Home / Hydraulic Tilting Melting Furnace

Category

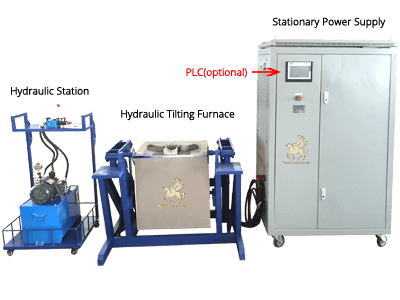

Hydraulic Tilting Melting Furnace

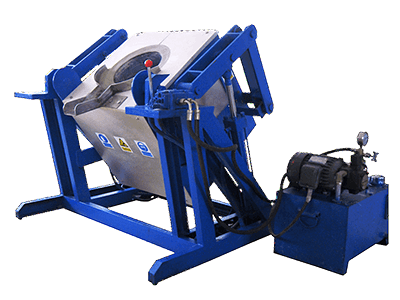

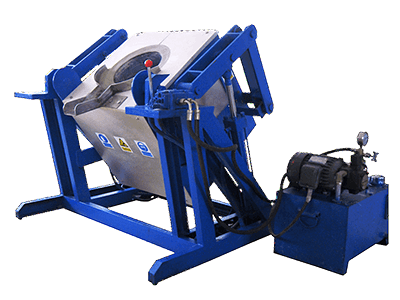

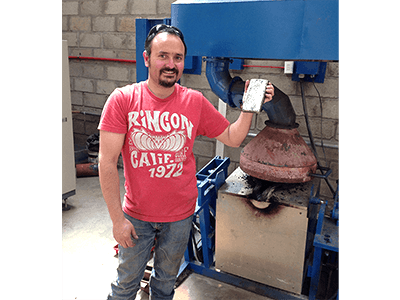

Small Induction Furnace Description

This type of hydraulic small induction furnace is designed for 50-250kg metal melting.The medium frequency induction power supply ranges from 15kw to 160kw with advanced IGBT technology.

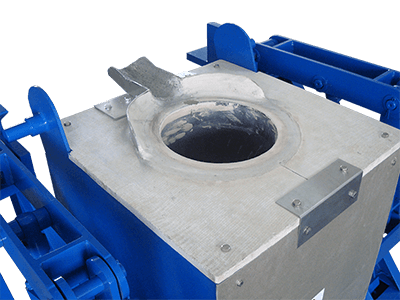

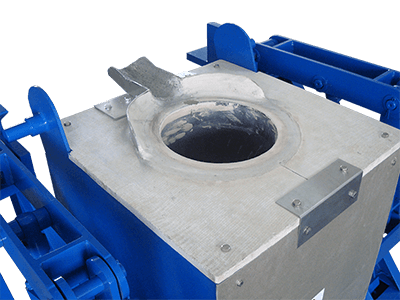

The steel frame construction ensures the furnace with lifelong working and reliability.

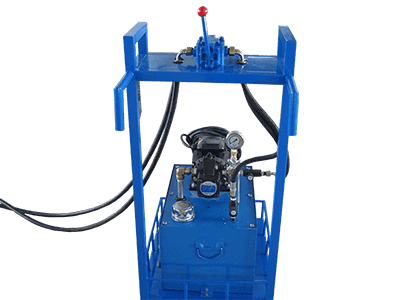

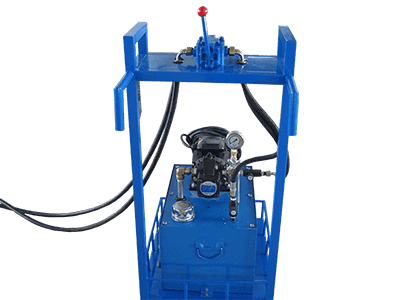

The tilting function of the small induction furnace is controlled by hydraulic box with remote panel trolley.It highly improves the furnace stability and operator’s safety.

Comparing others, this type of furnace is combined with magnetic yoke to improve melting efficiency much.

If you request high quality performance in melting process, this furnace will be your ideal choice.

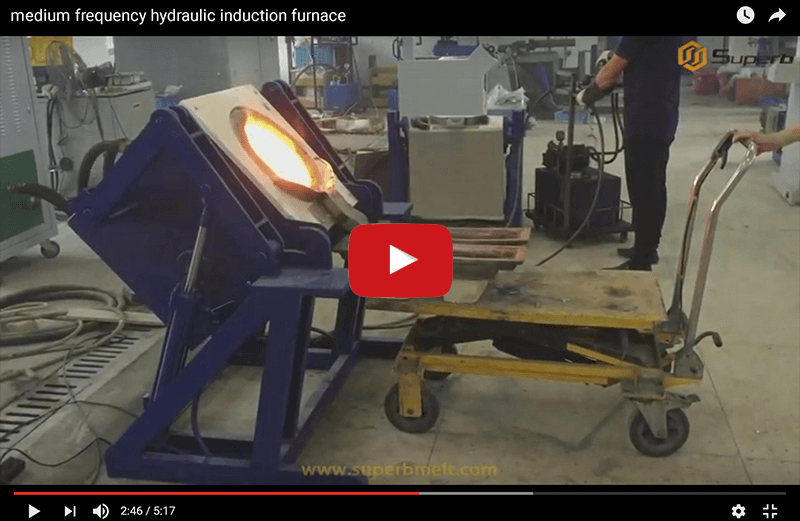

Video

Parameters

Power supply parameters of hydraulic small induction furnace

| Model | HMF-45 | HMF-70 | HMF-90 | HMF-110 | HMF-160 | |

| MAX input power | 45KW | 70KW | 90KW | 110KW | 160KW | |

| MAX input current | 68A | 105A | 135A | 168A | 240A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | |||||

| Oscillation frequency | 1K~20KHz | |||||

| Requirement of cooling water | Hydraulic pressure | ≥0.3Mpa | ||||

| Flow rate | ≥20L/Min | |||||

| Temperature of water | ≤45℃ | |||||

| Generator box | Weight | 52kg | 57kg | 91kg | 99kg | 134kg |

| Volume | 65×35×58cm | 78×40×88 | 78×50×88 | |||

| Transformer box | Weight | 38kg | 52kg | 68kg | 95kg | 95kg |

| Volume | 62×30×53cm | 64×48×58 | 64×65×61 | |||

Melting capacity parameters of hydraulic small induction furnace

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | |

| HMF-15 | 3kg | 10kg | 3kg | HMF-70 | 25kg | 80kg | 25kg | |

| HMF-25 | 5kg | 20kg | 5kg | HMF-90 | 40kg | 120kg | 40kg | |

| HMF-35 | 10kg | 30kg | 10kg | HMF-110 | 50kg | 150kg | 50kg | |

| HMF-45 | 18kg | 50kg | 18kg | HMF-160 | 100kg | 250kg | 100kg | |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | ||||||||

Details

Features

- Medium Frequency melting furnace for melting gold, silver, copper, iron, steel, stainless steel, aluminium and other metal materials.

- Easy installation: The video and manual book will be enough for the inexperienced work to finish the installation.

- IGBT power saves more than 20% at least than SCR.

- Easy operation: the worker can manage to learn that within several minutes.

- Constant 24 hours working.

- The strong steel shell furnace keep the melting system in a long life working.

- MF field force can stir the melting pool to achieve better melting quality.

- Pour the molten steel landing position basically unchanged through the hydraulic tilting device. That is convenient for worker to control the pouring with remote control panel.

- The furnace provides the following advantages: quiet operation, High efficiency, Self-diagnostics , Digital.

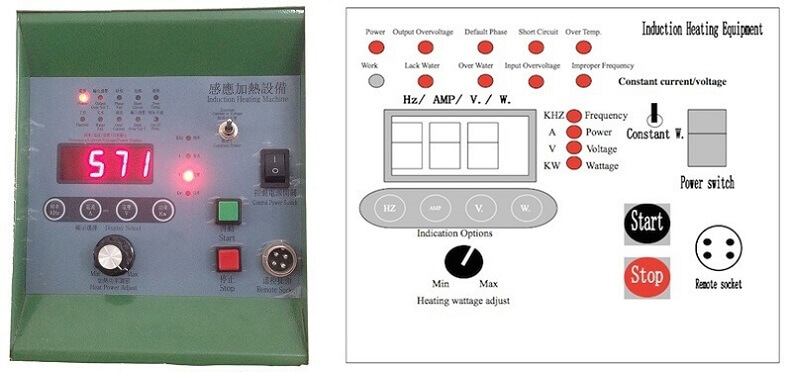

Power protection warning

Power Control

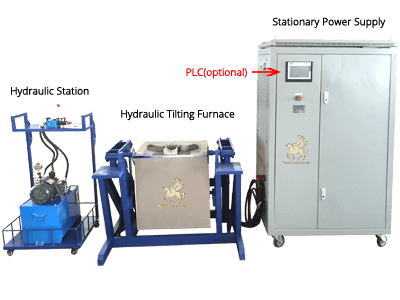

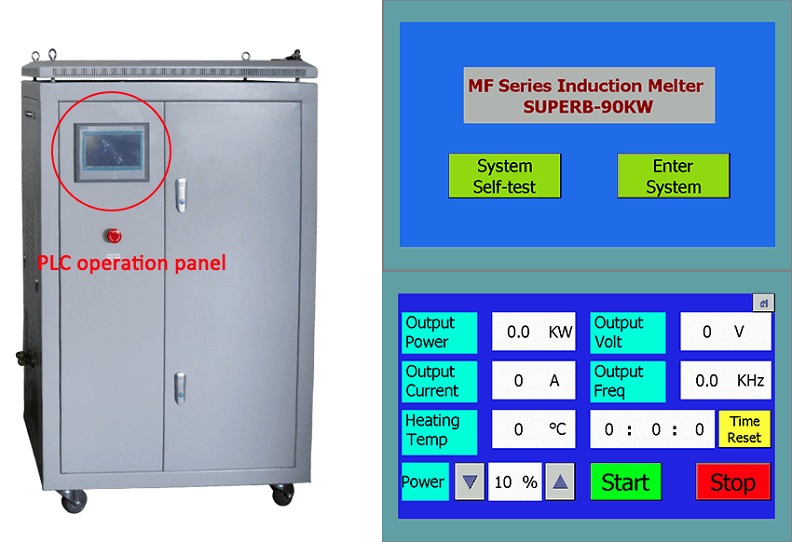

PLC control Panel of Tilting Metal Melting Furnace (optional)

- Lower power consumption, the IGBT technology saves 15-30% energy than KGPS,100% full load.

- Installation and maintenance are convenient, it can be finished by video or our manual guide. So it reduces the cost which you need pay for the engineers abroad for installation.

- The occupied land for the gold melting furnace is less than 1 square meter.

- The crucible replacement is very easy for different metal material.

- 24 hours constant working will meet your long time melting.

- Low pollution, low noise.

- Gold melting induction furnace with multi-protective functions to over-voltage, over-current, less water, over-heating with low fault rate and is safe and reliable.

Link here to know more about the PLC

Standard configuration of Tilting Metal Melting Furnace

Working

You Will Get Reply within 24 Hours

Contact Us

- 0086-755-28838424

- 0086-755-28883730

- 0086-18857719978

- sales@superbmelt.com

We Are Here

- No.55 Anhua Road, Henggang Town, Longgang District, Shenzhen City, China

Blog | Products |SiteMap | About Us | Privacy Policy

Scroll to Top