Small Vacuum Furnace

The most popular SuperbMelt Small Vacuum Furnace for jewelry on the market.

SuperbMelt Small Vacuum Furnace utilizes the process of melting high-quality finished gold, platinum, silver, and palladium in a vacuum environment. It provides customized melting solutions for jewelry manufacturers to create high-quality and unique jewelry pieces.

This melting furnace features advanced vacuum melting technology. It is not only extensively used in the jewelry industry, but it’s also employed in casting aircraft components, intricate valves for harsh conditions, refining high-purity metals and alloys, as well as remelting electrodes.

| Model number | SPB-VTB15 |

| Power source | 3 phase 380V, 50/60Hz |

| Power | 15 kw |

| Applicable metal | Gold, Silver, Platinum, Palladium, and their alloys |

| Melting time | 7-10 minutes |

| Max capacity | Palladium: 2 kg Gold: 3 kg Silver: 1.6 kg |

| Max temperature | 2600℃ |

| Water cooling requirement | ≥0.3Mpa, flow rate≥20L/min, ≤45℃ |

| Dimension | 690*1200*1100mm |

| Weight | 220 kg |

| Heating technology | Induction heating |

- Precise Control: Small vacuum melting furnaces provide accurate temperature control, enabling precise and controlled heating and cooling processes.

- Vacuum Environment: These furnaces create a low-pressure or vacuum environment, minimizing oxidation and unnecessary reactions during the melting and alloying processes.

- High-Quality Output: Controlled environment and precise heating contribute to producing high-quality alloys, metals, and jewelry.

- Customization: Furnaces offer customization options to tailor the melting process for specific materials and applications.

- Versatility: Capable of handling various metals and alloys, these furnaces find applications beyond the jewelry manufacturing sector, including aerospace and metallurgy.

- Reduced Contamination: The vacuum environment reduces gas and impurity contamination, resulting in cleaner, purer end products.

- Advanced Technology: Incorporating advanced vacuum and heating technologies for efficient, consistent results.

- Small Batch Production: Ideal for research laboratories and small-scale production, enabling controlled experiments and limited production runs.

- Jewelry Manufacturing: Particularly useful for jewelry manufacturers to create unique, high-quality jewelry through controlled alloying and melting.

- Multiple Materials: Capable of melting various materials, including precious metals like gold, silver, platinum, and other alloys.

- Research and Development: Valuable for material research, exploring new alloys, and studying phase transitions under controlled conditions.

- Safety Features: Furnaces are equipped with safety features to ensure safe operations in high-temperature and vacuum environments.

- Improved Efficiency: Modern design enhances energy efficiency, reducing heat loss during the melting process.

- Compact Size: Designed to fit smaller spaces, suitable for laboratories or small-scale industrial environments.

Why SuperbMelt Small Vacuum Furnace

Any Question About SuperbMelt Small Vacuum Furnace

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

More Induction Melting Furnaces for you to choose from

Guide for Small Vacuum Induction Melting Furnaces

Induction Vacuum Furnace vs. Conventional Induction Melting Furnace

- A vacuum induction boiler

minimises oxidation and undesirable reactions during melting and alloying processes by operating in a low-pressure or vacuum environment.

enables exact temperature control, leading to the manufacturing of high-quality alloys.

thanks to the vacuum atmosphere, contaminants and impurities are reduced.

Ideal for creating metals and alloys with high purity and precise characteristics.

frequently utilised for specialised uses including the development of high-purity materials and aerospace parts.

- Standard Induction Melting Furnace

operates under a typical ambient setting.

provides effective temperature control, however it can be more prone to oxidation.

suitable for a variety of melting applications, such as small-scale manufacturing, foundries, and metal casting.

To avoid contamination and guarantee product quality, additional safety measures can be necessary.

frequently used for melting and alloying purposes in a variety of industrial situations.

1.1, Benefits of Induction Vacuum Melting Furnace

- Minimized Contamination: Operating in a vacuum or low-pressure environment reduces the chances of oxidation and impurities, resulting in cleaner and purer end products.

- High-Quality Alloys: The controlled environment and precise temperature control contribute to the production of high-quality, consistent alloys with desired properties.

- Specialized Applications: Suitable for producing high-purity metals, specialized alloys, and materials with specific characteristics for industries like aerospace and electronics.

- Reduced Energy Consumption: The vacuum environment can improve energy efficiency by minimizing heat losses during the melting process.

- Enhanced Material Properties: Vacuum melting can lead to improved material properties due to reduced gas interaction, resulting in enhanced mechanical, thermal, and electrical characteristics.

- Minimized Waste: The optimized melting conditions lead to less material wastage and fewer rejected batches.

- Better Environmental Friendliness: The reduced oxidation and cleaner process contribute to a more environmentally friendly production process.

- Innovative Research: Ideal for research and development purposes, enabling the creation and testing of new alloys and materials.

- Customization: The furnace can be tailored to accommodate different materials, sizes, and melting requirements, offering flexibility in production.

- Improved Safety: The vacuum environment can reduce potential hazards associated with high-temperature processes, contributing to safer operations.

- Jewelry Manufacturing: Particularly useful for jewelry makers, allowing controlled alloying and the creation of high-quality, unique pieces.

1.2, Benefits of Conventional Induction Furnace

- Versatility: Conventional induction furnaces are suitable for a wide range of metal melting applications, making them a versatile choice for various industries.

- Rapid Heating: Induction heating enables fast and efficient heating of metals, reducing overall processing time.

- Strong Adaptability: These furnaces can handle different types of metals and alloys, making them adaptable to diverse manufacturing needs.

- Widespread Application: Conventional induction furnaces have a long history of use in various industries, indicating their reliability and widespread acceptance.

- High Melting Efficiency: Induction heating efficiently transfers energy to the metal, ensuring high melting efficiency.

- Scalability: These furnaces can be scaled up or down according to production needs, allowing for flexible manufacturing processes.

- Metal Casting: Particularly well-suited for metal casting applications, including foundries and production lines.

- Mature Technology: Conventional induction heating technology has been refined over an extended period, resulting in reliable and proven performance.

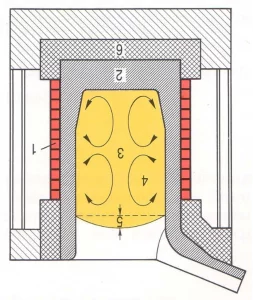

1.3, Principle of Operation for Induction Vacuum Melting Furnace

A vacuum atmosphere is produced by the induction vacuum melting furnace, which has clear benefits for the melting process. The hoover preserves the purity and quality of metals and alloys by, among other things, removing oxygen and other contaminants from the air and preventing oxidation and contamination. Secondly, the melting points of metals may be more precisely controlled when there are no gases present, ensuring a more precise and controlled alloying process. Most crucially, because there is no heat transmission through gases in a vacuum atmosphere, heating efficiency is better, which speeds up the rate at which metals melt. In conclusion, vacuum melting offers a better setting that ensures top-notch alloy preparation and exact control over material attributes.

Why Invest in a Vacuum Melting Furnace?

Investing in a Vacuum Melting Furnace offers several compelling advantages. Firstly, the vacuum environment minimizes oxidation and contamination during the melting process, leading to the production of purer and higher-quality alloys. Additionally, the controlled atmosphere allows for precise temperature regulation, ensuring consistent and desired material properties. Vacuum melting also enables the creation of specialized alloys with specific characteristics required for industries like aerospace and electronics. Moreover, the reduced interaction with gases enhances material properties.

Furthermore, when it comes to jewelry casting, the benefits of a vacuum furnace become even more pronounced. The vacuum environment prevents unsightly oxidation and surface defects on precious metals like gold, silver, and platinum, resulting in smoother and flawless jewelry pieces. Additionally, the controlled melting environment ensures accurate alloy compositions, allowing jewelers to craft intricate designs with the confidence that the final product will possess the desired qualities. In essence, investing in a Vacuum Melting Furnace, especially for jewelry casting, guarantees the production of high-quality, visually appealing, and precisely crafted jewelry pieces.

2.1, Applications of Induction Vacuum Melting Furnace

The induction vacuum melting furnace is used in a variety of industries, including the manufacture of jewellery, where it yields faultless, high-purity metals used to create priceless pieces of jewellery. Additionally, it is used in the production of superalloys, aircraft, electronic components, medical devices, and metallurgical research. Basically, the Induction Vacuum Melting Furnace makes a contribution to several industries by producing controlled, high-quality alloys that are adapted to particular requirements, ensuring performance, efficiency, and safety.

2.2, Characteristics of Vacuum Induction Furnace

By melting metals in a controlled, oxygen-free atmosphere, precise alloy crafting enables jewellers to produce high-quality, faultless jewellery pieces, preventing oxidation and surface flaws.

- Enhance Purity: Precious metals like gold, silver, and platinum are kept pure during the melting process, creating jewellery that is both attractive and valuable.

- Customised Compositions: Provides fine control over alloy compositions, enabling jewellers to create one-of-a-kind items with desired qualities, from colour to durability.

- Provides a dependable way to cast delicate and elaborate jewellery designs, guaranteeing that the finished item maintains its intricate intricacies.

- Consistent Quality: Ensures that the material qualities are the same throughout each piece, producing accurate and consistent outcomes.

- Workflow Efficiency: Because surface imperfections are reduced, less post-casting cleaning and reworking is required.

- Craftsmanship Confidence: Enables jewellers to confidently design high-end, unique jewellery pieces with improved material and aesthetic qualities.

Vacuum Induction Melting Furnace for Jewelry Melting

In order to ensure the purity and flawlessness of metals like gold, silver, and platinum, the vacuum induction melting furnace is the best tool for jewellery melting. It offers higher purity for jewellery metals and prevents oxidation. Jewellers can produce special alloy compositions with precise temperature control to get the desired jewellery qualities. Beautiful jewellery designs are produced as a result of the melting process, which preserves intricate details. The most effective reduction of oxidation results in smoother surfaces and fewer flaws in jewellery. In essence, the Vacuum Induction Melting Furnace raises the bar for jewellery creation by providing pure, adaptable, and intricately crafted metals while also improving workmanship and efficiency.

3.1, How to Create High-Quality Jewelry?

There are several crucial procedures involved in producing high-quality jewellery, one of which is using a vacuum induction melting furnace:

Material Selection: For the basis of fine jewellery, select high-purity metals like gold, silver, or platinum that have been melted and purified in a vacuum induction melting furnace. This will ensure the purity of the metals.

Design and Craftsmanship: Create complex, enticing designs that showcase ingenuity and aesthetic value, and then use technology to help experienced artisans bring those designs to life with accuracy.

Precious Gemstones: Include real, well-cut gemstones that match the elegance of the metal and raise the jewellery piece’s total value.

Pay close attention to the details while choosing settings, prongs, clasps, and chains to maximise both longevity and appeal.

Implement stringent quality controls during production, with the Vacuum Induction Melting Furnace helping to ensure that the materials are consistent and pure.

Work with skilled jewellery artisans who can turn designs into completed products of the highest calibre, supported by the initial purity of materials from the Vacuum Induction Melting Furnace.

Apply professional finishing methods, such as plating and polishing, to improve durability and appearance.

3.2, Why Use a Vacuum Furnace for Jewelry Melting?

Running in a vacuum ensures the metal’s purity and stops any reactions with oxygen, producing perfect pure metal.

- Improved Aesthetics: When oxidation is reduced, the jewelry’s surface seems brand-new, increasing its visual appeal and total worth.

- Customised Material features: Jewellers can create alloys with unique features, such as distinct colours or increased durability, by carefully controlling the temperature.

- Integrity of Complex Designs: The melting furnace safeguards fine details throughout the melting process, guaranteeing the accuracy of elaborate jewellery designs.

- Consistently Superior Quality: Each item of jewellery manufactured maintains a consistent degree of quality due to uniform material qualities obtained under controlled conditions.

- Enhanced Artistry: Giving craftsmen top-notch materials opens up more creative options for them, enabling the creation of remarkable and one-of-a-kind jewellery.

- Streamlined Production: Minimises time-consuming post-casting finishing, minimises surface flaws, and streamlines the jewellery manufacturing process.

- The ability to work with a variety of precious metals and alloys allows you flexibility and choice in material choices.

- These features emphasise the special benefits vacuum furnaces provide to the jewelry-making process, guaranteeing that the finished item is not only aesthetically pleasing but also of the highest calibre.

The vacuum induction melting furnace is composed of the vacuum furnace body, medium frequency power, vacuum system, cooling system and electric control system, all these contribute to the efficiency of the furnace.

Our furnaces range from small vacuum furnaces small vacuum furnaces measured in grams to bigger vacuum furnaces. This however gives users flexibility with regards to batch size.

Conclusion

The Vacuum Induction Melting Furnace’s functionality represents a paradigm-shifting development in the realm of jewellery manufacturing, and SuperbMelt takes great satisfaction in its cutting-edge technology as a keeper of purity, conserving the immaculate elegance of metals like gold, silver, and platinum. Each piece of jewellery produced by SuperbMelt’s vacuum induction melting furnaces has a surface that is as pure as the metal itself, preventing oxidation and ensuring that it has an everlasting lustre.

Additionally, one of the capabilities of SuperbMelt’s technology is exact alloying through regulated temperature control, which enables designers to incorporate personalised elements into their creations. This orchestra of carefully orchestrated procedures creates jewellery with distinct desired features in addition to being aesthetically beautiful. superbMelt uses the vacuum environment to boost efficiency, speed up the melting process, and reduce energy consumption – a sustainable practise that appeals to contemporary sensibilities.

Purchasing a SuperbMelt vacuum induction melting furnace represents a dedication to quality for the jewellery sector. Jewellers can produce one-of-a-kind, flawless works that go beyond simple adornment by fusing technology and art. Each masterpiece is the embodiment of the purity, accuracy, and unmatched artistry that have been redefined under the banner of the trusted brand, SuperbMelt, in the controlled environment of the SuperbMelt.

SuperbMelt Small Vacuum Induction Melting Furnace FAQ

1. What is a vacuum furnace?

A unique kind of furnace called a vacuum furnace runs in a controlled low pressure or vacuum environment. It is made to heat materials, often metals and alloys, using the least amount of atmospheric gas interactions. A vacuum furnace minimises oxidation, pollution, and undesired chemical reactions during heating processes by producing a vacuum or low-pressure atmosphere. Vacuum furnaces are especially useful for applications where precise temperature control and material quality are vital, such as in metallurgy, aerospace, electronics, and jewellery manufacture. This regulated environment is necessary for maintaining the purity and integrity of materials.

2. Why use a vacuum furnace?

Utilizing a vacuum or low-pressure environment strategically minimizes the likelihood of oxidation and impurity formation, leading to a heightened production of meticulously clean and pure end products. Vacuum furnaces find their niche in fabricating high-purity metals, specialized alloys, and materials boasting the specific attributes requisite in industries like aerospace and electronics. By significantly curbing heat losses during the heating process, the vacuum setting effectively heightens energy efficiency. This mechanism of vacuum heating, coupled with the diminished interaction of gases, catalyzes an enhancement in material properties encompassing mechanical, thermal, and electrical facets. The optimization of heating conditions culminates in reduced material wastage and a marked decrease in scrap rates, contributing to a more ecologically conscious production process. Beyond its immediate application, vacuum furnaces are an apt choice for pioneering research and development endeavors, facilitating the crafting and testing of groundbreaking alloys and materials. The customizability of vacuum furnaces across diverse materials, dimensions, and heating requirements empowers adaptable and agile production workflows. The inherent safety bolstered by the vacuum environment acts as a shield against potential hazards linked to high-temperature processes, fostering a secure operational landscape. Furthermore, industries like jewelry manufacturing reap pronounced benefits from vacuum furnaces, as they safeguard precious metals against oxidation and surface irregularities, culminating in the creation of flawlessly smooth final products. This amalgamation of benefits, harnessed through vacuum furnace utilization, embodies an epitome of precision, efficiency, and innovation across multiple domains.

3. Which applications require a vacuum furnace?

Vacuum furnaces are essential for generating high-purity metals and alloys for a variety of businesses in metallurgy. They are employed in the production of specialty alloys having particular mechanical, thermal, or electrical characteristics.

- Vacuum furnaces are essential to the aerospace sector’s ability to produce parts and materials that are very strong, resilient, and resistant to harsh environments.

- Electronics: To ensure the dependability and performance of electronic equipment, vacuum furnaces are used in the production of materials with exact electrical characteristics and low impurity levels.

- Medical Devices: The production of implantable materials, tools, and components with remarkable biocompatibility and structural integrity is made possible by vacuum furnaces.

- Superalloys are used in high-temperature situations like as jet engines, gas turbines, and industrial applications. Vacuum furnaces are essential to the production of superalloys.

- Vacuum furnaces are crucial instruments for metallurgical researchers investigating novel materials, alloys, and processes because they provide a controlled environment that ensures precise findings.

- Vacuum furnaces are used in the jewellery industry to produce higher-quality, precisely finished jewellery by preventing oxidation and contaminants.

- Vacuum furnaces are used in the semiconductor industry to create materials for very sensitive electronic components with controlled impurity levels.

- Heat Treatment: To ensure uniform material characteristics and reduce distortion, vacuum furnaces are used for heat treatment procedures like annealing, hardening, and tempering.

- Vacuum furnaces are essential for the development of new alloys, materials, and applications in a variety of scientific fields.

- Vacuum furnaces are used in the nuclear industry to produce materials for radioactive conditions, ensuring their stability and integrity.

- automobile Industry: High-performance automobile components with particular mechanical qualities are made using vacuum furnaces.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited