Electric Silver Melting Pot

The most popular SuperbMelt 1-2kg electric silver melting pot on the market

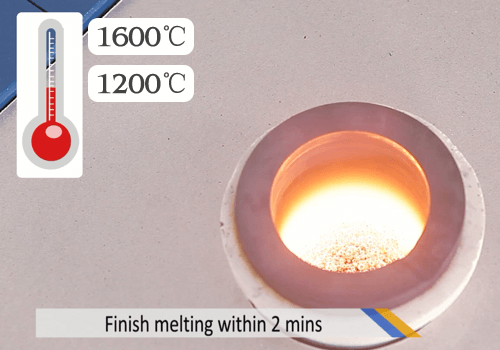

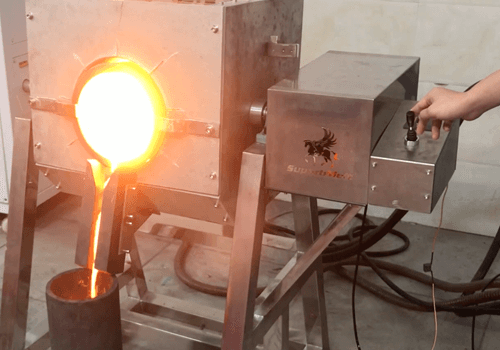

Superbmelt electric silver melting pot is suitable for melting up to 2kg of metals in 2 minutes. Metals that can be melted using a Superbmelt small electric melting furnace are gold, silver, copper, brass, bronze and their alloys. The maximum melting temperature is 1600 degree celsius.

Superbmelt electric silver melting pot has the latest IGBT induction heating technology that saves energy and makes melting efficient. The power required for melting is approximately 3.8kw. The DIY electric metal melting furnace is easy to use, transport and maintain. The melting speed saves time on production and increases efficiency. Superbmelt silver melting furnace is used in jewellery making and recycling, research and development, personalized melting, etc.

At Superbmelt, we ensure we meet our client’s specific needs. We provide you with 2 models of the electric melting furnace, the SPB-DH1 and SPB-DH2. Contact Superbmelt today for the electric melting furnace price in China.

If you wanna check silver melting pots with bigger capacity, Please click here.

- Superbmelt electric silver melting pot helps you to melt precious metals and base metals within 2 minutes. The maximum capacity of melting is 2kg. The silver melting furnace by Superbmelt allows you to melt 30kg of metal in approximately 1 hour.

- The latest IGBT induction heating technology ensures a fast melting process and helps to conserve about 15% to 30% of energy. The power required for melting with the Superbmelt electric gold melting furnace is between 3.5kw to 3.8kw.

- The DIY electric metal melting furnace has a maximum melting temperature of 1600 degree celsius, suitable for melting metals such as gold, silver, copper, brass, bronze and their alloys.

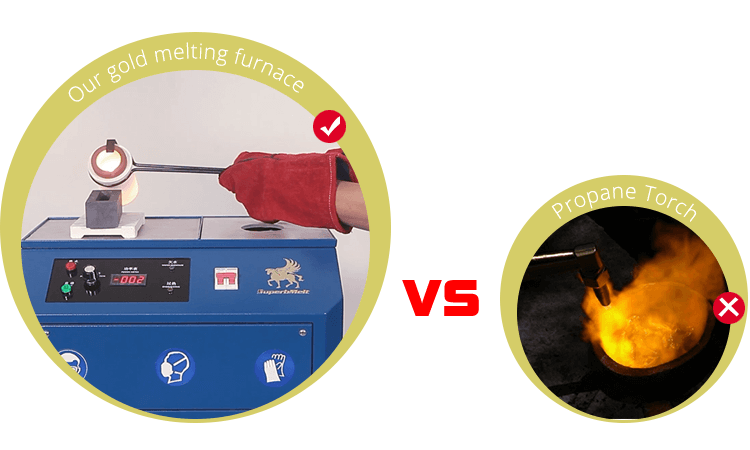

- Superbmelt small electric melting furnace prevents precious metal loss during the melting process. Loss of precious metal is very common to other methods of melting.

- The silver melting furnace is applicable in jewellery making and recycling, laboratory research, personalized melting, small-scale mining, etc.

- The electric silver melting furnace is easy to install use and maintain. The operation process is safe for both operator and the environment. Melting takes place in an enclosed chamber, this reduces the risk of molten metal accidents. The silver melting furnace does not release toxic gases into the environment.

- The process of molten metal removal is easy. This allows you to easily replace crucibles for multiple melting.

- The water cooling unit regulates the melting temperature and allows you to melt continuously for 24 hours.

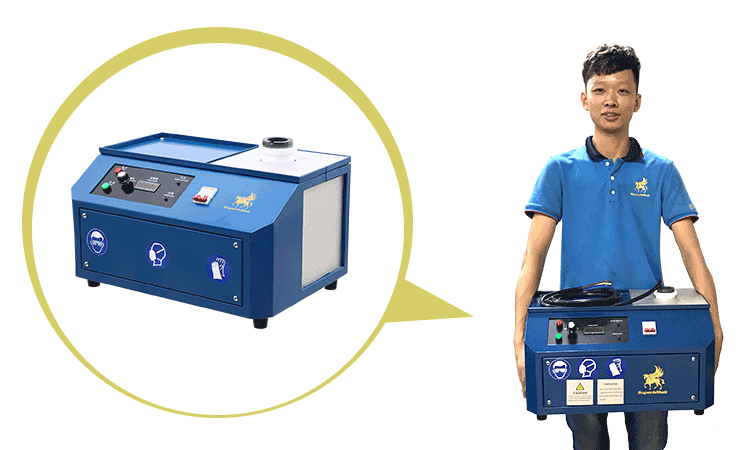

- Superbmelt silver melting machine for sale weighs about 21kg to 22kg, this makes it easy to transport. The compact size of the electric silver melting pot requires minimal space.

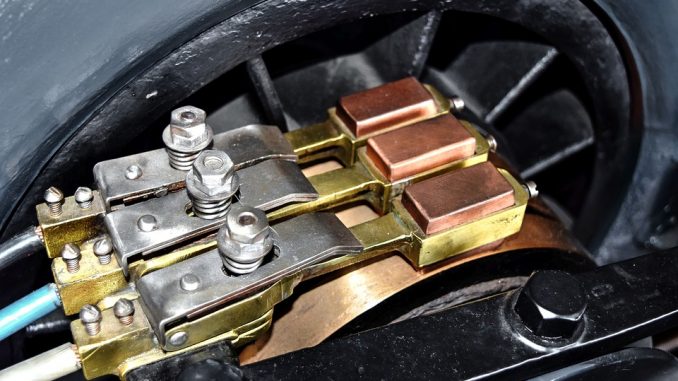

- The silver melting pot can be used with a graphite crucible and a silicon carbide crucible. This crucible also increases the efficiency of melting.

- Molten metal is highly homogeneous, contamination of metal is prevented with the use of the Superbmelt DIY electric metal melting furnace.

- Superbmelt electric silver melting pot is designed with high-quality material. This material is heat-resistant and ensures a long service life.

- Superbmelt small electric silver melting furnace has two models you can choose from to meet your specific needs.

| Model number | SPB-DH1 | SPB-DH2 |

| Power source | Single phase 220V, 50/60Hz | Single phase 220V, 50/60Hz |

| Power | 3.5 kw | 3.8 kw |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting time | 2 minutes | 2 minutes |

| Max capacity | 24K Gold: 1.2 kg 18K Gold: 1.0 kg 925 Silver: 0.6 kg | 24K Gold: 2.4 kg 18K Gold: 2.0 kg 925Silver: 1.2 kg |

| Max temperature | 1600℃ | 1600℃ |

| Temperature control k-type | Optional | Optional |

| Dimension | 520*400*330mm | 520*400*330mm |

| Weight | 21 kg | 22 kg |

| Heating technology | Induction heating | Induction heating |

| Cooling way | Water cooling | Water cooling |

Graphite crucible for gold/Silver melting Furnace

Small 1-2kg silver melting pot is portable size design, light weight, easy to carry and fix.

Why SuperbMelt Electric Silver Melting Pot

Any Question About SuperbMelt Electric Silver Melting Pot

Electric Silver Melting Pot Buying Guide

Application Fields of Electric Silver Melting Pot

Generally, the electric silver melting pot is used for melting silver metals. And this metal should consist of 1kg to 2kg so that it can melt easily in a small melting pot. Try to avoid keeping more silver at a time for melting. These electric silver melting pots are more suitable for requirements of small-sized melting.

Moreover, the silver melting kit requires a maximum temperature of 1600 degrees celsius for melting the silver. You can use this temperature maximum; if you are using less or more than this, it may not come perfectly. So you should take care of it. It takes hardly 2 minutes to complete the melting process. And it is the best thing about the silver melting kit.

It saves time in production because of its melting speed. Further, continuously the furnace can melt the silver for more hours. You can also estimate that within an hour, 30 kgs of silver can be melted. Along with that, the induction power of 3.5kw to 3.8kw has been used to melt the silver with the help of a SuperbMelt’s silver melting kit. You need not incur extra costs for the process of melting.

Today, the electric silver melting pot’s demands are growing slowly and steadily because the kit is safe to use for all, especially the small silver melting kit is very safe to use for all. This becomes possible to use for all due to an enclosed chamber usage in melting silver. The fact that the melting is held in an enclosed chamber is gaining popularity among various applications.

Along with that, the silver melting kit is using a simple control panel, which is making it easy to use for all. Furthermore, the small silver melting kit is easy to transport, maintain and use because of its compact-sized furnace. So, you can also try this as per your requirement.

The electric silver melting pot is used widely in various applications such as research and development, jewelry recycling, laboratory testing, jewelry casting, personalized melting, and many others. Some of the important points are covered in this chapter. Please have a look at it.

1.1, Smelting the silver ores

Most of the jewelry makers are very well aware of the silver melting kit. Therefore, these jewelry makers use these kits for smelting silver from their silver ores. Sometimes it happens that silver metals remains in the silver ores. So, the jewelry maker started using modern melting kits.

The jewelry makers use the silver ores temperature at around 900-degree C to get silver. While conducting the smelting process, you need to be very careful. Especially, silver ores needs to be carried properly.

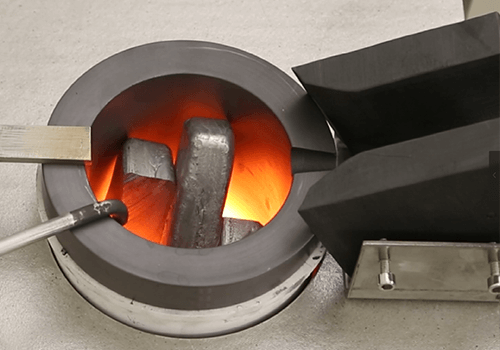

The induction furnace method is a very new addition in smelting the silver ores. It is widely considered for high production and low production. If you are searching for an environmentally friendly and efficient method for melting the silver, this is the best one for you. It takes hardly 2 to 10 minutes to complete the silver melting process.

Well, nowadays smelting the silver ores has become easy with using the special silver melting kit. If you are looking for steps how to conduct this whole process of melting silver in an induction furnace, you need to follow some steps. The first step for melting silver in an induction furnace is oxidation with flux. The next one is smelt with an Induction Furnace. The third step is to separate silver from flux.

If you follow these steps safely, you can get a better result. You can find this induction furnace across the world at a reasonable and affordable cost.

Nowadays, silver is used in various industries for various purposes like glass coatings, LED chips, batteries, dentistry, medicine, nuclear reactors, RFID chips, photography, photovoltaic energy, water purification, wood preservatives, semiconductors, touch screens, and others. If you think it is useful to your business, you can purchase this machine to profit from it.

Removing non-metal impurities from to collect silver

As mentioned above, sometimes it happens that silver metals remains in the silver ores or non-metal impurities remains in the silver. In this type of situation, you can use soda ash to thin down slag, clean, and purify the silver metals. Along with that, borax is used in silver ores as it helps to the silver from volatilizing off and keeps it clean and covered. Likely, you can remove all the impurities from silver.

Recycling old silver is a good method to reuse the same in the new model. For recycling the old silver, the silver melting kit adopts a green technology. This method is a very eco-friendly method as it does not generates noise and smoke and does not release harmful gases.

1.2, For recycling old silver

Recycling old silver is a good method to reuse the same in a new model. For recycling the old silver, the silver melting kit adopts a green technology. This method is a very eco-friendly method as it does not generates noise and smoke and does not release harmful gases. The recycling process of old silver saves carbon emissions and a vast amount of energy.

If you think that if you do recycle the old silver, it will lose its purity, then it’s a myth. It does not happen; the same purity stays with the new one. The SuperbMelt furnace silver melting kit is safe to use for all; especially, the small silver melting kit is very safe to use for all. This becomes possible to use for all due to an enclosed chamber usage in melting silver.

The fact that the melting is held in an enclosed chamber is gaining popularity among various applications. In this process, the soda ash is used as an ingredient to thin down slag, clean, and cover the silver metals. So, if you say can I recycle my old silver? Yes, you can with the best-quality metal melting machine. It can get ready within 10 to15 minutes.

1.3, For jewelry casting

Through the lost wax process, the jewelry casting can be done. In other words, while the jewelry-making process was conducted, it lost its wax. Jewelry shops widely use jewelry casting to create ornaments.

Basically, it’s a process of pouring melted silver into cavities for creating new ornaments. Here, the induction of SuperbMelt furnace is helpful in jewelry casting.

With this machine, you can melt the silver within very little time, and also it does not take much space. And, your jewelry product will be ready with the help of electric silver melting pot.

1.4, For industrial applications

If you think that theelectric silver melting pot is used only for jewelry making, then you are wrong. It has vast applications. For investment casting also you can use this machine. Those who are doing business in dealing with melting metals can also use these machines to make their business productive.

Nowadays, silver is used in various industries for various purposes like glass coatings, LED chips, batteries, dentistry, medicine, nuclear reactors, RFID chips, photography, photovoltaic energy, water purification, wood preservatives, semiconductors, touch screens, and others. If you think it is useful to your business, you can purchase this machine to profit from it.

How to Melt Silver Nowadays

Nowadays, you can melt the silver within a minute by using a high-quality electric silver melting furnace. You can melt the silver within an induction furnace, resistance furnace, and propane kiln. Moreover, the silver melting kit requires a maximum temperature of 1600 degrees celsius for melting the silver.

You can use this temperature maximum; if you are using less or more than this, it may not come perfectly. So you should take care of it. It takes hardly 2 minutes to complete the melting process. Try not to remove it from the furnace until the silver is completely melted.

2.1, How to melt silver by propane kiln

Nowadays, you can melt the silver within a minute by using a high-quality propane kiln. You can take the first step by putting your silver metal into a quality crucible and keep it to generate a maximum heat temperature of 1600 degrees celsius for melting the silver. You can use propane kiln or oxy-acetylene torches if you want to generate more heat.

Many people recommend using oxy-acetylene torches to place propane torches if it’s not available. But the negative thing is it takes more time to generate heat. And, if you are trying to make it in a fast mode, then the silver crucible or blow might get crack. So don’t spoil your hard work; if you don’t have time, simply you need to use a propane kiln to melt the silver. Here, you can save time.

Here are some of the items listed below that are important while melting the silver.

- Flux (mixture of borax and sodium carbonate)

- Propane touch

- silver ore

- Cubicle

- Ingot

Melting silver process by using Propane Torch

You can melt the silver by using Propane Torch. You need to make sure that your cubicle is capable of heating at 1,950-degree Fahrenheit. Along with that, you need to make a mixture of borax and carbonate. After that, you can melt this with a Propane Torch so that all the impurities will come at the top. At last, you can fill that into an Ingot. And the whole process is done.

2.2, How to melt silver by resistance furnace

For mining operations, the resistance furnace is specially developed and designed. Generally, the resistance furnace takes more time to melt the silver. A good quality resistance furnace can generate a maximum heat temperature of 1600 degrees celsius for melting the silver. If you look into the structure of the resistance furnace, it is sealed properly.

If you are planning to melt a large quantity of silver, then this is not at all suitable. The whole resistance furnace smelting procedure is not that expensive. But it is a little risky, and you need to have patience for the whole resistance furnace smelting procedure as it takes more time. Here, you need to give dedication and time to make it successful.

Melting silver process by using resistance furnace

You can melt the silver by usingelectric silver melting furnace or resistance furnace. The first step is designing the furnace by making a hole in the side of the cubicle where you can melt the silver. The next step is to set up your resistance furnace. Here, you can place the can in the middle, and then you need to set firebricks and clay around it.

Then you can start melting the silver that can be new or old; you can use it. Here, you can also use a hairdryer to control the heat coming from the machine. At last, you can add an oxidizing agent to it where you can remove all the impurities from silver.

2.3, How to melt silver in induction furnace

In the silver melting method, the induction furnace method is a very new addition. It is widely considered for high production and low production. If you are searching for an environmentally friendly and efficient method for melting the silver, this is the best one for you.

It takes hardly 2 to 10 minutes to complete the silver melting process. Try not to remove it from the induction furnace until the silver is completely melted.

Here are some of the items listed below that are important while melting the silver.

- Silver

- Induction smelting furnace

- Flux

Steps to melt silver in induction furnace

If you are looking for steps how to conduct this whole process of melting silver in an induction furnace, please look into the below steps:

- The first step for melting silver in an induction furnace is oxidation with flux.

- The next one is smelt with an Induction Furnace.

- The third step is to separate silver from flux.

If you follow these steps safely, you can get a better result. You can find this induction furnace across the world at a reasonable and affordable cost.

Nowadays, silver is used in various industries for various purposes like glass coatings, LED chips, batteries, dentistry, medicine, nuclear reactors, RFID chips, photography, photovoltaic energy, water purification, wood preservatives, semiconductors, touch screens, and others. If you think it is useful to your business, you can purchase this machine to profit from it.

The Kinds of Electric Silver Melting Pots that SuperbMelt can Provide

SuperbMelt is the one-stop solution that can help you to purchase the most powerful and effective electric silver melting pot that can simplify your production activities. The equipment comes in a diverse range of sizes and specifications. So, you can easily choose the suitable machine that is aligned with your exact production needs as well as your budget.

3.1, Mini 1-2kg electric silver melting pot

Our Mini 1-2kg electric silver melting pot is an ideal machine that can help you to meet your small-scale silver production requirements. The melting capacity of the machine is between 1 and 2 kg. The machine can quickly reach the maximum temperature of 1600 degrees Celsius, and the melting process would be completed within a couple of minutes.

The machine works by applying the induction power of 3.5 kW to 3.8 kW. Due to the high melting speed and string capacity of the machine, you can easily save time on the production process.

More importantly, the furnace can melt precious metals continuously for a long duration, so the production process could be carried out smoothly. If you are looking for an efficient and budget-friendly silver melting kit, then this is the best product available in the market right now.

3.2, Integrated 3-10 kg gold melting furnace

The integrated 3-10 kg gold melting furnace by SuperbMelt is designed for melting a large quantity of precious metals as compared to the mini kit. You can easily melt a substantial volume of metals such as gold, silver, copper, and many more within a few minutes. The furnace is very powerful and effective as the latest and most advanced IGBT technology has been integrated into it.

Due to the innovative design, you can easily and efficiently realize the top melting speed within 2 to 4 minutes. You can extract the crucible by using the matched tong. The machine is considered to be the best solution for a diverse range of applications such as laboratory work, research institutes, jewelry shops, and mining companies.

Some of the distinctive features of the machine that can be of high value for you include the easy installation process and lightweight nature. In addition to this, the 24-hours continuous working capability of the machine at maximum power can boost your production performance. The top speed melting rate can help you to efficiently complete the melting process per batch within merely 3 minutes.

While choosing a metal melting pot, it is very important for you to take into account the right kind of crucible. A good crucible could increase the overall efficiency of the melting process while saving the overall cost of consumables.

On the contrary, a machine with an ineffective crucible could affect the metal melting process as well as the quality of the output metal. You can choose the crucible and its dimensions, such as its weight and size, by taking into account your exact metal melting requirements.

One of the main highlights of our equipment is the top-notch protective board component. The protective board of the machine makes it highly resistant to fire as well as high temperature. Furthermore, if you want to connect it to the tap water for cooling purposes, you can do so by using the water inlet and outlet points. If you are looking for a suitable melting machine, our electric gold melting furnace can boost your end-to-end melting process.

3.3, 20kg-30kg manual tilting electric silver melting pot

Our 20kg-30kg manual tilting electric silver melting pot is unlike any other product in the market. The advanced specifications of the SuperbMelt furnace have the capacity of melting between 20 to 30 kg of precious and non-ferrous metals like gold, silver, and copper. With the help of this equipment, you can easily melt any metal up to a temperature of approximately 1800 degrees Celsius.

The powerful machine will help you to complete the melting process of a batch within the time frame of 6 to 8 minutes. You can conveniently tilt the machine for poring melted metals without the risk of spillage or splashing. So, if you are looking for an innovative manual machine to melt gold or other metals, SuperbMelt can take care of your needs.

3.4, 10-50kg chain tilting electric silver melting pot

With the help of our 10-50kg chain tilting electric silver melting pot, you can melt both ferrous as well as non-ferrous metals of your choice. The jaw-dropping power of the equipment from 15 kW to 90 kW can easily accommodate the massive weight of metals between the range of 10 and 50 kgs per batch.

The machine is designed with a solid motor drive chain tilting technology that can improve your production efficiency. The design supports proper tilting controls, which can help you to use it in a flexible manner. So, you can easily control and adjust the tilting speed as per your needs.

The machine is also equipped with an omnidirectional warning sign that can help you to identify issues such as water shortage, over-heating, etc. So, get this powerful Superbmelt furnace to boost your production efficiency.

3.5, 10-100kg motor tilting electric silver melting pot

If your melting needs are humongous and you are not getting the right kind of tools for production, SuperbMelt has a suitable solution for you. Our robust motor tilting electric silver melting pot is designed to support between 10 to 100 kg ferrous and non-ferrous metal melting.

The induction technology is based upon one-man pouring action. So basically, the body of the silver melting kit is mounted onto a steel frame, and you can manually control its body while tilting it. The silicon crucible is ideal for ferrous metal melting, whereas the graphite crucible is suitable for and non-ferrous metals.

The energy-saving design and fast-melting mechanism will simplify your production process. If you are looking for a pocket-friendly melting tool for metal casting with a small capacity, then the machine is the best option for you.

3.6, 50-250kg hydraulic tilting electric silver melting pot

Our hydraulic tilting electric silver melting pot is capable of designing a diverse range of metals such as copper, gold, silver, steel, zinc, and many more. The minimum weight requirement for the electric silver melting pot is 50 kg, whereas the maximum capacity is 250 kg. With the solid output power rating of 45 kW and 160 kW, your metal melting activities could get simpler and efficient like never before.

The Simens Control System (PLC) has been incorporated into the gold melting equipment. This technology boosts its level of precision, accuracy, as well as level of control throughout the metal melting process. If you are in search of a powerful and flexible metal melting machine, then this melting pot is the best option.

How to Choose the Right Smelting Equipment

If you want to melt metal like a pro, it is very important to make the right decision while choosing the best electric silver melting pot. As many options are available in the market, it might get quite perplexing to select the right machine.

If you are feeling confused, you do not have to worry anymore. We have prepared a useful guide that can help you to choose the right smelting equipment for your production needs.

“1.According to gold capacity

While making a choice, one of the key things that you need to keep in mind relates to the capacity of metal that a machine can withstand during the melting process. The broad range of melting machines that SuperbMelt has designed for your needs gives a glimpse into the capacity factor. So while choosing the ideal machine, you could select from 1kg to 500kg, based on your exact requirements.

For instance, if your requirement is small, then you could opt for our mini 1 – 2 kg electric silver melting pot for small-scale melting requirements. On the other hand, if your metal melting needs are larger, you must opt for machines that have more capacity. Generally, most goldsmiths and gold miners prefer mini gold melter. So, if you are also in the same professional field, you could opt for our mini gold melter.

The machine is small yet sturdy and powerful, and it can take care of your small-scale metal melting operations in an efficient manner. If your needs are higher, then we would recommend you our 5 kg gold melting furnace that can melt diverse metals within a few minutes. The innovative design can ensure that the metal is liquefied evenly and quickly.

If you work in the refinery, then the choice of the silver melting pot could range between 10kg to 1000kg. If your needs are so humongous, then we will recommend you our gold melting furnace that has a capacity of up to 500kg. Our hydraulic tilting melting furnace would be extremely useful in such a case as it can help you to carry out the metal melting activities in a flexible, safe, and efficient manner.

“2.According to customers’ business model

While selecting the right kind of smelting equipment for your needs, you could base your decision on your business model. Your metal melting needs and processes would vary based on your business activities. For instance, the machine that could be used by a jewelry shop or a goldsmith might not serve the intended purpose for a large miner. So, you need to take into account your business and metal melting requirements before making the selection of an ideal gold melting equipment.

For jewelry shops, goldsmiths as well as small gold miners, and small dealers, we would recommend our mini gold melter. This is an ideal choice as it is highly cost-efficient in nature. In addition to this, the technical specifications of the tool would make sure that the metal melting process is carried out in a smooth and efficient manner.

One of the main advantages that the users could enjoy would arise because of its portable design. The mobility of the machine would allow you to use it conveniently as per your exact production requirements. The fast-melting would also help you to shorten your delivery cycle.

The tiny yet study gold melting furnace is an ideal choice. Our mini electric melting pot could easily reach the maximum temperature within a few minutes and support a consistent metal melting process. Only within 2 minutes could you melt a batch of metal of 2 kg.

So within just one hour, you could easily melt 30 kg of metal with our electric silver melting pot. Similarly, you could opt for our integrated gold melting furnace if your metal melting requirements lie between the range of 3 kg and 10 kg.

If you work as a big miner, then automatically, your metal melting requirements would be much more huge and intense in nature. In such a case, you need to choose the right smelting equipment that can support your huge production needs. We would recommend you some of our most powerful gold smelting equipment, such as the motor tilting melting furnace,and the hydraulic tilting melting furnace.

By integrating our motor tilting electric melting pot, you could easily melt between 10 to 100 kg ferrous as well as non-ferrous metals melting efficiently. The modular design of the equipment would ensure that the volume of metal would not act as a hindrance in the letting process.

Similarly, with the help of our hydraulic tilting melting furnace, you could easily melt varying types of metals with the help of its huge output power rating capacity of 45 kW and 160 kW. You could use a remote panel trolley to control the tilting of the machine.

FAQ Guide

How do you melt and purify silver?

You can take the first step by putting your silver metal into a quality crucible and keep it to generate a maximum heat temperature of 1600 degrees celsius for melting the silver. While smelting the silver ores, sand is used at the top of the metal and the bottom of the crucible to avoid volatilize and sticking in the ores. Here, lard or oil is used in the silver ores as it is helpful to build up heat inside. Moreover, borax is used in the ores as it helps to the silver from volatilizing off and keeps it clean and covered. Along with that, the potash or lye is used as the ingredients in the silver ores to keep the silver clean. Here, you can also use the crushed ores as ingredients to make it heat or fire down faster. Also, soda ash is used to thin down slag, clean and purify the silver metals. Further, hydroquinone and wheat flour is used to add heat to make carbon. For more information, you can visit the company SuperbMelt.

How do you melt silver with borax?

The borax is used in the silver ores as it helps to the silver from volatilizing off and keeps it clean and covered. So, you can melt the silver with borax to cover and clean the silver. For more information, you can visit the SuperbMelt website.

How do you remove impurities from silver?

You can use soda ash to thin down slag, clean, and purify the silver metals. Along with that, borax is used in silver ores as it helps to the silver from volatilizing off and keeps it clean and covered. Likely, you can remove all the impurities from silver. Recycling old silver is a good method to reuse the same in the new model. For recycling the old silver, the silver melting kit adopts a green technology. This method is a very eco-friendly method as it does not generates noise and smoke and does not release harmful gases. For further more information, you can visit SuperbMelt.

What are the advantages of electric heating over other types of heating?

Electric heating has a number of benefits as compared to other forms of heating. Unlike other heating types, electric heating is environmentally friendly in nature. The smelting process ensures that consistent and perfect melted metal composition is produced. By using an electric silver melting pot, you can save a considerable amount of energy and thus reduce energy-related costs. The innovative technology that is used in electric heating increases the overall efficiency of the melting process, which can help you to optimize the production time.

Can I get 9999 gold and silver from your melting furnace?

The metal melting machines of SuperbMelt are designed to melt different kinds of ferrous as well as non-ferrous metals such as gold, silver, zinc, copper, etc. So our electric silver melting pot cannot purify precious metals such as gold. With the help of our equipment, you can remove non-metallic impurities from metals to extract the actual metal. For example, you could use our electric gold melting furnace to make new gold from old gold. But for the purpose of purifying metals, you would require a refining system.

How to choose the induction melting furnace you need?

While choosing the induction melting furnace that you need, you need to keep in mind a number of things, such as the metal melting capacity of the machine as well as your business model. For example, a small gold smelting equipment could be suitable for a goldsmith, but it might not be of much use for a large miner. Similarly, a large gold induction furnace of almost 100 kg capacity might be useful for miners, but it might not serve the intended purpose in a jewelry shop.

How efficient is induction heating?

Induction heating is the process in which the level of energy wastage is minimum, and the degree of efficiency is approximately 80 to 90 %. The machine to melt gold that is based on induction heating is considered to be efficient as it ensures that heat does not pass to the surrounding air. As there is no heat loss, energy is optimally used in the melting process. In this heating process, only the content of the pot gets heated, and thus power usage is efficiently controlled.

What is the difference between smelting and melting?

The melting process basically transforms a solid substance into its liquid state. The smelting process, on the other hand, converts an ore into its purest form. Thus smelting produces a pure element or a simple compound out of an impure ore. These two terms are used to describe two different chemical processes that take place while working with metals.

Can you melt gold and silver off electronics?

It is possible to extract and/or melt gold and silver from electronic items. But the process is highly complex and technical in nature, and thus there is the need to have proper equipment as well as knowledge to get involved in the metal melting activity. Silver melting kits are available that can be used for the purpose of recycling old silver or other precious metals like gold from electronics. Using a suitable gold silver melting machine can ease the entire process.

How do you smelt gold with borax?

Borax is a powdery white substance that is commonly referred to as sodium borate. It is commonly used as a cleaning agent in households. It can also be used for the purpose of smelting gold while using gold smelting equipment. A little amount of borax can be sprinkled onto the gold. Then the amount of heat needs to be increased so that the gold can melt. After a certain point in time, it would appear bright orange in color with a tiny tint of green color when it is close to the melting point. Ultimately all the pure and fine particles of gold would melt together and form a bright yellow ball.

How can you tell if something's real silver?

You can check the real silver with the simple stamp or mark of 900, 925, or 800 on the silver, which is also called an authenticate hallmark. You can also identify the fake silver with the magnet test, where you can check. If the silver is getting connected or sticks to the magnet, then it is a fake one. For more information, you can visit the company SuperbMelt website.

How do you separate gold from other metals by melting?

Gold can be separated from other metals by adopting the melting process. A process known as electro-parting can be adopted. It is a new gold refining process in which the gold metal is separated from other kinds of metals. In this refining process, gold is separated in an electrolytic cell like all the metals except potassium and gold dissolve. This procedure separates gold directly without involving any kind of dissolving. For separating gold from other metals using this method, dilute nitric acid is used. If you are interested in melting gold, you must check out the latest gold melting machine for sale and grab a machine that is within your budget range.

How do you melt gold jewelry?

The process of melting gold jewelry such as chains, rings, and other ornaments is very easy. First, you have to place the gold jewelry in a high-quality crucible and then can put them into gold melting equipment. After the machine has reached a suitable heating temperature of approximately 1100 degrees Celsius, the gold jewelry would gradually start to melt. After the melting process has finished, the liquefied or melted gold needs to be poured into a casting mold so that an ingot could be created. You can choose a machine to melt gold to carry out the process.

How do you get gold from gold ore?

Getting your gold from gold ore is extremely simple. For this, you would require suitable gold smelting equipment that can help you to produce pure gold in the form of a compound out of its impure ore.

Conclusion

In order to melt metals such as gold, silver, copper, and many more in an effective manner, it is very important to have a suitable furnace that can take care of all the melting and smelting needs.

The fundamental step to simplify the meting process involves the use of the right kind of electric silver melting pot. Only when the machine is working efficiently, you would be able to carry out the metal-related production activities efficiently.

SuperbMelt offers some of the most innovative and effective electric gold melting furnace solutions that can help you to easily and efficiently melt a diverse range of metals. The gold-silver melting machine and equipment that the business offers come in a diverse range of sizes as well as specifications.

So, you can choose the exact machine that is aligned with your production needs and expectations. In fact, SuperbMelt acts as the one-stop solution that can take care of all your metal melting needs.

One of the main highlights of the electric silver melting furnace and equipment is that they are highly innovative in nature. For instance, our gold melting equipment is based upon Simens Control System, which enhances the overall accuracy, flexibility, and control over the metal melting activity.

Each of the machines has been designed by taking into account the needs of the customers and clients that use metal in their production processes and activities.

Since technology and innovation have been integrated into each and every stage of our induction gold melting machine and equipment, they are highly efficient in nature. Moreover, high priority is given to the safety aspects so that businesses can use these tools while handling melted metals without compromising their safety.

The SuperbMelt furnace solutions that are available in the market are unlike any other solutions. This is because the machines combine flexibility, efficiency, and simplicity to ensure that you have total control over the metal melting process. The electric silver melting pot comes in diverse sizes. So, whether your production requirement involves a few kilograms or whether it involves hundreds of kilograms, you do not have to worry.

Our gold induction furnace solutions will make sure that all your melting and induction needs are taken care of in the most effective and efficient manner. That’s not all! One of the main reasons to choose our electric silver melting pot is the reasonable SuperbMelt price that you would have to pay. If you are thinking that purchasing a decent gold silver melting machine in the market would be extremely costly, and it could burn a hole in your pocket, you are mistaken. You can buy our innovative metal melting solutions at a very reasonable price.

Just you need to make sure to take into account your exact metal melting requirements while choosing the suitable electric silver melting pot. Making a careful decision will help you to reap the benefits for a long time as your metal melting process can become more efficient in nature.

Furthermore, the overall efficiency of your production activities will also get a much-needed boost with the help of our innovative and top-notch furnace solutions. Choosing the right kind of electric silver melting furnace can help you to complete the entire process within a few minutes without affecting the quality in any manner.

If you are in search of a reliable and trusted metal melting solution supplier, you can rely on SuperbMelt. We combine our experience, expertise, skills, and creativity to offer some of the best metal melting solutions that can simplify the process for you and give you complete control over the activity.

You can have a look at some of the most popular electric silver melting pot solutions that we offer to our customers. You can choose your machine from a plethora of alternatives that we have presented before you.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited