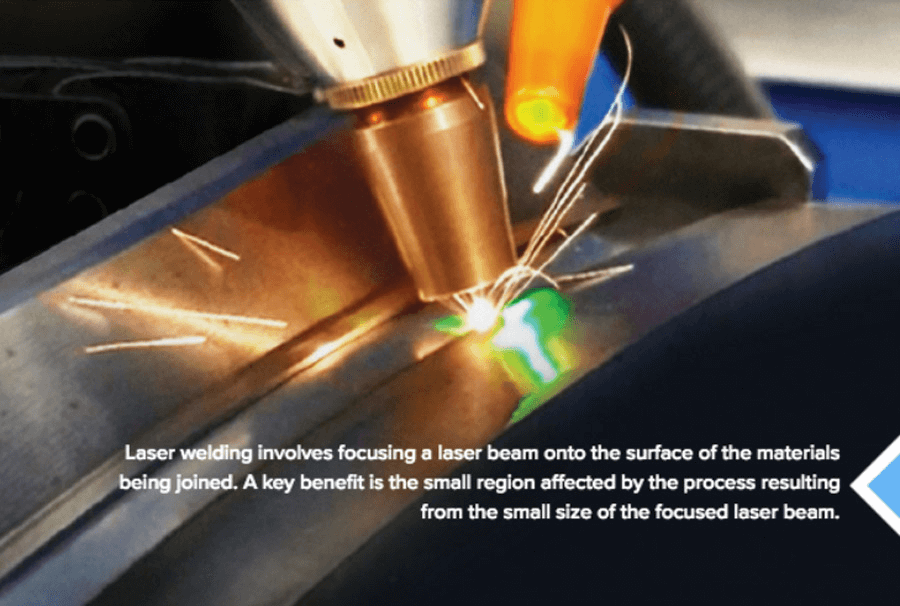

The laser has a finely focused laser beam that results in a minimal heat affected zone. During the laser welding process, the metal surrounding the broken parts is not affected or become molten. This precision heat source allows the user to laser weld metals close to heat sensitive stones such as pearls.

There are different jewelry laser soldering machines that suit both small and large jewelry repair needs. In all, the laser welding furnace is able to give you high quality jewelry repairs.

| Model | SPB-150WB |

| Wavelength | 1064nm |

| Max output power | 150W |

| Max pulse energy | 80J |

| Pump source | Single lamp |

| Pulse width | 0.1-20ms |

| Pulse frequency | ≤50Hz |

| Aiming and positioning | Microscope + camera system |

| Application | Welding and repairing various precious metal trinkets |

| Host power consumption | ≤5KW |

| Electricity demand | AC220V±5%/50Hz |

| Cooling system | Water cooling + air cooling |

| Dimension | 660x385x435mm |

| Weight | 49kg |

The mini laser welder is used to weld noble metal jewelry in the jewelry industry. It performs a clean and high quality welding for your business. The jewelry laser welder has a microscope and camera system that allows users to aim and position accurately when repairing. The maximum output power is 150W with a wavelength of 1064nm. The laser soldering machine price is very affordable for high quality jewelry repair purposes.

Parameter

- Power: 150W

- Pulse width: 0.1-20ms

The desktop laser welder is a compact size laser soldering machine used to repair jewelry in small jewelry stores. The jewelry laser welder makes remarkable and unnoticeable repair on your jewelry. It can repair several metal jewelry seamlessly. The jewelry laser welder has a microscope that helps users to aim and position accurately when repairing jewelry. The minimum spot diameter and laser power are 0.2mm and 200W respectively.

Parameter

- Power: 200W

- Pulse width: 0.3-20 ms

The split laser welder is a large size jewelry laser soldering machine used to repair jewelry on a large scale. You can weld several pieces of metal materials using this laser soldering machine. The microscope and camera system makes it easy to solder jewelry into a non noticeable repair. The wavelength and maximum output power are 1064nm and 200W respectively. The laser welding machine price is affordable and easy to use.

Parameter

- Power: 200W

- Pulse width: 0.1-20ms

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Jewellery Laser Soldering Machine

Any Question About SuperbMelt Jewellery Laser Soldering Machine

Jewellery Laser Soldering Machine Buying Guide

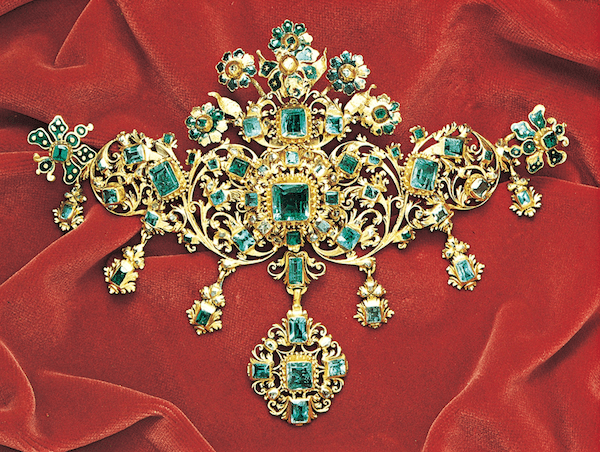

Do You Know that Jewellery is Soldered?

All the exquisite pieces of jewellery you adorn are not easily produced. They are made with many hours of hard work, which include expertise in many techniques. Soldering is a process in which two or more different metals are fused by melting a solder. The base metals which are joined do not melt. Solder is an alloy of two metals.

The main characteristics to be taken into account while choosing the metals to make the solder’s alloy are the low melting point. Common metals used as solder include tin, iron and lead. However, due to increased threats by lead, it is gradually being replaced by other metals.

Soldering can be carried out using different devices like a soldering torch, a soldering iron, a flame heater or an induction heater. The newest technology which one can use to do soldering is a laser beam.

1.1, The historical development of jewellery soldering

It is nearly impossible to track down the origin of soldering with absolute surety in the present-day scenario. Records from the past contain shreds of soldering evidence, which backed as far as the Bronze Age- probably even before 4000 BC.

Many pieces of jewellery excavated from this era have been beautified and rendered useful with soldering. Soldering has always been an integral part of metalwork. Civilizations like Mesopotamian civilization had used soldering at a very ground level dating back to almost 5000 years. All jewellery excavated from this period, like small neckpieces of earrings, contain traces of soldering.

It is believed that Sumerian swords, which were in use around 3000 BC, were put together through soldering. It is evident from the amazing gold work found from Egyptian civilization’s remains that the goldsmiths of this period were masters of soldering. Artisans of Troy were equally talented in this field.

The art of soldering has been passed down from generation to generation ranging through countless eras. It sophisticated over time and became a necessary means to get amazing results from a lump of any metal.

The most noteworthy achievement dating back to hundreds of years is the building of soldered long water pipes, spread across almost 400km of lead with seams by the Romans. They could withstand extreme climatic conditions and be no less sturdy than pipes of today. Their works done by goldsmiths are works of art one can admire the whole day.

The carvings done on every piece of jewellery adorned by the people of that era bring forward the goldsmiths’ sheer expertise in this sphere.

In recent years, soldering has advanced quite a bit. Around the mid-1800s, the first soldering irons started to appear in the markets of Detroit. In 1921, Ernst Sachs of Germany developed the first electric soldering iron for industry and initiated commercial production of a 200-watt electric soldering iron.

Presently, one needs precision programmable and temperature adjustable soldering stations to carry out the soldering of tiny bits of metals.

1.2, In which cases should jewellery be soldered?

Soldering has wide applications in the field of jewellery making. From joining two elements together or filling up empty spaces, soldering is the best option one can choose.

Soldering makes sure that the piece of jewellery produced is not distorted and is an exquisite piece. When carving in a precious stone on a metal or heating a metal to shape it, soldering can be used.

Laser soldering is the best option because it uses less time and has more efficiency. Hence, in the case of mass production of custom jewellery, production needs to be done fast, and hence laser soldering is used.

1.3, How to produce jewellery to be soldered?

The jewellery industry’s newest trend is to do away with the old traditional designs and opt for trendy custom-made pieces. It is not easy to customize the designs, considering the intricate works in demand in the present-day market. Previously, most of the designs were of the same category and required no much improvisation.

However, the tough work of replication intricate designs is made easy with the help of the newest technology in town- laser soldering technology.

It is not very popular currently, but it is expected to grow very famous with the growing demands. Making a piece of jewellery involves many steps- from gathering the design to fabricating each element to putting them together- it is a vast area of functions.

Soldering plays a key role in this aspect of producing jewellery. Starting from joining various design elements to reaching every significant part of it, soldering makes it easier. Making jewellery on a large scale includes soldering at every step.

Tools on the Market for Soldering Precious Metals

The solderer can use traditional soldering methods like using a soldering iron or induction heater to solder precious stones. When precious stones need to mount on a ring or a pendant, it is soldered and made to sit on the jewellery piece. The process is very detailed and has chances of distortion after the whole process cools down.

