Gold Tube Cutting Flower Machine

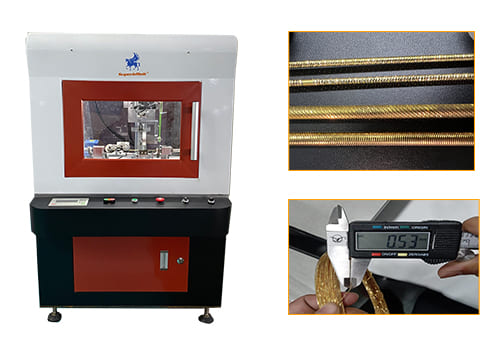

SuperbMelt Gold Tube Cutting Flower Machine helps process patterns on gold, silver, copper, and platinum round tubes and wires.

SuperbMelt Gold Tube Cutting Flower Machine is designed to process gold, silver, copper, and platinum tubes and wires, creating intricate patterns such as fish scale, nail, and cross patterns in just one minute.

Equipped with automatic straightening, material collection, and batch processing features, this machine significantly reduces labor costs and enhances production efficiency. It is an ideal solution for jewelry manufacturers seeking high-precision, automated engraving for decorative jewelry components.

Processing capacity:

- Wire diameter: ∅1.6mm – ∅4.0mm

- Tube diameter: ∅1.0mm – ∅4.0mm

| Technical Parameters | Values |

| Model | SPB- |

| Voltage | 220 V |

| Processing Specification (Wire) | Ø0.3~Ø1.0mm |

| Processing Specification (Tube) | Ø1.0~Ø4.0mm |

| Working Efficiency | 500-1000 mm/min |

| Maximum Spindle Speed | 24000r/min |

| Total Power | 1.8kw |

| Air Pressure | 3-4kg |

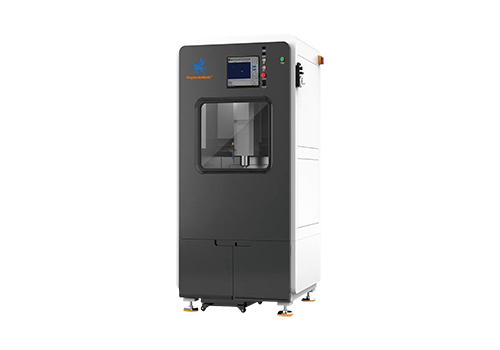

| Dimensions | 1280x700x1450mm |

| Weight | 150kg |

| Control Method | Switch Control |

High-Efficiency Automation

Equipped with automatic straightening, pattern engraving, and material collection functions, reducing manual intervention and significantly improving production efficiency.

Capable of processing entire rolls without the need for individual handling, making it suitable for large-scale production.

Wide Material Compatibility

Suitable for precious metals such as gold, silver, K-gold, platinum, copper, silver, and aluminum, as well as other metal materials for tubes and wires.

Can process straight lines and tubes with diameters ranging from ∅1.6mm to ∅4.0mm, meeting various jewelry manufacturing needs.

Multiple Exquisite Patterns

Capable of batch processing patterns such as fish scale, nail, and cross patterns, enhancing the design appeal and market competitiveness of jewelry.

Clear and delicate patterns meet the processing requirements of high-end jewelry.

Wide Range of Applications

Suitable for jewelry manufacturers, gold and silver processing factories, and accessory processing factories, supporting large-scale production.

Ideal for decorative processing of wires and tubes used in rings, bracelets, necklaces, pendants, and jewelry accessories.

Jewelry Industry – Pattern processing for gold, silver, K-gold, and other jewelry wires and tubes.

Metal Crafts Industry – Surface pattern engraving for metal decorative items.

High-End Custom Jewelry Manufacturing – Meeting personalized jewelry pattern design requirements.

This equipment, with its high-efficiency automation, precise processing, and diverse pattern options, is an ideal choice for jewelry manufacturers to enhance production efficiency and product quality.

Why SuperbMelt Gold Tube Cutting Flower Machine

More SuperbMelt jewelry Processing Equipment for You to Choose

Any Question About SuperbMelt jewelry Processing Equipment

Guide to the SuperbMelt Gold Tube Cutting Flower Machine

Introduction of Decorative Jewelry Tube Cutting

Decorative jewelry tube cutting is a specialized process in jewelry manufacturing that focuses on engraving and shaping metal tubes and wires into visually appealing patterns. Traditionally, artisans manually carved designs onto gold, silver, or copper tubes, a process that required exceptional craftsmanship but was slow, labor-intensive, and inconsistent in quality.

With the advancement of technology, modern equipment such as the Gold Tube Cutting Flower Machine has revolutionized this practice. These machines automate the engraving process, delivering intricate and consistent patterns like fish scale, nail, and cross designs within minutes. They support a wide range of materials—including gold, silver, platinum, copper, and K-gold—and can process tubes and wires of various diameters.

This transformation not only enhances production efficiency but also improves design precision, making decorative tube cutting an essential step for creating rings, bracelets, necklaces, pendants, and other jewelry accessories. By combining automation with creativity, decorative tube cutting ensures that jewelry remains both functional and artistically appealing in today’s competitive market.

1.1, Early Jewelry Tube Engraving

In traditional jewelry making, decorative patterns on gold and silver tubes were engraved entirely by hand. Skilled craftsmen relied on manual tools and years of experience to carve intricate designs, such as scales or lines, directly onto metal surfaces. This process demanded immense patience, precision, and steady craftsmanship.

However, manual engraving had several limitations. It was time-consuming, labor-intensive, and costly, as each tube required careful attention from artisans. Additionally, the results often varied from piece to piece, leading to inconsistencies in design and quality. While this method produced unique and highly artistic jewelry, it was not efficient enough to meet the demands of large-scale production.

1.2, Modern Jewelry Tube Cutting Techniques

With the rise of automation and digital control, jewelry manufacturing has entered a new era of efficiency and precision. Machines like the Gold Tube Cutting Flower Machine have revolutionized the decorative tube engraving process. Unlike traditional hand-engraving, these advanced systems deliver high-speed and highly accurate pattern cutting on wires and tubes, ensuring uniform quality across every piece.

By reducing human error and minimizing labor intensity, automated cutting machines not only enhance production efficiency but also maintain consistent results even in large-scale manufacturing. This innovation allows jewelry manufacturers to meet growing market demands while ensuring the beauty and delicacy of decorative patterns remain intact.

1.3, History of Patterned Jewelry Components

Patterned jewelry components have a long and rich history, dating back to ancient civilizations where artisans decorated gold, silver, and bronze ornaments with carved lines, geometric shapes, and symbolic motifs. These patterns were not only aesthetic but also carried cultural or spiritual meanings, often reflecting status, beliefs, or protective symbols.

During the Renaissance and later periods, advances in metalworking allowed for more intricate and delicate engravings on jewelry tubes, wires, and surfaces. Decorative techniques such as chasing, repoussé, and hand-engraving became popular, giving rise to finely detailed bracelets, necklaces, and pendants.

In modern times, patterned jewelry components continue to play a vital role in enhancing visual appeal and uniqueness. With the advent of automated machines, the industry shifted from purely handcrafted work to a combination of artistry and technology, ensuring both beauty and scalability in production.

1.4,Advantage of Modern Processing

Modern decorative tube cutting and engraving methods offer significant advantages over traditional handcrafting. Automated machines, such as the Gold Tube Cutting Flower Machine, combine precision, speed, and consistency to meet the demands of contemporary jewelry manufacturing.

Key advantages include:

High Precision: Patterns are consistently uniform across each wire or tube, eliminating the variability common in manual engraving.

Enhanced Efficiency: Automation drastically reduces production time, allowing for large-scale manufacturing without compromising quality.

Labor Cost Reduction: Minimal manual intervention is required, reducing dependency on highly skilled artisans.

Versatility: Machines can process a variety of materials—including gold, silver, platinum, copper, and aluminum—and create multiple intricate patterns such as fish scale, nail, and cross designs.

Scalability: Suitable for both mass production and high-end customized jewelry, enabling manufacturers to quickly respond to market demands.

By integrating modern processing techniques, jewelry manufacturers can achieve consistent quality, improved productivity, and greater design flexibility, giving them a competitive edge in the market.

What are the Gold Tube Cutting Flower Machines on the Market Nowadays

2.1, Automatic Tube Cutting and Engraving Machines

Automatic tube cutting and engraving machines are specialized equipment used in jewelry manufacturing to precisely cut and engrave decorative patterns onto metal tubes and wires. These machines have revolutionized the industry by offering high-speed, precise engraving, reducing labor costs, and ensuring consistent results.

1. SuperbMelt Gold Tube Cutting Flower Machine

Materials Supported: Gold, silver, platinum, copper, aluminum, and their alloys.

Tube/Wire Diameter Range: Suitable for straight tubes and wires with diameters ranging from ∅1.6mm to ∅4.0mm.

Key Features:

Automatic straightening, pattern engraving, and material collection.

Capable of processing entire rolls without the need for individual handling.

Supports batch processing of patterns such as fish scale, nail, and cross designs.

Ideal for large-scale production of decorative jewelry components.

Applications: Jewelry manufacturers, gold and silver processing factories, and accessory processing factories.

Learn More: SuperbMelt Gold Tube Cutting Flower Machine

2. eBay Gold and Silver Tube Cutting Machine

Materials Supported: Gold, silver, and copper.

Specifications:

No-load speed: 6800 RPM.

Rated power: 360W.

Rated voltage: 110V-220V.

Features:

Compact design suitable for small-scale operations.

Manual operation with basic cutting capabilities.

Applications: Small jewelry workshops and artisans.

Product Link: eBay Gold and Silver Tube Cutting Machine

3. TE-50Y Semi-Automatic Flower Tube Design Machine

Materials Supported: Stainless steel and other metals.

Features:

Semi-automatic operation with manual feeding.

Designed for embossing decorative patterns onto metal tubes.

Suitable for creating floral and other intricate designs.

Applications: Medium-scale jewelry manufacturers and metal craft producers.

Product Link: TE-50Y Semi-Automatic Flower Tube Design Machine

Comparison Table:

| Machine | Automation Level | Supported Materials | Tube/Wire Diameter Range | Key Features |

|---|---|---|---|---|

| SuperbMelt Gold Tube Cutting Flower Machine | Fully Automatic | Gold, silver, platinum, copper, aluminum | ∅1.6mm – ∅4.0mm | High-speed, precise engraving, batch processing |

| eBay Gold and Silver Tube Cutting Machine | Manual | Gold, silver, copper | Not specified | Compact design, basic cutting capabilities |

| TE-50Y Semi-Automatic Flower Tube Design Machine | Semi-Automatic | Stainless steel and other metals | Not specified | Embossing decorative patterns, floral designs |

For a visual demonstration of the SuperbMelt Gold Tube Cutting Flower Machine in operation, you can watch the following video:

SuperbMelt Metal Pipe and Wire Diamond Cutting Machine – YouTube

Why Equipment is Needed for Tube Cutting & Patterning

Automated tube cutting and patterning equipment, such as Gold Tube Cutting Flower Machines, CNC processors, and hybrid machines, is essential for modern jewelry manufacturing. These machines ensure high precision, consistent quality, and efficient production while handling various metals like gold, silver, platinum, and copper. They reduce material waste, enable large-scale production, and allow intricate patterns that are difficult to achieve manually, helping manufacturers meet market demand and expand creative possibilities.

3.1, History of Use in Jewelry

Decorative tubes and wires have been used in jewelry for centuries, dating back to ancient civilizations where artisans manually engraved patterns onto gold, silver, and other metals. These early techniques required skilled craftsmanship, patience, and time, often limiting production volume and making intricately patterned jewelry expensive and exclusive. Over time, as jewelry designs became more complex and demand increased, manual methods proved insufficient, leading to the development of automated and mechanized processes. Today, modern machines such as Gold Tube Cutting Flower Machines, CNC decorative tube processors, and hybrid tube-and-wire machines have transformed the industry, enabling high-precision, efficient, and scalable production of patterned jewelry components.

3.2, Source of Materials

The production of decorative jewelry tubes and wires relies on high-quality metals such as gold, silver, platinum, copper, and various alloys. These metals are sourced from mining operations, refined ingots, or recycled materials. Precious metals like gold and platinum are typically obtained from certified mines or suppliers to ensure purity and consistency, while base metals like copper and silver may come from both primary mining sources and recycled scrap. Choosing reliable, high-purity materials is essential for achieving durable, aesthetically pleasing jewelry and ensuring smooth processing in automated tube cutting and engraving machines.

3.3, Equipment Requirements

Creating decorative patterns on jewelry tubes and wires requires specialized equipment to achieve precision, efficiency, and consistency. Key machinery includes:

Gold Tube Cutting Flower Machines – Automatically engrave intricate patterns such as fish scale, nail, or cross designs on tubes and wires, while straightening and collecting materials.

CNC Decorative Tube Processing Machines – Provide digital control for highly precise cutting, engraving, and shaping of tubes, suitable for complex designs.

Hybrid Tube-and-Wire Machines – Combine cutting, patterning, and engraving for both tubes and wires, offering versatility and efficiency for various jewelry components.

Material Handling Tools – Automatic feeders, straighteners, and collection systems minimize manual intervention, improve production speed, and reduce errors.

Using these machines ensures high-quality, uniform patterns, supports large-scale production, and reduces labor costs, making them essential for modern jewelry manufacturing.

3.4, Why Precision Crucibles are Not Needed Here

Unlike metal melting or refining processes, decorative tube cutting and patterning do not involve melting or chemical processing of metals. Therefore, there is no need for precision crucibles, which are typically used to contain molten metals during smelting or casting. In tube cutting and engraving, the metals are already solid and shaped into wires or tubes, so the focus is on mechanical manipulation—cutting, shaping, and patterning—rather than on maintaining metal purity or controlling temperature. This eliminates the need for crucibles, simplifying the equipment requirements while still ensuring high-quality, intricate designs.

How to Get High-Quality Decorative Tubes

To achieve high-quality decorative tubes for jewelry, start with high-purity metals like gold, silver, platinum, or copper, and ensure consistent tube forming with precise diameters and wall thicknesses. Use automated machines such as Gold Tube Cutting Flower Machines or CNC processors for clean, uniform patterns, followed by proper surface finishing to enhance appearance. Rigorous quality control ensures defect-free, visually appealing tubes suitable for high-end jewelry applications.

4.1, Processing Capacity

The Gold Tube Cutting Flower Machine is designed for high-efficiency production, capable of processing a wide range of tube and wire sizes. It supports wire diameters from ∅1.6mm to ∅4.0mm and tube diameters from ∅1.0mm to ∅4.0mm. Equipped with automatic straightening, pattern engraving, and material collection functions, the machine can complete intricate patterns—such as fish scale, nail, and cross designs—in just one minute. This high processing capacity makes it ideal for large-scale jewelry manufacturing, reducing labor costs while maintaining consistent quality and precision across batches.

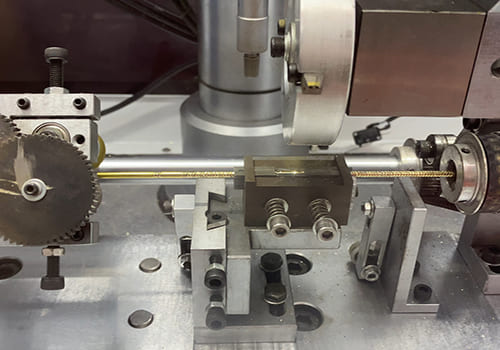

4.2, Pattern Engraving Process

The pattern engraving process on the Gold Tube Cutting Flower Machine is fully automated to ensure precision and efficiency. First, metal tubes or wires are straightened automatically to prepare for accurate cutting and engraving. The machine then applies programmed patterns, such as fish scale, nail, or cross designs, onto the surface of the tubes or wires with high consistency. Once engraving is complete, the material is collected automatically, minimizing manual handling. This streamlined process ensures uniform, high-quality decorative patterns suitable for large-scale jewelry production, while reducing errors and labor intensity.

4.3, Jewelry Decoration and Finishing

After pattern engraving, the tubes and wires undergo finishing processes to enhance their appearance and durability. Polishing or buffing removes any minor surface imperfections, while coatings or plating may be applied to improve luster and protect the metal. These finishing steps ensure that the decorative patterns are clearly visible and the jewelry components have a high-end, refined look. Proper decoration and finishing not only elevate the aesthetic appeal of the tubes and wires but also prepare them for assembly into bracelets, rings, necklaces, and other jewelry pieces, ensuring consistency and quality across large-scale production.

4.4 Choosing the Right Pattern Mold

Selecting the appropriate pattern mold is crucial for achieving the desired decorative effect on jewelry tubes and wires. The mold determines the shape, depth, and style of the engraved patterns, such as fish scale, nail, or cross designs. Factors to consider include the diameter and thickness of the tube or wire, the complexity of the design, and the type of metal being used. Using the correct mold ensures precise, consistent engraving, minimizes material waste, and enhances the visual appeal of the jewelry components. High-quality molds, paired with automated machines like the Gold Tube Cutting Flower Machine, enable manufacturers to produce intricate and uniform patterns efficiently.

How to Apply Tube Cutting Technology in Jewelry Manufacturing

Tube cutting technology enhances jewelry manufacturing by enabling precise, consistent, and intricate patterns on high-quality metal tubes and wires. Automated machines, such as Gold Tube Cutting Flower Machines or CNC processors, streamline engraving, reduce labor, and improve efficiency. After finishing and decoration, these patterned components can be assembled into bracelets, rings, necklaces, and other jewelry, ensuring high-quality, uniform products while minimizing waste and supporting large-scale production.

5.1, Difference Between Manual and Automated Engraving

Manual engraving relies on skilled craftsmen to carve patterns onto jewelry tubes and wires by hand. While it allows for artistic creativity and customization, it is time-consuming, labor-intensive, and prone to inconsistencies between pieces. In contrast, automated engraving using machines like the Gold Tube Cutting Flower Machine or CNC decorative processors delivers high precision, consistent patterns, and faster production speeds. Automated methods reduce human error, lower labor costs, and enable large-scale manufacturing, making them ideal for modern jewelry production that demands efficiency, uniformity, and intricate designs.

5.2, Best Processing Methods for Decorative Tubes

To achieve high-quality decorative tubes for jewelry, several processing methods are commonly used:

Automated Tube Cutting and Engraving

Machines like the Gold Tube Cutting Flower Machine provide fast, precise engraving of intricate patterns such as fish scale, nail, or cross designs. Automation ensures consistency, reduces labor, and allows large-scale production.CNC Decorative Processing

CNC machines use digital programming to cut, shape, and engrave tubes with extreme precision. They are ideal for complex patterns, custom designs, and high-end jewelry components.Hybrid Tube-and-Wire Machines

Hybrid machines combine cutting, engraving, and shaping functions for both tubes and wires. They offer versatility, supporting different materials and sizes while maintaining high efficiency.Finishing Techniques

Polishing, buffing, plating, and coating enhance the appearance and durability of engraved tubes, ensuring patterns are clear and jewelry components are ready for assembly.

Using these methods in combination ensures decorative tubes are precise, visually appealing, and suitable for both mass production and custom jewelry designs.

5.3, Choosing the Right Equipment

Selecting the appropriate equipment for decorative tube processing is essential to achieve high precision, efficiency, and versatility. Key considerations include:

Type of Metal

Ensure the machine can handle the specific metals you use, such as gold, silver, platinum, copper, or alloys, without causing deformation or surface damage.Tube and Wire Dimensions

Choose equipment that accommodates your required tube diameters and wire thicknesses, for example, ∅1.0mm–∅4.0mm for tubes and ∅1.6mm–∅4.0mm for wires.Pattern Complexity

For intricate designs, CNC decorative machines or hybrid machines provide precise control. For standard repetitive patterns, automated tube cutting and engraving machines like the Gold Tube Cutting Flower Machine are ideal.Production Volume

Consider machines with high processing capacity, automatic material feeding, and collection systems for large-scale manufacturing, while smaller units may suffice for limited or custom production.Automation and Efficiency

Machines with automated straightening, cutting, engraving, and material handling functions reduce labor, minimize errors, and improve overall production speed.

Choosing the right combination of equipment ensures consistent, high-quality decorative tubes while optimizing efficiency, reducing waste, and meeting both custom and mass-production requirements.

Conclusion

The Gold Tube Cutting Flower Machine and related decorative tube processing technologies have revolutionized modern jewelry manufacturing. From early manual engraving methods, which were time-consuming and inconsistent, to advanced automated machines, the industry now benefits from high precision, efficiency, and versatility.

Automated machines, CNC processors, and hybrid tube-and-wire equipment allow manufacturers to create intricate patterns on a wide range of metals, including gold, silver, platinum, and copper. These machines support various tube and wire sizes, offer high processing capacities, and reduce labor costs while minimizing material waste. Coupled with proper finishing techniques such as polishing, plating, and coating, the engraved tubes achieve a refined appearance suitable for assembly into bracelets, rings, necklaces, and other jewelry components.

By selecting the right equipment, considering the type of metal, tube dimensions, pattern complexity, and production scale, manufacturers can ensure consistent, high-quality decorative tubes. Overall, integrating automated tube cutting and engraving technologies enables jewelry makers to meet growing market demands, produce visually appealing designs, and achieve both efficiency and precision in large-scale or custom jewelry production.

FAQ Guide of Gold Tube Cutting Flower Machine

- 1. What is a Gold Tube Cutting Flower Machine?

- 2. What materials can this machine process?

- 3. What are the supported tube and wire sizes?

- 4. What types of patterns can this machine engrave?

- 5. How does the automatic system improve efficiency?

- 6. How fast can this machine engrave metal tubes and wires?

- 7. Is this machine suitable for mass production?

- 8. Can this machine work with customized designs?

- 9. What industries use this machine?

- 10. Does this machine require skilled operators?

- 11. How does this machine ensure engraving accuracy?

- 12. Can this machine be integrated into an existing production line?

- 13. What is the power consumption of this machine?

- 14. How do I maintain the machine for long-term use?

- 15. Does SuperbMelt provide technical support and training?

1. What is a Gold Tube Cutting Flower Machine?

A Gold Tube Cutting Flower Machine is a specialized device used for engraving decorative patterns on gold, silver, platinum, and other metal tubes and wires. It features automatic straightening, engraving, and material collection, making it ideal for jewelry manufacturing.

2. What materials can this machine process?

This machine is suitable for processing gold, silver, K-gold, platinum, copper, aluminum, and other precious and non-precious metals used in jewelry manufacturing.

3. What are the supported tube and wire sizes?

- Tube diameter: ∅1.0mm – ∅4.0mm

- Wire diameter: ∅1.6mm – ∅4.0mm

4. What types of patterns can this machine engrave?

The machine can engrave a variety of intricate patterns, including:

- Fish scale pattern

- Nail pattern

- Cross pattern

- Custom decorative designs

5. How does the automatic system improve efficiency?

The machine features automatic straightening, batch engraving, and automatic material collection, significantly reducing manual labor while increasing processing speed and consistency.

6. How fast can this machine engrave metal tubes and wires?

The machine is capable of engraving 500-1000mm tubes per minute, making it highly efficient for large-scale jewelry production.

7. Is this machine suitable for mass production?

Yes, the Gold Tube Cutting Flower Machine is designed for high-volume jewelry manufacturing. It can process whole rolls of wire or tubes continuously, reducing downtime and enhancing production efficiency.

8. Can this machine work with customized designs?

Yes, the machine allows for customized engraving patterns based on jewelry design requirements, offering flexibility in production.

9. What industries use this machine?

This machine is widely used in:

- Jewelry manufacturing (rings, bracelets, necklaces, pendants)

- Luxury metal accessories production

- Decorative metal craftsmanship

10. Does this machine require skilled operators?

No, the fully automated system makes it easy to operate. However, basic training is recommended to ensure proper usage and maintenance.

11. How does this machine ensure engraving accuracy?

The machine is equipped with high-precision cutting and engraving tools, ensuring uniform and flawless decorative patterns on all processed tubes and wires.

12. Can this machine be integrated into an existing production line?

Yes, the Gold Tube Cutting Flower Machine can seamlessly integrate into automated jewelry production lines, improving overall workflow efficiency.

13. What is the power consumption of this machine?

Power consumption depends on the specific model, but it is designed to be energy-efficient while maintaining high performance.

14. How do I maintain the machine for long-term use?

Regular maintenance includes:

- Cleaning the engraving tools

- Checking and lubricating moving parts

- Ensuring proper material feeding and collection

15. Does SuperbMelt provide technical support and training?

Foundry is one of the most energy intensiYes! SuperbMelt offers installation guidance, operational training, and after-sales support to ensure smooth operation and maximum productivity.ve metallurgical industries. Various sections of foundry melt, pattern making, melting, core making compressed air, etc.

© Copyright 2008-2026 Superb Electromachinery Co., Limited

© Copyright 2008-2026 Superb Electromachinery Co., Limited