Investment Casting Kit

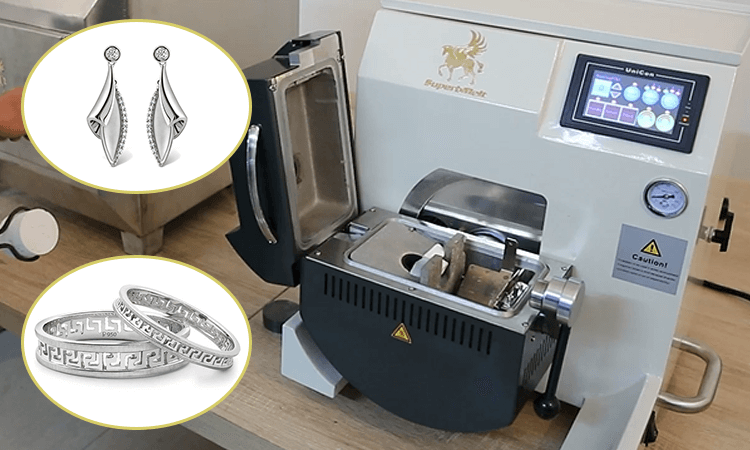

Leading Jewelry Investment Casting Kit Manufacturer of Vacuum Pressurized Jewelry Casting (SPB-MVC150)

Superbmelt investment casting kit is specifically designed for casting up to 300g of precious metals. Metals such as gold, silver, platinum and palladium can be cast with the Superbmelt vacuum casting kit.

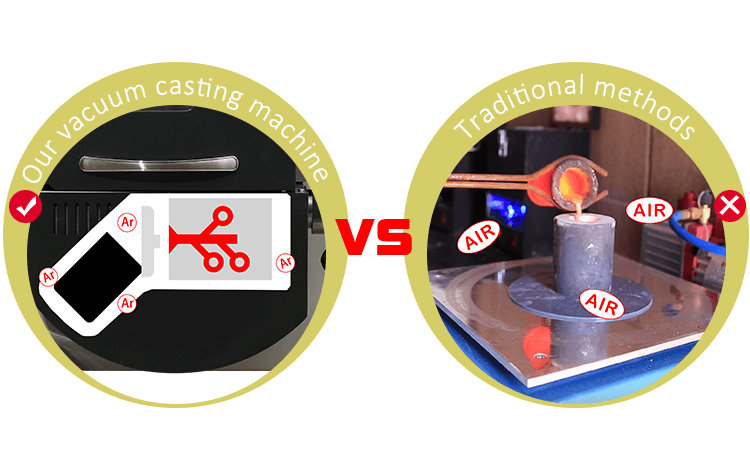

Superbmelt casting equipment for sale melts and casts metals at a temperature of 2600 degrees celsius under vacuum. The pressurized inert vacuum gases prevent shrinkage, oxidation and porosity of precious metals.

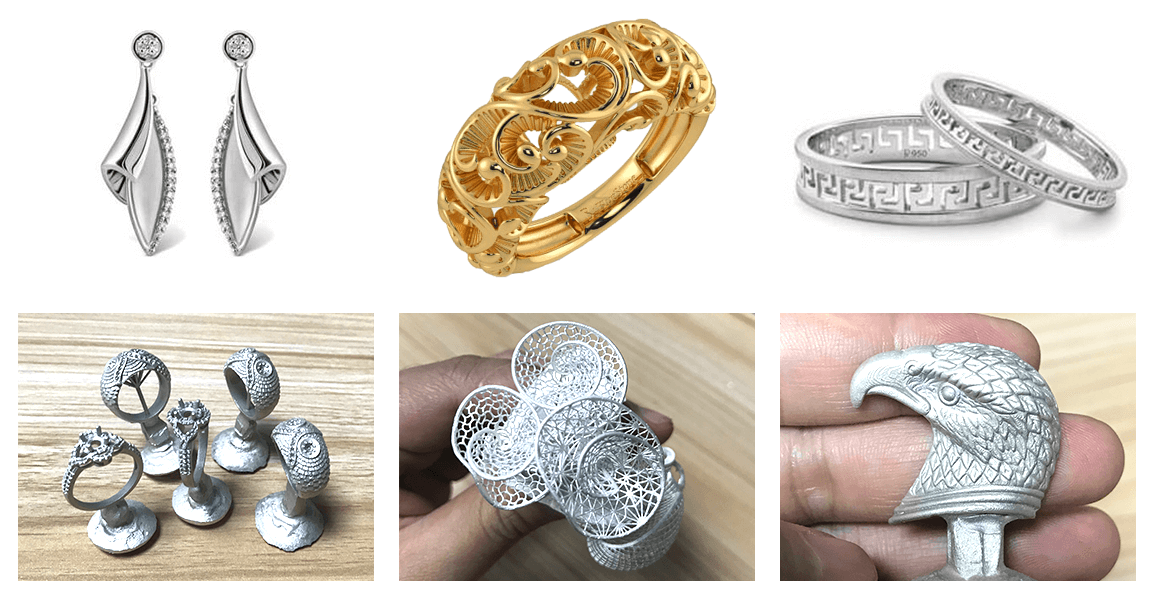

Superbmelt jewellery casting equipment is used to cast high-quality and long-lasting in the jewellery making industry.

We at Superbmelt provide highly efficient lost wax casting machines for a cost and time-saving jewellery production process.

- Superbmelt investment casting machine is suitable for casting 300g of precious metals such as gold, silver, platinum and palladium.

- The lost wax casting has a maximum melting temperature of 2600 suitable for casting high-temperature metals such as platinum and palladium.

- Superbmelt vacuum casting machine has an automatic PLC control system that automates the casting process for ease of use.

- The lost wax casting machine saves time and cost of jewellery production. Melting and casting are complete in approximately 6 minutes.

- Superbmelt vacuum casting equipment makes use of induction heating for melting which helps to save power consumption and prevent energy wastage.

- The maximum power required by Superbmelt lost wax casting starter kit is 4.5kw. This saves up to 30% of energy use compared to other methods of casting.

- The 220V power requirement makes the vacuum jewellery casting equipment easy to cast gold, silver, copper, steel, platinum and palladium.

- Superbmelt investment casting machine is equipped with a water cooling unit that helps the vacuum machine maintain its melting temperature and allows you to melt continuously for long hours.

- Superbmelt jewellery casting machine has an automatic flip function that ensures the investment flask is filled with molten metal for an efficient casting process.

- The pressurized atmosphere used by Superbmelt lost wax casting machine is argon, which ensures cast items have no porosity or shrinkage.

- Superbmelt mini jewellery casting kit makes use of quartz crucible which is durable and able to withstand extreme melting temperatures for an efficient casting process.

Mini jewelry casting machine parameter

| Model | SPB-MVC150 |

| Power Requirement | 220V |

| Power Consumption | 4.5kw |

| Maximum Temperature | 2600 ℃ |

| Melting Method | Induction Heating |

| Capacity | 300g Gold, platinum or 150g silver |

| Application | Gold, silver, platinum, palladium, steel, copper |

| Control System | PLC |

| Melting Time | 5-6mins |

| Gas Pressure | Max. 3.5 MPa |

| Pressurized Atmosphere | Argon |

| Ultimate vacuum | -0.1 MPa |

| Type of Crucibles | Quartz crucible |

| Cooling System | Water cooling |

| vacuum pump | built-in |

| automatic vacuum function | Y |

| Flip function | Automatic flip and vacuum casting |

Mini vacuum investment powder mixer parameter

| Model | SPB-MIPM1 |

| Power source | 220V |

| Power | 350w |

| Dimension | 540*510*390mm |

| Weight | 18kg |

Mini wax burnout furnace parameter

| Model | SPB-MWF1 |

| Power source | 220V |

| Power | 5kw |

| Chamber size | 300*200*120mm |

| Max Temperature | 1200 ℃ |

| Weight | 60kg |

2 years warranty

The warranty for our machine is one year longer than the warranty provided by other factories.

Strong service team

We will give response within 24 hours against your problem by our professional engineer.

Why SuperbMelt Investment Casting Kit

Any Question About SuperbMelt Vacuum Investment Casting Kit

FAQ Guide of Investment Casting Kit

Would you like to learn more about investment casting machine and other related topics? Then you need to go through this comprehensive guide. To make the points easier for you, we have answered some of the most frequently asked options by our customers.

Remember, at Superbmelt, we understand that you need to make the best decisions based on accurate information. As such, go through this piece and let us know if you need any sort of clarification. Our support team will accord you the best assistance possible.

The other thing you should take note of is that our investment casting kit does not consume a lot of power, gets the work done as fast as possible, and you will have the best user experience. Now keep reading this post in its entirety to learn more.

- 1. What is lost wax investment casting?

- 2. What are the different types of casting process?

- 3. What happens in the vacuum chamber?

- 4. What are the advantages of investment casting?

- 5. What tools or materials do we need for jewelry casting process?

- 6. What is a jewelry wax made of?

- 7. How is vacuum casting method different from centrifugal casting method?

- 8. What is investment casting used for?

- 9. 9. What kind of wax is used in investment casting?

- 10. What would be considered an advantage of investment casting?

- 11. How long does the platinum casting process take?

- 12. What do you mean by investment casting machine?

- 13. What is the temperature for platinum casting?

- 14. Are there risks involved in platinum casting? How can I avoid them?

- 15. How do you cast jewelry?

1. What is lost wax investment casting?

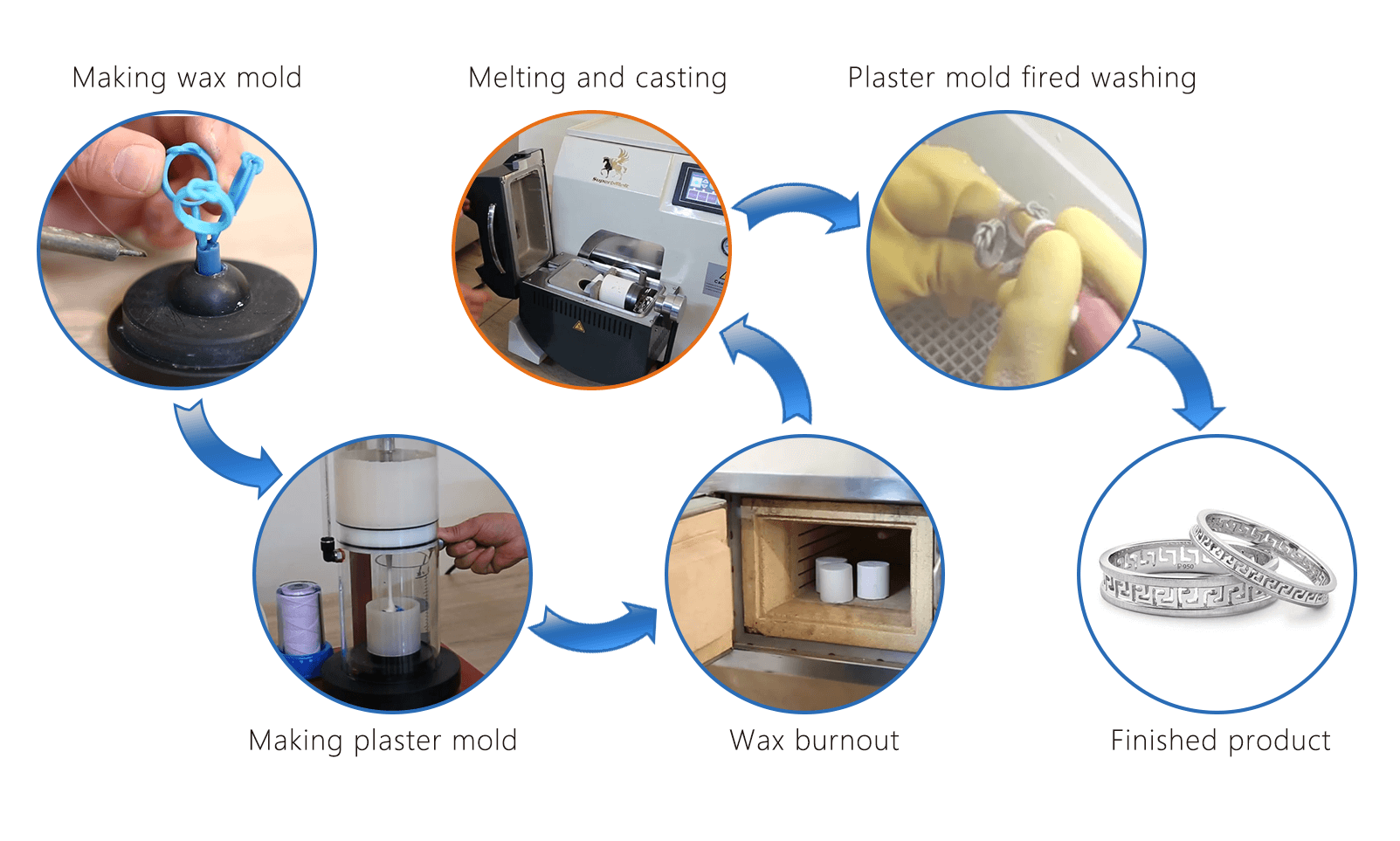

Before casting any jewelry or dental, you must have a wax model, which can be obtained through a 3D printer or traditional wax model making methods. In either case, the wax model determines the casting result. Next, we put the wax molds together to make a small wax tree. Of course, we cannot allow any wax mold to touch, make full use of the casting space and make high-efficiency production.

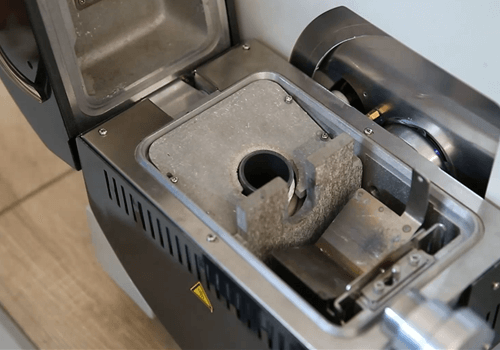

We put the wax tree in a container and then we can start producing plaster. At this time, we use a vacuum shaker. Under vacuum conditions, the formation of bubbles in the plaster affecting the casting is avoided, and the plaster is filled into the mold. Put the formed plaster mold in a high temperature baking wax oven, so that the wax melts and discharges. The next most important step is to use our mini casting vacuum casting machine, which is a combination of melting and casting, and everything is done under vacuum.

After installing the machine, put the gold into the dry pan, put the plaster mold in the same position, close the lid and start to melt. After the casting is completed, remove the plaster mold, clean the finished product in a sandblasting room, and go through a series of processes such as polishing and polishing. The exquisite jewelry is presented to you.

The SuperbMelt Mini Vacuum Pressurized Jewelry Casting Kit is designed to cast the largest. 300 grams of precious metals and dental metals; the highest temperature can reach 2600℃, suitable for the casting of gold, platinum, palladium and silver; this machine is specially designed for small batch jewelry casting, jewelry sample making, dental casting and some DIY precious metal casting; plus Pressure and vacuum casting ensure that castings are free of porosity and shrinkage; inert gas protection to prevent oxidation of precious metals; PLC control and automatic casting machine functions make manual casting operations more convenient and reduce failures. Any precision jewelry and metal artwork can be perfectly produced using Superbmelt vacuum pressure casting machine. We also provide a complete one-year warranty and on-site training services worldwide.

2. What are the different types of casting process?

Casting is a process that can be done in a wide range of ways. The method you choose to use determines what you end up with.

First, we have the sand casting which is the process one can used to produce sand molds. Sand casting might be a great choice for those looking to produce iron, sheet, and many other nonferrous alloy castings.

Next, we have what is known as the investment casting. With this method, you will need to make some patterns in a fusible material. You will cover the surface of the pattern with many layers of refractory materials.

We also have die casting. This one involves the use of high-pressure metal liquid by pressing it into a precision metal cavity at a very high speed. The metal liquid will then be cooled and solidified under extremely high pressure to form the casting.

There are many other types of casting like low-pressure casting, centrifugal casting, gravity die casting, and on the list goes.

3. What happens in the vacuum chamber?

The vacuum chamber might seem like a complicated place, but that is not what it really is. In this chamber the machine will suck out all the metal into the mold. Note that there is a need for enough force to resist the surface tension of your molten metal.

Unless that is done, your molten metal will just stay there because it will turn into a blob. In the vacuum chamber, there is adequate steady pressure to help you achieve the bottom line without breaking a sweat.

The molten metal is also placed in the vacuum chamber to make sure that there is no air bubbles on the inside. If the air bubbles are not gotten rid of, you will not end up with a product of the best quality.

4. What are the advantages of investment casting?

Investment casting comes with so many benefits. We will look at some of them in pros form. The first and main advantage of investment casting is that the design is highly versatile. You can cast your design in almost any shape that comes to mind.

Versatility of alloy selection is the next reason you should consider using the investment casting method and our investment casting kit. Did you know that you can cast all alloy bases such as nickel, aluminum, cobalt, and copper using investment casting? These alloys are mostly so hard to machine, which is why you should handle them with the help of investment casting.

Investment casting generally has a wide range of applications and comes with tight tolerances. Note that these are some of the many reasons you should consider investment casting.

5. What tools or materials do we need for jewelry casting process?

There are so many things you might want to make as a jeweler. If you would like to invest in this lucrative business, you might want to invest in these tools and materials;

- Flat nose pliers

- Round nose pliers

- Nylon tipped pliers

- Wire cutters

- Titanium alloy,

- Gray iron,

- Aluminum alloy,

- Steel,

- Copper and Zinc

There are other materials like practice material, ruler, disk punch, jeweler’s saw, and many more. Do not forget to invest in wire. Wires are highly versatile, so you need to know what exactly you need to invest in. We have aluminum, rose gold, gold-filled.

Best of all, once you have decided to become one of the best jewelers in the industry, it is vital to make good use of your imagination. If you can make outstanding items at all times, breaking through the market will become one of the easiest things.

Aside from investment casting kit, it is important to always have a lubricant when using a jeweler’s saw. That is the only sure way to keep your fingers safe when doing your thing. Also, the lubricant will ensure that the blades don’t break and that the cutting edge is also preserved.

But again, you don’t have to finish the product on your own due to the level of quality demanded by modern clients, and the fact that there are so many risks involved.

If you try to complete the process on your own, you might start the work, only to learn that you do not have everything that is needed. But since we are specialists, you will never feel disappointed if you let us do the work for you with our investment casting kit and other materials.

The safety standards and regulations are also up to par. As such, you don’t have to risk hurting yourself when our duty is to help you as you focus on other essential aspects of your business.

6. What is a jewelry wax made of?

You will need resin to make your jewelry wax with the help of investment casting kit. This is not a material that is very hard to find. But if you need help finding something of the best quality, do not hesitate to get in touch with Superbmelt. We have trusted dealers globally and we can help you get in touch with some of them.

7. How is vacuum casting method different from centrifugal casting method?

The difference between vacuum casting method and centrifugal casting method is not slight. Unless you are a newbie in the industry, you won’t notice the obvious difference that centrifugal casting method is a technique that is used to produce pipes while the vacuum casting method is used to produce other materials.

In centrifugal casting method, molten metal is poured into a cylindrical mold that spins rapidly. It is the same force of rotation that subjects pressure on your molten metal to provide the desired results.

In a nutshell, it is accurate to state that vacuum casting is a process meant for the elastomers, and you can complete the process with our investment casting kit. The vacuum is needed to draw the molten metal into the mold to give you the desired shape or product.

Many experts will say to you that vacuum casting becomes the best method whenever there is an entrapment problem. While that is true, you might also have many other valid reasons to employ vacuum casting technique.

There is also a huge difference between the machine used for vacuum casting, and the one you will need for centrifugal casting. Your centrifugal machine will make use of the weight of the molten metal as well as the centrifugal force available.

A vacuum casting machine, on the other hand, will use a vacuum to suck your molten metal into the available mold. There is the need of a force to help counter the surface tension of your molten metal.

We wouldn’t wish for you to forget that the vacuum casting method is currently the best, which is why you should give our investment casting kit a shot. It leverages the latest technology to give you the perfect finished products you and your clients deserve. If you would like to learn about and benefits of our kit, be sure to check out our main websites and the “Machines” tab.

8. What is investment casting used for?

The process of investment casting can be useful during applications such as making jewelry, precision parts, etc.

Investment casting is a process that comes in handy when you need to make complex-shaped materials that also need tighter tolerances, better surface finishes, and thinner walls that you can get with the help of sand casting.

The thing that makes investment casting stand out from the crowd is the manner in which the mold is created. Some parts of the pattern are made using wax, and then the wax is immersed into a super-fine ceramic.

In the ceramic slurry, there is an alumina and colloidal silica. From there, you will have the mold dried and heated right inside an oven so that the wax melts out to give you a ceramic shell mold that you will then use for casting in our investment casting kit.

Investment casting technique can also be termed as the lost wax process. That name comes from the fact that to complete the process, you will have to melt and get rid of the wax. If you are not sure how to complete this method, we can help you come up with the best parts for your operations.

9. What kind of wax is used in investment casting?

With the help of technology, manufacturers can use a range of methods to craft complex parts of machines and many other things. Investment casting is an old method, but is still used to date. It is a process that involves coming up with a component out of a wax.

Here are some of the waxes you can use in investment casting to create various parts.

Primarily, there are two types of wax you can use to complete this process; they include castable resin and non-castable resin. These are the general types of wax you should always consider using for your lost wax investment casting.

10. What would be considered an advantage of investment casting?

This lost wax casting equipment is designed for casting only small quantity of precious metals (within 300g). It is designed very simple; leaving room for a DIY casting.

This product comes with an inbuilt vacuum pump as compared with other castings kits in the market which doesn’t always come with a vacuum pump.

The automatic intelligent Simen control system (PLC) makes your whole casting process very safe seamless.

The vacuum casting machine automatically stop the machine when an error is detected.

This product is designed fully automated. Both your melting and casting chambers can be flipped automatically during operation. This feature saves you more money it terms of manpower needed to handle your casting operations.

The precious metal casting equipment can cast any of your precious metals in the shortest amount of time possible. This machine is capable of reaching your metal casting temperature (max. temp of 2600℃) in split seconds by a 4.5Kw induction generator

The furnace powerful inbuilt generator speeds up your production process coupled with savings in utility for power consumed

11. How long does the platinum casting process take?

The platinum casting process should be ready in a matter of two weeks.

supposed to protect yourself from when dealing with platinum casting. First the ultraviolet rays will be emitted and they might damage our eyes. As such, you need to have eye protection whenever you are dealing with platinum.

You are also supposed to use lenses that are approved by the department of health. You must never use regular lenses or dark lenses because they will never protect your eyes from ultraviolet rays. If you don’t know the right glasses to use, be sure to get in touch with some jewelry suppliers.

12. What do you mean by investment casting machine?

An investment casting machine/kit is the gadget you use to ensure that you get enough pressure or heat to cast your investment without any problem. It should come with an oven where the heating and letting of the wax takes place.

Our jewelry casting machine is a perfect example of a casting machine you should consider using. If you would like to learn more, see the features of our investment casting kit and you will get the gist of what we are talking about.

SuperbMelt vacuum jewelry casting kit (SPB-MVC150) is a top-quality product that is specifically designed to hold metals whose weight do not exceed 300g gold, platinum or 150g silver.

The mini vacuum metal casting machine comes with a quartz and an inbuilt furnace. It is capable of heating up to a maximum temp of 2600℃. The above features makes this product suitable for casting tough metals such as gold, platinum, palladium and silver. etc.

Jewelry casting kit (SPB-MVC150) is equipped with a gas chamber. The gas chamber that releases pressurized inert gases which completely eliminate any form of porosity and oxidation during the casting process. This feature that gives your final cast the touch of class and a feel of quality.

13. What is the temperature for platinum casting?

There is no standard temperature for platinum casting. However, when you begin to cast, you will need a temperature that ranges between 3362 Fahrenheit and 3392 Fahrenheit. Before you begin working, you want to make sure that your machine can produce enough temperature to let you do the work without any hiccups.

Note that you will need the torch to melt your metal and get it into it molten state. For a long time, platinum has proven to be one of the trickiest materials for casters. The truth is, you will struggle to cast it.

Platinum is a very reactive material, which explains why it is also hard to cast. Most of the time, you will notice that it reacts with the crucible.

14. Are there risks involved in platinum casting? How can I avoid them?

There are so many things you are supposed to protect yourself from when dealing with platinum casting. First the ultraviolet rays will be emitted and they might damage our eyes. As such, you need to have eye protection whenever you are dealing with platinum.

You are also supposed to use lenses that are approved by the department of health. You must never use regular lenses or dark lenses because they will never protect your eyes from ultraviolet rays. If you don’t know the right glasses to use, be sure to get in touch with some jewelry suppliers.

15. How do you cast jewelry?

Before using the investment casting kit, the first step is to make your wax mold. You will need a 3D printing machine to make your wax mold. The machine can also help you print the design drawings. The second step involves making the cast plaster. To complete this step, you will need a gypsum powder mixer to help you come up with the plaster moulds that you will use for the jewelry casting.

You should have your burnout plaster mould. You will need it to melt and flow the wax right in the plaster and as well as a plaster mold is obtained.

Now you are ready to commence the melting and casting process. At this stage, you will use the vacuum pressurized casting machine bu customizing it to melt and cast silver, gold, and any other precious metal.

Now the part is ready, but you will need to clean it. Now you need to use the palster cleaning machine to clean the finished product.

Closing Thoughts

Investment casting is a process that comes in handy when you need to make complex-shaped materials that also need tighter tolerances, better surface finishes, and thinner walls that you can get with the help of sand casting.

The thing that makes investment casting stand out from the crowd is the manner in which the mold is created. Some parts of the pattern are made using wax, and then the wax is immersed into a super-fine ceramic.

Note that Superbmelt’s investment casting kit is the best thing you can currently find on the market. It comes with a number of important features that will make your company stand out from the crowd. Once you place your order on our website we will do our best to deliver the product as soon as possible to your location.

All users are strongly advised to use the user manual with which the product is delivered. If you have any questions, feel free to book appointments with our agents online or offline. Our mission is to ensure that you have the best experience using our investment casting kit.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited