Jewelry Melting Equipment

Top Manufacturer in China

- With the power is 3.5-160kw optional

- With the capacity of 1-250kg gold/silver/platinum

- Adopt IGBT induction heating technology

- 15-30% energy than KGPS, 100% full load

Apply Our Best Quotation

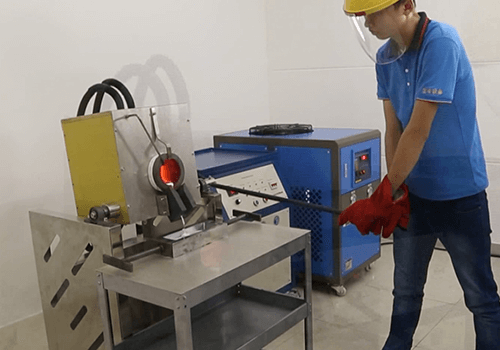

Top Jewelry Melting Equipment

Superbmelt jewellery melting equipment is used for melting gold, silver, copper, brass, bronze, platinum, palladium, etc. The smelting equipment in China has the capacity of melting between 1g to 250kg of metal conveniently. The maximum melting temperature is between 1600 degree celsius to 2800 degree celsius.

Superbmelt jewellery melting equipment has an inbuilt IGBT induction heating technology that makes melting efficient, fast and high-quality. The electromagnetic induction stirring system makes molten metal homogenous. Superbmelt jewellery melting furnace is used in jewellery production, foundries, laboratories, mining, scrap recycling, personal uses, etc.

At Superbmelt, we offer our customers a wide range of metal melting furnaces that meet their specific applications. Contact Superbmelt today for the best jewellery melting equipment for your business.

Superbmelt Jewelry Melting Equipment list

The mini jewellery furnace by Superbmelt is suitable for melting up to 2kg of gold, silver, copper, brass, bronze and their alloys. The maximum melting temperature is 1600 degree celsius, capable of melting in 2 minutes. The small gold melting furnace is compact in size. It is suitable for use in jewellery making, personalized melting, research and development, etc. The mini gold melting furnace can melt continuously for 24 hours.

Parameter

- Capacity: 0.6-1.2kg

- Power: 2.5kw/3.8kw

- Application: gold, silver, copper, iron etc.

Superbmelt integrated jewellery melting equipment is designed for melting up to 6kg of gold, silver, copper, brass, bronze, and their alloys within 4 minutes. The maximum melting temperature required for melting with the gold melting equipment is 1800 degree celsius. The maximum power required for melting is approximately 25kw. It is used in jewellery making, metal recycling, etc. The silver melting furnace is easy to use, maintain and transport.

Parameter

- Capacity: 1.5-4kg

- Power: 15kw/25kw

- Application: gold, silver, copper, iron etc.

Superbmelt manual tilting jewellery melting equipment is used to melt precious metals of about 12kg of metal at a maximum temperature of 2800 degree celsius. This temperature is suitable for melting platinum and palladium. Each batch of melting is complete within 5 minutes. The manual tilting device makes it easy to remove molten metal. The maximum power required for melting is 15kw. It is used in jewellery making, mining industries, metal recycling, etc.

Parameter

- Capacity: Max. 10kg

- Power: 15kw

- Application: gold, silver, copper, iron etc.

Superbmelt split jewellery melting equipment is suitable for melting up to 30kg of precious metals and base metals. The maximum temperature and power required for melting are 1800 degree celsius and 35kw respectively. The metal melting furnace has a tilting device that makes it easy to remove molten metal. The gold melting furnace is easy to use. The melting equipment for jewellery is used for efficient melting in foundries, scrap metal recycling, etc.

Parameter

- Capacity: 12.5-15kg

- Power: 25kw/35kw

- Application: gold, silver, copper, iron etc.

Superbmelt chain tilting jewellery melting equipment is an industrial size melting furnace. It is suitable for melting up to 50kg of ferrous and nonferrous metals. The maximum power required for melting by the metal smelting equipment is approximately 45kw. The gold melting equipment performs an excellent melting for industries such as scrap melting, foundries, mining, steel production, etc. The melting furnace is designed for the easy removal of molten metal.

Parameter

- Capacity: 10-50kg

- Power: 15kw/45kw

- Application: gold, silver, copper, iron etc.

Superbmelt motor tilting jewellery melting equipment is suitable for industrial metal melting. The metal melting furnace can melt up to 100kg of gold, silver, copper, iron, etc. The maximum power required for melting is between 15kw to 160kw. The electromagnetic induction system ensures the uniformity of molten metal. Superbmelt foundry smelting equipment is applicable for use in scrap metal recycling, foundries, mining industries, etc. The metal smelting furnace is designed for the easy removal of molten metal.

Parameter

- Capacity: 10-100kg

- Power: 15kw/160kw

- Application: gold, silver, copper, iron etc.

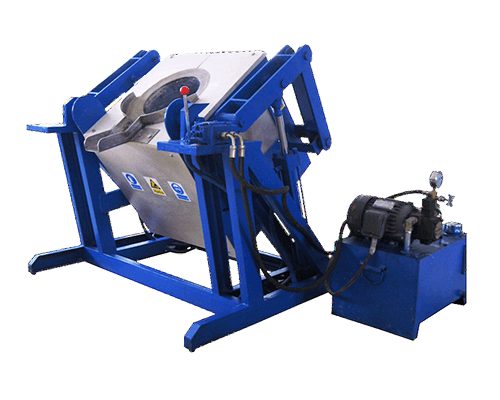

The hydraulic jewellery melting equipment by Superbmelt is designed to melt up to 250kg of ferrous and nonferrous metals. The gold smelting equipment has a maximum power requirement of 45kw to 160kw. The PLC control system makes it easy to use and makes melting highly efficient. The smelting equipment for sale is applicable for use in foundries, ingot industries, mining, scrap metal recycling, etc. The hydraulic tilting design makes it easy to remove molten metal.

Parameter

- Capacity: 50-250kg

- Power: 15kw/160kw

- Application: gold, silver, copper, iron etc.

Why You Could Choose Superbmelt

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

ISO CE SGS approved

Professional certification bodies certify that the machines are of high quality.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Jewelry Melting Equipment Buying Guide

Gold is one of the most used cast pieces and is generally made through a process called vacuum casting. Under this process, the hot metal in the melted state is poured into a mold, and then the mold pressure is lowered to about 2.0 atmospheres. As a result, the melted material properly real into the mold corners, and you will get the perfect shape.

However, melting gold is not an easy process, and there should be a perfect level of consistency in the temperature while melting gold. Otherwise, the metal will not melt properly, and you may face issues in consistency.

When it comes to getting pure gold from the ore, you need to melt the ore at around 1600-degrees C. Well, even though you can use different melting tools for this, choosing the right one is crucial. Therefore, you need something using which you can attain the required temperature faster and melt the gold in the proper way.

This is where you can use a jewelry melting furnace. With time, gold melting machine has become very popular mining and jewelry making industry.

Now the central question is how to choose the best gold smelting equipment to melt gold? In the market, you will find many options and models with different features that will make your buying process a little confusing. However, to help you out in this, we have written down this guide. Here you will find all the required information that will help you in making the right decision.

However, before diving deep into that, it will be better for you to know more about the machines and how they are used to lower the metal oxide to get the pure base metal. So, let’s start with the application of the gold melting machine.

Application Fields of Jewelry Melting Equipment

For almost all metals, melting is the first step to produce valuable products. SuperbMelt is a leading manufacturer of the electric gold melting machine and has emerged as a most reputed name in different industries.

SuperbMelt offers different models of induction furnaces with various capacities. These machines will lead to faster melting rates, low metal loss, constant & precious temperature control, and maximum efficiency.

Jewelry melting equipment has different applications in different industries. Here is a detailed analysis of the application of gold melting equipment.

1.1, Smelting the gold ores

Talking about smelting gold, this is a process of extracting gold from the ore it is mixed with. After the smelting process, you will get around 95 percent pure gold as it may contain other elements, for example, iron, aluminum, copper, and silver.

Most of the large companies prefer to smelt gold on-site, while some jewelers do that at the shop using a mini induction furnace. Gold smelting is done by utilizing very high pressure, different chemicals, and heat to break down the ore and melt the gold. When heated at a higher temperature, the gold gets separated from the impurities.

To smelt gold, you need to produce a heat of 1046-degree C or 2150-degree F as this is the melting point of gold. If you are looking for a perfect machine for gold smelting, you can always use an induction melting furnace. Such machines can be used to smelt gold mines, gold dust, and gold ores to remove the non-metal impurities so that you can extract the purest gold from the ore.

You all know that smelting gold is a very dangerous process, and some smelting processes use liquid mercury. But when you are using an induction furnace, you don’t have to worry about these things. So, get the machine now and enjoy a hassle-free gold smelting process. Let’s have a look at the process of melting gold.

- First, you need to carefully crush the gold ore and then place that in a pot or crucible.

- Then you need to put the pot into a furnace or use a propane torch to heat it to 1064-degree C.

- Then add different oxidizing agents, for example, cyanide, to remove the impurities.

- Once done, you need to pour the gold into the mold and let it cool.

That’s it. You have successfully obtained gold from the ore, and that can now be used to make different gold products.

1.2, For recycling old jewelry

Do you have some old jewelry pieces? Do you know you can now melt them and create new pieces? You might be wondering how? Well, the traditional process of melting old jewelry is very time-consuming and harmful. But the latest old smelting machines have made the process a lot easier.

If you can’t trust a jeweler to give your old gold jewelry, then you can melt the gold at your home using a mini-induction furnace.

All you need to get the correct type of smelting equipment to melt the old jewelry, and then you can cast them into new pieces. You can also use this machine for various semi-furnished products, for example, rods, tubes, plates, and more.

An induction furnace, while melting gold, doesn’t produce any pollutants. Besides, induction heating can spread efficiently. As a result, the metals can absorb the heat efficiently. These machines are so fast that you can melt 2 to 5 kg of gold within just 10 to 15 minutes.

The process of melting down the gold

- Take the pieces that contain gold. In general, gold makes up around two percent of the metals as well plastic housing.

- Now, you need to strip out the metals and use different chemical compounds that can react with gold. Using this, you can get precious metal.

- Besides, you can also melt the entire metal component using an electric gold melting machine to separate gold from the impurities.

- You need also need to add an oxidizing agent to the crucible to remove the remaining impurities.

1.3, For jewelry casting

Before you can cast any jewelry, you need to make sure that the gold is properly melted. This way, it will turn into an aqueous state. Once done, you can utilize the smelting process and enhance the purity level of the gold. Speaking about jewelry casting, it is the process of creating mold. After the creation of the mold, the mould is filled with melted gold to obtain the desired jewelry pieces.

This process is called the lost wax casting. And it can be done using a good quality machine. As the process includes loss of wax, it is named like this. To melt gold for jewelry casting, you can use an induction gold melting furnace. A good quality gold melting machine can offer the following benefits:

- The melting process is very fast and can be done within 5 to 10 minutes.

- The machine comes with inert gas protection, utilizing Argon or Nitrogen.

- The equipment produces pressurized casting that can prevent porosity as well as oxidation. Besides, you will also enjoy a better casting density.

- The temperature level remains constant throughout the process.

These are some of the significant benefits that have attracted different industries to use advanced induction furnaces.

1.4, For industrial applications

From the metals that are obtained from the Earth’s core, gold is the most valuable and useful. The metal has diversified properties that make it very useful. For example, gold is very easy to work, doesn’t tarnish, can be easily hammered, and can be combined with other allows or metals. So, this metal is used for different industrial applications.

In computers and electronics

Gold is well-known as a highly efficient conductor and can easily carry a small number of electrical charges. So, gold is used in different electronic devices, like cell phones, televisions., GPS devices and more.

In dentistry and medicine

Gold can be used to make crowns, orthodontic appliances, bridges, and other dental products. The reason behind this gold is non-allergenic, easy to use, and chemically inert. Tiny amounts of gold isotopes can be used in differential diagnosis and various radiation treatments.

Apart from this, god is also used in the aerospace industry. This is used to coast the inside of the shape shuttle to keep the astronauts protected from the heat and infrared radiation.

SuperbMelt produces gold smelting machines that can be used for different industrial applications, and you can enjoy an excellent level of performance.

We have designed and developed the best smelting furnaces that can be used for various industrial applications. You can use them for non-ferrous metals so that you can get pure product. As a result, you will earn a good reputation in the market. These machines are easy to use and safe.

How to Melt Jewelry Nowadays

2.1, How to melt jewelry by propane kiln

You can melt gold and other metals using a propane kiln. But how to do that? To start, you need to get a good quality crucible that to gold the gold. To remove the impurities, you can use a small amount of flux. Now, apply the propane torch to the gold to melt it. While using a propane kiln, you should give maximum importance to your safety as an accident can occur.

Once that is done, you can add the melted gold into a mold to give it a shape. If you are melting gold dust, then slowly apply the flame. Otherwise, the flame can blow out the powder.

That’s why it is not advisable to use this method of melting while melting gold dust. Besides, this method can take time and not always safe.

2.2, How to melt jewelry by resistance furnace

A resistance furnace is generally developed for mining operations. However, if you compared it with the induction furnace, you will find resistance furnaces are time-consuming. But this melting machine can produce around 1500-degree C of temperature.

In this, the furnace works as a heat source. The machine uses electric heating elements to transform the energy into the final heat. That heating energy is used to heat the gold. Using a resistant furnace, you can easily smelt high amounts of gold. But you may not find it suitable in some cases.

If you want to avoid a massive amount of electricity bills, then this machine is not suitable for you. Besides, these machines can develop different heat complications, and you may end up with unevenly smelted gold. So, how to deal with such issues? Well, this is where you can use induction gold smelting equipment. Induction machines can perfectly remove impurities.

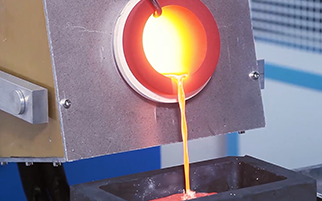

2.3, How to melt jewelry in induction furnace

If you are looking for a melting machine that can be used in different industries and offer you the best result, then for an induction furnace. This is an electrical furnace that heats the metals using induction heating technology.

This is a perfect option for low and high production levels. So, these machines can be found at mining facilities, gold refining plants, and retailing. The machine is so powerful and efficient that it can melt 10kg of gold within 15 minutes.

To use this, put gold into a crucible and add-flux. Then place the crucible into the induction furnace. Now, set the temperature level and heat it. After a few minutes, remove the impurities and then leave the melted gold to get cool.

That’s it. You have not the purest form of gold to be used for different applications. It has been proved that induction furnaces can increase your productivity.

2.4, Comparison: Why induction furnace is the best choice

Well, whether you are a professional jeweler or a novice, induction jewelry melting equipment will be a perfect option for you. The machines are designed to smelt different types of precious metals without affecting their natural qualities. Besides, you can use them in the process where there is a requirement for an accurate supply of heat energy.

The best thing is that you can get induction jewelry melting equipment under your budget, and they are compact in design. The heat will be applied evenly to the metal within a few minutes, and you will get the result much faster. This offers a clean form of melting process, and the melting efficiency level is also good.

Some model has a water-cooling system that keeps the machine running for hours, and you don’t have to worry about the overheating issue. Want to know more about the induction furnaces and the models that you can buy? Then keep reading to explore more. Here is the list of types of jewelry melting equipment or furnaces that you can buy from SuperbMelt.

The Kinds of Jewelry Melting Furnaces that SuperbMelt can Provide

Having the right kind of equipment is a necessity if you work in the jewelry-making industry. SuperbMelt offers a diverse range of jewelry melting equipment and tools that can help you to efficiently melt varying types of ferrous and non-ferrous metals such as zinc, gold, silver, copper, and many more.

With the help of our innovative and operator-friendly jewelry furnace solutions, you can take care of all your production requirements smoothly. The best thing is that our versatile metal melting machines come in different sizes, and specifications so you can choose the tool that is aligned with your needs as well as budget.

3.1, Mini 1-2kg jewelry melting equipment

SuperbMelt mini melting equipment is the perfect tool that can optimally take care of your small-scale metal melting processes. With the help of this jewelry melting equipment, you can easily melt any piece of metal, such as gold, silver, etc., that weighs between 1 and 2 kg. The compact machine is designed in such a manner that it can reach the maximum heating temperature of 1600 degrees Celsius in no time.

The ergonomic design of our jewelry furnace will help you to melt a batch of 2 kg of jewelry within a short span of 2 minutes. It means that it would take only an hour to conveniently melt 30 kg of jewelry with our melting equipment. If you are looking for an efficient and robust jewelry melting device, our mini metal melting tool can boost your production process.

3.2, 1-4kg platinum jewelry melting equipment

If you are looking for a reliable and innovative platinum melting machine, your search ends right at SuperbMelt. Our jewelry melting equipment is an inventive technological creation that is designed to deliver superior melting action on precious metals such as silver, gold, and platinum.

The jewelry furnace can instantly reach the maximum heating temperature of approximately 2600 degrees Celsius. This is an ideal machine if you want to melt metals between the weight range of 1 and 4 kg. The best part is the entire melting process of one batch will take hardly five minutes of your time.

Our design can ensure your safety while boosting your production efficiency. As this machine can run for 24 hours, it can make your jewelry melting process both productive as well as efficient in nature.

3.3, Integrated 3-10 kg jewelry melting equipment

Our integrated melting equipment is the perfect tool that can help you to melt jewelry made from precious metals such as silver and gold. We have integrated the most advanced IGBT Induction Technology into the system that can help you to attain top melting speed within only 2 to 4 minutes.

If you are looking for highly functional jewelry melting equipment that can be used in research institutes, jewelry shops, labs, etc., then we have the best solution for you. You can enjoy a host of advantages by choosing the jewelry furnace for your metal melting activity.

For instance, the solid monitoring and diagnostics system of the machine can guarantee high reliability, stability, and safety of the equipment. You can use the tool for 24 hours continuously without worrying. So, if you want to enhance your production process, the innovative tool by SuperbMelt can help you accomplish the feat.

3.4, 20kg-30kg manual tilting jewelry melting equipment

Our manual tilting melting equipment comes with some of the most innovative features that are new in the market. With the help of our highly energy-efficient and cost-efficient jewelry melting equipment, you can melt 20 to 30 kg of jewelry made of non-ferrous metals such as silver, aluminum, and gold.

The machine can reach the heating temperature of 1800 degrees Celsius. So, you can easily melt any metal within six to eight minutes. The vigorous induction power supply of 25 to 35 kW can simplify and enhance the process of metal melting. The digital induction technology of our jewelry furnace will surely upgrade your production process by providing an efficient and seamless operation.

The machine is designed to function on a continuous basis. The highly durable product casting can ensure that there is no disruption in the functioning. So you do not have to worry about any kind of irregularities or disruptions in your production operations.

3.5, 10-50kg chain tilting jewelry melting equipment

SuperbMelt has designed a powerful chain tilting melting furnace that can help you to melt jewelry between the weight ranges of 10 to 50 kg. With the help of this jewelry melting equipment, you can melt both ferrous as well as non-ferrous metals. The digital Simens Control System (PLC) can ensure that the melting process is done in a quick and efficient manner.

The machine is designed in a compact way by taking into account the convenience and simplicity factors. Our powerful jewelry melting furnace has an astounding power rating of 15 to 90 kW. The integrated IGBT technology in the machine can help to minimize your level of power consumption by almost 15 to 30 %.

A distinctive feature of our jewelry melting equipment is that it is designed with modern motor chain tilting technology. It can improve your metal meting process considerably as you can safely and easily pour melted metals.

3.6, 10-100kg motor tilting jewelry melting equipment

If your jewelry melting needs are huge, you need to opt for powerful and efficient jewelry melting equipment that can meet your exact requirements. SuperbMelt’s motor tilting metal melting pot can help you to melt jewelry made from non-ferrous and ferrous metals like gold, silver, etc. The induction technology, modular design, and robust performance can boost your production process.

The machine is based on one-person pouring action. It comes with graphite as well as a silicon crucible. You can use the graphite crucible while melting non-ferrous metals such as silver and aluminum. The silicon crucible can be used while melting jewelry made from ferrous metals such as steel.

An important feature of our jewelry melting equipment is the state-of-the-art screen touch control function. By simply touching the screen, you can control the metal melting process. The furnace has been ergonomically designed to give you ample flexibility while performing the metal melting operations. You can operate the machine continuously for 24 hours without facing any disruption in its performance and functionality.

3.7, 50-250kg hydraulic tilting jewelry melting equipment

SuperbMelt has designed a powerful electric induction metal melting pot that is capable of melting metal between the weight ranges of 50 to 250 kg. The solid output power rating of 45 to 160 kW can ensure that you can use a single machine to melt a substantial volume of metal.

The application of IGBT is one of the main highlights of the jewelry melting equipment. With the help of the machine, you would be able to efficiently carry out the metal melting process while minimizing your power consumption.

How to Choose the Right Jewelry Melting Equipment

The advancement of technology is needed in every industry because it enhances performance and working conditions. Technology in the melting furnace field is also started growing rapidly and advancing performance. There are many types and models of melting furnaces that are based on the substance you want to melt.

To choose the right jewelry melting equipment, you need to know what kind of material you want to melt, and depending on that, and you can choose the right jewelry melting equipment. There are different equipment for different materials such as gold, platinum, silver, and others. Choosing the right equipment for the jewelry melting process is essential for the great outcome of your work.

4.1, Capacity

Depending on the use, the Capacity of the jewelry melting equipment varies. There are different types of equipment available for different jewelry melting processes, and each piece of equipment has a different Capacity. The Capacity of equipment is often defined as the amount of metal such as gold, platinum, or silver that can be melted at once.

The Capacity often starts from 1-2 kg, and it means you will be able to melt 1-2 kg of any piece of metal easily. Starting from 1-2 kg, the Capacity goes up to 50-250 kg. The Capacity is chosen depending on where and how it is used. So, while choosing the right jewelry melting equipment, you must choose the Capacity you need and then select it accordingly.

4.2, Power usage

The melting equipment will consume power according to the Capacity, and the larger is the Capacity, the more power it will need. But there is some advanced equipment that is built with energy-efficient technology and gives high performance. So, if you want to buy the right jewelry melting equipment, then you must choose equipment that will consume less power than usual.

The integrated IGBT technology in the equipment can reduce the level of power consumption by up to 30%. There are also portable gold melting machine, or mini gold melting machine available that consumes less power. So, choose the right equipment to save your power and money.

4.3, Temperature range provided by the jewelry melting equipment

The temperature of jewelry melting equipment is one of the essential features. You need to choose the right jewelry melting machine according to your temperature needs. The high-temperature feature can help you with doing your work easily. The higher the temperature can go, the less time it will take to melt the metal. For example, if the machine can reach a temperature level of 1800 degrees Celsius, then the metal will be melted within six to eight minutes. So before purchasing a machine must check the temperature feature.

4.4, Safety provided by the jewelry melting furnace

It is extremely important to have a melting machine that offers safety while melting metals at a high temperature. As the melting process goes under high temperature, the machine generates high heat, and it can cause problems. A good melting machine can provide you a safe way to melt the metals. With the modern and advanced technology now, it is possible to have lower risk while melting machine and this equipment generate lower heat that is less harmful. So, while choosing the right melting machine, make sure to buy one that provides better safety.

4.5, Variety of metals that can be used in the jewelry melting equipment

The most important thing in a jewelry melting machine is the varieties of metals it can be used for. There is some equipment that can only work to melt a particular metal such as, gold, silver, or platinum. So, while choosing a melting machine, make sure that it can be used with different types of materials. If the melting machine can be used for varieties of metal, then it will be more efficient for you, and you don’t need to buy one machine to melt a particular metal, and instead of that, you can buy one melting machine that will help you to make all the melting work easy and simple.

FAQ Guide of Jewelry Melting Furnace

Does jewelry lose value when melted?

When melted, the jewelry may or may not lose its value depending on the material, but in most cases, it does. For example, when you melt 24 karat gold, then nothing will be lost, and the amount will stay the same. But if the gold contains other elements such as zinc, copper, nickel, or others, then the weight of it will decrease so does the value. The loss in value Depends on the purity of and grade of the piece of jewelry. In the case of silver, the value will almost remain the same if the melting of it is done properly.

How do you smelt jewelry with borax?

To melt jewelry with borax, all you need to do is sprinkle a little borax in the jewelry and then increase the heat amount until the jewelry starts to melt and the color of it changes as it nears its melting point. Borax lowers the melting point of the jewelry. In the case of gold, the gold prospector was a piece of ore, and then they mix it with the borax in a plastic bag. After that, the bag is placed in a bowl and then heated, which makes the borax work, and once the borax melts, it can lower the melting temperature of other elements in the ore.

How do you separate gold from other metals by melting?

The method of separation holds from other metals, which consists in the smelting process of gold other that will separate other metals from the gold. This method can be done anywhere but given the high temperature, and it is always safe to use professional services. A crucible made of graphite clay is used to keep liquid gold, and it must resist 1000 degrees or more.

How do you smelt gold jewelry?

Smelting gold is a process to extract gold from the ore, and after smelting, gold is 90% pure, but it is still not pure enough to be accepted by the market because it still contains minerals such as iron, silver, copper, and aluminum. Large companies smelt the gold on-site to reduce the cost but can’t refine gold. Smelting gold can be done by using high pressure, heat, and other chemicals to break the ore and melt the gold to separate it from other impure metals, and in this process, the golf must be heated to 1046 degrees Celsius. But the smelting method of gold is very dangerous, and many people still use liquid Mercury to separate gold from other metals.

How many degrees does it take to melt gold jewelry?

You will be able to melt gold when it reaches its melting point. And the melting point of gold is 1943 degrees Fahrenheit or 1064 degrees Celsius. This is the highest amount of temperature needed to melt ant metal, and this is due to the high heat resistance of gold, and as well as the conductivity. When the temperature of the gold reaches 1064 degrees Celsius, then it can melt gold jewelry. And this degree refers to pure gold, and this can be found in gold coins or bars.

What is borax used for in melting gold?

Borax is a common substance used to melt gold and turn it into liquid. Borax allows the gold to melt in a safe way and well-ventilated area in the home. To melt it, you need charcoal and use it as a container, and after that, take a piece of gold and place it in the charcoal container. Sprinkle a little amount of borax into the gold piece and then increase the amount of heat on the torch until the gold reaches its melting point. The gold color will change, and it will look like bright orange color with a green tint.

Can you melt down gold to make jewelry?

Yes, you can absolutely melt down your gold to make jewelry but make sure you are using pure gold because the problem with melting your gold to turn into new jewelry is that you don’t know what kind of material is mixed with it. If the gold is not in its purest form, then melting it to make new jewelry can end up in poor quality. And if you want to make new jewelry from melting gold, then you can also add other elements to make it stronger. 24 karat gold would be perfect for making new jewelry.

Could we melt silver in this induction melting furnace also?

Yes, you can melt silver in an induction melting furnace too. The best part about using an induction melting furnace is that you don’t need to know about how it works. The induction works easily with power supply, and the power supply generates a current that goes through the copper coil, and this coil generates magnetic flux, and this flux goes around the silicon carbide than the best transfer to silver, and the temperature of the silver increase to its melting point. When the temperature reaches 1000 degrees Celsius, then the silver starts melting.

How much gold is lost when melted?

The loss of gold while melting depends on the purity of the gold. If the gold is 24 karat, then it will not lose anything because the 24 karat gold has fewer impurities, so it doesn’t oxidize or vaporize. If the gold contains other elements such as zinc, copper, nickel, and others, then it will oxidize from the gold, and the loss can be seen. The loss can be < 1-5% depends on the purity of the gold. The melting point of gold is 1064° Celsius, so it won’t melt until it reaches this temperature.

How do you get gold from gold ore?

There are various methods performed to extract gold from ore. One of the most common techniques uses cyanide in different ways. In one method, the ore is put into a tank that contains a weak solution of cyanide and zinc. In this method, the zinc causes a chemical reaction that separates the gold from ore; after that, the gold is removed from the solution with the help of a filter. In the carbon-in-pulp method, the ore is added to the water before adding cyanide. Then carbon is added to it to form a bond with gold. Then the carbon gold particles out into a solution that separates out the gold from the ore.

How do you get impurities out of gold?

There are many methods used to get rid of impurities in the gold. Melting the gold is one of the oldest methods. It gets impurities out from gold with fire. But the melting point of gold is 1064 degrees, which is why it can be dangerous. In other methods, a mixture of nitric acid and hydrochloric acid is used to separate the gold from the impurities, and then it can be washed away with water. At the end of the process, you will find only gold and water, and it will be 99.99 percent pure gold. After drying this, you will get gold powder; however, this process won’t work if there is a large amount of silver present.

At what heat does jewelry melt?

The jewelry will melt depending on the jewelry material. If the jewelry is made from gold, then it will take a high amount of heat to melt it. Because gold has the highest melting point, it means it will take very high heat to melt, that is 1943 degrees Fahrenheit or 1064 degrees Celsius. So if the jewelry is made from silver, then it will take less amount of heat to melt, that is 961.8 degrees Celsius.

What flux do you use to melt gold jewelry?

Manganese dioxide is the best flux for melting or refining gold jewelry, and it can be used as a flux to melt other precious materials as well. Assay potassium carbonate can also be used to melt gold jewelry.

What is the process of smelting jewelry?

The smelting of jewelry can be done with a high amount of temperature. Smelting is a method to get rid of impurities by applying heat in order to extract the base metal. The smelting of jewelry is done by using heat, high pressure, and different types of chemicals to melt and break the ore and separate the impurities.

What is the best way to melt gold?

The best way to melt gold is to heat it at a high temperature, and the temperature must be 1064 degrees Celsius; that is the melting point of the gold. A crucible container is specially made to hold gold because it can withstand extreme heat, and a crucible is made from carbon clay. Another way to melt gold is with an electric furnace. An electric furnace is designed to melt metals like gold and silver. The electric furnace is easy and simple to use. You can also use a propane torch to melt gold, but you need to extremely careful with it. But with the help of a torch, you will be able to melt gold within few minutes.

How fast can gold jewelry melt?

It depends on the melting process you are applying. As gold needs so much amount to reach its melting point, that is 1948 degrees Fahrenheit, and that is why it needs some time to melt. If you are applying a high amount of heat, then it will take few minutes, or it can go up to 7-8 minutes. With the help of an induction furnace, your gold jewelry will melt in less time.

Where can I get my gold melted down?

You can melt down your gold at any shop that offers this service. Also, you can melt it at your home easily. With the advancement of technology, there are many gold melting machines available that can help you to melt down your gold. An electric furnace is an example of it. You can also melt gold with the help of a gold melting pot kit in your home.

Can you melt off gold plating?

Yes, you can melt the gold plating, and it needs less temperature than melting gold jewelry. The temperature required is 710 to 787 degrees Fahrenheit. Nowadays, much fake gold jewelry is available using gold plating, and with time their color fades away.

What temperature can the induction melting furnace reach?

An induction melting furnace is an electrical furnace that generates heat when power is supplied to it. There are various types of induction furnaces available, depending on the need. The induction melting furnace is often used to melt metal, and it doesn’t have a limit to the temperature. But the materials that are melted have a limitation. The highest temperature reached in open-air is about 3300 degrees Fahrenheit.

What is the difference between an electric arc furnace and an induction furnace?

Electric arc furnace produces arc heating through graphite electrode, and the heat is generated from electrode discharge. The temperature of the arc is above 3000 degrees Celsius, and it offers high melting speed and high production efficiency. Apart from that electric arc furnace needs a small area, and it is an energy-saving option. The electric arc furnace is environmentally friendly as well, and the temperature is easy to control. At the same time, an induction furnace is an electric heating machine that needs electricity to generate heat. When the AC current passes through the sensor, then the electric energy transfers into heat energy in the surface area. An induction furnace gives faster heating than an arc furnace.

How do you know if it is real gold?

Gold is often available in the market, and it is mixed with impurities. But there are some ways to find out if the gold is real or not. You can look Fri the hallmark to know the percentage of gold an item consists of, and the hallmark is often printed on the jewelry. You can see the karate from 0 to 24, and less than ten karat gold is considered fake gold. Make sure to use a magnifying glass to see the hallmark. Also, you can find if any discoloration or color problems, and if you see any type of discoloration, then it is a fake hold. Real gold gives a shiny color. Also, you can rub the jewelry against your clothe or skin to test its purity.

Conclusion

Advanced technology has made everything easy, and nowadays, jewelry melting has become an easy and simple process. In the traditional methods, jewelry melting was complicated, and it involved risk. By now, with the help of jewelry melting equipment, you will be able to melt jewelry without any trouble. When you are going to buy a jewelry melting machine, be sure about the needs, size and Capacity.

Talk with the dealer, and understand the complete process, then decide which one to buy. If you are buying for business use, then buy as per your requirement. There are many types of jewelry melting equipment available in the market, so choose the best-suited one as per your requirement.

The machine has an omnidirectional warning system that can ensure a safe and secure melting process. This system has been incorporated to prevent any kind of malfunction or disruption due to over-heating, shortage of water, etc. You can melt any metal only within 20 to 30 minutes with the help of the melting furnace.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited