Jewelry Laser Engraving Machines

Top Manufacturer in China

- SuperbMelt laser engraving machine has high performance and high quality for necklaces, bracelets, rings and other jewelry of various metals and shape.

- Fast and precise, with beautiful and permanent engraving results, high efficiency and save energy and time costs.

- Engraving a series of functional personalization marks such as text symbols, graphic images, two-dimensional codes, barcodes, serial numbers, patterns etc.

- For customers with high technical requirements, we are also equipped with 3D effect technology.

Jewelry Laser Engraving Machine Solution Supplier

SuperbMelt Jewelry Laser Engraving Machine meets the current personalization demands of the jewelry industry, facilitating the rise of custom-made jewelry.

It can easily customize various precious metal jewelry pieces and engrave any patterns or text on different shaped jewelry gifts and jewelry boxes. This includes names on rings, photos on necklace pendants, and patterns on bracelets.

For jewelry manufacturers and retailers, Jewelry Laser Engraving Machines are essential. Unlike traditional processing methods, laser engraving uses high-density laser energy to melt the metal surface, forming a permanent mark.

This method doesn’t require tools and fixtures to contact the jewelry like traditional hand engraving, avoiding damage or deformation due to internal stress. For fine jewelry markings that are nearly impossible to achieve by hand, laser engraving machines provide an excellent solution. They offer higher efficiency and precision, and lower costs.

As a high-tech device, the fiber laser engraving machine can help the jewelry manufacturing and metal ornament industries solve all metal marking issues. The SuperbMelt laser engraving machine is computer-controlled to ensure precision. The laser marking machine operates at very high speeds.

Jewelry Laser Engraving Machine List

The laser beam of the fiber laser engraving machine is generated by a laser generator. When acting on a metal object, in a certain state, the light energy will be converted into heat energy, melting the surface layer of the metal jewelry, and then forming a designated pattern and text.

SuperbMelt provide 20/30/50W laser engraving machine which is high speed, high precision, high efficiency and low power consumption.

The finished engraving effect is smooth, the marking is clear and beautiful.

Ideal for fine precious metal jewelry engraving, For example, the personalizations name or photo and brand logo on the jewelry, are all realized in this way.

The machine is highly automated, the processing time of each work piece is short, and the batch processing efficiency can be maximized.

Portable Fiber Laser Engraving Machine

SuperbMelt portable marking machine adopts an integrated module design, and the model is compact and no need too much space.

It is suitable for small and medium-sized jewelry studios, optical shops, etc.You could also choose 20W of this model for entry-level use because the price is affordable.

The laser beam is of high quality and the light spot is very small, which means that even very detailed jewelry pieces can be finely marked.

The service life is very long, and the machine has been equipped with an air cooling system, which can work continuously without a complicated constant temperature and humidity water cooling system.

The configuration of the integrated system makes it very convenient for customers to use, and it can be operated without professional training or hiring professional staff.

Parameter

- Marking Range:110X110mm/175X175mm

- Repeatability: 0.01mm

- Min Line Width: 0.017mm

Box Fiber Laser Engraving Machine

SuperbMelt box laser marking machine has a beautiful appearance and is also a mini model. It has a protective covers, which can make the workpiece work in a dust-free and closed environment, making the finished product more perfect. At the same time, it also effectively avoids laser stimulation to the operator’s eyes and plays a protective role.

This one has 20-50W for option is perfect for small metal jewelry factories and friendly to first-time customers. Moreover, the machine is simple to use and have a compact laser source, which only needs to be simply air-cooled.

Parameter

- Marking Range:100X100mm/200X200mm

- Repeatability: 0.02mm

- Min Line Width: 0.01mm

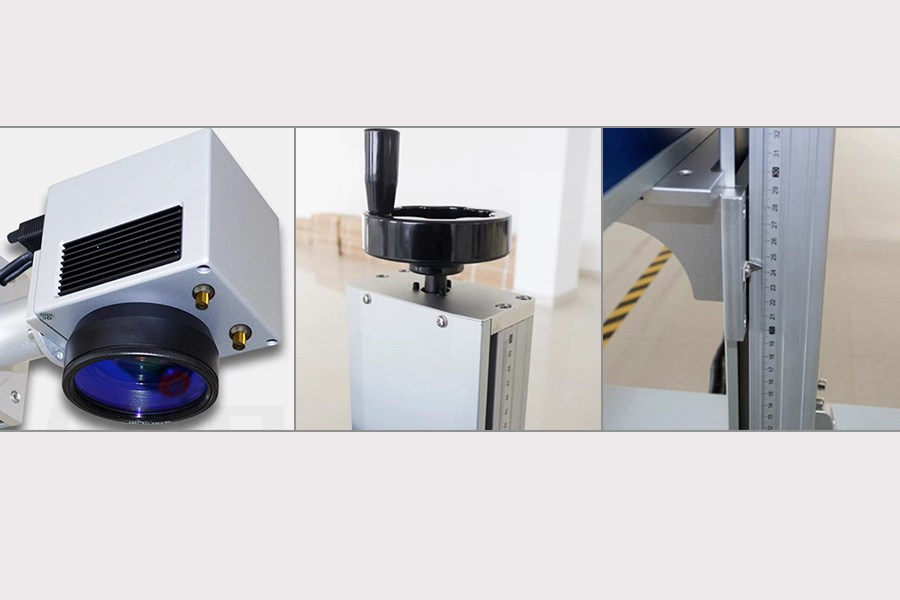

Vertical Fiber Laser Engraving Machine

SuperbMelt vertical fiber laser marking model is larger and has a simple appearance, which is suitable for medium and large jewelry processing or manufacturing plants.Power can be customized from 20-50w.

The machine is highly reliable and can be used in industries that require high precision and smoothness.

The machine has an integrated built-in computer design, no need to buy an additional computer, large desktop space, workers can operate directly on the workbench, which is more convenient to use.

The marking range can be adjusted and custom according to customer requirements, and the maximum can reach 110x110mm. Suitable for large pieces of jewelry and some metal work pieces.

Parameter

- Marking Range:110X110mm(customization)

- Marking Speed:≤7000mm/s or ≤13000mm/s

- Min Line Width: 0.01mm

Guide of SuperbMelt Jewelry Laser Engraving Machine

How to Use SuperbMelt Jewelry Laser Engraving Machine to Engrave Metal Jewelry

Step 1: Design the Content of Marking

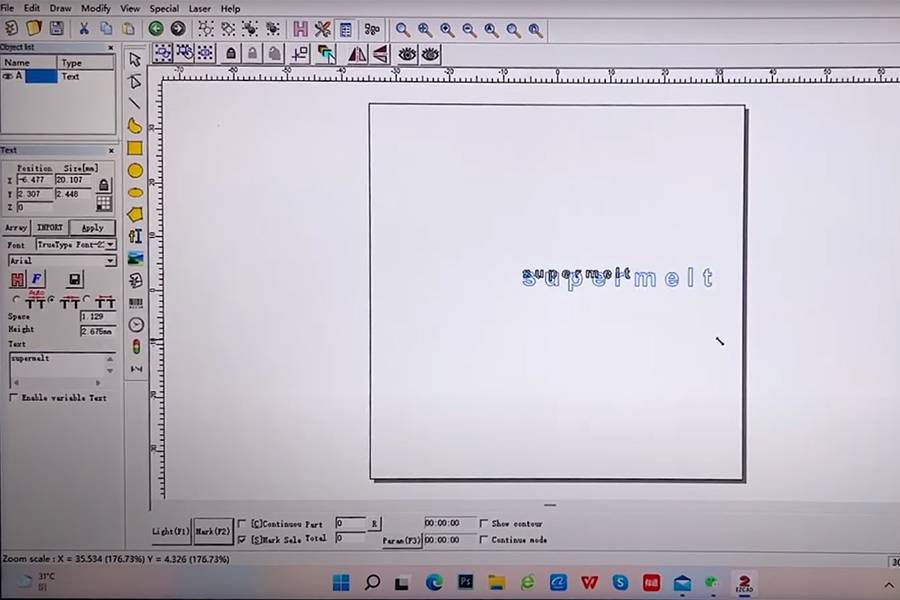

The designer needs to draft the pattern or text through the software, and connect the marking machine to the computer. For vertical marking machine just need to import the file.

Step 2: Selects the Pattern or Text to Be Marked

Open the CAD software, click on the text or pattern to be marked, take the text as an example, click FI, import the text to be marked, and then click apply, you can drag the mouse to adjust the text size and make content keep center.

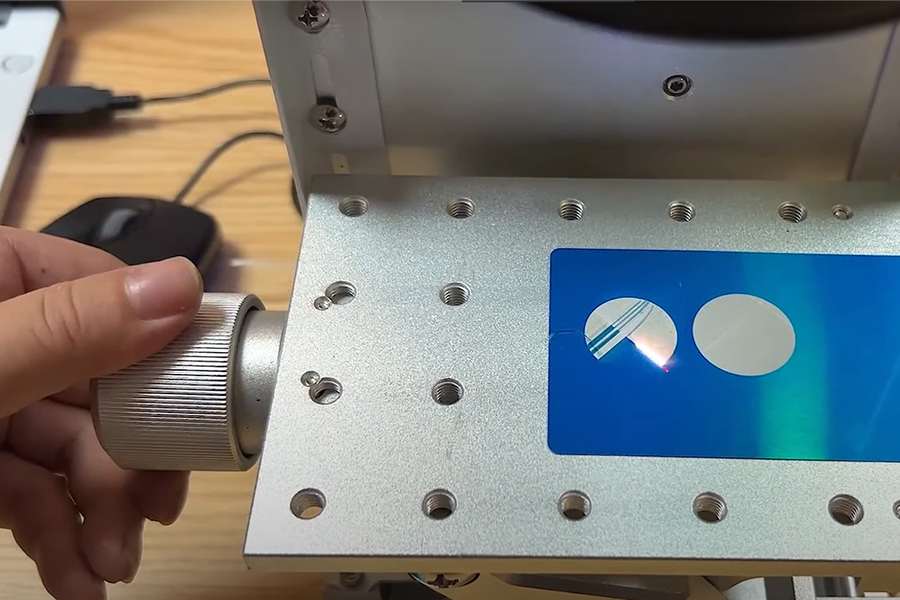

Step 3: Find the Optimal Focus Distance

Import a circle, click continuous processing, mark the circle continuously to fill it, and then click the red light indicator, you can preview the marking range in this step, the red line frame on the workbench indicates the marking range, click mark , and adjust the height of the lifting platform, and then determine the best position for marking.

Step 4: Mark the Workpiece

After determining the best position, delete the circle, select the content to be marked, click to cancel continuous processing, place the work piece on the platform, and indicate the red light again, determine the marking range and adjust the size of the content, turn off the red light Instruct, and mark. After marking is completed, close the software and turn off the device.

What are the Uses of SuperbMelt Jewelry Laser Engraving Machine

Fiber laser technology has made numerous fashion accessories creative designs of jewelry on the market popular today. Like some gold and silver rings, bracelets, necklaces, etc., this method also used to individual engraving on watches,glasses and other products, Any other shapes or materials can achieve functional markings like patterns, textures, personalizations design, even can engraving photo.

Engraving on Jewelry Rings

Today’s fashion trend is for unique, like engraving custom content on rings, which are forms young person will favor.

SuperbMelt laser marking machine is equipped with a rotating accessory to complete simple and fast engraving on the curved surface, such as personalized name on the inner of rings.

Engraving on Jewelry Necklaces

Laser engraving machines are used to engrave many flat metal materials, such as barcodes and QR codes on metal products, individual patterns on necklaces and material marks of standard fonts and characters on jewelry nameplates, such as 925 silver, 9999 pure gold, etc.

The plane engraving is relatively simple. It can be placed directly on the workbench and the focal length can be adjusted to complete the marking.

Engraving on Jewelry Bracelets

Many bracelets engraved with exquisite patterns and animal patterns on the market, which generally made of precious metals such as gold, silver, platinum, as well as some alloys, jade and other materials. If carved by traditional way, not only is the finished product rough, but many details cannot be completed.

With the SuperbMelt jewelry laser engraver, it only takes a dozen seconds to easily mark complex patterns, and the effect is very significant. Save time and cost, also greatly improve work efficiency.

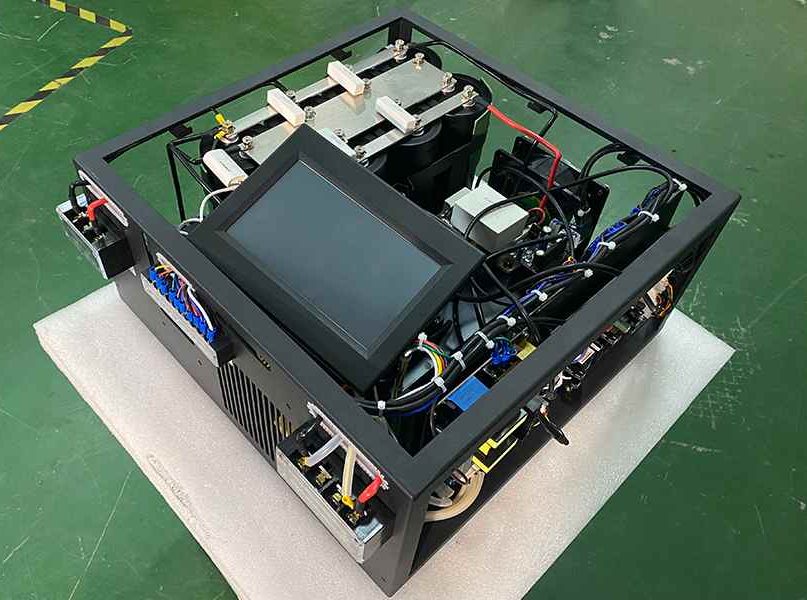

What is Composition of SuperbMelt Jewelry Laser Engraving Machine

1. Laser Power Supply

The fiber laser needs laser power to provide power, installed in the control box, the AC voltage is AC220V.

2. Fiber-Optic Laser

SuperbMelt laser sculpture machine adopts a pulsed fiber laser with good laser mode and long service life, which is installed in the casing of the marking machine.

3. Galvo Scanning System

The galvanometer scanning system is composed of an optical scanner and servo control, and is designed with new technologies, new materials, new processes and new working principles.

4. Focus System

The focusing system works by using an F-θ lens to focus a parallel laser beam to a point. The F-θ lens affects the focal length. The marking effect and range are also determined by it.

5. Computer Control System

The most important control and command part of the entire marking machine is the computer control system, which is also the carrier of software installation. The workpiece is marked by controlling the acousto-optic modulation system and the galvanometer scanning system.

How to Care & Maintenance

- Protect Power and Keep Clean

Keeping the power off when the machine is not running and close the fiber optic lens cover to avoid dust contamination and protect the lens.

- Avoid Moving While Working

When the marking machine is working, avoid moving the machine then cause damage.

Avoid Stacking Clutter

Avoid stacking other things on the marking machine then affect the cooling effect of the machine.

- Clean the Focusing Lens

When the surface of the focusing lens is contaminated, carefully remove the focusing mirror and wipe its lower surface.

- Emergency Stop

Once the machine fails, you should press the emergency button to stop the machine and cut off the power to avoid accidents.

- Keep Dry and Ventilated

The working environment should be kept dry and ventilated.

How to Choose the Right Laser Engraving Machine As a Custom Jewelry Maker

Advantage of Jewelry Laser Engraving Machine over Manual Machines to Control the Engraving Process

Non-direct Contact Processing

Fiber laser processing technology does not have to touch the surface of the work piece to be marked unlike traditional manual processing.

The engraving machine using high-tech laser technology that only needs to concentrate the energy on the surface of the work piece, and does not need direct contact processing, so it will not damage the surface of the work piece, and there is no cutting force, so the marking quality is very high.

Wide Range of Processing Materials

SuperbMelt jewelry laser engraver can process a very wide range of materials, various brittleness, high melting point and high hardness non-metallic and metal materials can be marked. Traditional marking machines can only process certain non-metallic materials.

Reduce Raw Material Loss

The laser beam of SuperbMelt marking machine has the characteristics of high energy density, the aggregation is very fine, and the impact on the processed work piece is small, so the loss of raw materials is greatly reduced.

Complex and Wide-ranging Marking Content

Some fine patterns and structures on the jewelry surface are almost impossible to complete in traditional marking methods. And it doesn’t work well.

SuperbMelt laser engraving machine can mark any detailed content, including text, photos, patterns, shapes, numbers, etc.

Fast Processing

Compared with the traditional time-consuming and labor-intensive marking methods, our SuperbMelt adopts the marking technology that is highly integrated with the computer, which can realize rapid processing and greatly improve.

Low Energy Consumption

Although for the initial investment, the high-tech laser equipment is higher than the traditional equipment, but because SuperbMelt laser technology can be processed at one time, the energy consumption is much smaller than the traditional equipment, and the life is longer, which greatly reduces the investment cost in the later stage.

How to Choose a Jewelry Laser Engraving Machine

Product Features to Be Marked

Before purchasing a laser marking machine, customers need to consider the product characteristics that need to be processed, such as size, material, etc.

For metal and non-metallic materials, customers should choose the correct type of laser marking machine.

For example, fiber laser marking machine is more suitable for the processing of gold and silver jewelry, while CO2 marking machine can realize non-metallic crafts, packaging boxes etc. processing.

The marking format determines the price, so it is also necessary to consider the product size and select the marking format corresponding to the machine.

Machine Features

After determining what type of machine you need, you should delve into the machine’s characteristics.

For example, the structure and size of the equipment should be selected according to the conditions of the working environment. If you are a small processing shop, then you can choose a box type or a portable type because it takes up less space.

For large-scale processing plants, it is more suitable for desktop marking machines, and the integration of computers and machines can achieve more convenient work.

Laser Power

The output power of the laser determines whether the processing effect can meet the requirements, the processing speed is also affected by the power.

The choice of wattage needs to be determined according to the effect you need. General materials, including metals, alloys, gold and silver jewelry, etc., can achieve very beautiful effects with 20w. If the marking depth is required to be higher, it will take 30 or 50w to complete.

Maintainability of The Machine

The machine needs to have good maintainability, such as fault diagnosis, operation error warning and other functions, and the downtime should not be too long. In addition, the ease of maintenance and cost in the later period need to be considered, which requires understanding whether the after-sales service system of the manufacturer is complete.

SuperbMelt have a professional after-sales team, which can connect problems online or offline in real time and solve them in time.

Difficulty of Operation

A simple device can save a lot of training costs, for small processing plants, there is no need to hire additional professional technicians to operate, which also greatly reduces the cost of employment.

The button structure of SuperbMelt laser engraving machine is simple, and the operation is flexible and convenient. Great for entry-level customers.

What Laser Techniques in a Jewelry Laser

Laser Steaming

By means of high temperature marking, the surface material is evaporated.

This method minimizes material loss.

Laser Erosion

Another widely used method for engraving jewelry is etching or laser foaming, which is done with a fiber laser marking machine, by melting the surface material to deposit and cool it into the desired shape.

Laser Bonding

A material is placed on the workpiece to be marked and combined with the original material by laser bonding. This method can be more flexible to get the shape that needs to be marked.

Laser Coating

By carving on an outer material on top of the workpiece, the raw material is completely protected from damage, which is suitable for materials that are valuable and must remain intact.

Laser Coloring

Laser annealing is a marked shape by repeatedly moving over the workpiece to decolor the laser area, which is suitable for materials that require sharp contrast.

Laser Ablation

Laser ablation is to add a coating to the workpiece that needs to be marked, and then the coating on the engraving surface is engraved to form the content. This method can also protect the original material well.

Types of Laser Engraving Machines

Laser markers are currently widely used in various industries, and there are three main types: fiber laser marking machines, CO2 laser marking machines, and UV laser marking machines.

Fiber Laser Engraving Machine

The most widely used is the fiber laser marking machine. The machine has a small appearance. It outputs laser light from a fiber laser, and then completes the marking through a high-speed scanning galvanometer system.

This method makes the output beam quality and reliability high. The machine has a long life and is energy-saving and environmentally friendly, and is widely used in jewelry and other metal industries and some non-metal industries.

CO2 Laser Engraving Machine

CO2 laser marking machine is a high-performance laser equipment marking by expanding the laser beam, galvanizing mirror, focusing, and finally controlling the deflection of the galvanometer.

The marking speed is fast, and it is suitable for marking most non-metallic materials.

UV Laser Engraving Machine

The UV laser marking machine belongs to the cold laser technology, which breaks the bonds between atoms or molecules through the action of laser energy, and turns them into small molecules to gasify and evaporate.

This method is more suitable for customers with extremely high marking accuracy, such as cosmetics and pharmaceutical packaging industries.

Types of Engraving Technologies

Chemical Corrosion

Electrochemically corrode the designed graphic template on the surface of the workpiece and then form a black graphic mark. This method is low in cost for batch processing, but requires a template and chemical corrosion, and the marking precision is poor.

Ink Coding Printing

The principle of printing pattern characters and digital patterns on the surface of various objects through the deflection of charged ink particles by a high-voltage electric field. This method has consumables, so the use cost is high, the marking is unstable, easy to fall off, and the precision is relatively low.

Mechanical Stamping

Punch directly on the surface of the object with a mechanical punch. The cost of customizable punch is high, and the marking content cannot be changed. Direct contact can easily cause deformation of the object. This method is only suitable for large quantities of metals that require low precision.

Mechanical Engraving

Automatically controlled by computer, using high-strength alloy cutter head to process the project. For example, pneumatic marking machines, CNC metal engraving machines, etc. are all based on this principle. However, the speed is slower and the precision is lower, and it is a direct contact processing.

Laser Galvanometer Marking

The computer automatically controls the galvanometer to change the laser light path, and then marks the surface of the object. It is currently the most ideal marking process in the marking industry. Because of the high speed and high precision

FAQ Guide of Gold and Silver Laser Engraving Machine

- 1. What is a gold and silver laser engraving machine used for?

- 2. What materials can be engraved using this machine?

- 3. Is a gold and silver laser engraving machine suitable for personalization of jewelry?

- 4. Can it handle fine and detailed engraving?

- 5. What file formats are compatible with the machine?

- 6. Is it user-friendly, even for beginners?

- 7. Is the engraving permanent?

- 8. Can it engrave on curved or irregular surfaces?

- 9. What safety precautions should be taken when operating the machine?

- 10. Is maintenance required, and what does it involve?

- 11. Can I engrave text in different fonts and languages?

- 12. What industries benefit from gold and silver laser engraving machines?

- 13. What is the difference between a gold and silver laser engraving machine and other laser engravers?

- 14. Are there any limitations to the size of items that can be engraved using this machine?

- 15. Can it engrave both flat and curved surfaces without adjustments?

1. What is a gold and silver laser engraving machine used for?

A gold and silver laser engraving machine is primarily used for adding intricate designs, text, and patterns onto gold and silver jewelry or objects.

2. What materials can be engraved using this machine?

These machines are versatile and can engrave various metals, including gold, silver, platinum, and more.

3. Is a gold and silver laser engraving machine suitable for personalization of jewelry?

Yes, these machines are perfect for customizing jewelry with names, dates, or personalized messages.

4. Can it handle fine and detailed engraving?

Absolutely, the laser technology allows for precise and intricate designs, making it ideal for detailed engraving.

5. What file formats are compatible with the machine?

Most machines can work with common vector formats like DXF, AI, SVG, and more.

6. Is it user-friendly, even for beginners?

Many machines come with user-friendly software and interfaces, making them suitable for both beginners and experts.

7. Is the engraving permanent?

Yes, the engraving is permanent and resistant to wear or fading, ensuring long-lasting personalization.

8. Can it engrave on curved or irregular surfaces?

Depending on the machine, some are equipped with rotary attachments for engraving on curved or irregular objects.

9. What safety precautions should be taken when operating the machine?

Safety goggles and proper ventilation in the workspace are recommended when using laser engraving machines.

10. Is maintenance required, and what does it involve?

Regular maintenance includes cleaning the lens, ensuring proper ventilation, and checking the laser tube for any issues.

11. Can I engrave text in different fonts and languages?

Yes, you can use a variety of fonts and engrave text in multiple languages as long as they are supported by the software.

12. What industries benefit from gold and silver laser engraving machines?

These machines are used in jewelry manufacturing, gift customization, promotional items, and more.

13. What is the difference between a gold and silver laser engraving machine and other laser engravers?

Gold and silver laser engraving machines are specifically designed for engraving precious metals with the utmost precision.

14. Are there any limitations to the size of items that can be engraved using this machine?

The size limitations may vary depending on the specific machine, so it’s essential to check the working area of the equipment.

15. Can it engrave both flat and curved surfaces without adjustments?

Some machines are equipped with automatic focusing systems, allowing for easy switching between flat and curved objects.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited