Choosing Correct Metal Melting Induction Furnace

As for the same type of intermediate frequency metal melting induction furnace, the price has vary widely in price. Take 1 ton of furnace which is widely used as example, prices is different and vary many times in different suppliers.

There are many factors related to the price, such as the furnace structure, material usage, electric components selection, technical content, after sale service, quality and so on. Now, there are some main components you must pay attention to:

The furnace shell and magnetic yoke

In point of shell choosing of aluminum shell furnace, the standard weight of the shell of 1 ton furnace should be 400Kg cast aluminum alloy. So the thickness should be 40mm. But some manufacturers often apply less weight and thickness. It saves their material cost, but will highly increase the security hidden trouble.

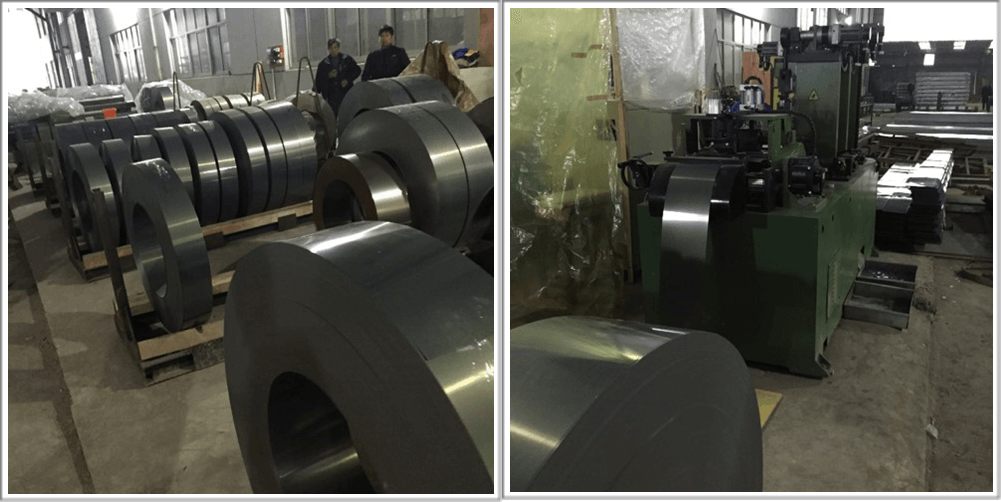

As for steel shell induction melting furnace, the most important part is to choose magnetic yoke. Concerning the same steel frame furnace, the different yoke choice will lead to big price gap. The new Z11 cold rolled silicon steel sheet with high permeability shall be selected for manufacturing. The silicon steel sheet thickness should be up to 0.3mm. Using profiling structure, the intrados should be the same as cylindrical curvature of induction coil, so that the yoke can be close to the outside of the induction coil. And the divergence of the magnetic field lines around coil can be in the maximum constraint. The magnetic yoke is fixed by welding stainless steel plates on both sides, cooled by water. (Some manufacturers use silicon steel which is waste, non-oriented , and even removed old transformers to produce yoke)

The core of metal melting induction furnace is induction coil.

The price of coil made by cold extrusion brass is much higher than the one made by cast brass. The surface treatment of the coils which should be made by T2 cold extrusion giant brass section copper uses electrostatic spraying, reaching to H-class insulation. To protect its dielectric strength, the surface needs be wound dressing by mica and E-glass ribbons, and then paint insulating moisture-proof enamel coating. Between the coils turn-to-turn, have to leave some space to coat the refractory clay. When painting,the refractory clay should penetrate in to the gaps to strengthen clay adhesion to coils.After refractory clay building is completed, the neat entire inner surface should be easy for removal of the lining to protect the coil.At last, setting some turns of water-cooled stainless steel tubes at both ends of coils to increase the overall rigidity, benefit for heat dissipation. (Some manufacturers use T3 cast copper or brass which is with poor conductivity and easy to break, then conduct to water leakage.The attention must be paid to that).

coils of metal melting induction furnace

coils of metal melting induction furnaceSCR

The quality of SCRs which different manufacturers take use of is generally uneven. The good quality SCR has good temperature sensitivity, fast response and low failure rate. So pls choose well-known manufacturers of SCR to ensure the machines more reliable and stable. (In the choice of SCR, the requirements about SCR manufacturers name should be stated. H good quality SCR company contains: Xiangfan Taiji, Xi’an Electric, etc.)

Reactor

The main material of reactor is silicon steel sheet. we should choose new product produced by the regular manufacturers, do not use the recycled silicon steel sheet.

Water pipe clamp

There are a large number of water connections in the whole set of IF metal melting induction furnace. Strictly speaking, the pipe clamps should be made of stainless steel clamp, the better is to use the copper Slipknot. Slipknot is easy for installation and removal , need no maintenance. Particularly suitable for watercooled cables, conducive to the current transfer and the water leakage does not happen, safe and reliably.

In addition, beside above points, a few factors is also very important, such as capacitors and resistors, cooled inverter cable, copper drain, etc., which will affect the quality and price of the metal melting induction furnace. Here, we do not make the detailed description. Hope you can pay attention to them when you purchase the machine. Try to require manufacturers to provide details of the main components, not just consider the price while ignoring the structure and quality of the equipment inside. In Superb electromachinery co.,ltd. you will see the superb details about the machine.

Silicon steel sheet cutting in Superb. They are the material to make the magnetic yoke .

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited