Jewelry Rolling Mill Machine

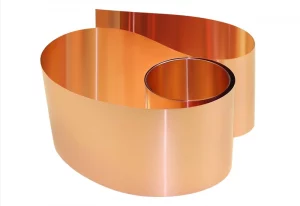

Introduction of Jewelry Rolling Mill Machine

Jewelry rolling machine is used to reduce the thickness of metal sheets or wires while making the metal surface smooth and uniform. It is usually widely used in jewelry manufacturing and processing industries.

It works primarily by means of two cylindrical pressure rollers made of hardened steel. Apply pressure and adjust the nip to reduce the thickness as the metal material is placed into the rollers. Different product requirements can use different horsepower of pressure, from 7.5p-50p, to achieve the required thickness and effect of metal.

The double-headed jewelry rolling machine can make various specifications of precious metal sheets or wires such as gold, silver and platinum, which are then used to make jewelry products, like hollow bangle, rings, chains, etc.

There are various types of jewelry rolling machines on the market, from manual rolling mill to electric double head rolling mill and even continuous jewelry rolling machine. The choice of machine depends on the factory capacity and the level of precision of the finished product.

Factories with large production capacity and diversified jewelry products can consider Superbmelt wire and sheet rolling machine, which has a double-head design, can pressing wire and sheet as the same time, and has higher work efficiency.

How to Use a Rolling Mill for Jewelry Making?

Jewelry rolling mill machines are important to jewelry manufacturers as they help in the precise pressing of metal sheets and wire. Here are the steps to making jewelry with an electric rolling mill:

- Before Working:

The electric rolling mill should be placed in a dry, spacious, well-ventilated place with powering supply. It is also necessary to keep the workbench area clean, so that the rollers can be better maintained.

- Preparation:

Determine the properties and dimensions of the pressed metal, in the case of harder metals it is recommended to anneal it to soften it to be more ductile before pressing the sheet or wire. This prevents the metal from cracking or breaking or even destroying the rolling mill during rolling.

- At Working:

Adjust the rolls on the wire and sheet rolling mill to the desired thickness and shape. Two workers work together to place the metal block or strip between the rollers and adjust the roller gap to hold it in place.

Press the start switch and quickly feed the metal into the roller. It is important to apply even pressure and avoid forcing the metal through the rollers as this could damage the machine or the metal.

After the metal has passed through the roller, it is removed and inspected for any marks or blemishes. Then adjust the gap and continue rolling repeatedly with thinner dimensions.

- After Working

After the desired thickness and shape is achieved, stop the equipment then clean the rollers and machine to prevent debris or residue from building up.

By following these steps, you can effectively use an electric roller machine for jewelry making and achieve precise and professional results.

Get Price of Jewelry Rolling Mill Machine

Details of Jewelry Rolling Mill Machine

- Customizable Pressure Roller

SuperbMelt jewelry rolling mill is a double-head design, and the pressing roller can be customized according to the production capacity and product demand, and the sheet and wire can be pressed at the same time. To realize multiple purposes of one device, it is more cost-effective for factories with various products.

- Independent Motor

With the use of an independent motor, the speed of the pressing roller of the equipment can be adjusted, making the production more flexible.

- Hard Steel Material

The pressure roller is made of DC53 hard steel. According to the different product requirements of customers, the pressure roller can also be customized. For example, tungsten steel can make the finished product have a mirror effect.

- Professional Slotting Data

Grooving according to Italian data, no loss will be caused during rolling, resulting in a higher quality finished product.

- No Need to Manually Refuel

The automatic lubrication device of the double head rolling mill greatly improves the production efficiency, saves more labor time and ensures the safety of workers.

| Model number | SPB-2YXP-10P |

| Power | 7.5kw |

| Voltage | 3 phase 380V,50/60 Hz |

| Roller size | 120*200mm * 2 |

| Roller material | DC53 |

| Rotation | 22/30 Double Speed |

| Rolling thickness | 12mm – 1.0mm |

| Rolling square | 1*1mm ~ 12*12mm |

| Max product width | 190mm |

| Lubrication | Auto Lubrication |

| Size | 980*650*1450mm |

| Weight | 980kg |

Metal sheet and wire reduction: To achieve uniform thickness, metal sheets and wire can be reduced in thickness using a rolling machine. When producing wire of a specific diameter or metal sheets that are too thick for jewelry-making, this is extremely helpful.

Making wire: Wire can be made in a variety of diameters using a electric rolling machine. When creating wire for jewelry findings like jump bands or ear wires, this is helpful.

Any Question About SuperbMelt Jewelry Rolling Mill Machine

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited