Jewellery Manufacturing Machines

SuperbMelt offers a range of product assembly line equipment (jewelry, coins, necklaces, rings)

Professional Production Line Machinery Solutions for Jewelry, Coins, and Rings

SuperbMelt offers a range of product manufacturing equipment that covers the production of various items, including jewelry, rings, necklaces, and coins.

Whether you are a gold prospector, a small to medium-sized jewelry business, or a new jewelry entrepreneur, we have professional training programs to help you address all your product manufacturing needs.

SuperbMelt specializes in jewelry manufacturing machines and coin production equipment, with highly specialized equipment and a professional training team.

Throughout the jewelry and coin industry, SuperbMelt provides top-notch production equipment and an after-sales team to assist you in bulk production.

SuperbMelt ring, necklace, coin production line equipment

Ring production line equipment

SuperbMelt employs a precise and innovative process for crafting exquisite jewelry rings. This involves the use of specialized machinery, each serving a crucial purpose in the production line:

3D Jewelry Scanner: Our 3D scanner captures intricate design details and the ring’s shape with exceptional precision. This technology ensures that even the most complex and intricate designs are accurately replicated.

3D Wax Printer: The 3D wax printer takes the digital designs and turns them into tangible wax models. This step is vital for ensuring that the design’s intricate details are accurately translated to the physical model.

Plaster Mixer: The plaster mixer is used to create a precise and durable mold for casting. It ensures that the mold material is thoroughly mixed and free of air bubbles, which is crucial for creating high-quality rings.

Wax Burner: The wax burner is essential for creating the wax models of the rings. It allows us to mold and shape the wax to form the basis for the final ring.

Casting Machine: The casting machine is where the magic happens. It’s used to pour molten metal into the plaster mold created earlier. This process allows us to transform the wax model into a stunning, solid metal ring.

These machines collectively form the backbone of our jewelry manufacturing process. They enable us to seamlessly transform digital designs into tangible, beautiful jewelry pieces, ensuring precision, accuracy, and quality at every step of the way. The result? Exquisite rings that meet the highest standards of craftsmanship and artistry.

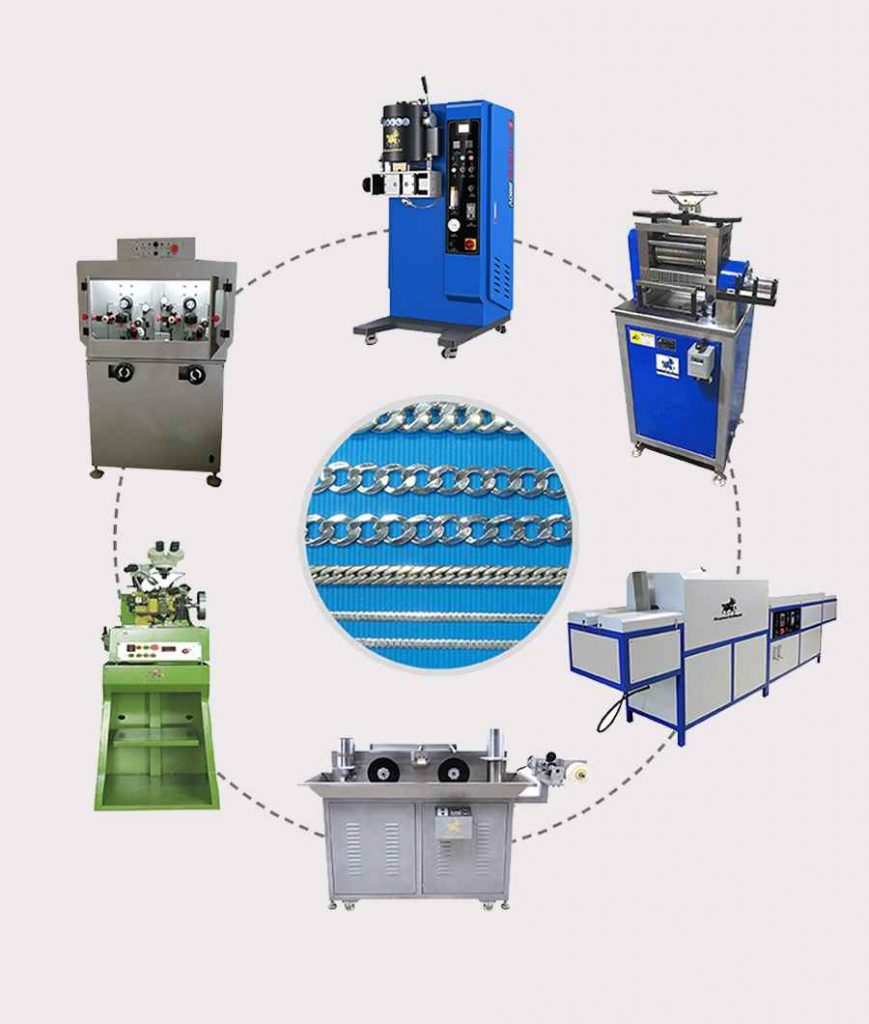

Necklace Production Line Equipment

At SuperbMelt, we employ a highly precise and innovative process to craft exquisite jewelry necklaces. This process relies on specialized machinery, with each machine playing a crucial role in our production line:

Vertical Continuous Casting Machine: The continuous casting machine is used to inject molten metal material into specific-shaped continuous casting billets for subsequent processing. It serves as the starting point for necklace manufacturing, ensuring the purity and uniformity of the metal.

Hydraulic Press: The hydraulic press is employed to compress the continuous casting billets into the desired shape and size. This step is vital to ensure the accuracy and durability of the metal portion of the necklace.

Wire Drawing Machine: The wire drawing machine is used to draw the metal billets into wires of the required diameter and texture. This is a critical component of necklace chains, demanding high precision.

Annealing Furnace: The annealing furnace is used to heat and cool metal wires, enhancing their ductility and malleability. This is crucial for bending and shaping the necklace.

Chain-Making Machine: The chain-making machine shapes the metal wires into the intricate details and structures that form the necklace chain. It’s the final step in creating the necklace, ensuring uniformity and quality.

These machines collectively form the backbone of our jewelry necklace manufacturing process. They guarantee the accuracy, durability, and aesthetics of the metal portion, resulting in high-quality jewelry necklaces. Each machine plays a critical role in different stages of manufacturing, ensuring the final product is both exquisite and long-lasting.

Coin Production Line Equipment

SuperbMelt employs a range of specialized machines, each playing a crucial role in coin manufacturing, to create stunning coins or colored coins:

Vertical Continuous Casting Machine: The continuous casting machine is used to melt high-quality metal material and inject it into molds of specific shapes, forming the foundation of the coins. This ensures that the metal part of the coin possesses outstanding quality and uniformity.

Hydraulic Press: The hydraulic press is employed to compress metal billets into the required shape and size for coins. This step is vital to ensure the accuracy and durability of the coins.

Embossing Machine or UV Printer: The embossing machine is used to add intricate designs and patterns to the surface of the coins, while the UV printer is utilized for coloring. Both contribute to giving the coins a unique appearance and character.

Annealing Furnace: The annealing furnace is used to heat the coins to increase their toughness and ductility. This is crucial to ensure that the texture and shape of the coins meet requirements.

These machines work in close coordination, forming the core of the coin manufacturing process. They guarantee the quality and accuracy of the metal part of the coins and imbue them with a distinctive appearance and value. Whether producing standard coins or colored ones, each machine plays a pivotal role at different stages of manufacturing, ensuring the final coins are both exquisite and durable.

Creating Excellence in Jewellery Manufacturing Equipment with SuperbMelt

We at SuperbMelt are experts in designing finely built jewellery making equipment. Our equipment is made to meet the wide range of requirements of the jewellery business, from making magnificent coins to creating exquisite necklaces and rings.

For the creation of necklaces, our cutting-edge machinery guarantees the highest standards of quality and accuracy. We provide a wide selection of jewellery manufacturing equipment to make necklaces that are both attractive and strong, ranging from continuous casting machines to wire drawing machines.

Rings: Exquisite precision is needed to create elaborate and personalised rings. Each ring manufactured by SuperbMelt is guaranteed to exceed the greatest levels of craftsmanship and creativity thanks to the company’s equipment, which includes 3D jewellery scanners and casting machines.

Coins: Accuracy and quality are critical while producing coins. We have the tools necessary to create genuinely remarkable standard and coloured coins, including hydraulic presses, embossing equipment, and UV printers.

Customise Your Production Line: We are aware that every jeweller has specific needs. Because of this, we give you the option to modify your production line to suit your unique requirements. If you want to create necklaces, rings, or coins, SuperbMelt has the know-how and equipment to make it happen.

Experience the difference in quality, accuracy, and personalization when you choose SuperbMelt for your jewellery making equipment. With our cutting-edge technology and unrivalled industry knowledge, take your jewellery creation to new heights.

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited