1.The characteristics of medium frequency coreless induction furnace for aluminium melting.

1.1.oxidation degree of Aluminum composition is small, burning loss is small.

Aluminum is a kind of active metal. When it is heated for casting, the temperature reached around 700 degrees Celsius, (the melting point of pure aluminum is 660 ℃). Oxygen reaction of aluminum is easy in the air at the moment to generate the Al₂O₃. That is burning phenomenon. Al₂O₃ powder will be removed as slag, it is the loss of the aluminum. Under the action of electromagnetic stirring, aluminum liquid will billow. The burning loss degree of aluminum liquid which is the oxidation degree is related to the degree of liquid aluminum billowing. The more fierce aluminum liquid billowing will lead to greater air contact area then more serious oxidation. On the contrary, the loss is smaller.

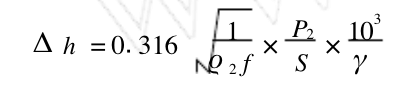

In order to clarify the problem clearly, Formula 1 and diagram 1 as follows:

In formula:

ΔH represent the stirring height (also called hump height) by /cm;

ρ2 represent the resistivity of aluminum liquid by /Ω.cm;

f represent medium frequency power supply frequency by /Hz;

P2 represent power consumption by /kW;

S represent the burden surface area which is surrounded by sensor /cm2;

γ represent liquid aluminum liquid proportion by /kg and cm-2.

As the formula, under the condition of constant power, the higher frequency is with lower aluminum liquid string height, the liquid metal billowing will be weaker. On the contrary, it is stronger. So as to reduce the loss of liquid aluminum, increasing frequency is a good way. Medium frequency induction furnace has higher frequency than line frequency furnace, so taking use of intermediate frequency furnace can reduce the loss of aluminum components, reduce the degree of oxidation of aluminum components.However, the too high frequency will increase the difficulty of furnace manufacturing (due to magnetic leakage). Anymore the furnace lining life will be greatly reduced. So An appropriate frequency should be chosen to achieve the best results.

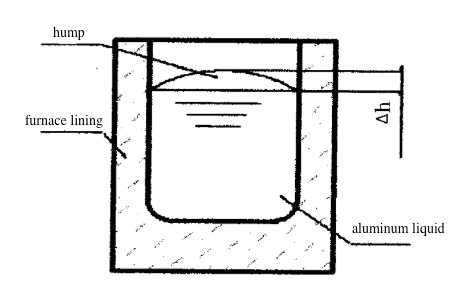

Diagram 1 Induction aluminum melting furnace

1.2 Intermediate frequency coreless induction furnace for melting aluminum has higher efficiency than the electric resistance furnace

Medium frequency coreless induction furnace to melt aluminum is based on the principle of electromagnetic induction heating, the heating efficiency can reach 0.59, and it can improve the melting rate by improving power.

The resistance type furnace with radiating heat to transfer Heat, according to the results of the previous design, the total efficiency is only 0.15 ~ 0.30.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited