Automatic Wire Cutting Machine

SuperbMelt specializes in manufacturing various automated processing equipment for jewelry and craftwork

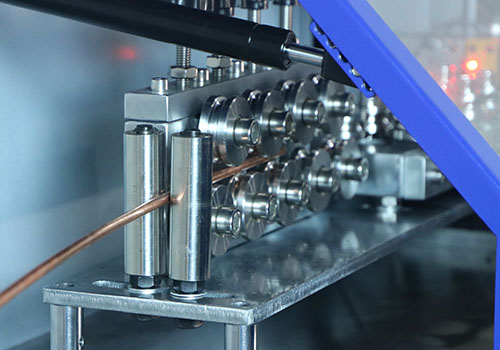

SuperbMelt Automatic Wire Cutting Machine is primarily used for cutting metal wires such as gold, silver, platinum, and aluminum. It is widely employed in industries such as electronics, semiconductor, material research, precious metal processing, and artcraft manufacturing for purposes like evaporation coating, new material development, and crafting.

Automatic Wire Cutting Machine can cut 20-220 segments of metal wires per minute, with diameters ranging from 2-6mm. It boasts highly precise cutting capabilities, allowing for adjustments in cutting length and speed as per specific requirements to address cutting needs effectively.

With its automation features and high efficiency, the Automatic Wire Cutting Machine streamlines production processes, making them more convenient and productive.

- Electronics Industry: Used for cutting and processing wire materials for electronic components, circuit boards, etc.

- Semiconductor Industry: Utilized in the manufacturing and processing of semiconductor devices, including chips, integrated circuits, etc.

- New Material Research: Employed in the research and development of new materials for exploring their properties and applications.

- Precious Metal Processing: Used for processing and handling precious metal materials such as gold, silver, platinum, etc., including jewelry making, financial investment, etc.

- Craftsmanship: Utilized in the production of various crafts and decorative items, such as metal engraving, metal sculpture, etc.

| Model number | SPB-XVS100 |

| Power source | 220V |

| Power | 4 kw |

| Applicable metal | Gold, platinum, silver, copper, aluminum, nickel, titanium and other metals |

| Cut off speed | 50~220 pieces/minute |

| Cut off diameter | Ф2/3/4/5/6mm |

| Length tolerance | plus or minus 0.02mm |

| Cut off length | With positioning 3~50mm/without positioning 3~3000mm |

| Dimension | 1300*690*1440mm |

| Weight | 380KG |

| straightening function | Ф2-6mm |

- Smooth Cutting Edge and Uniform Weight: Each piece has smooth edges and a consistent weight thanks to the accurate and reliable cutting provided by our automatic wire cutting machine.

- Intelligent Control for Simple Operation: Our machine’s sophisticated control systems minimize the learning curve for operators by making machine operation simple and intuitive.

- High Accuracy and Precision with ±0.03 Tolerance: Utilize our device to produce exacting outcomes, guaranteeing that every cut adheres to strict tolerances of ±0.03.

- Quick Speed Up to 200 Cuts per Minute: Increase productivity with our machine’s fast cutting capabilities. It can handle up to 200 cuts per minute, which enables effective mass manufacturing.

- Using automatic feeding features can help you streamline your manufacturing process and provide a fluid workflow by minimizing operator involvement.

- Efficiency-Boosting Straightening Device: Our machine has an integrated straightening device that reduces material distortion and boosts overall cutting efficiency.

Why SuperbMelt Automatic Wire Cutting Machine

Any Question About SuperbMelt Automatic Wire Cutting Machine

Guide to Automatic Wire Cutting Machine

Applications of Automatic Wire Cutting Machine

Automatic Wire Cutting Machine is capable of cutting metal wires into precise segments, which can then be utilized for semiconductor deposition coating through evaporation. Its features include smooth cutting edges, uniform weight distribution, intelligent control for easy operation, high precision with a tolerance of ±0.03, fast cutting speed of up to 200 pieces per minute, automatic feeding, and a straightening device. These capabilities make it suitable for various industries requiring efficient and accurate wire cutting solutions.

1.1, The electronics and semiconductor industry

- Protective Coating: Electronic equipment covered with coating are shielded from moisture, chemicals, and other outside elements. This increases the dependability and lifetime of electrical devices.

- Enhanced Performance: By strengthening an electrical device’s conductivity, wear resistance, or corrosion resistance, coating can make it work better. Electronic gadgets are now more dependable and effective thanks to these advancements.

- Electromagnetic Shielding: Coating is utilized in some electronic applications to offer electromagnetic shielding, preventing external electromagnetic interference and preserving device functionality.

- Optical Applications: Coating is used in optoelectronic devices and display technologies to control optical characteristics including absorption, transmission, and reflection in order to create certain optical effects and performance.

- Conductive Coatings: Coatings can be used to provide conductivity for electronic devices such as touchscreens, or they can be used to link circuit components.

- Microelectronics Manufacturing: To guarantee the precision and stability of integrated circuits (ICs) and other microdevices, coating is frequently employed in crucial production steps.

1.2, The financial industry

- Production of Bullion: Automatic Wire Cutting Machines are necessary for the processing and refinement of gold bullion. They make it easier to produce standardized gold grains, also known as bullion bars, which are frequently traded commodities in the financial markets, by accurately cutting gold wires into segments.

- Asset Management: Automatic Wire Cutting Machines are used by financial organizations, such as banks and investment firms, to handle gold wires for asset management. The effective conversion of gold wires into conventional forms by these devices facilitates the management and storage of precious assets, such as gold reserves.

- Jewelry Manufacturing: The creation of valuable jewelry products is closely related to the financial sector, even though it is largely linked with the jewelry business. In the jewelry industry, automatic wire cutting machines are essential because they cut gold wire into sections that are then utilized to make elaborate jewelry pieces that are valuable investments.

- Numismatics: Another field in the financial industry where Automatic Wire Cutting Machines are used is numismatics, which is the study and collecting of coins and currencies. In order to produce personalized coins and commemorative products for investors and collectors interested in numismatic assets, these devices help process gold wires.

- Central Banks and Reserves: Automatic wire cutting machines are frequently used by central banks and government organizations in charge of maintaining the country’s reserves to process gold reserves. These devices help to manage and store precious metal reserves more effectively by transforming bulk gold resources into standardized forms.

- Financial Products Backed by Gold: Exchange-traded funds (ETFs) and gold certificates are two examples of financial products that are indirectly made possible by automatic wire cutting machines. These devices assist the underlying assets that underpin these financial instruments by making it possible to transform gold wires into standardized forms efficiently.

1.3, The handicraft manufacturing industry

- Wire Sculptures: To create the precise lengths and forms needed for delicate wire sculptures, artists and artisans employ Automatic Wire Cutting Machines. These devices provide consistency and precision in wire cutting, allowing artists to precisely realize their imaginative thoughts.

- Metal Jewelry Making: In the handicraft sector, automatic wire cutting machines are essential to the manufacturing of metal jewelry. These machines increase the efficiency of jewelry production operations by facilitating the assembly of jewelry components including chains, clasps, and ornamental embellishments by cutting metal wires into segments of appropriate lengths.

- Wire Art and Decor: Exquisite designs are frequently achieved by exact wire cutting in handcrafted wire art and decor pieces, such as wall hangings, sculptures, and ornamental accents. With the use of automatic wire cutting machines, craftspeople may precisely cut metal wires to produce unique items that enhance the visual appeal of interior spaces.

- Metal Crafts: Automatic Wire Cutting Machines are essential in the manufacturing of several metal crafts, including decorations, candle holders, and mobiles. These devices aid craftspeople in precisely and consistently assembling a wide range of metal craft objects by cutting metal wire into the desired lengths and forms.

- Products That Are Customized: Handicraft producers frequently fulfill bespoke orders that call for unique designs and requirements. Automated wire cutting machines let producers swiftly cut metal wires to specific specifications, enabling them to complete custom orders for customers looking for one-of-a-kind, handcrafted goods.

- Development of Prototypes: Automatic Wire Cutting Machines are used to make prototypes and samples of metal-based items throughout the design and prototyping stages of handicraft production. By helping designers and craftspeople experiment with various wire arrangements and dimensions, these devices aid in the creation of innovative product ideas and concepts.

How to cut the gold line at present

Wire cutting machines are specialized pieces of equipment used for gold wire cutting. These devices are made to accurately cut gold wire into the lengths or segments needed for a variety of uses in the jewelry-making, electronics, and craft sectors. Feeding the gold wire into the machine, adjusting the length and number of the needed cuts, and turning on the cutting mechanism to create the necessary segments are the steps in the procedure. By guaranteeing precision, uniformity, and effectiveness in the process of cutting gold wires, these devices help producers satisfy certain output demands and quality benchmarks.

2.1, Metal saw

One kind of cutting instrument made especially for cutting different kinds of metal, including gold, is the metal saw. It is made up of an abrasive disc or toothed blade that spins quickly to efficiently cut through metal. Hacksaws, circular saws, band saws, and abrasive saws are just a few of the several kinds of metal saws available. Each kind is appropriate for a particular application and set of metal cutting needs. Depending on the kind of saw and blade chosen, a metal saw can be used to cut gold lines with accuracy and cleanliness. However, because of their precision and efficiency, specialist wire cutting machines are frequently chosen for cutting delicate materials like gold wire.

2.2, Plasma cutting machine

In the metalworking industry, plasma cutting machines are indispensable instruments that offer accurate and effective cutting solutions for a wide range of uses. These devices slice through electrically conductive materials including copper, brass, aluminum, and steel using a high-velocity plasma stream. Plasma cutting produces plasma at temperatures as high as 30,000 degrees Fahrenheit by driving a gas through a narrow nozzle while an electric arc is passed over it. This melts the metal and expels the molten material to produce precise, clean cuts. Plasma cutting systems with CNC technology provide exact control over the cutting process, making it possible to create complicated shapes and sizes with repeatability and accuracy.

Plasma cutting machines provide a cost-effective and adaptable alternative for cutting operations in both prototype and production, thanks to their high cutting speeds, limited heat-affected zones, and capacity to cut a wide range of metals.

SuperbMelt can provide cutting machines

A variety of cutting machines from SuperbMelt are available to satisfy different industrial requirements. Our cutting machines are designed to perform reliably, precisely, and efficiently in a variety of settings. SuperbMelt offers the answer whether you need to cut metal for manufacturing, fabrication, or other uses. Our cutting machines maximize efficiency and save waste while ensuring precise and clean cuts thanks to their cutting-edge designs and cutting-edge technologies. To find out more about our cutting machine options and how they can help your company, get in touch with us right now.

3.1,Automatic Wire Cutting Machine

SuperbMelt automatic rod cutting machine can cut 50-220 pieces of metal evaporation materials such as gold, platinum, silver, copper, aluminum, nickel, and titanium per minute, with diameters ranging from 2-6mm. These products are primarily used in the electronics and semiconductor industries for thin film deposition and coating, making the automatic rod cutting machine essential in the coating industry.

Rod cutting machine is also suitable for cutting gold wire into the required dimensions for processing into gold beans used for investment, wealth storage, and financial transactions. The bars produced by this machine are also applicable in industries such as handicraft manufacturing, automotive production, and furniture manufacturing.

SuperbMelt automatic rod cutting machine features feeding and calibration functions, enhancing processing efficiency and production accuracy in the coating and gold bean investment industries.

3.2, Automatic gold sheet cutting machine

The main difference between automatic gold slicers and rod cutters is what they cut. The automatic gold sheet cutting machine is specially used to cut metal sheets, while the rod cutting machine is specially used to cut metal rods. Although they are both cutting equipment used in the metalworking and fabrication industries, they are designed and work slightly differently to accommodate different shapes and materials of metal materials.

Conclusion

A wide selection of cutting machines from SuperbMelt are available to satisfy different industrial requirements. Each equipment is designed to provide effective, accurate, and dependable cutting solutions; they range from the Automatic Gold Sheet Cutting equipment to the Automatic Wire Cutting Machine, which is essential for the proper segmentation of metal wires used in semiconductor deposition coating and gold bean manufacturing. These machines, which are equipped with sophisticated characteristics including automated functions, rapid cutting rates, high accuracy, and intelligent control, improve productivity and simplify operations in many industries, such as finance, electronics, and handcraft manufacture. Businesses can depend on SuperbMelt’s cutting equipment to efficiently satisfy their varied cutting requirements because of our dedication to innovation and quality. Get in touch with us right now to learn more about our cutting machine alternatives and how they may help.

© Copyright 2008-2021 Superb Electromachinery Co., Limited

© Copyright 2008-2021 Superb Electromachinery Co., Limited