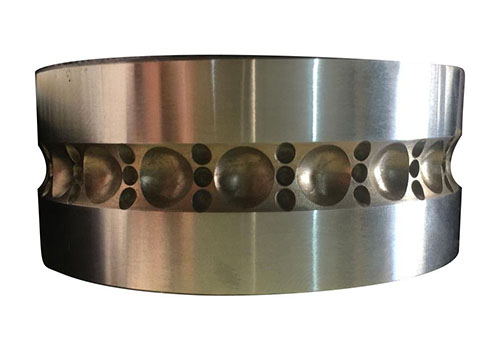

Bangle Grooving Die

SuperbMelt: China Leading Jewelry Mold Manufacturer (Necklaces, Watch Straps, Bangles, etc.)

SuperbMelt Bangle Grooving Die is designed for various shapes, styles, and sizes of bangles, and it can be customized to create grooves based on specific design requirements. By using the bangle grooving die, jewelry makers can incorporate decorative patterns, textures, or text onto the bangles, enhancing their uniqueness and artistic appeal. This facilitates the customization and personalization of bangles, catering to the diverse preferences of consumers in the market.

The Bangle Grooving Die is utilized on SuperbMelt’s automatic hydraulic press for shaping and molding bangles. The use of these dies enables jewelry makers to meet a variety of design needs, assisting them in crafting a diverse range of personalized and unique jewelry pieces.

- Diverse Designs: To satisfy varied jewelry needs, the mold designs accommodate a variety of jewelry kinds, such as bracelets, watchbands, necklaces, and more.

- Extremely Customizable: The molds may be made to fit certain design requirements, enabling the addition of text, textures, and artistic patterns to further enhance the jewelry’s distinctiveness.

- Suitable for all Sizes and Shapes: They provide versatility and a multitude of options, and they may be used on jewelry of all sizes, shapes, and styles.

- High-quality Materials: The molds are dependable instruments for the fabrication of jewelry since they are made with high-quality materials that guarantee their longevity and durability.

- Making a Variety of Jewelry: In order to satisfy consumer demand, jewelry producers employ molds to create a variety of individualized, artistically expressive items.

- Compatibility with Hydraulic Presses: SuperbMelt automated hydraulic presses may be used with certain molds to provide a more productive molding process.

- Jewelry Design and Production: A variety of jewelry pieces, such as necklaces, bracelets, rings, and more, are made using molds. They may provide jewelry a variety of textures, patterns, and forms.

- Personalized Customization: Jewelry designers may build one-of-a-kind items that meet the exact specifications of their clients thanks to molds that accommodate customized patterns.

- Text and ornamental Patterns: Mold designs make it possible to add different text, ornamental patterns, and textures to jewelry, which enhances its originality and artistic expression.

- Enhanced Production Efficiency: Certain molds may be used with automated machinery, including hydraulic presses, which helps to ensure that high-quality jewelry is made while also increasing production efficiency.

- Application to Different Materials: Molds are appropriate for a variety of jewelry production processes since they can be utilized with a wide range of materials, including metals and alloys.

Why SuperbMelt Bangle Grooving Die

Any Question About SuperbMelt Bangle Grooving Die

About SuperbMelt Bangle Grooving Die Guide

Die

1.1, How are Dies made?

In the field of jewelry manufacturing, molds are specialized tools designed and crafted for shaping, molding, and cutting the raw materials of jewelry. These molds are typically made of sturdy materials such as metal or hard alloys and are shaped and sized according to the designer’s specifications. The purpose of jewelry molds is to impart specific appearances, textures, and shapes to the jewelry during the manufacturing process, ensuring that the final products meet the design requirements. These molds can include various types, such as molds for rings, necklaces, bracelets, and more, each contributing to the creation of unique and market-demanding jewelry pieces.

1.2, What is the purpose of Dies?

Dies are used to cut, shape, or mold materials into desired patterns or forms. Die sets are specialized instruments used in the jewelry production process to shape and mold jewelry components. They are frequently constructed of metal or other sturdy materials. A typical association of the term “dies” is with the production of metal pieces by means of stamping, forging, or extrusion.

Diets, also known as molds, are essential tools used in the jewelry industry to create the precise forms and patterns needed for different jewelry items. For instance, a ring die may assist in forming the precise shape of a ring, while a bangle grooving die can be used to produce complex patterns on a bracelet. Die sets ensure that every component is manufactured with uniformity and accuracy, meeting design requirements.

In conclusion, dies are instruments that aid in the accuracy and repeatability of material shaping. They are particularly crucial in the jewelry industry for producing the unique and intricate details seen in various pieces.

1.3, Why do jewelry need Dies?

- Shape and Form: The unique shape and form of jewelry is achieved by the use of dies. Dies assist in forming the raw materials into the appropriate configurations for jewelry of any kind, including rings, necklaces, bracelets, and other items.

- Pattern & Design: In order to create complex patterns, designs, and textures on jewelry, dies are essential. They boost the visual attractiveness of jewelry by enabling designers to incorporate distinctive and intricate details.

- Consistency: Die sets guarantee uniformity throughout the production process. Jewelry producers can create several pieces with the same form and design by employing standardized dies, which helps them keep their product quality constant.

- Efficiency: The production process is streamlined when dies are used. Die-cutting machines make it possible to produce jewelry in larger quantities more quickly and effectively than by hand, shaping each piece individually.

- accuracy: Jewelry manufacturers may create complicated patterns and precise details because to the high level of accuracy provided by dies. When crafting intricate and refined objects, this accuracy is especially crucial.

- Reproducibility: Die sets enable the repeated production of particular designs. This is essential for designing jewelry collections and completing bulk orders with reliable quality.

Benefits of Jewelry Dies

There are several advantages to using jewelry dies in the production process

- Uniformity and consistency in the forms and patterns of the items are guaranteed by jewelry dies. This is essential to preserving a high standard of quality throughout a jewelry line or collection.

- Efficiency: The production process is streamlined and expedited by the use of dies. This is particularly crucial for mass-producing jewelry goods and satisfying high demand.

- Precision: Dies make it possible to create elaborate patterns and fine details. Jewelry artisans are able to create exquisite textures and patterns, which enhance the objects’ overall beauty.

- Reproducibility: Accurate replication of jewelry designs is possible with dies. This is necessary whether you’re making several items for a huge order or a particular collection so that they all have the same shapes and designs.

- Customization: Die sets may be tailored to provide distinctive and personalized designs in addition to providing uniformity. This adaptability enables jewelry manufacturers to satisfy a wide range of client tastes.

- Time and Money Savings: Using dies cuts down on human labor, which results in time and money savings for the production process. Additionally, it reduces material waste, which raises the total cost-effectiveness.

- Versatility: Jewelry dies may be made to fit a wide range of jewelry pieces, such as bracelets, necklaces, rings, and more. Their adaptability to many forms and styles stems from their flexibility.

- Pattern Creation: On jewelry surfaces, dies are used to create precise patterns and textures. This talent improves the final items’ aesthetic attractiveness.

Conclusion

A vital component of jewelry production is the SuperbMelt Bangle Grooving Die, which gives jewelry designers the ability to create intricately detailed and highly individualized items. This die may be adjusted to create unique textures, patterns, and text to improve the creative and distinctive quality of bangles. It is not only suitable to a variety of forms, styles, and sizes of bangles. Jewelry designers may personalize and customize bangles with the Bangle Grooving Die, meeting a variety of customer requests in the market.

The die’s merits are found in its varied design, high degree of customisation, suitability for bangles of various sizes and shapes, and use of premium materials that guarantee lifespan and durability. It fulfills a variety of design requirements and improves production efficiency when combined with SuperbMelt’s automated hydraulic press.

In conclusion, the SuperbMelt Bangle Grooving Die, with its excellent design and material quality, not only adds originality and creativity to the jewelry-making process, but it also gives jewelry manufacturers dependable and effective production equipment. This die gives each item of jewelry the ability to display a distinct creative appeal because to its variety of forms, styles, and patterns.

FAQ Guide of Bangle Grooving Die

- 1. What is Bangle Grooving Die?

- 2. Which types of bracelets does SuperbMelt's Bangle Grooving Die cater to?

- 3. How can this mold be customized for patterns on bracelets?

- 4. Does using Bangle Grooving Die enhance the uniqueness of bracelets?

- 5. How does SuperbMelt's Bangle Grooving Die ensure the quality of crafted bracelets?

- 6. How does the Bangle Grooving Die collaborate with hydraulic presses?

- 7. Which types of metals or alloys is this mold suitable for?

- 8. How does SuperbMelt's Bangle Grooving Die maintain consistency in bracelet production?

- 9. Does the Bangle Grooving Die support diverse designs in bracelet making?

- 10. How to clean and maintain the Bangle Grooving Die to ensure performance?

1. What is Bangle Grooving Die?

Bangle Grooving Die is a specialized mold designed for bracelet manufacturing, used to create various shapes and styles of bangles.

2. Which types of bracelets does SuperbMelt's Bangle Grooving Die cater to?

SuperbMelt’s Bangle Grooving Die is suitable for bangles of various shapes, styles, and sizes, customizable based on design requirements.

3. How can this mold be customized for patterns on bracelets?

The Bangle Grooving Die can be customized to create different grooving patterns, including textures, text, etc., for personalizing bracelets.

4. Does using Bangle Grooving Die enhance the uniqueness of bracelets?

Yes, the Bangle Grooving Die assists makers in creating unique, personalized bracelets, adding to their artistic appeal.

5. How does SuperbMelt's Bangle Grooving Die ensure the quality of crafted bracelets?

SuperbMelt manufactures the Bangle Grooving Die with high-quality materials to ensure durability and precise molding of bracelets.

6. How does the Bangle Grooving Die collaborate with hydraulic presses?

The Bangle Grooving Die can collaborate with SuperbMelt’s automatic hydraulic press to enhance production efficiency and consistency.

7. Which types of metals or alloys is this mold suitable for?

The Bangle Grooving Die is suitable for various metals and alloys, including gold, silver, and other precious metals.

8. How does SuperbMelt's Bangle Grooving Die maintain consistency in bracelet production?

The design and manufacturing of the Bangle Grooving Die are aimed at ensuring each bracelet has the same shape and pattern, maintaining consistency.

9. Does the Bangle Grooving Die support diverse designs in bracelet making?

Yes, the Bangle Grooving Die supports a variety of bracelet designs to meet different market demands.

10. How to clean and maintain the Bangle Grooving Die to ensure performance?

Cleaning the Bangle Grooving Die can be done using appropriate cleaning tools and methods. Regular checks to maintain a smooth mold surface are recommended.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited