Home / Closed Type Water Cooling System

Category

Closed Type Water Cooling System

Water Cooling System Description

The water cooling tower is appliedin industrial furnaces, such as induction melting furnace, induction welding furnace, induction forging furnace, blast furnace, muffle furnace, etc. circulating system is available.

1. Use soft water circulating cooling

2. Occupy small area,move easily.

3. High cooling effciency.

4. Low operate cost.

Details

Parameters

Water Cooling System Parameter

| Furnace (T) | Power (KW) | Cooling water flow (T) | Pump power (KW) | Pump head(M) | Inlet diameter (mm) | Outlet diameter (mm) | Water volume (m3) | Cooling water flow(T) | Pump power (KW) | Pump head (M) | Inlet diameter (mm) | Outlet diameter (mm) | Water volume (m3) |

| 0.05 | 100 | 5 | 2.2 | 32 | DN40 | DN50 | 10 | 7 | 2.2 | 32 | DN40 | DN50 | 14 |

| 0.1 | 175 | 6 | 2.2 | 32 | DN40 | DN50 | 12 | 8 | 2.2 | 32 | DN50 | DN65 | 16 |

| 0.15 | 220 | 7 | 2.2 | 32 | DN40 | DN50 | 14 | 10 | 3 | 32 | DN50 | DN65 | 20 |

| 0.25 | 310 | 7.5 | 2.2 | 32 | DN60 | DN65 | 15 | 15 | 4 | 32 | DN65 | DN80 | 30 |

| 0.5 | 400 | 8 | 2.2 | 32 | DN50 | DN65 | 16 | 20 | 4 | 32 | DN65 | DN80 | 40 |

| 0.75 | 600 | 9 | 3 | 32 | DN50 | DN65 | 18 | 30 | 5.5 | 32 | DN65 | DN80 | 60 |

| 1 | 800 | 10 | 3 | 32 | DN50 | DN65 | 20 | 40 | 7.5 | 32 | DN80 | DN100 | 80 |

| 1.5 | 1200 | 15 | 4 | 32 | DN65 | DN80 | 30 | 60 | 11 | 32 | DN80 | DN100 | 120 |

| 2 | 1600 | 20 | 4 | 32 | DN65 | DN80 | 40 | 80 | 15 | 32 | DN100 | DN125 | 160 |

| 2.5 | 2000 | 25 | 5.5 | 32 | DN65 | DN80 | 50 | 100 | 15 | 32 | DN100 | DN125 | 200 |

| 3 | 2500 | 30 | 5.5 | 32 | DN65 | DN80 | 60 | 125 | 22 | 32 | DN125 | DN150 | 250 |

| 3T-60T IF specific cooling requirements please contact with our company. we will make the best scheme according to the actual situation. | |||||||||||||

| Above parameters only for reference, the equipment changes according to the actual situation, please contact with the sales manager. | |||||||||||||

Work Principle

Water Cooling System Work Principle

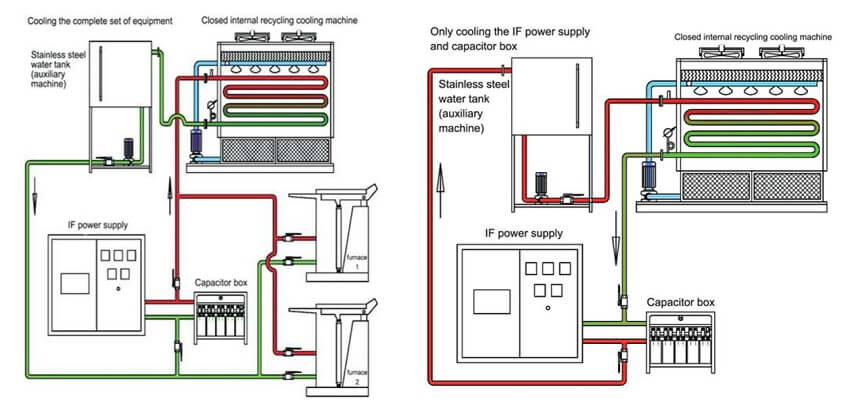

Pure water in closed type water cooling system for copper coil within cycle, the working fluid heat flow through the coil by coil scattered into the water, at the same time units around the outside the normal temperature air from the air inlet grille into the chassis, and the water flow in the opposite direction, upward flow through the coil,a small portion of water evaporation and heat, saturated hot humid air from the top of the cooling tower fan discharge to the atmosphere, the remaining water into the bottom water disk, the water pump is recycled to the water distribution system and spraying to coil, in order to reduce the temperature of the fluid inside the pipe all kinds of. Hot air of water box not evaporation of the water is water retaining plate interception and through the PVC heat exchange layer, PVC heat exchange layer in which the water is flowing in the air cooling, temperature is decreased. Fall into the water by the water pump bottom plate, is recycled to the water distribution system, back to pour into the coil, so for circulating cooling. This equipment widely used in induction furnace cooling, cold rolling mill, continuous casting cooling, etc.Work Digram

Water Cooling System Work Digram

Features

Water Cooling system Mainly used in casting /forging/smithing /heat treatment and machinery cooling

- Fully enclosed circulating cooling, eliminate the pipeline jams caused by debris.

- Use soft water circulating cooling; no overheat damage of power supply, silicon control, capacitor, IGBTmodule, induction coil caused by incrustation.

- No need of water pool and cooling tower, occupies small area, and moves easily.

- High cooling efficiency and low operate cost.

- Low water consumption, meet requirement of environment protection

Components

Water Cooling System Components

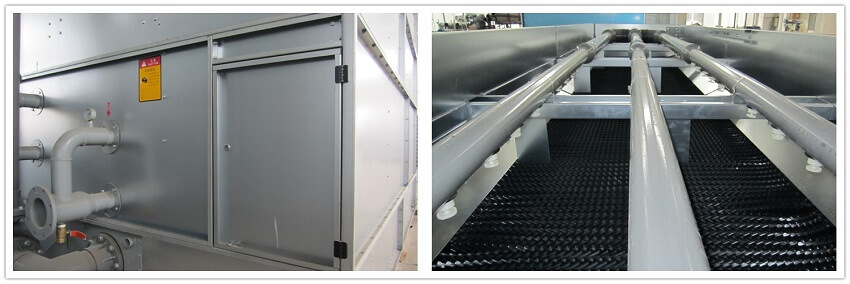

Access Door

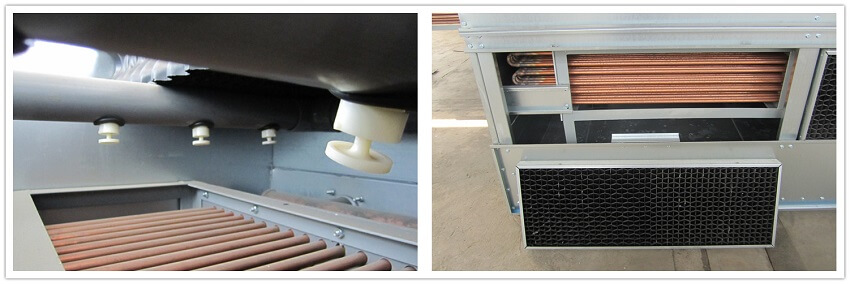

Air-inlet grille

Spray Header

Spray tube

Spray Pump

Power Supply Cabinet

Draught fan

Water Pump for water tank

You Will Get Reply within 24 Hours

Contact Us

- 0086-755-28838424

- 0086-755-28883730

- 0086-18857719978

- sales@superbmelt.com

We Are Here

- No.55 Anhua Road, Henggang Town, Longgang District, Shenzhen City, China

Blog | Products |SiteMap | About Us | Privacy Policy

Scroll to Top