However, laser soldering is used these days to make work easier. There are many soldering machines available in the market. The most preferred soldering machine to solder jewellery among various jewellery soldering machines is the gold laser soldering machine.

We at Superbmelt provide you with the best quality soldering machines at affordable prices. Our machines

are equipped with the best technology to ensure that your precious metals are intact and no damage is caused to them.

2.1, What to prepare before soldering jewellery?

Soldering using conventional methods require a lot of prerequisite materials. However, with laser soldering technology, nothing much is required. Only the jewellery laser soldering machine is required with an excellent power source and very few other controlling devices.

The workplace needs to be well ventilated and organized.

One should take the jewellery piece’s characteristics into account to decide the laser beam’s power, which needs to be applied.

In addition to the laser beam’s power, the beam’s geometry should be an important aspect, as well.

A pyrometer needs to be kept handy. Different materials require different temperature range. The pyrometer used as a temperature measuring tool continually monitors the joint’s surface temperature being soldered every 10ms during optimal process control. Moreover, the use of a pyrometer speeds up the soldering program generation process.

Apart from the physical components, various other parameters need to be kept account of. The thermal profile control applied to each joint allows the optimization of these soldering parameters.

Another thing that needs to take care of is the ratio of the hole’s size and the pin. If the hole is too tiny or too large compared to the pin’s diameter, poor adherence cases may occur. Hence, it is important to keep the ration optimal.

The advanced level of automation of the laser soldering system gives rise to a very repetitive process. The jewellery laser soldering machines offer a high range of precision and controllability, and hence the devices are normally mated to automated precision.

For a given laser soldering tasks in jewellery making, every joint has its own individual particular thermal mass and reflectivity. Therefore, it demands a precisely defined unique laser impulse. Any slight deviation such as bent lead or a slight change in the amount of solder paste may lead to an open or destroyed joint. To avoid such problems, the person concerned with carrying out the task should maintain the laser impulse.

During the process of soldering, the position and the movement of the laser beam is controlled externally. This action is carried out by a device called the galvanometer. These galvanometers are computer-controlled and are specifically programmed for every particular component. The paths thus designed are stored in the computer interface for future reference.

If all the parameters are arranged beforehand, the soldering will happen smoothly without much trouble.

2.2, Different industries apply different methods

Soldering can be classified broadly into three categories:

- Soft Soldering

- Hard Soldering

- Brazing

Different industries employ different methods based on their particular requirements.

Soft Soldering:

The temperature required for soft soldering is below 400-degree Celsius. The metals used in this type are mainly alloys like tin with a melting point of less than 350-degree Celsius. The lower temperature makes sure that the bond is strong. The initial requirement for soft soldering is soft lead. It is used for soldering electric connections and fuses electronic components onto the circuit boards.

An industry where soft soldering is used:

Soft soldering is mainly used in industries like electronics and plumbing.

Hard Soldering:

Hard soldering requires a higher range of temperature to melt the soldering metal. It ensures a stronger bond. The metal used in this case is usually brass or silver. Hence, it is often referred to as “silver soldering”. It is mostly used to join metals like silver, gold, copper etc. Compared to brass, silver melts at a lower temperature. Due to its high price, it is less commonly used.

An industry where hard soldering is used: Hard soldering is mainly used in the jewellery making industry and plumbing industry.

Brazing:

Brazing requires a very high range of temperature and produces the strongest bonds. Here the metal is heated but not melted. It produces the cleanest soldered metals.

Brazing should not be considered synonymous with welding. Both the phenomena are very different and should not be confused. The differences have been elaborated below.

Both are basically metal-joining sheet metal techniques within the overall sheet metal fabrication process, but each operation differs in certain aspects. Putting it simply, welding is a process that puts together metals by melting the base metal and doing fusion, while brazing joins metals by melting and flowing a filler metal into the joint.

In brazing, the metal used for filling has a lower melting point than the metal that has to be joined. In welding, the requirement is the quiet opposite. The metal, which is the filler metal, has a higher melting point than the base metal, similar to soldering.

Fabricators don’t melt the base metal in case of brazing. However, in welding, fabricators melt the base metal and join each workpiece together.

Brazing uses capillary action, and welding employs the action of fusion.

An industry where brazing used: Brazing is used for pipe fittings and has a wide range of application in the tool industry.

The other types of soldering include-

- Induction soldering:

Induction soldering is when two or more metal items are fused by melting them with the introduction of electromagnetic fields between the metals for easy melting and flowing a filler metal (solder) into the joint interface.

The filler metal (solder) has a lower melting point than the base metal, which is being worked on. Induction soldering heats the workpieces in an RF (Radio Frequency) field. It is a non-contact process and hence desirable.

Induction soldering does not involve the melting of the joints.

Induction Soldering often results in a weaker joint than a brazed one. However, this can be ignored for many applications, especially when you work with sensitive electronics or small components. It causes less thermal stress.

- Wave soldering:

Wave soldering is when a circuit board is soldered by moving it over a wave of solder. It is a very stable process- both mechanically and electrically. It gets the work done within a few seconds and produces solid joints.

It is mainly used for assembling PCBs on a large scale for commercial purposes due to its short operation time. One can use it for both hole-mounted components and surface-mounted components.

However, with evolving technology every other day, wave soldering is less used day by day.

- Stained glass soldering

Stained glass soldering is the most difficult kind of soldering and requires high skills. The soldering iron used in this case should be at least 80W. It is an amazing method to produce great beautiful ornaments or other pieces of work on glass.

- Laser soldering

Laser soldering is a way of using a laser beam to heat a joint and fuse them. It is a non-contact process and is the newest technology to solder metals.

2.3, Different methods are needed for different metal jewellery

Making jewellery requires joining intricate pieces together without distortion. The common method used for making metal jewellery is laser soldering.

Laser soldering uses a laser beam to melt the solder. Since the laser beam is very narrow, it can be concentrated into a tiny space where the soldering iron tip might not reach. It is a speedy process.

There are mainly two categories of laser soldering.

Pulsed infrared fibre lasers are used for minimal operations. They can do engraving tasks and have multi-purpose use. one can use them to texture a particular surface or cut fragile edges. They have the best application for material removal. In case, while soldering, you have uneven deposits on the surface, this technique can resolve the problem.

The continuous pulsed laser has a meagre output power. The laser is produced for a long time without time gaps.

2.4, Comparison of jewellery soldering methods

The jewellery soldering methods are:

- the chip or pillion soldering

- sweat soldering

- the probe or pick soldering

The comparison between the different soldering methods are as follows:

| The Chip or Pillion soldering | The Sweat soldering | Probe or Pick soldering | |

| Area of application | Chip soldering is used for placing chips in between joints. | Sweat soldering is used for joining two pieces of sheet metal. | The probe soldering is employed when a wire needs to be soldered on a design, or a very narrow space needs to be soldered. |

| Method of application | For chip soldering, the following steps need to be followed: At first, flux needs to be applied to the chips, and a torch is to be lit. The area surrounding the jewellery being is heated. After bubbling begins, the torch is directed towards the metal with prolonged movement to ensure its deposition. When the metal starts to change colour, subject the flame to a smaller area to heat both the surfaces, which must be joined. After that, wait for the solder to flow. If a place is left unsoldered, you can solder the site directly by applying the torch now on that area. Then, dip the soldered metal into water and followed by pickling. | For sweat soldering, the following steps are followed: At first, the chips which will be soldered are put between the two metal surfaces. One must take care that chips are places evenly long the metal so that the solder flows everywhere without leaving any empty spaces in between. With the help of the torch, you can maintain the direction of the solder’s flow. The surrounding areas are heated, and after the flux bubbles appear, the torch is applied to the metal. When the solder flows, the charcoal needs to be moved to ensure that all places are filled properly. If there are some gaps left, one can fill them by applying the flux and heating until the solder flows and joins the surfaces. | For probe soldering, the following steps are followed: In the beginning, an average-sized solder is cut and dipped fully into the flux. Then, the chip is put on the charcoal, and the torch is lit. When the flame is placed right on top of the chip, it will be curling into a small probe-like structure. The probe is placed on the joint and followed by steps carried out in chip soldering. |

Why Do You Need a Laser Solderer to Solder Your Jewellery

Soldering is a process that includes a large amount of heat. The amount of energy emission happening while soldering metal is very high. The welder should take all the necessary precautions into account.

The workplace should not be congested, and most importantly, it should contain a first aid kit lest an accident occurs. Carrying out soldering is not an easy task and requires years of expertise.

For doing the task, only people involved in this field should be trusted and counted on. Furthermore, laser soldering is a new technology. Handling a beam of the laser is not a cakewalk and should not be taken lightly.

In jewellery making, the intricate designs need very fine and detailed laser work, which the person carrying out the welding should do with care and patience. Hence, it is recommended to consult a professional and get the job done rather than yourself.

3.1, Advantages of laser soldering method for jewellery compare to other methods

The laser soldering method is comparatively new. It has many advantages to itself.

Firstly, it is a non-contact process which implies that it does not place a heavy load on the PCB and leaves it clean and ready for use every time.

Furthermore, it is a more stable and trustworthy process because it efficiently applies heat without uneven application.

One can use it to solder very tiny bits of metals in confined and limited space where a tip cannot fit. Since the laser is not deflected easily, it fits perfectly well into confines places. It gives the desired outcome. Jewellery makers can use this feature to produce excellent details on a large scale which otherwise would have required very detailed craftsmanship and expertise.

It facilitates the joining of dissimilar pieces together, which gives trendy and cool designs. It is the best option to work with those small components that stand a chance to melt when subjected to heat.

The best part of using a laser soldering machine is its high accountability and less care required for maintenance. A person can control the solder joint temperature externally with minimum chances of distortion. It works with amazing precision and higher rates of efficiency compared to any other means.

Furthermore, with the intricate designs produced on a large-scale maximizing efficiency, sales and profit will also increase.

A significant advantage of laser soldering is its ability to reduce intermetallic compound formation due to rapid joint formation, which results in a high-quality joint.

It also has a low maintenance cost. Once you purchase a jewellery laser soldering machine, it will work fine for the next many years without compromising the results’ quality.

It is effortless to use and flexible according to the user’s needs. It can be adapted according to the design and the industry it is being used in.

3.2, With laser soldering, you don’t need to spend extra time preparing for work in advance

Laser soldering is a highly automated process and requires less human labour. It is mainly a machine-assisted process with high rates of precision. The required parameters like the laser beam’s width and geometry, the laser’s power, and the effective process time can easily be controlled and do not require much expertise or effort. It is a speedy process, and if used with little expertise, it will give the desired result. It is a self-cooling process and does not require extra time for cooling before you can do the next soldering.

In recent time, customers are extremely perfectionists when it comes to the work’s precision. No other process will guarantee such efficient work within such a short period.

It is a selective soldering method and enables the smallest and exact amount of energy to be pointed to the particular soldering region. Even if those places are difficult to reach out to, this method reaches without causing any collateral damage caused due to side effects of extreme heat.

How to Choose a Laser Soldering Machine

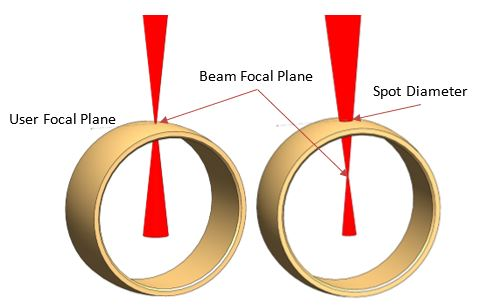

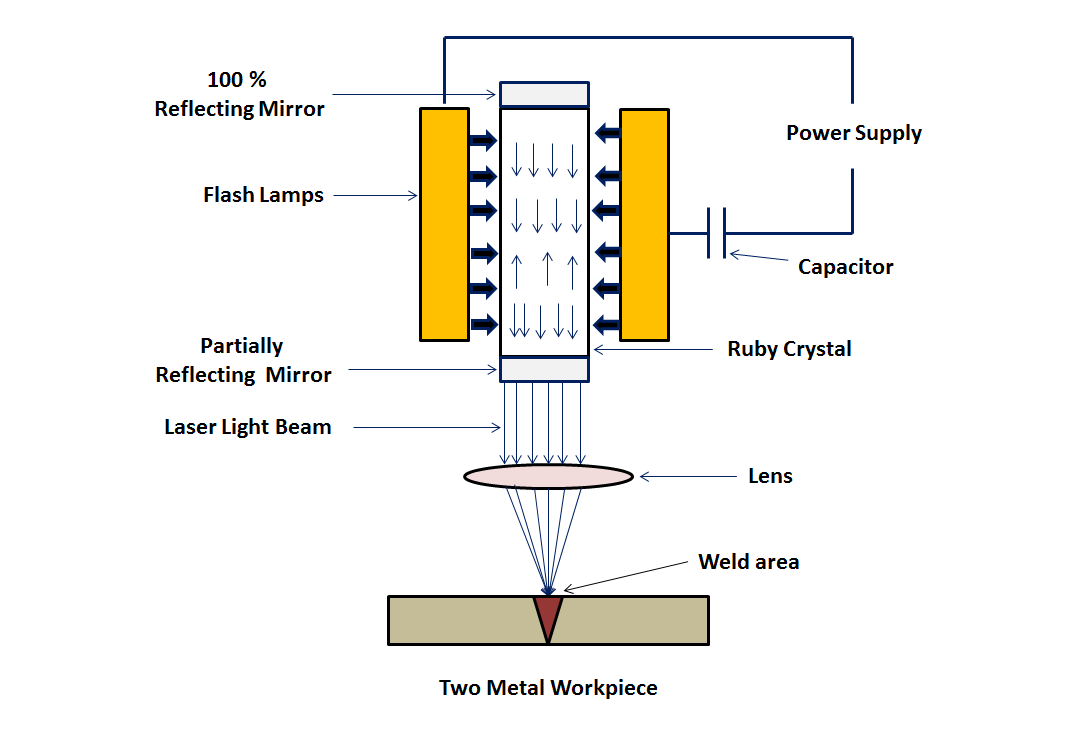

In the laser beam welding process, two metals are joined using a high energy laser beam. The laser beam is pointed to the hole or cavity between the two metals. The huge heat of the beam melts the metals, and a mixture of both metals fills space. After the cooling process, a strong and long-lasting weld is created.

It uses the principle that when an energy particle hits an atom, its electrons get excited. After cooling off, the excited electrons return to the ground state, and they emit a photon. Photon is a particle of light. The radiation stimulation controls this photon’s emission, and we get a very high concentrated laser beam.

The kind of weld produced depends on the execution time. One should carry it out at a speed of approximate meters per minute. For thin metals, this speed is perfect. But for thick metals, this speed in meters per minute produces narrow and deep welds.

4.1, What should be paid attention to when purchasing jewellery by welding machine?

The first aspect which needs to be paid attention to is the durability of the jewellery. While buying a jewellery piece, no one wants it to be a one-time use product and want the investment to be a waste. People have a notion that welding makes the jewellery weak and prone to breakage. However, jewellery made with high-quality welding, like laser welding does not pose that threat. The jewellery is sturdy and very long-lasting.

The next criteria are the price of the jewellery. The jewellery costs quite a big amount. However, the price is worth it since it is of good quality. One might be able to buy multiple jewellery pieces with the same amount- but a customer should prefer quality over quantity.

After the price of the piece, a customer should take the maintenance cost into account as well. A piece of jewellery produced with laser welding technology is long-lasting and does not require much aftercare. They have very less possibility of getting spoilt within a short period.

The buyer should consider the intricacy of the design. In case you are looking for a customized design, jewellery laser welding machines produce the best quality without any compromise.

Superbmelt have taken into account all the parameters mentioned earlier and will be more than happy to give you the best quality welding machines in the market. We understand what your requirement exactly are hence, can fulfill all the requirements.

4.2, What Kind of jewellery laser soldering machine is suitable for your needs?

The type of laser soldering machine used depends on the area of work. Its use in jewellery making is a very new concept. Gold laser soldering machine is the most used laser soldering machine in the market. It is handy and easy to use.

The beam used for soldering is very narrow, making it possible to reach every minute region where a traditional metal tip could not have reached. It has a wide range of application. Since it is operated on the power source, there are fewer chances of operational fatigue, making it the ideal mass production process. Jewellers can also use it for repairing a damaged piece.

4.3, What parts are the core of laser soldering and how to maintain them?

The main elements of the laser machine are as mentioned below:

- Power Source: A high voltage power resource is required for the operations. It is applied across the laser machine to produce a laser beam. The power density is controlled externally. A high-power density initiates a tiny time gap for heating the surface layer to the boiling point.

- CAM: It is computer-aided manufacturing. Here the laser machine is loaded with the computers, which is programmed to perform the welding process. CAM does all the main work of the controlling action during the welding process by laser. It fastens up the welding process to a greater extent. Speed is one of the main parameters which needs to be kept in mind while carrying out the process. If the rate is too fast, the resultant welding is shallow, and in case it is too slow, the welding causes the melting of the metal to an excessive extent. Hence, the worker should maintain the welding speed to adequately welded metal without much distortion or porous surface.

- CAD: It is called Computer-aided Design. It is used to design the algorithm for welding. Here computers are used to create the workpiece and how the welding is performed on it.

- Shielding Gas: A shielding gas may prevent the workpiece from oxidation during the welding process. The gases which are commonly used are helium, argon and nitrogen. Another function of the gas is to protect the focusing lens from the bursting liquid droplets and other metal vapours. It is also used for dispersing the plasma shielding in case of high-power welding.

- Pulse Power and Pulse Width: The Heat affected zone determines the pulse width, i.e., the lengthier the pulse width, the larger the heat affected area. In other words, the length of the pulse is directly proportional to the heat-affected zone. The peak power is measured in watt and directly impacts the peak power’s density. It is the peak power density that maintains the extent of weld penetration. The weld penetration increases with every 1/2 power of the pulse width.

- Off-focus Volume: Laser welding requires an off-focus or defocus mainly because the laser beam tends to evaporate into a hole. This evaporation is caused due to the extreme power density at the centre of the focal point.

- Focus optics: This is the part that mirrors the end section of the fibre perfectly. The fibre optic’s work is to transfer the beam to the focus head point. The ratio of the collimating lens and focus determines the size of the welding application point. Furthermore, the focus optics could be used to ideally obtain the spot’s size for the application of the beam or provide a modified spot size when a more significant core diameter fibre has to be used to regulate an enhanced power.

Conclusion

Laser welding or Laser soldering technologies is comparatively new in the market. They are the perfect mix between the conventional methods of welding and the advance use of technology. However, they are less commonly used due to their less know popularity and huge price range. Simultaneously, although their price is high, the outcome of laser welding is much stable and permanent compared to other techniques. Hence, the price is justified.

The laser enhanced technology can reach all the industry sectors, which were impossible for the traditional welding methods to carry out the assigned task. Due to a more electronic approach, the efficiency of the work is increased.

Moreover, laser welding is a very new concept for jewellery makers. They are not used to working with this high-end technology. It will require some time for them to get accustomed to the working of this technology.

Laser welding efficiently reduces the period of work. The prerequisites of carrying out laser welding are significantly less, and an adequately spaces place with room temperature is sufficient.

The adhesion it produces is much better and does not require any further processing.

Undoubtedly, one can exclaim that laser welding is the jewellery industry’s future and many other industries.

Laser soldering is better than the conventional methods of soldering. It is faster and has higher rates of efficiency. Although it uses less time, it is the best method for mass production. There are fewer chances of uneven deposition of the metal or the bond being brittle. The bond made is long-lasting and sturdy.

This laser technology has the potential to have a big market value very soon. Since it is machine operated with less manual labour, it has very few chances of error. For jewellery makers, it is a must-have and ensures the execution of detailed designs without much hassle or trouble.

FAQ Guide

Where is the laser soldering machine used?

Laser soldering machine has its applications mainly as a jewellery laser soldering machine. It is used to implement joining the intricate pieces of metals together and produce the designs quickly. It can be applied to fill porosity and make customized designs. It is easy to reach all those small nooks and corners where a soldering iron tip cannot reach. Ring resizing, reassembling broken pieces of jewellery are some common uses of laser soldering machines.

Can you laser solder aluminium?

Soldering aluminium is not easy, like soldering copper or brass. Aluminium has a strong and protective oxidation layer over it which makes it difficult to be soldered. It requires the proper kind of technique and expertise with the work. One can always laser solder aluminium, and it is by far the best way to solder Aluminium. The laser beam concentrates a huge amount of heat on a particular confined space and makes it easy for the metal to melt. With the right quality of equipment, the Aluminium can be laser welded.

What is the principle of laser beam welding?

The basic principle of laser beam welding is the heating effect produced by a precisely pointed laser beam. It is a fast method and causes little to no distortion. The process is based on using a controlled laser beam that transfers energy to the soldering location. The absorbed energy heats the solder until it reaches its melting point temperature leading to the joint’s soldering. Hence it requires no contact.

What materials can be laser welded?

Laser welding uses very high energy beams. All metals cannot endure these energy pulses. The materials which can be laser welded are:

- Die steel: Die steel produces the best welding. S136, SKD-11, NAK80, 8407, 718, 738, H13, P20, W302, 2344 are some of the die steel varieties used for welding.

- Carbon steel: For good quality welding, if the carbon content exceeds 0.25%, it needs to be preheated.

- Titanium alloy: This welding is used mainly in the glass industry

- Stainless steel: Stainless steel has a significant linear expansion coefficient. Due to laser welding’s extreme heating, this sizeable linear expansion coefficient is reduced, ensuring super-quality welding without pores.

- Copper and Copper alloys: Welding of copper or copper alloys has disadvantages like pores, welding stress, thermal crack and extreme distortion. Hence, laser welding is the best option.

- Plastic: The materials include PP, PS, PC, ABS, polyamide, PMMA, POM, PET, and PBT. Plastics like polyphenylene sulphide PPS and liquid crystal polymer have very low laser transmittance and cannot use laser welding technology directly. To overcome this difficulty, generally, carbon black is applied.

- Aluminium alloy: Aluminium is highly soft and has a protective oxidation layer, beam welding has an exact heat affected zone that one can control externally, making it great for aluminium. The alloys which can be welded include alloys like Alnico (aluminium, nickel, copper), Al-Li (lithium, sometimes mercury), to name a few.

- Magnesium alloy: The alloys include ASTM-1A (Fed Spec QQ-M-54), alloyed with manganese, and ASTM-AZ31A (Fed SPec QQ-44), which is alloyed with aluminium, manganese, and zinc.

- Inconel: It is an alloy of nickel-containing chromium and iron and is highly resistant to corrosion.

- Kovar: It is an alloy of nickel-cobalt ferrous type.

- Copper Beryllium: It is an allow which contains 0.4 to 2% of beryllium by weight with approximate 0.3 to 2.7% of other alloying elements such as nickel, cobalt, iron or lead. However, owing to increased threats due to lead, it is less likely to be used.

- Ni-Chrome: It is an alloy of nickel with chromium, and sometimes iron is added to this alloy.

- Nitinol: Nitinol is a mixture of titanium and nickel. Depending on the weight ratio, we have Nitinol 55 and Nitinol 60. In Nitinol 55, nickel is 55% by weight, and similarly, in Nitinol 60, nickel is 60% by weight.

Does welding weaken metal?

Whenever metal is subjected to extreme heat changes, its fundamental physical characteristics change. Mostly its structure and grain size are affected the most. There are high chances of the metals getting annealed, resulting in reduced strength, softer and increased elasticity, or the metal may become more complex and prone to breakage. In the case of welding, it works under a very high range of temperature. There is usually a heat-affected zone or commonly referred to as HAZ. Depending on the base material’s characteristics, the duration for which it has been welded, the HAZ is affected. The degree to which the HAZ is affected varies with the temperature it is subjected to while the process. The time taken to cool after the process of welding is also a determining factor. Adverse effects of welding are primarily seen in cases of cold-rolled steel. The metal gets weak, and it becomes less durable.

Does soldering require additional metal?

The requirement of additional metal is dependent on the metal which is being worked within the process. If one cannot maintain the filler temperature, you can add another metal and the present metal to modify its melting point. In general, there is no such requirement. Soldering is an independent process.

Where is laser welding used?

Laser welding is used in a variety of industries. Photovoltaic module manufacturing, Electronic manufacturing, Automobile application, Medical application are to name a few. The main laser welding application is in areas where it is difficult for conventional welding methods to reach. For example, in places where detailed and outstanding work needs to be carried out, one can use the laser welding process.

Which types of laser can be used in jewellery welding?

There are mainly four categories of lasers that one can use in jewellery welding:

- Gas lasers: They usually use Carbon dioxide or TEA- Carbon dioxide as the base mixture. The wavelength is around 10.6 micrometres, dependent on the gas pressure. They can be pulsed or continues wave (radar) operated.

- Solid State lasers: Their wavelength is around 10.6 micrometres. They can be pulsed or continues wave (radar) operated.

- Fibre lasers: They use Yb fibres with a wavelength of 975 nano meters. They can be Q-switched or ultra-short pulsed or continues wave (radar) operated.

- Semiconductor lasers: The LD (laser diode) laser have a wavelength of 1070 nanometres. They can be pulsed or continues wave (radar) operated.

Can you solder with a laser?

Laser soldering is the newest technology in town. Joints produced by laser soldering are very sturdy and long-lasting. It is a comparatively new technology and has no physical or mechanical contact, making it worth using. It eliminates the risk of distorting sensitive components. Robots can produce micro-sized laser beams for soldering barrow regions which would have been difficult for the traditional soldering iron tip to reach. Laser gold soldering machines are high in demand.

How strong is laser soldering?

The main advantage of laser soldering is its amazing ability to apply heat in the exact position without creating much mess. The solder joint is designed with perfect precision. The joint thus formed is very strong and long-lasting compared to other conventional soldering methods. The possibilities of it breaking are significantly less. Hence, it is applicable for creating permanent joints that are less brittle and have fewer cracking chances under extreme external pressure.

Does welding consume precious metals?

Welding does not consume precious metals. When used with the right technology and required precautions, it produces a premium quality outcome. Moreover, laser welding is just the right option to use when using any other method that might consume precious metal. We at Superbmelt have provided our jewellery laser welder with the right technology perfectly suited for this purpose.

Does welding require additional metal?

Welding usually does not require additional metal. However, depending on the base material, you might need different metal to maintain the melting point. But laser welding requires no addition of extra metal, and that is an added advantage.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited