Electro Polishing Equipment

More Detals of Electro Polishing Equipment

When it comes to achieving flawless, high-quality jewelry, SuperbMelt Electro Polishing Equipment stands as a game-changer for the jewelry industry. This advanced electro polishing machine is designed to deliver 360° corner-to-corner polishing for a perfect, mirror-like finish on every piece. Whether it’s rings, bracelets, or other jewelry pieces, this machine offers precision and efficiency, giving you superior results every time.

Key Features of SuperbMelt Electro Polishing Equipment:

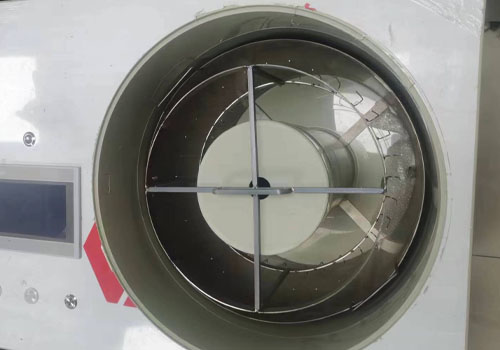

- 360° Polishing: Unlike traditional polishing methods, SuperbMelt’s electro polishing equipment ensures that every surface of the jewelry is polished evenly, without any missed spots or uneven surfaces. The unique design allows for a full-circle, 360° polish that gives a smooth, gleaming finish to every piece.

- High Efficiency: The SuperbMelt electro polishing machine is capable of polishing 20 to 138 jewelry pieces in a single operation, making it ideal for batch production in the jewelry industry. This significantly speeds up the production process while maintaining top-notch quality.

- Wide Compatibility: This machine works perfectly with gold, silver, and copper, giving jewelers the flexibility to polish a wide range of materials. It is highly versatile, catering to various jewelry types, from rings and bracelets to more intricate designs.

- Precision and Consistency: Designed to handle delicate and intricate pieces, the SuperbMelt electro polishing machine ensures consistent results, making sure every piece is polished to perfection.

Cost-Effective Solution: With its ability to handle multiple pieces at once, this machine reduces labor costs, increases production efficiency, and minimizes material waste, ultimately boosting your bottom line.

Get Price of Electro Polishing Equipment

Features of Electro Polishing Equipment

Before and after comparison of jewelry ring polishing: 360° no dead angle polishing, fast speed, good quality.

Each session can hang 20 to 138 pieces of jewelry for electropolishing, thereby increasing production efficiency.

By changing the electrolyte, different metals including gold, silver, copper, and k gold can be polished.

Details of Electro Polishing Equipment

- Jewelry Manufacturing: Excellent for polishing jewelry made of priceless metals like platinum, silver, and gold, such as necklaces, bracelets, earrings, and rings. For processing these goods’ intricate details and complex shapes, electropolishing works particularly well.

- Watchmaking: The process of creating a perfect, smooth surface by polishing the cases and other parts of luxury timepieces.

- Medical Device Manufacturing: Used to polish implants and surgical tools, which have very strict requirements for hygienic standards and surface finish.

- Automotive Industry: Used to polish exterior trim pieces and vital automotive performance components, like exhaust system components, to improve look and performance.

- Electronics Industry: Excellent for enhancing electrical performance and corrosion resistance when polished, precision electronic components include connectors and metal sections of printed circuit boards (PCBs).

- Aerospace Industry: Used to polish metal parts of spacecraft and airplanes to improve corrosion resistance and lower air resistance.

- Manufacturing of Pipes and Valves: Used in the polishing of industrial pipes and valves, which frequently have to endure the strict durability standards of extremely corrosive conditions.

| Model number | SPB-GR3

|

SPB-GR2

|

SPB-GR1

|

| Power supply | AC 220V/DC 0-15V | AC 220V/DC 0-15V | AC 220V/DC 0-15V |

| Power | 1kw Max 50A | 2.3kw Max 150A | 4.5kw Max 300A |

| Machine hook | 20pcs | 60pcs | 138pcs |

| Batch productioncapacity | Silver: 6.5kg Copper:6.5kg K gold:5kg | Silver: 52kg Copper:52kg K gold:40kg | Silver: 97.5kg Copper:97.5kg K gold:75kg |

| Electrolyte capacity | 5L | 40L | 75L |

| Metal electrolyte ratio | Copper: 1.7L electrolyte: 1.3L water Silver: 1.3L electrolyte: 2.6L water K gold: 4L electrolyte (No water) | Copper: 13L electrolyte 26L water Silver: 13L electrolyte: 26L water K gold: 40L electrolyte (no water) | Copper: 25L electrolyte/ 50L water Silver: 25L electrolyte/ 50L water K gold: 75L electrolyte (no water) |

| Size | 465mm*335mm*41mm /28kg | 81mm*1010mm*700mm /70kg | 810mm*600mm*70mm /120kg |

| Abrasive dosage | 3 kg | 15 kg | 25 kg |

| Applicable metal | copper , silver, K gold, (No pure gold, platinum) | copper , silver, K gold, (No pure gold, platinum) | copper , silver, K gold, (No pure gold, platinum) |

- High Capacity Processing: This feature improves batch processing capabilities by processing 20 to 138 pieces of gold, silver, and platinum jewelry, such as bracelets and rings, at once.

- No-Dead-Angle Polishing: Electropolishing technique achieves high-standard polishing results even on intricate designs by precisely polishing all of the jewelry’s corners and intricacies.

- Enhanced Production Efficiency: Compared to conventional methods, the machine’s rapid and effective polishing capabilities save a significant amount of polishing time and increase production.

- Cost Savings: Lowers operating expenses over time by minimizing costs related to material consumption and mechanical wear.

- Environmentally Friendly: Electropolishing has a smaller environmental impact than chemical polishing since it employs fewer hazardous chemicals.

- Widespread Applicability: This product has a variety of uses, including polishing electronic devices and jewelry as well as other precision components.

- Better Product Quality: Particularly in the high-end market, uniform polishing improves the items’ overall appearance and competitive advantage.

Any Question About SuperbMelt Electro Polishing Equipment

Superbmelt’s professional technical team and sales team are at your service

(7/24hours service)

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited