Jewelry Melting Furnace

Top Manufacturer in China

- With the power is 3.5-160kw optional

- With the capacity of 1-250kg gold/silver/platinum

- Adopt IGBT induction heating technology

- 15-30% energy than KGPS, 100% full load

Apply Our Best Quotation

Top Jewelry Melting Furnace

The jewelry melting furnace is used for convenient melting of precious metals, base metals and their alloys. The jewelry melting furnace has the capacity of melting metals from 1kg to 250kg suitable for meeting small, medium and large melting needs.

The jewelry melting furnace is equipped with an IGBT induction technology that helps to save between 15 to 30% of energy, at the same time increasing the speed of melting.

The power required for melting in the jewelry melting furnace ranges from 3.5kw to 160kw capable of reaching temperature ranging from 1600 degree celsius to 2800 degree celsius capable of melting ferrous and nonferrous metals.

The electromagnetic stirring system present in each of the furnaces ensures a uniform consistency in molten metal, therefore metals are high quality after casting.

Superbmelt Jewelry Melting Furnace list

The mini jewelry melting furnace is designed for melting up to 2kg of metals within 2 minutes. The power required for melting is between 2.5kw to 3.8kw with a melting temperature of 1600 degree celsius. This is why it is used for personalized melting and other small melting needs. It is able to melt evenly and continuously for long hours, with no shrinkage, no porosity and no oxidation.

Parameter

- Capacity: 0.6-1.2kg

- Power: 2.5kw/3.8kw

- Application: gold, silver, copper, iron etc.

The integrated jewelry melting furnace is used for melting up to 6kg of metals within 4 minutes. The maximum melting temperature is 1800 degree celsius capable of melting gold, silver, copper, etc within 4 minutes. The induction heating technology helps in a fast melting process requiring only 15kw to 25kw of power. The jewelry melting furnace is reliable for a continuous and efficient melting. It is easy to use, transport and maintain.

Parameter

- Capacity: 1.5-4kg

- Power: 15kw/25kw

- Application: gold, silver, copper, iron etc.

The integrated manual jewelry melting furnace is designed for melting up to 12kg of metals in approximately 5 minutes. The melting temperature is 2800 degree celsius, capable of melting high temperature precious metals like platinum and palladium and other metals. The furnace is designed for easy removal of molten metal after melting. The maximum power required for melting is 15kw. It is reliable for a continuous and efficient melting operation.

Parameter

- Capacity: Max. 10kg

- Power: 15kw

- Application: gold, silver, copper, iron etc.

The jewelry melting furnace is suitable for melting precious and base metals of about 30kg. The melting temperature is 1800 degree celsius capable of melting metals within 8 minutes. The maximum temperature required for melting is between 25kw to 35kw. The jewelry melting furnace is designed for easy removal of molten metal. The water cooling unit allows the furnace to melt continuously for 24 hours. The furnace is reliable for an efficient and fast melting process.

Parameter

- Capacity: 12.5-15kg

- Power: 25kw/35kw

- Application: gold, silver, copper, iron etc.

The jewelry melting furnace is suitable for melting up to 50kg of metals. The maximum power required for melting is between 15kw to 45kw. The induction heating system helps to conserve up to 15% to 30% of energy. The electromagnetic induction stirring system ensures a smooth consistency of metal, leading to no porosity, no shrinkage and no oxidation of metal. The jewelry melting furnace is able to melt continuously for medium and large melting applications.

Parameter

- Capacity: 10-50kg

- Power: 15kw/45kw

- Application: gold, silver, copper, iron etc.

The motor jewelry melting furnace is used for industrial melting applications because it is capable of melting up to 80kg of metals. The maximum power required for melting is between 15kw to 160kw. The IGBT induction heating technology saves up to 15% to 30% of energy. The jewelry melting furnace is designed for easy removal of molten metal, which makes it safe to use. It is completely reliable for a continuous and smooth melting process.

Parameter

- Capacity: 10-100kg

- Power: 15kw/160kw

- Application: gold, silver, copper, iron etc.

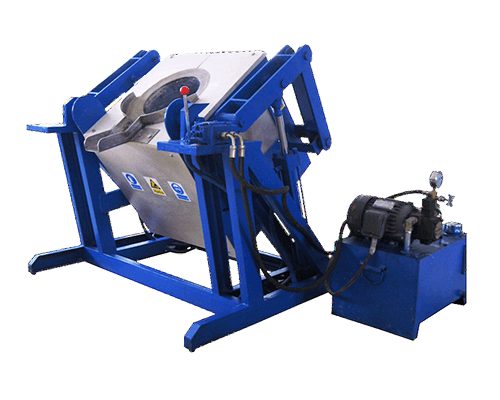

The hydraulic jewelry melting furnace is used for large industrial melting applications because it is capable of melting up to 50 kg to 250kg of ferrous and nonferrous metals. The maximum power required for melting is between 15kw to 160kw. The induction heating technology helps to save up to 15 % to 30% of energy. The electromagnetic stirring system helps to ensure a consistent mix which will prevent oxidation, porosity and shrinkage of metal after casting.

Parameter

- Capacity: 50-250kg

- Power: 15kw/160kw

- Application: gold, silver, copper, iron etc.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Jewelry Melting Furnace Buying Guide

Application Fields of Jewelry Melting Furnace

1.1, Smelting the gold ores

Speaking about smelting gold, it is the process of extracting gold from the core ore it comes combined with. After smelting, you will get 90 percent pure gold, but it is not suitable for jewelry production as it contains iron, aluminum, copper o silver. One of the essential parts of gold mining is smelting the gold properly. If it is carried out improperly, gold will remain in the ore. All the profits from gold are generally settled by purity and weight. So, you need to make sure that you are getting the purest gold from the ore.

Fort this; you need to heat the ore at a perfect temperate. As per the experts, gold should be heated to an excess of 1064-degrees C or 2100-degree F. Smelting gold is done by utilizing high pressure, heat, and various chemicals to spate gold from the ore. This is where you can use a jewelry melting furnace. Such furnaces are designed to produce the required amount of heat and melt the ore within 10 to 15 minutes, based on the size.

1.2, For recycling old jewelry

It has been seen that most people are now recycling their old jewelry and creating a new piece of gold jewelry from that. Well, sometimes, they may have some sentimental reasons to re-use gold.

For example, if you have a great and unbreakable feeling about your grandmother’s wedding ring that is more than 100 years old ring, it is understandable that you will want that actual gold to be used in your design no matter what. Well, this is possible, and all you need to melt that piece of jewelry to get gold.

You can get a mini metal furnace or small gold melting machine and can melt the gold. Besides, you can also take the help of a professional refiner who will refine the alloys out of gold. After that, they can use the obtained gold and add a little more gold to create a new piece of jewelry. Well, even though it is a non-economical way, but you can go for it.

If you some outdated pieces of gold jewelry, then it makes sense to consider how you can utilize the gold to form a new one that will have some wearable designs. Even though it can be tough to find a trusted jeweler who can do that for you, you can use an induction melting furnace or jewelry melting furnace to get it done.

Re-casting your gold jewelry

In different cases, your used gold jewelry pieces can be completely melted down to make something new. This can be a great option if you have a piece with sentimental value, and that piece is now not matching with your personal style or has been damaged.

In general, recycling doesn’t present a cost-saving option over buying a piece of new jewelry. You might be wondering why? Well, this can be a little challenging if the gold jewelry piece is less than 24K gold. On the other hand, 14K or 18K gold is not considered 100 percent pure and comes combined with other metals.

Each of such metals has a different melting point and, when heated, can behave differently. On the other hand, a jeweler will not be able to determine the exact metal content without carrying our expensive testing. Since the melting temperature of gold is around 1064 centigrade, this can be a complex process.

However, by using the right type of melting equipment, you can get it done. Now, you might be thinking about how to purify gold at home? Well, the process is straightforward. All you need to add a little bit of nitric acid and then hydrochloric acid. Let the mixture sit for around 30 minutes.

Then you need to filter it to eliminate the impurities and treat it to neutralize the acids. You will find a muddy solution. Now, properly rinse the muddy part three to four times and then treat that with aqueous ammonia. This will from white vapor. Now rinse the gold and let it dry.

1.3, For jewelry casting

Speaking about jewelry casting, it is an art form that is hundreds and thousands of years old. Since the time that man achieved the ability to melt different metals, artisans have been pouring molted gold into different cavities. The castings were then pried from the encasements in which they were poured.

However, modern technology has changed the way of jewelry casting. Now, most of the jewelry casting is carried out through the lost-wax methods. Under this method, jewelry models are developed using wax carving and are encased in the investments. Then the investments are heated to extreme temperatures to incinerate the gold. After that, the intricate cavity is filled with molten metal, or you can say gold.

Remember that platinum and gold casing are two different things and require different procedures. Platinum melts at an extreme temperature and requires specialized skills, equipment, and plaster investments. On the other hand, gold casting encompasses different karats and colors.

Well, this is where you will need a good quality induction furnace. For faster gold melting times for a small batch of gold, copper, or silver melting, you can use an induction melting furnace. Such equipment is ideal for both high volume and low volume melting. On the other hand, their compact design allows each model to fit easily in any place. The machines are so fast that you can melt 2 to 5 kg of gold within around 5 to 10 minutes.

The utilization of induction melting furnace is common in many different industries as it offers versatile solutions to deal with many different types of metals without taking up a lot of space. For all your metal melting requirements, you can always use the mini induction furnace or a regular-sized induction melting furnace.

1.4, For industrial applications

Do you know around 17 to 18 percent of the world’s total steel is utilized for making different mechanical equipment? On the other hand, gold jewelry production across the world also has increased a lot. However, one of the first steps to creating such products is melting.

If you are running a gold jewelry business and looking for a perfect way to melt gold ore or used gold jewelry, you can always use the induction melting furnace as it offers faster melting rates while maintaining maximum efficiency. This will let the users get top-quality material. Here are some industrial applications for which you can use induction furnaces.

Investment casting

Most of the companies are now using induction melting for investment casting as these machines come in a wide variety of air and vacuum furnaces. Such furnaces are designed and developed to work perfectly for different types of metals.

Precious metals melting

Gold, silver, or platinum, all these are precious for many, but induction furnaces can be used to properly melt precious metals without worrying about any contamination. These are a great way to refine gold and utilized it for jewelry manufacturing.

Copper melting

The modern induction furnaces can also be used to melt custom castings. These are developed to offer the melting you need for most copper applications.

Aluminum melting

Another popular application for induction melting is aluminum melting. These furnaces are highly energy-efficient and can perfectly convert alumina into 100 pure aluminum alloys.

Alloy manufacturing

Induction furnaces are also used in alloy manufacturing, thanks to their maximum flexibility and optima uniformity. Those dealing with alloy manufacturing can count on induction furnaces.

How to Melt Jewelry Nowadays

2.1, How to melt jewelry by propane kiln

One of the most traditional gold melting equipment is propane kiln. Using this method, you can melt a gold bar within a few minutes. Just place the gold in a crucible and then place the crucible on a surface. Make sure the surface is fireproof. Now, you need to bring the lighted torch near to the gold. It will melt the gold.

You can also melt other types of materials in this process if you want to lower the melting temperature by combining gold with borax. If you want to produce more heat, you can also use the oxy-acetylene torch instead of the propane torch. If you want to melt the gold powder, supply the same amount of heat to get perfectly melt gold.

2.2, How to melt jewelry by resistance furnace

In general, the resistance furnace melting system is developed for various mining operations. If you compare this with the induction furnace, you will find this time-consuming. However, the best resistance furnace can offer you the facility to operate it at different temperatures, up to 1600-degrees C. Such equipment comes with an automatic temperature-controlling feature. These are perfectly sealed, and that prevents heat from getting out.

On the other hand, such a furnace also has a gaseous medium to effectively prevent oxidization as well as hardening of the gold sample. However, keep in mind that these are not good for melting gold in a large quantity. For considerable quantity metal melting, you should use an induction jewelry melting furnace.

2.3, How to melt jewelry in induction furnace

The induction furnace is widely used in low as well as high production levels, whether at the gold refining plants, mining facilities, and during retailing. Different studies have proved that the process is very efficient as the machine is environmentally friendly.

It is designed not to produce harmful emissions as the heating system of the induction furnace is generated from the alternating magnetic current and then is directed to the crucible. Besides, as it doesn’t require combustion, the furnace will not heat up the environment where the workers are. For melt jewelry or other materials.

The furnace comes with a nonconductive crucible holding the metal that needs to be melted and surrounded by copper wire. A powerful and continuous alternating current moves through the wire. The coil then creates a magnetic field that can penetrate the metal. To melt the metals, you need to heat the furnace at around 1650-degree C, and to get the purest form of gold, you need to add some flux in the melted gold.

The machine produces the eddy currents that can cause a perfect stirring of the melt. The induction furnace is suitable for the gold melting purpose. This is also called an electric gold melting machine.

2.4, Comparison: Why induction furnace is the best choice

The induction melting furnace is perfect for melting gold as well as different alloys. Those metals can be non-ferrous or ferrous metals. Such materials need to be melted before you can produce or form them. If you look, you will find multiple reasons to use an induction furnace for melting gold or silver. Well, let’s talk about some important reasons.

- To remove impurities from the material

Non-ferrous and ferrous metals are melted in highly heated furnaces before they can be cast. For the casting industries, removing impurities from the melted metal is quite a crucial separation method. There are some methods such as the utilization of different deoxidants, for example, aluminum or silicon or adding magnesium to the melted metal can be sure to remove sulfur or oxygen.

If you are looking for any cost-effective or improved technologies, then you can use SuperbMelt induction melting furnace that makes the process of separating impurities faster and easier. Just choose the machine based on your requirements, and you are all set to go.

- Melting metals to create the alloy

You can’t create alloys without melting metals. In fact, some metals that you are using are a perfect combination of one metal, and they can combine both metal or nonmetal elements. Alloys offer better hardness, corrosion, and heat resistance, and electrical conductivity. Using a quality induction melting furnace, you can perfectly combine the alloy’s properties to create metals that can be used for multiple purposes. If you are in search of the best quality melting furnace, get in touch with SuperbMelt now.

- Melting metals for industrial casting

Industries as well as foundries that deals with metal use induction furnace for various parts, for example, roads construction, automotive parts and more. Different metals are melted to cast them into various sizes and shape. You can use high-performance industrial induction furnaces for industrial melting.

Induction furnaces are the game changer

It has been seen that many manufacturers have now started using induction melting furnaces, especially the jewelry industry. But what is the reason behind this? Well, modern induction furnaces have some considerable advantages over traditional heating equipment in terms of power consumption as well as thermal efficiency.

Talking about the heating method of the traditional heating tool, you need to heat the equipment first, then conduct the temperature, and the metal is then melted at a very high temperature. Well, there can be a heat loss in this method, and this can increase the surrounding temperature.

You will not face such issues while using SuperbMelt’s induction melting furnace. The machine is designed and developed to utilize induction heating technology to heat the metal. On the other hand, the induction smelting furnace’s body is made of high-quality thermal insulation material, and there is a robust structure. That means the heat loss is smaller.

It is also proved that the non-contacting heating method of the metal can lower the energy loss, and you will enjoy better thermal efficiency, around more than 75 percent. Compared with traditional heating equipment, you can save around 20 to 60 percent of energy. Considering all these factors, it can be said that buying SuperbMelt’s induction furnace can be an excellent option for you. Don’t think much; visit the site and get a free quote now.

The Kinds of Jewelry Melting Furnaces that SuperbMelt can Provide

Nowadays, more and more jewelry manufacturers are using induction jewelry melting furnaces for jewelry processing. Do you know what the reason behind that is? Well, compared to the traditional melting machines or equipment, the induction version has considerable advances in terms of thermal efficiency.

However, keeping in mind the growing demand for quality jewelry melting furnaces, SuperbMelt has introduced different types of melting furnaces that will successfully satisfy their melting requirements. Let’s have a look at some significant types of melting furnaces that you can buy from SuperbMelt.

3.1, Mini 1-2kg melting furnace

Speaking about the SuperbMelt mini 1-2kg melting furnace, this machine is designed to effectively meet different special metals, for example, brass, silver, copper, gold, and more, in up to 2kg capacity. The maximum temperature limit of this machine is 1600-degree C and can melt 2kgs of metal within just 2 minutes.

This mini gold melting machine can melt 30Kg of metal in one hour. As the size is portable, this is quite popular among private or small melting businesses. Using this you can save more energy. Use it now and enjoy the desire results.

3.2, 1-4kg platinum melting furnace

Don’t go with the name, as it can melt different metals, not just platinum. You can use it to melt gold, silver, platinum, and other allows. The temperature level of the machine can go up to 2600-degree C.

In terms of quantity, it can effectively melt metals from 1kg to 4kg in around 5 minutes. It comes with a robust electromagnetic stirring system that can effectively prevent uneven metals’ surfaces. Besides, it comes with a strong water pump system that can regulate the machine during metal melting.

3.3, Integrated 3-10 kg melting furnace

Are you looking for a robust and affordable 5 kg induction furnace? Don’t look here and there and choose SuperbMelt’s melting furnace. This compact-sized powerful machine can get the melting task done within a few minutes. As the name suggests, the machine is best for metal quantities ranging from 3 to 5 kg.

It can melt copper, gold, and silver in just 4 minutes. The machine is designed to consume less power and has some useful and easy-to-use features. Talking about one of its significant features, it comes equipped with a robust cooling system that keeps the machine working for 24 hours. You won’t find this feature in other machines.

3.4, 20kg-30kg manual tilting melting furnace

If you are looking for a perfect melting furnace for non-ferrous metals, such as copper, brass, silver, or gold, choosing this machine will work best for you. It can melt up to 30Kg of metal within 8 minutes at 1800-degree C of maximum temperature. This tilting furnace has a unique Omni-directional warming system to make sure that you are using the machine safely while melting the metal.

Besides, it also comes equipped with an advanced asynchronous generator to attain the desired melting point faster. Furthermore, a water cooling system can keep the machine carrying out the melting process for hours. The machine’s crucible and safety refractory are detachable. The machine designed and developed by SuperbMelt is 100 percent reliable and is environment-friendly as it will not generate any harmful gasses while melting the metals.

3.5, 10-50kg chain tilting melting furnace

This 10 kg melting furnace is best for most jewelers. This is designed to meet all types of metals, like silver, platinum, gold, copper, and more. The best thing about the product is it can easily accommodate three furnaces at a single time, offering your better productivity. If you are looking for a powerful furnace to melt high volumes of metals, then this machine is for you.

The machine’s power consumption level range from 15KW to 90KW. Furthermore, the machine has IGBT technology, and you can save around 15 to 30 percent of power, and it functions with zero-emission. So, it completely environment friendly.

What’s more? The furnace has a robust crucible and can change. It comes with an Omni-directional warning system that can notify you about short-circuit, over-voltage, over-current, and over-heating.

On the other hand, the motor drive chain tilting technology makes it easy to pour the melted metal. With a lower level of pollution and noise, it can run for 24 hours. However, it is advisable to check the 50 kg induction melting furnace price by getting a free quote from SuperbMelt before finalizing your deal.

3.6, 10-100kg motor tilting melting furnace

Speaking about this powerful machine, this motor tilting melting machine utilizes advanced induction technology to melt materials with a quantity range from 10kg to 100 kg. You can use this machine to melt materials like silver, brass, stainless steel, gold, steel, lead, zinc, brass, and more. The input power level range from 15KW to 160KW. It doesn’t consume much power, but still, you can trust this machine to enjoy an efficient material melting process.

The crucible that you will get with it is replaceable, and you can quickly complete the process. Though a high-end machine, it comes with many easy-to-use features accompanied by a user manual. No matter what is your melting purpose, this melting furnace is for you. Besides, it can be used to melt non-ferrous as well as ferrous metals. However, to use it, you need to mount the machine on a steel frame. Melting of different metals can now be done continuously for 24 hours with its unique tilting metal melting technique.

3.7, 50-250kg hydraulic tilting melting furnace

When it comes to enjoying the maximum flexibility when it comes to melting different types of metals, you can trust this hydraulic tilting melting furnace. The machine can effectively melt up to 250 Kg of gold, silver, iron, copper and etc. The power consumption level is around 45KW to 160KW. On the other hand, it has IGBT technology that will help you in saving around 15 to 30 percent power while using the machine.

The machine comes with a convenient crucible that is replaceable. It has a tilting feature that can be controlled with the remote trolley panel. The entire process of melting can take around 10 to 15 minutes based on the metal quantity. This hydraulic tilting melting furnace has an advanced control system that will make sure that you are not exceeding the input and output parameters. Without facing any complications, you can keep using the machine for 24 hours.

While using the machine, you don’t have to worry about over-heating, over-current, over-voltage, and more. What’s more? Its unique magnet yoke helps it to improve the metal melting efficiency. The robust stainless steel made structure keeps the machine running for long.

How to Choose the Right Jewelry Melting Furnace

Companies dealing with different molten metals, they understand how to pick the best quality induction furnace that will meet the need of their valuable customers. The various conditions under which the companies melt the metals play an important role in the products’ quality. So, while buying a machine, whether for melting gold jewelry at home or for industrial use, you need to choose the best one.

When you begin shopping for such machines, you will find that there is a huge variety of melting furnace and their purposes. On the other hand, the different furnaces will come with different heating capacities. How to get the best one? To help you in this, we have mentioned down the factors that you need to consider. Have a look.

4.1, Capacity

One of the essential factors to consider is the size or capacity of the induction jewelry melting furnace you are buying. This will determine the suitability of your production unit as every company has its unique requirements. While some furnace’s capacity is 2 Kg, some can support up to 250kgs and more. So, choose based on your production and melting requirements. Consider the size of your melting foundry. You can go for a 10 kg melting furnace or a 5 kg induction furnace considering your requirements.

4.2, Power Usage

In terms of usage of power, you need to know how much energy will you need to keep the melting furnace or jewelry furnace running. There are some types of furnaces that will need high voltages, and some will run, consuming a moderate power supply.

Make sure that you have sufficient power to run the furnace and you are ready to pay for the expenses. If you are looking for the right one, SuperbMelt’s furnaces will be the ideal option for you as their power capacity can go up to 160Kw.

4.3, Temperature Range Provided by the Jewelry Melting Furnace

Why should you make this a primary consideration? Well, if the machine supports different temperature ranges, you can use that single machine to melt different materials. It is advisable to choose a machine that can support a temperature range of 500-degree C to 2000-degrees C.

4.4, Safety Provided by the Jewelry Melting Furnace

You should buy an induction furnace that can offer you more control over the work. For example, you should be able to control the emission of dust, smoke, and other harmful pollutants. On the other hand, you need to make sure that the furnace has temperature control features using which you can regulate the power supply of the machine.

In general, the induction furnace should have a lower oxidation rate. Because it will translate to less waste generated in the smelting process, and you will witness better production result. If the jewelry melting furnace has a high oxidation rate, you will face issues like low quality and fewer unit production.

Besides, you need to understand the service quality of the melting furnace manufacturers and suppliers. Remember that customer service is a crucial reason to consider whether you will stick to a supplier. Furthermore, ensure the manufacturers gives a warranty for their products.

4.5, Variety of Metals That Can Be Used in the Jewelry Melting Furnace

You need to consider what types of metals the machine can support. For example, if you are looking for a machine that can melt copper, silver, iron, or gold, you can go for SuperbMelt. If you want to melt platinum, palladium, or their alloys, you can use a vacuum induction melting furnace. As you will be using the machine for jewelry production, you will need a machine that can melt silver, gold, and platinum. Always trust SuperbMelt for a quality jewelry furnace.

Well, it can be said that looking for an induction furnace requires a lot of caution as this particular type of equipment comes in different forms. On the other hand, there are different capabilities and sizes, and that’s why you should take your time to find a perfect one that suits your needs.

FAQ Guide of Jewelry Melting Furnace

Does jewelry lose value when melted?

Yes, when melting gold, it may lose value. However, that will ultimately depend on the melting methods you are using. In general, standard losses from the refining gold can be around 1 percent to 2.5 percent from the mass or melt losses and an extra 1.5 percent to 2.5 percent on under carat losses. Well, for better results, you can always go for a SuperbMelt jewelry melting furnace and can lower the value degradation while melting your gold.

How do you smelt jewelry with borax?

In the gold jewelry refining process, borax plays a crucial role. When you melt jewelry or gold equipment, borax is placed with the jewelry in the crucible and then heated at the required temperature. When you heat the crucible, borax will start work and separate the gold from any impure material. As a result, you will get pure gold. Remember that borax doesn’t affect your gold. When it comes to extracting gold effectively, you can always use the borax-based refining method. In fact, the material is affordable.

How do you separate gold from other metals by melting?

You can easily separate gold from other metals. For this, you need to follow some easy steps. First of all, you need to heat the furnace and make sure the temperature is 1200-degree C. Now, combine sodium borate chemicals and silica into the furnace and form a slag. You should use a good quality gold melting pot for this. Now, let the metals dissolve. After a few hours, the gold will start to dissolve. Then, let the liquid gold move to the smelting vessel. Once done, let the gold cool and then remove it from the vessel, and then remove the slag to get your gold.

How do you smelt gold jewelry?

You can melt unwanted gold and re-use it to make different pieces of jewelry. You can melt it through different methods, such as using a gold melting machine, propane torch, powerful microwave, and resistance furnace. However, as per the experts, you should always use the best gold melting equipment or machine for better results. The machines designed and developed by SuperbMelt are quite efficient for large-size as well as small-size gold jewelry production. On the other side, with this, you can save money as the machine consumes less power.

How many degrees does it take to melt gold jewelry?

In general, gold is a malleable metal, and one ounce can be beaten out to around 185 square feet. On the other hand, gold is also considered one of the heaviest metals, and the atomic number is 79. The melting point of gold is around 1,948-degree F or 1064-degree C. On the other hand, gold’s boiling point is around 5,173-degree F. By melting gold; you can regain raw material for the production of new industrial, dental gold, coin, jewelry, and more.

What is borax used for in melting gold?

Speaking about borax, it is one type of flux that is widely used for the smelting of god. It has some benefits like better profit margin, offers a pure separation process, lower energy cost, and more. When you use it while melting gold or silver material, it will perfectly dissolve oxides as well as other impurities. Besides, it helps in creating the fluid borate slag that collects on the surface of the melted gold, and you can easily remove it from the surface to get pure gold. However, you should use a high-quality smelting pot for gold for faster and better results.

Can you melt down gold to make jewelry?

Well, in general, some experts will suggest you not melt your old gold jewelry to make new jewelry pieces. However, if you are planning to get gold from the ore, then you can melt it using gold melting equipment or jewelry melting furnaces that are quite easy to use. For the best quality machines, you can go for SuperbMelt’s machine.

Could we melt silver in this induction melting furnace also?

Speaking about silver, this is a common and widely used precious metal used in medical supplies, electronics as well as jewelry. Well, when you have a suitable machine, you can even melt this material at home. So, you can use an induction melting furnace to melt silver. Different from gold’s melting point, silver’s melting point is around 965-degree C, and SuperbMelt’s machines are designed to melt different types of material, including silver.

How much gold is lost when melted?

Remember that gold doesn’t evaporate when it melts. Besides, if you are melting 24 karats of pure gold, then you won’t lose anything during the melting process as it will not vaporize or oxidize. Sometimes, gold can contain different elements such as nickel, zinc, copper, and more that can fume or oxidize when melted. In such cases, you can face minor losses. In some cases, losses may occur during filling or sawing the object. However, using SuperbMelt’s melting machine, you can keep the chances of losing gold during melting low.

How do you get gold from gold ore?

In general, the process of separating gold from the ore is called cupellation. Under this process, the ores are treated under high temperature effectively, and this way, they are separated from noble metals, for example, silver or gold, from the base metals. When heated at high temperatures, noble metal will not oxidize; however, zinc, copper, lead, and other base metals will oxidize. Well, SuperbMelt has made the process of getting gold from the ores comfortable. Using gold smelting equipment or an induction furnace at 1064-degree C, you can separate gold from the ore. Get it now.

At what heat does jewelry melt?

Well, for this, you need to consider the melting temperatures of some common metals used for making jewelry. For example, if you want to melt gold jewelry, it will melt at 1063-degree C. On the other that, the melting temperature for silver and platinum is 961-degree C and 1770-degree C, respectively. If you are looking for a perfect way to melt different metals or jewelry, you can always go for smelting equipment available at SuperbMelt.

What flux do you use to melt gold jewelry?

To melt gold jewelry and to avoid any type of contamination, you can use different types of flux, such as hydrochloric acid, silica, sodium nitrate, ammonium chloride, borax, zinc chloride, and more. However, one of the widely use fluxes is borax.

What is the process of smelting jewelry?

As mentioned above, smelting is a process of separating the metal from the ores. In general, the metal that is found in the ore is oxidized, so you need to carry out a chemical transformation to remove the oxygen. The ore is dumped into the jewelry melting furnace, or you can use portable gold melting machine. Besides, you need to add-flux, the chemical cleaning agent. The jewelry is then heated to a high temperature, around 900-degree C. When the mixture melts, the impurities and the precious metal separate.

What is the best way to melt gold?

You can smelt jewelry using a propane torch, an induction melting furnace, or using resistance furnace. However, for the best result, we would like to suggest you to use SuperbMelt’s melting furnace, which is quite popular across the world.

How fast can gold jewelry melt?

Well, for a faster-melting result, you can use SuperbMelt’s jewelry melting furnace, and the machines can be configured to processing up to 12kg of gold. Based on different types of machines, the entire process of melting jewelry will vary. For example, using integrated induction melting furnace from SuperbMelt, you can melt up to 5kg of gold in under 2 to 4 minutes.

Where can I get my gold melted down?

You can quickly melt your gold using different types of jewelry melting furnaces offered by SuperbMelt. For example, based on your melting requirements, you can go for the integrated melting furnace, manual tilting melting furnace, moto tilting melting furnace, or hydraulic tilting melting furnace. All these machines require easy setup and relatively easy to use. Check them out and place your order now.

Can you melt off gold plating?

Yes, it is possible. For this, all you need to use the right chemicals, methods, and machines. For example, if you want to remove gold from the circuit boards, you can mix 2 parts of muriatic acid into one part of hydrogen peroxide. After a few days, you will find gold floating around the pot. Now, you need to add some borax to the collected gold flakes and heat them using a crucible. This way, you can get the gold.

What temperature can the induction melting furnace reach?

Well, the advanced induction furnaces don’t have any limit to the temperature that they can attain. For example, the melting machines designed to melt gold can easily reach up to 3000-degree C. So, such machines are good for melting different precious metals. When it comes to melting platinum, you can set the temperature at 2000-degree C.

What is the difference between an electric arc furnace and an induction furnace?

Speaking about the electric furnace, it generally functions on a principle where arc generates heat and melts the metals. On the other hand, in the case of an induction arc furnace, the heat is generated using electromagnetic induction. If you compare, you will find that an induction furnace will heat up much faster than an arc furnace. If you want to witness a faster melting process of precious metals, buying an induction furnace will be a perfect option for you. As they are easy to use and high in quality, induction furnaces are widely used in different industrial induction furnaces.

How do you know if it is real gold?

To know the purity of the gold, you can use different methods, such as chemical tests, magnet rest, hallmark tests, and more. But these methods may not offer you an accurate result. So, it is advisable to use SuperbMelt’s handheld XRF precious metal analyzer. Using this, you can know the purity level of the metal within a few seconds.

Conclusion

In any industry, technological improvement is quite crucial. The reason behind this is it helps in making the desired progress that is related to working conditions and performance. Well, in connection to that, the technology in the field of induction melting furnaces is improving continually and also advancing rapidly. Now, you can melt different precious metals and can also easily separate gold from the ores using an induction melting furnace. While lowering the cost, using such a foundry induction furnace, you can also improve your productivity.

In general, the better thermal efficiency of such a furnace is quite conducive in lower the cost of the power as well as the small furnace or equipment maintenance costs. Different studies have proved that the production efficiency of induction jewelry or metal melting furnaces is unmatched by traditional heating equipment. With time, this method of melting metals is gradually replacing the traditional resistance furnace with low heat.

So, don’t think much and get in touch with SuperbMelt now to buy the best quality induction melting furnace at the best prices. At SuperbMelt, we develop high-end induction melting furnaces that will perfectly fit different types of applications. With the machines, you can easily attain a temperature up to 1600-degrees C. The best part about the machines is using this; you can melt non-ferrous as well as ferrous metals, like platinum, silver, iron, gold, and more.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited